How to insulate a well for the winter: review of the best methods + choice of materials

A water well is most often used as a source of water for autonomous water supply.It can be used seasonally or year-round. If you plan to draw water in winter, you need to think about how to insulate the well for the winter and avoid problems with water interruptions, equipment breakdowns and pipe ruptures.

We will tell you how to thermally insulate an independent water source, eliminating the formation of ice plugs in the system. Here you will learn how to insulate a mine shaft and the water lines extending from it. Our advice will help you decide on the best method and material for insulation.

The article thoroughly examines the basic rules and subtleties of organizing a system for protecting an independent water supply from freezing. For a visual understanding of the topic, diagrams, photo illustrations, and video tutorials are attached.

The content of the article:

Features of well protection from cold weather

Incompetent arrangement of the water intake often creates obstacles to the normal operation of the source. Errors and shortcomings are especially acute during the winter period.

Operation of a well that is not protected from freezing by reliable thermal insulation in frosty conditions makes it difficult for ice to form on the water surface and the formation of ice plugs in the pipeline.

As a result, the pumping equipment and the system as a whole operate under increased load. A large plug can deform or even rupture HDPE pipes, from which external water supply branches are most often constructed.

Plugs and ice crust in the well appear if the water intake is not operating at full capacity. Those. if there are breaks in operation sufficient for water to crystallize. Even if the owners of an autonomous water supply system do not count on such pauses in functionality, measures to prevent them in the form of installing an insulation system must be carried out.

Events for insulation of the water supply system are carried out from the point of entry into the house to a depth that is 20-30 cm below the level of seasonal soil freezing. This value can be found in the collections on construction climatology SP under the number 131.13330.2012 and in SNiP under the number 23-02-99.

The depth of freezing is determined in accordance with the conditions of the region and the type of soil covered by the freezing zone. Its value is obtained empirically based on long-term observations.

If the water supply is introduced into the house through the foundation of an uninsulated basement, the branch before entering the heated room must also be insulated. The use of materials for insulating objects located in the ground has its own specifics.

Insulation materials must have the following properties:

- Do not absorb water or have a protective waterproof shell. If water is absorbed into the insulation and then freezes, then with a high probability, due to the increase in the volume of water when it turns into ice, the insulation layer will be destroyed.

- Do not lose their properties under soil pressure. The pressure of the earth mass from above or its movements can crush the insulation and increase its thermal conductivity.

- Not of interest to or susceptible to insects and rodents.

The last point is very important, because in the summer mice can take the insulation into their nests, and in the winter they can dig passages in it to get to the warm pipes. All this will lead to direct access of cold to the water supply elements.

Sometimes, to protect the well and water supply system from cold, it is enough to perform procedures that do not require special knowledge about the principles of insulation of an underground water supply system. The water that is supplied to the system from the depths has a positive temperature (usually from 7 to 13 degrees Celsius).

If there is a risk of water freezing, then it is necessary to adjust the operating mode of the system so that water is supplied in small portions, but as often as possible. Constant circulation of underground water, the temperature of which by definition is above 0º C, will prevent icing.

Insulating the head and pipes during not very cold winters in the southern regions of Russia or when the water supply is deep can be done without any special frills using sawdust or straw. To do this, you need to dig a hole near the head and a ditch along the water supply pipe, cover them with dry sawdust or straw and bury the hole again.

This procedure must be carried out every year in the fall, so that the sawdust and straw do not have time to rot by winter. To eliminate freezing for a longer period of time or if the proposed methods do not guarantee a positive result, a different approach to solving the problem is necessary.

Protection of the well head from freezing

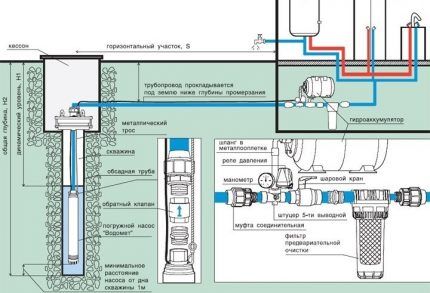

A caisson for a well is a reservoir buried in the ground located above the mouth of the mine. It is necessary for convenient access to the main elements of the water intake system for the purpose of repairs and regular maintenance.

