Well caisson: what it is, types, purpose, comparative overview of designs and installation rules

An autonomous water supply system solves the problem of providing water to houses located far from urban infrastructure. An important nuance of arranging such a system is the complete protection of the well from all kinds of negative factors. For this purpose, a special device called a caisson is installed.

A caisson is a chamber designed to construct a wellhead below the earth's surface. It is built above the water intake to provide convenient access and the ability to install equipment for water supply at home. There are several varieties of such structures. It is important for a developer who is going to start arranging an autonomous water supply to carefully study all types of caissons for a well and choose the best option for himself.

Self-installation of a caisson for a well is quite affordable if certain rules are followed. Let's try to understand the types of caissons and the rules for their installation.

The content of the article:

What is a caisson and what is it for?

A caisson is a sealed container. Initially, caissons were used for underwater work, but later their scope of application expanded significantly. In particular, such products began to be used to protect the well head.

Most often, the owner assumes year-round operation of an autonomous water supply system. However, doing this under conditions of sharp annual temperature changes is very difficult. Summer heat and severe winter frosts significantly complicate the operation of the well.

At subzero temperatures, water coming from the depths will certainly freeze and spoil, and in the worst case, rupture the pumping equipment.

For the smooth functioning of the well, the owner must ensure a stable positive temperature at its head. A caisson is used for this purpose.

It is a sealed container that is buried in the ground and fixed to the casing. With additional insulation, the device will protect the well from low temperatures. In addition, the sealed container prevents groundwater and waste water from entering, which can damage moisture-sensitive devices.

In addition, the caisson is the optimal place for installing pumping equipment. Here it will be reliably protected not only from groundwater, but also from insects and rodents that can damage the devices.

A closed caisson limits unwanted access to the head by unauthorized persons.

In addition, all the equipment necessary for operating the well can be placed inside the structure:

- purification and filtration systems, reverse osmosis;

- pumping apparatus;

- pipelines and shut-off valves, including those with pneumatic or electric drive;

- automation responsible for controlling the pump and the entire water supply system.

A caisson is a container with a neck that closes with a hatch. The height of the structure is usually at least two meters, since the casing pipe enters the structure at a depth of 1-2 m.

The geometry of the products also varies. They can be round or quadrangular in cross section. In the first case, their diameter should not be less than 1 m, otherwise it will be very difficult for a person to fit inside the chamber. It is important to choose the correct dimensions of the caisson.

A structure that is too small will be inconvenient for placing equipment and carrying out maintenance and repairs. A large camera will be unreasonably expensive. The outside of the caisson is most often insulated.

A hole is made at the bottom of the tank into which the casing pipe is inserted. The side walls contain technological holes for laying electrical cables and supplying water pipes. In addition, a ladder is installed inside the caisson; the folding version is especially convenient.

A new well owner always wonders whether it is necessary to install a caisson, since this is a rather expensive undertaking? Yes, you can do without a caisson. But it's not that simple.

Firstly, in this case it is necessary that the well outlet be in a heated room, for example, the basement of a house. This is necessary to protect equipment from freezing. It should be understood that the noise level from constantly operating devices will be high.

Secondly, you will have to use borehole adapter. This device is a compact plumbing adapter that is mounted into the casing pipe.

It consists of two parts. The first is installed on the casing below the GPG level, the second is fixed to the water intake pipe. After that, a sliding connection is mounted in a “dovetail”, with the help of which both parts of the adapter are connected inside the well.

The device is extremely easy to install and use. In addition, for many well owners, its cost, which is much lower than that of a caisson, seems very attractive. But you need to understand that installing the adapter significantly complicates subsequent preventive repairs and inspection of the well. In addition, all equipment will have to be located inside the building.

Types of caissons and their characteristics

The shape of the caissons is very different. Round in plan and rectangular, with or without an extension at the bottom.

Meanwhile, they are clearly divided into three main types based on the material of manufacture:

- Concrete.

- Brick.

- Metal.

- Plastic.

- Polymer sand.

Earlier versions with the walls of a wooden frame can now only be regarded as a curiosity or useless exotic due to the high cost, complexity of execution and low consumer properties.

The material from which the sealed chamber is made largely determines its performance characteristics. Let's take a closer look at the features of devices made from different materials.

