Methods and technologies for cementing wells: how to prepare and pour cement slurry

After drilling a well in loose sandy soils, a stage begins aimed at strengthening the casing pipes.At the same time, the trunk should be protected from damage, aggressive effects of groundwater, corrosion and other negative phenomena. We are talking about a process such as cementing wells.

Carrying out cementing work on your own is quite difficult, but it is possible if you have knowledge about the technologies for carrying out the event. We will tell you why you need to carry out cementing and what you need to pay attention to when performing work. For clarity, the material contains thematic photos and videos.

The content of the article:

Why cement a well?

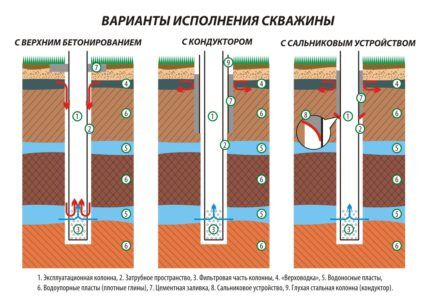

Well cementing is a process that follows immediately after completion drilling operations. The cementing procedure consists of introducing a cement solution into the annular or annulus (if the casing pipe is placed in a wider polyethylene pipe), which hardens over time, forming a monolithic wellbore.

The cement mortar in this case is called “plugging”, and the process itself is called “plugging”. A complex engineering process called well cementing technology requires certain knowledge and special equipment.

In most cases, water sources can be plugged with your own hands, which is much cheaper than hiring specialists.

Correctly performed plugging of water wells contributes to:

- ensuring the strength of the well structure;

- protecting the well from ground and surface waters;

- strengthening the casing pipe and protecting it from corrosion;

- increasing the service life of the water source;

- elimination of large pores, voids, gaps through which unwanted particles can enter the aquifer;

- displacement of drilling mud by cement, if the former was used during drilling.

The quality of the produced water and the operational characteristics of the well will depend on how well the cementing is carried out. Cementing is also carried out for abandoned wells that will no longer be in operation.

Stages of cementing a water source

The entire cementing process consists of several stages, each of which has its own nuances:

- Preparation of cement slurry to fill the annulus.

- Supply of prepared cement to the well.

- Injecting cement slurry into the annulus.

- The period of hardening of the cement mortar.

- Checking the quality of cementation.

Each stage requires the use of certain tools and special equipment. It is better to make calculations of the required materials before the start of grouting work, because The plugging process must last continuously and if, for example, you do not have enough cement mortar, this will most negatively affect the quality of cementing. Let's look at the most important stages in more detail.

Stage No. 1 - preparation of equipment

All work on cementing aquifer wells must be carried out strictly in accordance with technical requirements, violation of which will lead to poor-quality cementing.

When starting to plug a well, you should know that this is an irreversible process; it is impossible to correct anything after the solution has begun to be supplied into the annulus of the well, therefore the preparatory work, namely the preparation of a solution for cementing and the selection of equipment, must be approached as responsibly as possible!

The easiest and most effective way is to rent equipment on a vehicle platform. Such a complex will be able to prepare a cement solution and pump it into a well under pressure, while the source of energy for operating the equipment is a powerful automobile engine.

If using units based on a special vehicle is not possible, then you will need:

- mixer for preparing cement mortar;

- a high-pressure pump that pumps solution to the well;

- cementing head for pumping solution into the well;

- filling plugs (the quantity depends on the cementing method);

- various small equipment (hoses, measuring containers).

As a hose, many experts recommend using a flexible fire hose instead of traditional HDPE pipes with a diameter of 32 cm. It is flat and fits perfectly into the interpipe space, ensuring efficient supply of solution.

Stage No. 2 - preparing the solution

The cement slurry for cementing a well must meet a number of requirements and have:

- high adhesive properties with surfaces of any type;

- high strength after hardening, resistance to mechanical stress;

- plasticity and good fluidity to fill all cracks and voids;

- chemical neutrality in relation to tamponed soil layers;

- resistance to erosion by groundwater;

- no shrinkage during hardening.

Also, the solution must have such a consistency that it can be easily delivered to the well and injected. The solution must be easily washed off from the equipment, not be chemically aggressive towards it and have a minimum loss coefficient during transportation to the well.

