Reinforced concrete rings for wells: types, markings, production nuances + the best offers on the market

Reinforced concrete rings are used in the construction of functional and inspection points of underground engineering systems. They are used in the construction of water supply and sewer wells of various categories and purposes. In order to correctly select reinforced concrete products, you need to know the performance characteristics.

We will talk about what physical, mechanical and practical qualities reinforced concrete rings for wells should have. The article we propose provides recommendations for selection and discusses the specifics of labeling. A rating of responsible manufacturers offering certified products is presented.

The content of the article:

- General description of reinforced concrete rings

- Types of reinforced concrete modules

- Labeling and production process

- Additional elements for wells

- Advantages and disadvantages of reinforced concrete products

- TOP 10 best manufacturers in Russia

- No. 1 - Kirov Plant of Reinforced Concrete Products

- No. 2 – Concrete concrete plant 24/7

- No. 3 – Factory of industrial construction parts

- No. 4 - Monolith Stroy group

- No. 5 – Tambov Concrete Concrete Plant

- No. 6 – Terem LLC

- No. 7 – Kipensky reinforced concrete plant

- No. 8 – Plant for the production of building materials

- No. 9 - Dmitrovsky MZhBK plant

- No. 10 – Gurovsky Concrete Concrete Plant

- Conclusions and useful video on the topic

General description of reinforced concrete rings

The principle of production of reinforced concrete rings regulates GOST 8020-2016. Explains the purpose of the structures, size and markings GOST 8020-90.

The well ring is a monolithic structure, shaped like a hollow cylinder. It is made from heavy poured concrete mixtures, different fractions of crushed stone, sand and specific chemical additives.

Reinforced with metal rod and wire to obtain the following characteristics:

- increasing tensile strength;

- strengthening basic strength;

- increasing resistance to compression during operation.

Used in industrial construction to create collectors, water supply, sewer and gas pipelines. Used for laying underground cable, electrical and telephone networks.

In the private sector, reinforced concrete rings are used:

- in the building water intake wells;

- in the arrangement septic tanks with different numbers of cameras;

- in construction absorption wells, collector and observation points all types of sewer systems.

If there is a quality waterproofing ensures complete tightness of vertical shafts and horizontal lines. Does not require regular maintenance and does not lose specific qualities and strength characteristics over time.

Types of reinforced concrete modules

The simplest standard models are produced without additional fasteners. Their end resembles a smooth, even rim both at the top and at the bottom.

When laying, they are placed one on top of the other and fastened with metal brackets. The joint area is covered with cement mortar or dry repair mixture.

After such treatment, the system acquires optimal integrity and tightness. Correct insulation in the contact area of concrete elements extends the operational life of the shaft and almost completely eliminates water leakage through the cracks between concrete elements.

Euro-rings are available with a practical milling-type locking connection. There are protrusions at the top of such products, and deep recesses at the bottom.

During installation, the elements are inserted into each other, thus providing a monolithic and strong connection that does not require additional processing in the joining area.

This facilitates and speeds up the process of creating a communication system and reduces the overall financial costs of the project. A well shaft made of Euro-rings with a lock is not afraid of seismic activity with shifts and maintains the integrity of the structure even on very unstable soils prone to subsidence.

A monolithic glass is a one-piece structure made of a row ring and a bottom. Used in places with increased requirements for tightness, for example, for sewer tanks.Provides a high level of protection to the surrounding soil and does not allow the contents of the well to seep into the ground or enter groundwater.

Labeling and production process

The entire process of manufacturing rings for wells is clearly regulated by separate legislative acts and technical conditions. GOST 10180 describes in detail the quality and strength characteristics of a concrete mixture suitable for the production of modules.

Standard 10060 determines the requirements for frost resistance of the material. The required level of water resistance is reflected in the document 12730. Deviations from the norms are allowed in minimal percentages and only for certain parameters.

Technological features of factory production

To produce a well ring, a professional concrete mixer, an automatic vibroform and a crane-beam, designed to work with loads weighing from 1 to 2 tons, are required.

A special concrete mixture is used as raw material. It includes:

- fresh additive-free cement with a good rate of strength gain;

- coarse sand with crushing of 2.0-2.3 microns (preferably without or with minimal presence of clay lumps and dust particles);

- crushed stone fraction 5-10 mm, but not more than 5-20 mm;

- process water without impurities;

- superplasticizer.

All components in a certain proportion are placed in special equipment.It thoroughly kneads the composition, giving it a homogeneous, fluid consistency without lumps or clots.

At the next stage, reinforcement elements made of steel wire with a diameter of 8-12 mm are placed in the molding container (formwork). This frame gives the ring additional strength and provides good resistance to compression/tension during operation.

There are two vertical rods on opposite sides of the structure. They act as ears and facilitate the subsequent removal of the ring from the mold.

Then the prepared cement composition is poured inside the formwork and automatic vibration is activated. During the processing process, all voids are evenly filled, and the concrete acquires the necessary integrity and density.

After 24 hours, the product is removed from the vibroform and moved to an open area to stand. After a week, the ring acquires about 50% of its basic strength, and becomes fully usable after 28 days.