Option #1 - chamber made of concrete rings or bricks

Until recently, the most common type was a caisson made of concrete rings. It is quite simple to make, the design is strong and durable.

Such caissons are made in two ways. In the first case, industrially produced reinforced concrete rings are laid on the prepared base. Once the desired height is reached, a plate with a lid is placed on them.

Installation of reinforced concrete rings is simpler and faster than the same work on installing a plastic or metal caisson, under which it is necessary to dig a foundation pit in advance.

The second method involves pouring the structure yourself. A foundation is being built on which the reinforcement for the walls is assembled, and after they are poured, for the floor slab with the hatch.

In both cases, the finished structure has all the advantages of concrete caissons:

- Undeniable durability and strength. Concrete is a very durable material that successfully withstands strong mechanical stress.Soil movements will not affect the integrity of the chamber, and cracks will not appear on its walls. The service life of a properly constructed concrete structure is several decades.

- A very significant mass. Reinforced concrete is heavy, which prevents the chamber from floating when the groundwater level rises. For the same reason, the concrete caisson does not require additional fastening in the ground during installation.

Experts point out that concrete chambers have many disadvantages. First of all, you need to understand that concrete is a hygroscopic material. It absorbs moisture very well, which penetrates inside the chamber and destroys its walls. That is why, to ensure a long service life of the structure, high-quality waterproofing work should be carried out.

For processing, you should choose only highly efficient modern materials. Particular attention is paid to the joints of the rings, the area of connection with the concrete base and the place where the casing passes through the bottom of the caisson. Practice shows that it is very difficult to achieve complete moisture resistance of a structure.

Another disadvantage of the concrete chamber is poor thermal insulation. To ensure temperatures acceptable for equipment operation, you will need to insulate the container.

Large weight, as in the case of a metal caisson, is an advantage and disadvantage of the design. Installation of concrete rings is impossible without the use of special equipment, and transportation is also difficult. All this significantly increases the cost of installing a caisson, while the price of the rings is relatively low.

In addition, the heavy weight of the camera negatively affects its operation. Over time it is possible gradual sagging of the device, which will inevitably lead to deformation of the equipment installed in it. The presence of a large number of shortcomings makes concrete caissons little in demand. They increasingly prefer other options.

Brick structures have similar pros and cons. True, its construction takes much longer, but in construction you can use broken and used material.

To manufacture the structure, a concrete base is built, on which brick walls are subsequently erected, and a ceiling with a lid is mounted on them. There are two ways to arrange such structures: with and without backfill.

The first involves digging a pit, the size of which exceeds the future caisson. After the walls of the chamber are laid out and dry well, the voids are filled with soil. In this case, there are no empty spaces left behind the caisson walls into which rainwater can flow.

The option without backfill involves preparing a pit, the size of which exactly corresponds to the future structure.When laid, the bricks are adjacent to the wall, however, there are no guarantees that there will be no voids behind them. The first option is considered more labor-intensive, but also of higher quality and durability.

The advantages of brick caissons include:

- High reliability and durability. A properly constructed brick wall can withstand serious mechanical stress. It has sufficient strength to resist possible soil movements. In addition, the large mass will not allow the structure to float to the surface; additional fastening during installation will not be required for it.

- Relatively low thermal conductivity. Brick walls do not conduct heat well, so they have good resistance to low temperatures. Such caissons retain heat, so additional insulation of the structure is required only in areas with very harsh winters.

- A significant advantage is profitability. The cost of a brick chamber, especially if it is made from used material, cannot be compared with plastic, concrete or metal counterparts. The price of a brick caisson is much lower, which is very attractive for well owners.

Today, reinforced concrete and brick structures are increasingly losing ground to their metal and plastic counterparts. The surrender of positions is justified not only by the efficiency of installation, but also by the price of structures fully prepared for installation.

Option #2 - metal caisson

This is, in fact, a large metal box with threaded bushings welded into the walls for the passage of communications.Most often it is made from sheet metal, the optimal thickness is 3 - 4 mm. The best option is stainless steel. But it seriously increases the cost of the design. Sometimes there are more interesting designs made of aluminum.

The metal caisson is quite simply constructed and reliable. Easy to install and lasts a long time. Very durable design, with certain skills and availability of tools can be made independently. Requires mandatory high-quality insulation.