The process of preparing cement mortar for tamponing consists of uniformly mixing the components included in its composition, followed by pouring water into it with special additives previously dissolved in it.

The simplest solutions that you can prepare yourself are:

- Portland cement + quartz sand (1:1) + special additives and water until the required consistency is obtained. This solution has a low density, and its preparation is difficult, because the sand included in the composition often precipitates and the use of the solution becomes impossible.

- Portland cement + barite (1.1:1) + special additives and water. The disadvantage of this solution is its low strength.

- Portland cement + filler. Asbestos (on sandy soils) and fibrous materials are used as fillers.

To prepare the cementitious mixture, it is best to use Portland cement cement, which is a type of silicate-based cement.

Such cement, of course, is more expensive than ordinary Portland cement, but its strength characteristics are much higher than those of ordinary cement. Barite is a heavy mineral that increases the density of the solution. You can buy barite at a hardware store that sells bulk building materials.

Special additives included in cementitious solutions mean various substances that give the solution special properties.

These include:

- setting accelerators cement (calcium chloride, soda ash, potash), used if cementation occurs at temperatures below +5 degrees;

- retarders, used to prevent rapid hardening (these are calcium or sodium chlorides, sodium nitrite, etc.);

- plasticizers to obtain optimal viscosity (polymer modifiers);

- frost-resistant additives (organosilicon compounds coupled with plasticizers);

- desiccant additives (substances obtained from compounds belonging to the groups of sugar, citric, tartaric and tetraoxyadipic acids), etc.

Special additives are mixed in water, which is subsequently used to prepare cement slurry. The solution is mixed using special machines - mixers. Sometimes manual kneading is allowed, but it requires some skill and a lot of labor.

Stage No. 3 - pouring solution into the well

The main methods of cementing wells are:

- continuous or single stage;

- two-stage;

- cuff;

- the opposite.

All methods of cementing water wells are based on one principle - pumping cement slurry into the annulus. At the same time, the choice of cementing technology depends on specific conditions: soil type, well depth, casing pipe material, climatic and hydrogeological conditions of the area.

The selected water well plugging technology should ensure:

- filling the entire well section with solution to the full depth;

- completely displace the flushing liquid (if any);

- creation of high-strength cement stone, resistant to physical, mechanical and chemical influences;

- high rate of adhesion to the soil walls of the well and casing pipes.

For deep wells, segmental cementing is used, i.e. Not the entire well section is cemented at once, but only its individual segments.

This process is very complex and practice shows that it is almost impossible to do it yourself. Therefore, we will take a closer look at the technology of one- and two-stage and sleeve cementing.

Single-stage or continuous cementing

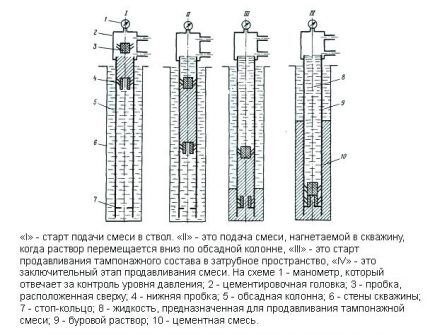

This method is most often used for cementing domestic aquifer wells. During its implementation, the cementing solution is pumped into the annulus.

The solution is pumped under pressure using equipment that is installed on the platform of a special vehicle or permanently near the well. The cementing solution, under its own weight, moves to the base “shoe” of the casing, filling all the annular cavities.

Before starting cementing work, it is carried out well cleaning, and then a lower plug is inserted, which will act as a limiter. The concrete pump is turned on and the pumping of the plugging solution begins, under the influence of which the plug is lowered until it reaches the “shoe” of the casing.

After pumping the solution, the upper plug is installed and compaction of the cement mixture begins until the upper plug rests against the lower one. This will mean that the solution has filled the entire annulus. Compaction is carried out using a vibrating press using a concrete pump to pump the solution.

The cemented well is left alone for 36-48 hours for the solution to completely harden. This method is only suitable for shallow, evenly shaped wells. The disadvantage of this method is the inability to track the moment when the cement slurry reached the bottom point of the well alignment.

