Pumping stations for wells: how to choose, connection and installation features

The automated process of supplying water from a well to a residential building, garden and vegetable garden will help minimize the time planned for household chores. The “heart” of water supply networks are pumping stations for wells - devices that pump water from a source to water collection points.

For their smooth operation, you need to know the nuances of the location, installation and connection of pumping equipment. Do you agree?

We will tell you how to correctly select a pumping station to supply water to a country house. Here you will learn everything about the rules for laying water lines from the water intake to the house. Taking into account our advice, organizing a water supply with a well as a source will not cause the slightest difficulty.

The content of the article:

How is the pumping station constructed?

The level of comfort in a country house is to a large extent determined by the presence of a professionally adjusted water supply system, the main component of which is a pumping station.

The structure of the devices involved in organizing the water supply must be known in any case. It will come in handy if you are laying the water supply yourself or entrusting installation work to professionals.

Knowing the principle of operation of individual elements of the system, in the event of an accident or failure of one of the devices, you will be able to independently, and most importantly, quickly carry out pumping station repair or replacement.

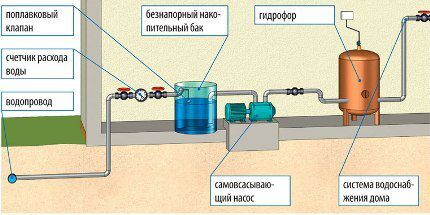

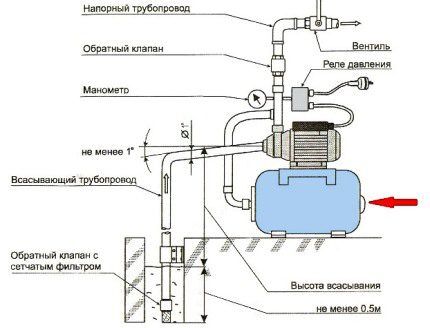

So, the most important components of a water supply scheme using a pumping station are the following:

- water intake device with filter;

- check valve that prevents water from flowing in the opposite direction;

- suction line - pipe leading to the pump;

- pressure switch to regulate water supply;

- pressure gauge showing exact parameters;

- hydraulic accumulator – automatic storage;

- electric motor

Instead of a hydraulic accumulator, a more modern and practical device, sometimes a storage tank is used, which has several disadvantages (weak pressure, inconvenient installation, etc.).

However, now that many modern inexpensive models with a hydraulic accumulator have appeared in stores, there is no point in independently assembling a system with a storage tank.

If you decide to purchase a container for collecting water, try to take into account the following nuances:

- The reserve tank is installed in the highest possible area (for example, in the attic) to create the necessary pressure.

- The volume of the tank should be such that a reserve of 2-3 days is maintained in case of failure of the pumping equipment (but not more than 250 liters, otherwise sediment accumulation is possible).

- The base for mounting the container must be reinforced with beams, slabs, and additional floors.

The reserve storage tank, like membrane equipment (hydraulic accumulator), should be equipped with a filter. In addition, it is mandatory to install a safety pipe to drain excess water.The hose connected to the pipe is led into the drainage system or lowered into containers intended for storing irrigation water.

The operating principle of the pumping station is cyclical. As soon as the water supply in the system decreases, the pump turns on and begins pumping water, filling the system.

When the pressure reaches the required level, the pressure switch is activated and turns off the pump. The relay settings must be set before starting to operate the equipment - they depend on the volume of the tank and the characteristics of the pump.

Criteria for choosing a station for a well

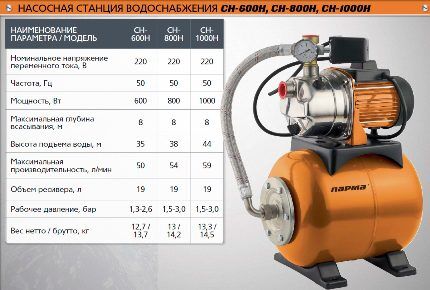

When purchasing a pumping station, you should pay attention to the pump parameters and factors characterizing the water source (in our case, a well), including its distance from the building.

For example, it would be useful to clarify the following values:

- Maximum water intake depth. We are interested in the dynamic water level, that is, the average for 1-2 days with constant water use. If you take into account the static level, you can make mistakes in the calculations.