When choosing or designing such a device, it is important to pay attention to its shape. Ideally, it should be such that there are as few welds as possible and they are made to the highest possible quality. The slightest defect in the seam will lead to subsequent loss of tightness of the caisson.

The use of a metal container has a number of advantages:

- High strength and flexibility. Steel is a very strong and rigid metal, which guarantees the integrity of the caisson body during any, even the most significant, ground movements. The flexibility of the material prevents the possible occurrence of cracks in the structure. Plastic containers are much inferior to metal ones in this regard.

- Long service life. Practice shows that the average service life of high-quality metal caissons is about 50 years. This is quite comparable to the service life of the well itself. Thus, a properly installed and properly operated container will be enough for the entire period of operation of the water supply source.

- Excessively large mass. The heavy metal chamber is characterized by resistance to soil heaving. It does not need to be additionally secured during installation.Under no circumstances will such a caisson be pushed to the surface. Moreover, it will not float up on its own, which happens with poorly secured plastic analogues.

- Necessary and sufficient tightness. A well-equipped metal caisson is airtight. It reliably protects the equipment placed in it from high water and groundwater.

Metal products also have disadvantages. The most significant - susceptibility to corrosion. To avoid trouble, you should regularly coat the chamber walls with a fresh protective layer of paint and varnish materials. It will be very easy to do this from the inside, but almost impossible from the outside.

Both the internal and external surfaces of the chamber are processed. Moreover, at least two or three layers of paint are laid on the seams. Products made independently should be processed in the same way.

Another minus - high thermal conductivity. This makes it necessary to install an additional insulating layer not only for the lid, but also for the entire structure.

Significant weight, which refers to the advantages of metal caissons, can also be attributed to their disadvantages. The impressive weight of the structure seriously complicates its transportation and installation, which is often impossible to carry out without the use of special equipment.

The cost of steel products produced in factories is higher than that of plastic analogues. Therefore, you can find a large number of metal caissons made at home, the quality of which cannot be vouched for.

Although welded seams are of good quality, they can crack when the metal is deformed. Therefore, even if the metal caisson is made of stainless steel, it still requires waterproofing. Ferrous metal must be covered with waterproofing. At the same time, even if the insulation is glued very tightly and does not allow water to pass through, it is not regarded as waterproofing.

Simply put: first to the walls thermal insulation is attached to the outside - foam glass, extruded polystyrene foam or something similar - fibrous materials will not work here at all. Then the structure is covered with waterproofing or a similar material.

Option #3 - plastic caisson

The most modern can be considered caissons made of polymers. Their advantage is their low cost, ease of transportation and installation, and durability. Plastic has good thermal insulation characteristics, and therefore is often used without additional thermal insulation; it does not need protection from underground water.

For the production of such caissons, three types of polymers are used: polyethylene, polypropylene and fiberglass. Two methods can be used to make a plastic container:

- Extrusion welding. A dense and durable seam is formed under the pressure of hot air. Particularly effective when working with corrugated surfaces.

- Rotational formatting. The result is cast containers with a solid body.There are no seams, which ensures complete tightness.

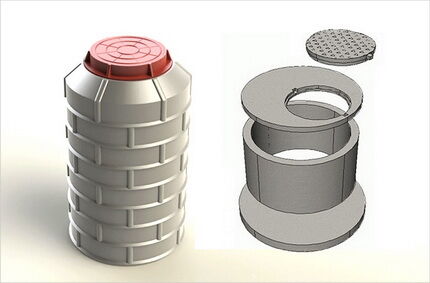

Plastic chambers usually consist of two parts: above the caisson and the caisson. The first may have a smaller diameter. A distinctive feature of the design is a crimp coupling, which ensures the tightness of the connection between the casing and the caisson.

The containers can be equipped with special pipes designed for introducing cables and water pipes. Plastic well caissons have many significant advantages:

- High corrosion resistance. Plastic is not subject to the destructive effects of corrosion, which allows containers made from it to last 50 years or more. In addition, the cameras do not require additional anti-corrosion treatment with special agents. This saves money and time for the owner.