How are products labeled?

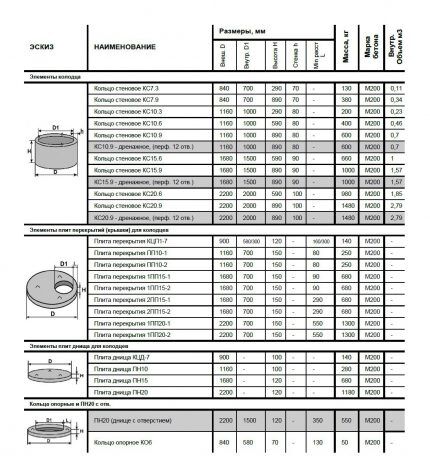

All reinforced concrete products are marked with an alphanumeric abbreviation generally accepted in the state. This allows you to quickly determine the size and scope of each individual element when purchasing.

Letter combinations are deciphered as follows:

- KS – wall ring, available for placement in confined spaces;

- KLK – module for creating drainage networks and local storm sewer systems;

- KO – fundamental support that ensures the stability of the well base;

- KFC – fragments for arrangement of collector networks and drainage communications;

- KVG – products for installing water wells and laying gas pipelines.

The numbers next to the letters indicate the height, thickness, specific gravity and internal diameter of the ring. Understanding these values, purchasing suitable reinforced concrete products will not be difficult.

Additional elements for wells

Regardless of the purpose of the well, it will not be possible to get by with rings alone during installation.

In order for the entire system to function correctly and not fail in the future, the following elements will certainly be needed:

- Base slabs (bottoms) - are placed at the base of the structure, level the base surface and give stability to the entire well shaft.

- Support floors – are a concrete circle with a hole closed by a standard manhole cover. They take on and evenly distribute the external load over the surface. They ensure the safety of the entire well and protect it from collapse and cracking.

- Additional rings – have a standard diameter, but less thickness. Designed to raise the current height of the well to a higher level.

- Well hatches (lids) – are produced in the shape of a regular circle. Depending on operating conditions, they are divided into sidewalk and highway. They are characterized by high strength and good resistance to intense loads.

The presence of additional accessories ensures complete tightness of the system, prevents sewage from entering the network, protects pipes from freezing in winter and extends the service life of communications.

All additional elements must be selected based on the conditions in which the system will be operated. This approach allows you to create a stable, sealed network with a large working resource.

Advantages and disadvantages of reinforced concrete products

Well rings made of reinforced concrete are very popular and are included in the list of the most popular building materials. This is due to their specific physical and structural characteristics.

The main advantages of the product include:

- Extended operational period. Concrete reinforced with steel wire is neutral to any environment, including aggressive ones, and, according to manufacturers, can last at least 100 years.

- Maintaining rigidity and structural integrity on active soils. Wells made of reinforced concrete rings are installed even in areas with seismic activity up to 8 points.

- Wide range of models. Products are available in a variety of sizes. This makes it possible to select suitable reinforced concrete products for any purpose and need.

- Pronounced frost resistance. It is ensured by a strong bond between the reinforcing elements and the concrete mixture, which occurs after the final drying of the workpiece.

- High tightness. The seams fit tightly together at the joints and prevent groundwater and other foreign substances or materials from penetrating inside.

Finished products are sold at the best price and are suitable for arranging communication networks of any scale.

Disadvantages include the weight and dimensions of the product. Transportation and installation require professional equipment with good power and a team of craftsmen.

This inevitably entails additional material costs and an increase in the total cost of installation work.

You can make reinforced concrete rings for installing a small well in your country house with your own hands. Homemade production technology is described in detail in next article, which we highly recommend reading.

TOP 10 best manufacturers in Russia

In the Russian Federation, about 250 different enterprises are professionally engaged in the production of reinforced concrete rings and other components for wells. We invite you to take a closer look at the 10 most significant and responsible manufacturers.

No. 1 - Kirov Plant of Reinforced Concrete Products

The Kirov Plant of Precast Concrete Products occupies a leading position in the production of reinforced concrete products in the Volga region.In addition to well rings and related parts, the company produces about 2,000 types of products for civil engineering and the construction of engineering structures.

No. 2 – Concrete concrete plant 24/7

This plant is located in the Moscow region. Since 2004, it has been producing high-quality well rings and other reinforced concrete elements. Clearly withstands the 28-day cycle of formation of finished products.

To increase the strength characteristics, the product is reinforced with corrugated steel wire. To add elasticity, plasticizers are added to the working mixture.

Constantly improves the production process and introduces its own innovative developments aimed at improving the physical and mechanical properties of products.

No. 3 – Factory of industrial construction parts

This plant in Surgut has been producing reinforced concrete for over 45 years. It has a laboratory accredited by the State Construction Committee for multi-stage control over product quality. Supplies reinforced concrete structures for many industrial sectors, including oil and gas.

The internal equipment is modernized and meets modern production standards. The concrete mixing plant was completely reconstructed, the stock of metal molds was updated, and a plasma cutting machine was purchased for the reinforcement shop.

This makes it possible to produce prefabricated reinforced concrete products in large volumes that comply with the standards and requirements of GOST.