- Nominal head of the unit. The conditional height of the water column that pumping equipment can create. Calculate using the formula, summing up the suction value, the length of horizontal sections of the pipeline, vertical lift and losses for transportation through the pipeline.

- Pumping station performance. For calculations, you can take the average water flow at all water collection points (for example, a faucet at a sink - 0.15 m/s, a shower or washing machine - 0.3 m/s). The total value should not be higher than the well's flow rate, otherwise the source will not be able to cope with the supply.

- Power supply voltage. In household networks this is 220 V (except for powerful stations with three-phase motors, where the voltage is 380 V).

- Power consumption. The spread of energy consumed by stations is impressive. On average 500-2000 W. The choice of circuit breaker type directly depends on the power.

- Volume of the hydraulic accumulator reservoir. From 24 l (for a family of 1-2 people) to 100 l (6 people or more).

It is clear that without knowledge of the technical nuances, before choosing and purchasing a unit, it is better to consult with a specialist who is well versed in household pumping equipment.

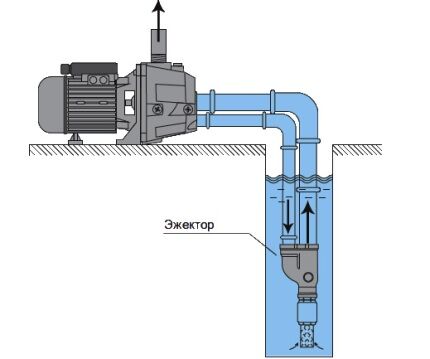

Choice well pumping station depends on the depth of the excavation. For example, if the depth reaches 12-15 m, a device with a built-in ejector is needed, more than 20 m - with an external ejector. Thanks to the looped suction, the lifting force of water increases, but the efficiency drops sharply and energy consumption increases.

How to choose a location for equipment?

To operate pumping equipment, try to comply with some conditions:

- minimal distance of the station from the water source;

- required temperature conditions;

- the ability to reduce noise levels;

- convenient location of equipment for maintenance.

Taking into account the listed factors, the most suitable places for installing the station are the caisson, the basement of the house and the boiler room, although each place has its own pros and cons.

A caisson is usually called a structure built in the ground. It is installed directly above the exit of the wellbore, and a deep pit is dug, which should be below the freezing level of the soil. If the pump is not installed deep enough, it will not be able to operate year-round, as it will fail at the first frost.

The caisson requires waterproofing and additional insulation of the upper part - the roof. In addition, the volume of the room must be sufficient to allow repairs to be made if necessary.

The advantage of installing a pumping station directly above the wellhead borehole caisson the fact that the operating unit will be located away from residential premises and will not cause discomfort with loud noise.

A good option for installing a station is a basement. It is located further from the well than the caisson, but in the basement it is easy to equip a place for installation. Taking into account the threat of flooding, the unit is installed on a small, stable hill.

In the basements of country houses, utility rooms are often arranged (laundry rooms, storage rooms, cellars for storing canned food), so heating is provided in advance. If, however, the basement is not heated, you need to take care of additional thermal insulation, and even more practical - install an additional radiator.

We do not recommend installing a boiler room next to living rooms, since the noise level of operating equipment is quite high. If you decide to install a pumping station in a hallway or closet, try to isolate the room as much as possible.

There is another solution, but it will be of interest only to those who visit the dacha exclusively in the summer.

You can purchase a compact portable unit and install it in a small temporary shelter - a wooden structure that resembles a box.The main thing is that the structure is protected from precipitation. For the winter, the pumping station, along with a temporary water supply system, is dismantled and placed in a warm room.

Instructions for installing a pumping station

Let's consider the most popular option for installing a station, in which the unit is located on the territory of the house (in the basement or utility room), and the suction line, lowered into the well, is equipped with an ejector.

External work - from well to house

External measures include installation of a suction well device - external ejector, laying a main line to the foundation of the house or preparing a site (utility room) for installing a pumping station if it is located in the basement.

The closer the well is to the house, the better, as this guarantees stronger water pressure and a minimum of problems with laying the water supply. The main task of drillers is to equip the well by installing a casing pipe in accordance with the norms and requirements; they do not deal with the external design of the well head.

Thus, before starting work, the well is a piece of pipe about 1 m high, sticking out of the ground.

We decided to install a well with a pumping station for pumping out on the territory of the house, therefore, there is no need to create an additional room in the head area - it is enough to design the head itself, maintaining a tight connection between the pipe and the water supply.