- Completely sealed. The chamber, made of polymer, is absolutely sealed. Special fittings have been developed for technological holes, providing complete protection from moisture. Thus, additional waterproofing of the water pressure side of the structure will not be required. Whereas for caissons made of other materials, for example, reinforced concrete, this is a prerequisite.

- Light weight. The design is lightweight, which greatly simplifies the process of installation and transportation. Installation of a plastic caisson can most often be carried out without the use of special equipment, which allows for significant savings. This is not possible when installing a concrete or metal structure.

- Sufficient rigidity of the container. The manufacturer has the ability to vary the thickness and shape of the walls in plastic caissons, creating structures with a given rigidity.Models are available with internal stiffeners that increase the strength of the container. By the way, you can choose modifications with a reinforced base, designed to work in conditions of high groundwater levels.

- Good thermal characteristics. Plastic has low thermal conductivity, so in most climate zones the walls of the caisson will not need to be additionally insulated. Only the lid of the container needs protection from the cold. If the caisson will be used in areas where severe frosts are possible, it is worth insulating its walls.

- Possibility of equipping with additional elements. Manufacturers of plastic containers offer many elements that will make the operation of the caisson convenient. This could be an additional internal ladder, a special shelf for insulation for the lid, a folding overhead part that makes it easier to descend into the structure, and much more.

Among the disadvantages of plastic containers, two are worth noting. First - susceptibility to deformation. To mitigate this disadvantage, you should select a caisson for your soil type. On sale you can find various modifications with wall thicknesses from 10 to 40 mm.

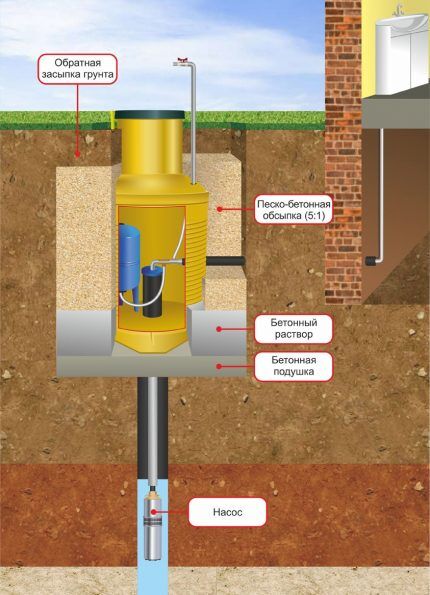

In addition, you can replace the external soil backfill with cement fill. Its width can vary between 80-100 mm along the entire perimeter of the caisson. Another option is backfilling with a sand-cement mixture. Experts recommend using a ratio of 5:1.

The second disadvantage is buoyancy chamber made of plastic. You can get rid of it by placing a concrete cushion at the base of the container. After installation on a concrete base, you will need to secure the plastic structure, which will prevent it from being pushed out of the ground.All these measures increase the cost of installing such caissons.

Pros and cons of plastic caissons:

Option #4 - polymer sand caissons

Relatively recently available prefabricated polymer sand wells have become an excellent option for arranging caissons. The container is assembled from several rings, a cone-shaped lid with a hatch and a bottom. It is made of modern composite material, which includes sand and plastic.

The rigidity necessary for the operation of the container is achieved by adding sand to a matrix made of polymer.

Polymer sand chambers are relatively low cost and have many advantages:

- Resistance to external influences. The composite material is not subject to corrosion, does not enter into chemical reactions, and has high strength. It successfully resists mechanical stress, is frost-resistant and has a very low moisture absorption coefficient.

- Extremely simple installation. The design is produced in the form of elements equipped with tongue-and-groove locking connections. This allows you to quickly and efficiently assemble a container of the desired size. No special equipment is required to install it in place.

- Light weight of individual elements. The weight of each of the parts for assembling the polymer-sand structure does not exceed 60 kg, which makes it possible to assemble the camera together with an assistant. Transportation of rings and other elements of the caisson can be carried out using a trailer to a passenger car.

- Ensures perfect sealing. A properly assembled polymer sand chamber is completely sealed. To make technological holes in its walls, ordinary household tools can be used. After installing the pipes, the holes must be sealed with any suitable compound.

- Long service life. The manufacturer guarantees that its product will last at least a hundred years without changing its properties. Since products made from polymer sand are still quite “young”, it was not possible to test this in practice.