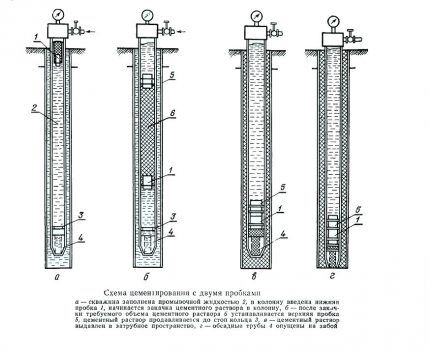

Two-stage filling system

This cementing method was developed for oil industry wells. Due to the fact that it requires the use of serious industrial equipment (a powerful concrete pump), it is not often used in well construction. Two-stage cementing is used in the following cases:

- the cement mortar sets so quickly that cementing cannot be completed in one cycle;

- when it is necessary to select two sections in the annulus that are separated by a significant distance;

- at great depth of the well, when it is impossible to carry out work in one cycle.

In other cases, the use of a two-stage method is impractical due to the duration of the process and economic indicators.

The principle of two-stage cementing is based on the fact that cement is pumped into the annulus in two stages.

The first portion of cement slurry is loaded and pressed. The bottom plug is lowered, which, by the action of the solution, the plug sinks to the bottom. The second portion of the solution is pumped 12-36 hours after the first portion has completely hardened.

Application of the cuff method

This cementing method is used if only the top part of the well needs to be strengthened. In this case, the initial task will be to determine the level to which cementing will be carried out.

The level is marked along the casing by installing a special collar. The lower part of the valve is reliably protected by a cuff from penetration of the plugging solution.

The solution is pumped in exactly the same way as during single-stage cementing. The cuff method is used if the upper part of the well is located on sandy soils, and the lower part is located on clayey soils. This is quite rare, so this method is not widely used.

The process of formation of cement stone

The process of cement stone formation begins immediately after pumping the plugging solution and lasts from 12 to 36 hours. The main factors influencing the duration of hardening of the solution to the state of cement stone:

- properties of the components included in the solution;

- soils, casing material;

- hydrogeological and climatic conditions at the site;

- injection density, correct implementation of the plugging process.

During the hardening period, it is necessary to leave the well at rest. It is prohibited to use cables, crowbars, or wires to assess the quality of cementation, because this may compromise the integrity of the resulting cement stone.

Cementation quality assessment

It is worth noting: despite the fact that assessing the quality of cementation of aquifer wells is a very important step, it is impossible to carry it out independently.

To carry it out, special laboratory equipment is required, which is very rare even among organizations involved in drilling.

If you still intend to evaluate the tamponing performed, you can order a quality control service in one of three ways:

- acoustic, based on tapping the walls of the casing, with subsequent processing of the obtained data by computer programs;

- radiological, when measurement using radio devices;

- thermal, based on the principle of measuring the heat generated when the cement mortar hardens.

At home, you can use a simplified thermal method by measuring the temperature at the walls of the well. When it becomes equal to the surrounding air temperature and becomes 0.5-1.5 degrees lower, then we can talk about complete hardening. However, even after this, it is recommended to wait 2-3 days and only then put the well into operation.

After completing the inspection, the wellhead is cleared of cement slurry residues using bailers. Then a leak test is performed by pumping water under high pressure into the well pipe for 30 minutes. The criterion for tightness will be a decrease in pressure by approximately 0.3-0.5 MPa. The well is now completely ready for use.

Conclusions and useful video on the topic

The videos below are about wells in the oil and gas industry, but the principle of the work technology is the same as for water-bearing wells.

Procedure for one-stage well cementing:

Specifics of the production of lip cementation:

Technological features of two-stage cementing:

Cementing is a complex process that requires the use of specialized equipment. However, this does not mean that it is impossible to do it yourself. By choosing and correctly preparing the grouting solution, using a minimum set of units, you can easily handle the job yourself.

In any case, the operation of a well without strengthening the barrel with cement will not last long, and the costs drilling a new water source will be no less.

If, after studying the material, you still have questions about how to properly cement a well after drilling, or you have valuable knowledge on this issue, please leave your comments in the block below.

The plugging process should be taken into account when calculating drilling costs, so as not to overpay later. You need to contact the organizations that were involved in drilling the well: they have reports on the work carried out with geological and hydrogeological sections constructed for the site, they know how to properly drill and plug a well, and not do everything at random. Unfortunately, now everyone who is not too lazy is engaged in drilling, even without approximately knowing the properties of the soil and the depth of the aquifer.