To lay a main line that will function year-round, you will have to dig a trench below the freezing level. Accordingly, the casing will also have to be dug to this level.

Thus, the pipes will go from well head to the hole in the foundation of the house.An important condition is the slope of the water supply in the direction of the source, so that in case of drainage, water can flow naturally into the well.

The hole in the foundation should not be too high in relation to the main line - sudden changes and bends negatively affect the pressure force and the functioning of the system as a whole.

After a hole has been punched in the foundation and a trench has been dug, three steps must be performed directly related to the installation of pumping equipment:

- assemble and install the ejector;

- secure the head hermetically;

- prepare a site for installing a hydraulic accumulator.

The ejector is a cast iron part with three threaded holes. When connecting it to pipes, it is necessary to use sealing paste, fum tape or flax, otherwise the tightness will be broken.

If the outer piece of casing extends high above the ground, the excess portion must be cut off. It may be difficult to find a head for a two-pipe device; in this case, you can assemble the device from a head for a single-pipe station. To do this, a branch of the same diameter is welded to the casing pipe at a right angle.

To calculate the length of vertical pipes, for which roll-type polyethylene products are often used, it is necessary to add 2 meters to the dynamic water level.

You should not lower the end of the device close to the bottom, as the coarse filter will quickly become clogged.If polyethylene pipes do not straighten (because they have been stored in a roll for a long time), they can be slightly heated with a hair dryer.

The ejector is threaded onto pipes, sealed tightly and lowered into water. Procedures for sealing joints and securing knees must be carried out on a solid base. If you try to fix the parts by weight, you risk drowning the ejector in the well. You will have to buy a new station, because the ejector is not sold separately.

External pipes are laid in trenches and brought into hole in the foundation of a house, then connected to the couplings of the centrifugal surface pump. To make the pipes fit more tightly, they must be inserted all the way, tightened by hand, and then secure the result with a gas wrench. Sprinkling of the pipeline should only be done after testing the system.

It is better if at the time of immersion of the ejector the pumping station is already installed on a specially prepared base. It must be stable and strong, reaching a height of up to half a meter.

You can make a concrete platform, put together a table from wooden blocks or lay brickwork - the main conditions are to ensure safety and stability.

After the ejector connected to the suction line has lowered the water, and it, in turn, is attached to the pumping station, you can begin internal work on installing home wiring.

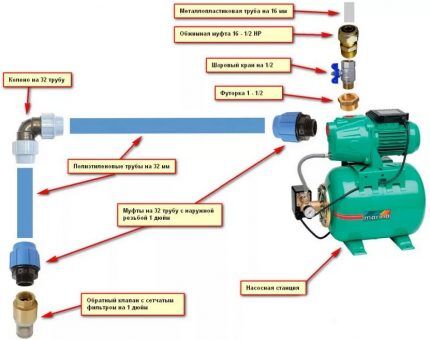

Installation of shut-off valve and filter

We will not discuss in detail the connection of water points, but will consider the installation of a section of pressure pipes to the filter. As main elements inside the house, you can use polymer pipes with a set of fittings of a suitable diameter. Parts made from the materials mentioned are easy to install and replace if the need arises.

You need to start with the sidebar locking device, which will make it possible to install plumbing equipment and also shut off the home water supply network in the event of an accident or long-term departure.

The best option is considered to be a reliable ball valve with an American connection. If desired, it can be quickly replaced or removed without dismantling the remaining parts of the line.

Buy only high-quality brass taps, since cheap fakes with silumin-containing alloys quickly fail and often cause flooding.

The primary filter should be located next to the hydraulic accumulator, in a place convenient for maintenance. The regularity of washing the cartridges - the main filter filling - depends on the saturation of the water with lime, iron and other microelements.

There should be no inclusions such as coarse sand or pieces of clay on the internal section of the water supply; they are filtered out even before the water enters the membrane tank.

Typically, the filter comes with an installation key, which makes the installation process easier.The housing must be installed so that on one side there is a pumping station, on the other there is a distribution line to the points of consumption. The pipes along their entire length are fixed to the wall with clamps, at turns and at fastening points - with special fittings.

When assembling the network, make sure the connections are tight, otherwise when water moves under pressure, the line may leak.

Checking the system operation - test run

Testing the operation of the water supply system is the final stage pumping station connections to the well. In order for the procedure to go without “surprises,” you should remember a number of important rules.