However, it is impossible to guarantee tightness at the joints of structural elements of the container. Therefore, experts recommend that before starting to assemble the camera, you should take precautions and coat future joints with sealant or usually bitumen mastic. This connection will better retain moisture.

A little about the polymer sand well, which can be used as a caisson:

General installation recommendations

From an engineering point of view, the installation of a caisson for a well is required to accommodate equipment and protect well head from damage, entry into the storm water intake area and pollution.

A caisson for a well is much more profitable in terms of operating costs - unlike ground-based structures, it, as a rule, does not require heating (provided that it is below the calculated freezing depth). Although there cannot be any other option - if it stands higher, it will simply be squeezed out in the winter.

A buried caisson can also be squeezed out by soil. Especially in cases where the site has problems with high occurrence of perched water. Therefore, it is recommended to “anchor” not only lightweight plastic systems, but also more stable metal systems.Technically this is done very simply. A concrete slab is poured under the caisson for the well, to which the bottom of the caisson is attached using anchor bolts.

In high, non-flooded areas, you can do without a concrete base - a fairly good sand cushion. But even here, having a heavy slab under the caisson will not hurt. Therefore, it is always better to plan it, outside the geological features of the site. In any case, the caisson is placed strictly vertically - compliance with this condition is mandatory.

The height of the structure is about two meters - this size allows you to conveniently work, place equipment, and bury the caisson below the freezing depth.

Even if all conditions are met, it is a good idea to install heating electric cable - just in case of force majeure.

The electric cable powering the pump and automation is not placed directly in the ground. It does not require burial like water pipes, but it still needs to be protected. It is double insulated, but this is not enough. It is better not to use corrugation for these purposes, which is very popular in external laying. HDPE pipe is best suited.

The pipe with the electric cable is laid shallow underground - about 30 cm from the surface. The considerations here are simple - the frost is not terrible, but just in case, you need to take care that the communication is not accidentally damaged. The guideline is simple: we dig deeper than the bayonet of a shovel.

The pipe with water is buried deeper - below the freezing depth. Entering the house on the surface is possible only if the pipeline section is insulated from the level of seasonal freezing to the point of entry into the building. It is better to raise the equipment above the caisson floor. Not much, but definitely. In case of flooding.

All electrical devices in the caisson must be grounded. And it would be nice to introduce it into the electrical circuit RCD. Security is never too much. Rather, it may not be enough.

The well casing passes into the caisson through a coupling that is slightly larger in diameter. For example, taking into account the current assortment, a common casing pipe with a diameter of 133 mm will require a sleeve of 146 mm.

The well pipe should not be level with the bottom of the chamber - always a little higher. The excess is within 40 - 50 cm. In case there is flooding.

The sleeve and the siege pipe are sealed at the junction. A cap is placed on the well - a special sealed cover, in which there are holes for the cable of the submersible pump and the passage of the HDPE pipe from the pump. The power cable of the pump is also attached to it. The cover protects the wellbore from dirt and random debris.

The entrance to the caisson chamber is traditionally designed in the form of a hatch. The design depends on personal preference. In any case, the option with two hatches is preferable - simply for reasons of heat conservation.

The exit under the well pipe is usually made locally. It doesn't have to be clearly centered. It is quite acceptable to shift it and make it asymmetrical. But here we must remember that the well exit and the caisson hatch must be coaxial - this is very convenient when repairing and installing equipment.Simply put: it is advisable to install the entrance hatch directly above the well head.

All about installation and connection

The installation procedure is, in general terms, similar for all types of caissons. Although there are some features that will be discussed below.

The pit for the caisson is chosen to be at least 30 cm larger than the caisson itself. This will help to install it more accurately, correcting the coincidence of the well pipe and the sleeve for its passage. In addition, this will allow the walls to be insulated or strengthened, as required by the plastic structure.

As already mentioned, the well casing is cut taking into account the future height of the chamber floor. The bottom of the pit is covered with a sand cushion 20-30 cm thick. The sand backfill is spilled with water to compact it. A concrete slab reinforced with steel mesh is cast on top of the cushion.

You can place anchor bolts on it in advance to secure the caisson. But there is a high chance of making a mistake. Therefore, it is much more convenient to first install the caisson in place, and then drill holes for fasteners in the slab.