No. 4 - Monolith Stroy group

Since 2007, the Monolit Stroy group located near Moscow has been engaged in the production, sale and delivery of concrete mixtures and reinforced concrete structures for various purposes. The company's product range includes rings of different diameters, bottoms and plates for creating wells.

All products are certified and sold at the best price. Additionally, the company provides customers with bonuses, discounts and preferential conditions for large wholesale purchases, while at the same time providing prompt delivery of goods directly to the facility under construction.

No. 5 – Tambov Concrete Concrete Plant

The Tambov plant, which became a joint-stock company at the end of 1992, plays a significant role in the reinforced concrete structures market. Throughout its existence, the company has never ceased its activities and even during periods of crisis it operated with a profitability of at least 15%.

Now the manufacturer spends the main profit on internal re-equipment of workshops, the purchase of high-quality raw materials and improving the general qualifications of personnel. Delivery deadlines are never missed, and all obligations to shareholders are fulfilled without delay.

No. 6 – Terem LLC

Terem LLC has been manufacturing reinforced concrete structures since 1998 and is considered one of the largest enterprises in the Krasnodar region. The workshop workers are equipped with high-tech equipment that allows them to produce not only standard, but also non-standard products with good strength and physical characteristics.

No. 7 – Kipensky reinforced concrete plant

The Kipensky reinforced concrete plant, located in the Leningrad region, has been operating in the building materials market since 2005. It offers prefabricated structures for various purposes to wholesale and retail customers. The production process at all stages is controlled by leading process engineers.

The modern concrete mixing plant at the enterprise's disposal allows us to produce an increased volume of products without compromising their quality. The finished product meets the requirements of GOST in all respects and is distinguished by reliability, resistance to aggressive environments and durability.

No. 8 – Plant for the production of building materials

The building materials production plant in Stavropol is a powerful high-tech enterprise with innovative Spanish equipment.

The workshops are equipped with:

- “Compacta” line for manufacturing products by vibration compaction;

- new generation Tensyland molding machine;

- a progressive device for creating well rings and related concrete elements.

This allows us to efficiently and quickly carry out not only standard, but also very large orders for reinforced concrete structures.

No. 9 - Dmitrovsky MZhBK plant

The Dmitrovsky MZhBK plant has been producing reinforced concrete products for various purposes since 1952. It successfully produces not only standard products, but also specific structural elements according to the customer’s technical specifications.

Has an impeccable reputation in business and industrial circles. Cooperates with large government clients and supplies products for strategic facilities. Cargo delivery is carried out via highways and railways.

No. 10 – Gurovsky Concrete Concrete Plant

Gurovsky Concrete Concrete Plant is the largest manufacturer and supplier of prefabricated reinforced concrete products in the Central region of Russia. Strictly complies with the requirements of current technical specifications and GOSTs.

In its own research laboratory, it conducts research activities on batches of manufactured goods and tests progressive innovations that help improve the physical and mechanical properties of rings for wells and other products.

All of the above companies produce large volumes of reinforced concrete structures, have certificates of conformity and are considered reliable suppliers for both industry and the private sector.

Conclusions and useful video on the topic

A detailed description of the production process of a reinforced concrete ring at a large enterprise:

How to correctly and safely load reinforced concrete rings into a well:

How to make a convenient and practical septic tank for a private home from concrete rings with your own hands. Useful tips from an experienced home handyman:

It is advisable to purchase reinforced concrete rings for arranging communications for various purposes from trusted manufacturers.Such enterprises strictly adhere to the current specifications and create products with excellent physical and mechanical characteristics.

Products made in accordance with GOST standards serve for a long time, are resistant to external conditions, do not deform during operation and completely last for the period specified by the manufacturer.

Would you like to talk about how you selected rings to build a drinking well or septic tank on a country plot? Do you have interesting information that would be useful to site visitors? Please write comments, share useful information, post photos related to the topic of the article in the block below.

Building a well from concrete rings is now the most common method, so there should be no problems with the material. The main thing is to carefully inspect each ring for cracks and chips. You need to make sure that it is of the correct shape, check its strength, and make sure that there is reinforcement. Be sure to check the certificate stating that the product is suitable for drinking water. Well, take a responsible approach to the installation of each part of the well, because the quality of the water received will depend on this.

What to pay attention to when shipping rings? Should there be any accompanying documentation?

Marking of rings in accordance with GOST, accompanying documentation is provided by the manufacturer or supplier. When shipping, pay attention to the integrity of the rings so that there are no chips, cracks or other defects.

Also keep in mind that concrete rings must be marked accordingly:

1.KO - support ring intended for the fundamental part of the well;

2. KS - reinforced concrete wall ring used in small or extremely narrow sections of wells.

It is these two types of rings that you need; you do not need other markings (KVG, KFK, KLK), since these rings are not suitable for wells.

Hello. Keep purchase receipts and other documents so that you cannot be accused of theft. We had this happen on the street - they brought the rings to a common well, and by coincidence they stole them on the next street. She provided checks on the street. And besides, if you have rings lying around for a long time without installation and not behind a fence, get permission from the administration to store building materials.