For full operation of the equipment, it is necessary to complete the installation of external water supply and installation of internal wiring. To check, you can also turn off the tap of the internal part, and use the watering line instead (if it is provided for by the project).

Equipment preparation procedure:

- Fill the inside of the accumulator with water (required!) by unscrewing the tank cap and using a funnel. It will take about 10-12 liters of liquid to fill the pump and adjacent pipes.

- Screw the filler cap tightly.

- Check the pressure parameters in the accumulator (they are indicated in the technical specifications and are 1.2-1.5 atmospheres).If the pressure is lower, it is necessary to pump up the air to the required level using a compressor.

- Let the water flow by opening the valves on the main lines.

Only after completing all of the above steps can you connect the electrical power. As soon as the motor starts, water will fill all the pipes. It is necessary to ensure that the air is completely removed from the lines, then you can turn off the tap.

Next, you need to monitor the pressure - as soon as it reaches the parameters set by the manufacturer (up to 3 atmospheres), the automation (pressure switch) should operate and turn off the water supply.

If the testing was successful, it is necessary to complete the installation of the system: finally secure the pipes inside the building, backfill the street main.

HDPE pipes - an alternative to steel mains

Let's take a closer look at the pipes connecting the submersible equipment and the surface centrifugal pump.

When choosing pipes for external water supply, you need to focus on factors such as:

- convenient transportation;

- easy installation that does not require highly qualified knowledge;

- strength, abrasion resistance;

- elasticity and deformation of shape without loss of functional qualities;

- non-toxic, safe for moving drinking water.

All of the above requirements are met by pipes made of low-density polyethylene. Unlike metal analogues, they do not deteriorate due to corrosion over time. The average service life of HDPE pipes is 50 years.

We recommend purchasing only high-quality, labeled products with the following data indicated on the outside:

- variety;

- external diameter;

- wall thickness;

- nominal and maximum pressure.

On the pipe, which is necessary for laying the pressure line from the well, it is possible to indicate the purpose - “drinking”. For use in the country, products with a diameter of 32 mm and a wall thickness of 2.4 mm are suitable. The blue stripe indicates that the pipes are intended for pumping water (yellow – for transporting gas).

How to insulate an external water supply?

Laying the main line below the freezing level of the soil solves the problem of additional thermal insulation, but it is not always possible to dig deep trenches. It is necessary to place the pipes at a shallow depth, having previously insulated them on all sides.

Previously, the only acceptable method was used - they wrapped the products with a heat-insulating material, for example, a mineral wool shell, then with waterproofing so that water did not penetrate from the outside.

Nowadays, several modern methods have appeared that increase the efficiency of heat saving. For example, the use of pipes, factory-made, enclosed in a hard polystyrene foam shell.

The most effective way is to use heating electric cable. The water supply pipeline has a diameter of 32 mm, which means that it is enough to stretch the cable along the main line, securing it directly to the pipe.

The only disadvantage of the electric heating system is its dependence on power supply. However, country homeowners who constantly live off-grid always have an alternative source of energy available - a gas, diesel or gasoline generator.

Conclusions and useful video on the topic

They will help you understand the nuances of installing a pumping station for wells.

Video #1. Useful tips for self-assembly and installation of a pumping station:

Video #2. Features of installing a pumping station in the basement:

Video #3. Installation instructions for the Grundfos MQ pumping station:

We recommend connecting pumping equipment yourself only to those who have already encountered the installation, replacement or repair of pumping stations. For beginners, it is better to turn to people experienced in this matter, or at least carry out all the work under their control.

Would you like to tell us about how you installed a pumping station to draw water from your own well or well? Do you know the nuances of connecting equipment that are not mentioned in the article? Please write comments in the block below, ask questions, share your impressions, useful information and photos on the topic of the article.

In my house I installed an autonomous water supply using water from a well. We pump it out with a deep-well pump; before the hydraulic tank it passes through a coarse filter. After rough cleaning, I use a water softener. Softened water is supplied to the storage tank.Water is distributed from the tank throughout the house through an automatic pumping station installed to compensate for the pressure drop. I would like you to add information about water softening systems.

Automated water supply systems are becoming increasingly common in our gardening. Summer residents, who were the first to decide to create comfort for themselves in this way, clearly demonstrate all the conveniences from its use. You can do everything as in a city apartment - toilet, shower, sink in the kitchen, watering the plants with water at ambient temperature.