Nowadays there are many fastening options that expand and wedge in holes, and therefore there are no special problems in choosing something suitable.

Now let's dwell a little on the features of this or that design scheme.

Installation of a caisson made of concrete rings

The technology is not particularly different from the installation well rings. Only to a much shallower depth. The rings are fastened together with steel plates in case of ground movement.

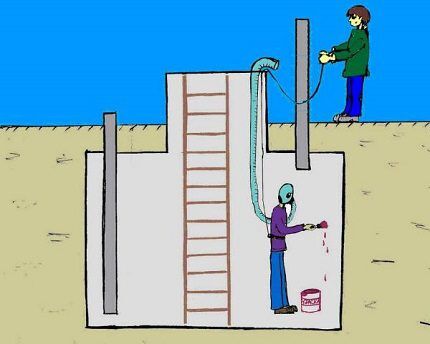

The seams between the rings are filled with cement mortar and reinforced - coated with clean cement mortar without adding sand or other thinning additives.

Concrete still allows water to pass through, albeit not intensely. Therefore, it is necessary to take care in advance of waterproofing the walls of the caisson. Often for these purposes, roofing felt or polymer films are used, glued through the mediation of bitumen mastic. The method has a right to life, but it is better to use reinforced materials glass insulation or waterproofing. Or similar ones.

Concrete resists cold and freezing quite well, but its standard characteristics are still not enough. Additional insulation is required. Here it should be taken into account that the insulation used should not absorb water - otherwise it will be useless. And resist soil pressure - over time, soft insulation materials can be compressed by the soil to the thickness of a paper sheet.

Therefore, preference is given to the most dense and durable varieties, often to different types of slab insulation. We can recommend foam glass - but this is a very expensive option. Extruded polystyrene foam will be a more affordable insulation material. Or, as it is called for short, EPPS.

The cheapest insulation will probably be polystyrene foam. It is easy to work with and its increased flammability will not play a role when located in the ground. But it resists compression less well and is not very durable - after a few years it will have to be replaced.

Not only the walls are insulated, but also the ceiling. But this is much easier than insulating a wall. We just take into account that the insulation should not extend beyond the perimeter of the caisson - otherwise it will simply be torn off during shrinkage - the structure is still quite heavy.

Another interesting point. There are often recommendations not to make a bottom for concrete caissons. That is, install the rings directly on the sand bed and gravel drainage. The motivation is simple: if condensation occurs, it will go into the soil.

Or the second option for this solution: do not fill the seam between the lower ring and the concrete base with cement mortar. The reason is the same - to allow possible condensation to escape.

It is difficult to recommend such execution options for repetition.It would be because this scheme will only work on a high, dry area. In other cases, a depression two meters below the surface of the earth will do the trick - the caisson will be flooded at least once a year. And, therefore, will not fulfill its role.

The problem of condensation is solved by normal insulation. As a last resort, we simply introduce ventilation into the structure - like in a cellar.

The absence of a concrete base under the rings is completely unacceptable - due to the small support area. In other words, there is a risk of large shrinkage. Which, in turn, is fraught with deformation of the incoming pipes. The principle of the approach is simple: everything should serve for a long time and reliably. The fewer adjustments and interventions required subsequently, the better.

The passage of pipes through the walls is insulated in the same way as the entries through the foundation of the house - with cement mortar and bitumen mastic from the outside.

Installation of metal caisson

Installation of a metal caisson necessarily requires a cast base plate and fastening with anchors. Before installation outside, the caisson box is covered with waterproofing. It is primed from the inside. This is mandatory even for stainless steel. Insulation is required. The method of passing communications is somewhat different.

The well casing pipe is simply passed into a sleeve hermetically welded to the bottom. For other inputs, bushings are welded into the walls. The necessary fittings are simply screwed into them, thus leading out the water lines (to the general water supply, for watering the garden, to the pool and so on) and running the power cable to electric pump.

Usually everything happens in this sequence:

- A pit is being dug for a caisson.

- The base is made - a sand cushion and a concrete base slab.

- The well casing is cut to size.

- A caisson is placed over the pit on beams or channels and carefully aligned until the well pipe and liner coincide.

- The caisson is finally installed in its regular place.

- Auxiliary trenches are being dug to supply water to the house and others.

- All communications are connected.

- Insulation and waterproofing are being hung.

- The caisson is covered with soil and buried.

There may be additions and rearrangements to this scheme, depending on the site conditions and tasks. But it’s better to dig trenches for the supply line to the caisson after it’s installed - just jumping through extra ditches and holes at this moment is not entirely convenient.

Installation of plastic caisson

In general, the process is very similar to manipulating the metal version. The difference is that when sealing the joint between the casing pipe and the sleeve, not welding is required, but PVC glue.

And the passage of pipes through the walls is carried out not through threaded bushings, but through special couplings, which are then closed with sealing caps.

An important feature is that waterproofing and insulation are not required, but mandatory protection from soil compression is required. It's easy to do. The gap between the walls of the pit and the caisson is filled concrete mass. No need for high-strength composition. A solution with a ratio of 5:1 is sufficient, which means: 5 parts filler and 1 part cement. As a filler, a mixture of sand and crushed stone.

The measure is necessary, even if there are stiffening ribs on the polymer body. But all these troubles are not so high when compared with previous options. In addition, such a concrete shell makes the entire structure stronger and more resistant to extrusion. Which affects the overall service life.

More details in the photo galleries:

Conclusions and useful video on the topic

The rules for installing a caisson and placing equipment in it are slightly different. It all depends on the type of construction, but in general terms it is repeated: the principle itself is important.

Caissons are an element necessary for high-quality well construction. It is very important to choose the right device, because the operation of the entire system will depend on it. It is impossible to clearly determine the best caisson. This must be decided by its future owner. When choosing, you need to take into account the characteristics of the area, the well and your financial capabilities.

The rules and subtleties of installing a caisson for a well are not so numerous. Even if the developer is not confident in his own abilities and will not solve the problem on his own, knowledge of the basics will allow him to control the work performed on the site by the contractor. After all, the comfort of living in the future depends on the quality of their implementation.

Are you seriously thinking about installing a caisson? Or maybe you have already carried out similar work yourself or have valuable knowledge that you want to share with visitors to our site? Please share your experience and leave your comments at the bottom of the article.

Of course, a plastic caisson is a reliable and durable option. And for those who do not need to save, this is the best choice for constructing a well.For budget country housing or a small summer cottage, when price matters, I would recommend concrete rings. The main question is that the rings must be of high quality. Then there will be enough of them for your lifetime. And the issue price will be significantly lower.

Previously, in order to pour a monolithic reinforced concrete caisson, it was necessary to arrange formwork and install a reinforcement skeleton. We needed information about the physical and mechanical properties of the soil; for pouring, the concrete had to be at least grade 400. Now, structures made of plastic or metal make our lives easier. But nevertheless, it is always necessary to follow a number of rules common to the construction of all caissons so that they serve for a long time and do not cause inconvenience during operation.

I consulted about installing a caisson, and they told me that it would really be better with it. I took it with an insulated lid, since in winter there are periods with severe frosts, so that nothing would freeze, I decided to play it safe. Well, and of course, made of plastic, it does not freeze, condensation does not form, metal in this regard is significantly inferior to polymers. This pleasure cost a little more than 22 thousand rubles. But I didn’t think about it right away, and then it was too late, the design turned out to be not very convenient to use, there are no loops for the lid and sleeve for the casing pipe. So pay attention to this too.

Tell me about plastic caissons - how is their reliability? Will it hold up if I have a parking lot nearby where I park my car?

Hello, Sergey. The plastic caisson is a fairly durable structure.If you consider that usually plastic caissons for wells are buried in the ground, backfilled and filled with concrete, then you can safely park your car nearby.

If the site is concreted and is not located in close proximity to a plastic caisson, then there is nothing to worry about. How far is the parking area?

And one more clarification, if the car is not a passenger car, but a truck, then it is better to move the site.

I saw a lot of plastic caissons, just flat, there are not even stiffening ribs, and signs of reinforcement of the walls, smooth, they will gradually be squeezed out of the ground by groundwater. I even squeezed out the iron ones, I installed a plastic Bio-s, with lugs, it’s been standing for two years, it doesn’t rise, the walls are reinforced with iron rings.