Mounted inside the insulated caisson hydraulic accumulator, pumping equipment and filters to remove them from the house and remove noise. If the equipment is placed in a heated room, a caisson is not installed, but an adapter is installed.

Both the well with and without a caisson must be insulated so that direct contact of the elements of the water supply system with frozen rocks is excluded throughout the entire thickness of the freezing soil.

Basic principles of caisson insulation

Even if the well head is located below the soil freezing depth, the main part of the caisson is located above this mark. If its walls have significant thermal conductivity, then negative temperatures can drop to the top and the water in the system will freeze much lower than Construction Climatology indicates.

By geometry caissons for wells can be cylindrical or rectangular, this does not affect the method of insulation. In terms of insulation costs, cylindrical objects are more profitable, and from the point of view of ease of installation of material supplied in the format of rigid slabs, it is easier to insulate rectangular objects.

According to the material, caissons can be concrete, metal and plastic, although concrete structures are now rarely used due to the complexity of their installation and the fragility of concrete when exposed to moisture.

Insulating the caisson from the inside is important if its body is sealed due to the properties of the material or reliable waterproofing. In this case, there is no need to protect the insulation from moisture.

In addition, soil movements or other external influences will not affect the integrity of the insulation layer. As a rule, for internal insulation, products based on polystyrene foam or expanded polystyrene are used.

Insulation of the caisson from the outside is carried out to preserve the internal space or if bulk materials are used. It is advisable to insulate plastic structures from the outside, protecting them from severe frosts, during which the plastic becomes brittle.

External insulation is carried out using any materials, but it is necessary to take into account possible soil movement, exposure to water and the risk of damage to the insulation layer by insects and rodents.

Since heat loss will still occur with any insulation of the well, it is necessary to compensate for it due to the influx of heat. It will happen anyway due to the positive temperature of the water in the pipes passing through the caisson and the heat generated by the operating devices.

If there is a possibility that the insulation may not be enough, then you can install a basic heating element complete with a temperature sensor.

Since the internal space of the caisson is small, with normal insulation, it is enough to use an ordinary incandescent lamp with a power of 40-60 watts or a heating wire 3-5 meters long as a heating element.

Installation of casing pipe for the cap

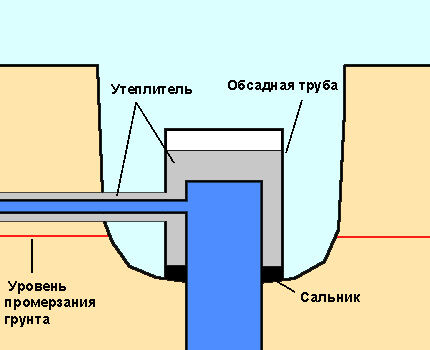

If the caisson was not provided for when designing the water supply, and the head is located above the soil freezing level, then it can be insulated using an additional casing pipe, the Ø of which is greater than the Ø of the stationary casing by two thicknesses of insulation.

To install an additional length casing pipe it is necessary to dig a hole around the head to the depth of soil freezing plus 0.3 m and insulate the head. An additional pipe must be installed on top, and the space between the casings must be filled with glass wool or mineral wool.

It is undesirable to fill the gap between two casing pipes with sprayed thermal insulation options due to the inability to control the uniformity of the application of the insulating layer.

The pipe must be metal, since in the cold the plastic becomes more fragile and soil movements can damage it.

It is also necessary to ensure that there is no water in the space between the casing pipe and the head. Mineral wool loses its thermal insulation properties when it absorbs moisture, and the polystyrene foam shell can be deformed when ice forms.

To prevent getting wet, before laying the thermal insulation in the gap between the casings, it is necessary to install an oil seal. The outer size of the gland must be equal to the diameter of the additional casing, and the inner size must be equal to the diameter of the main casing.

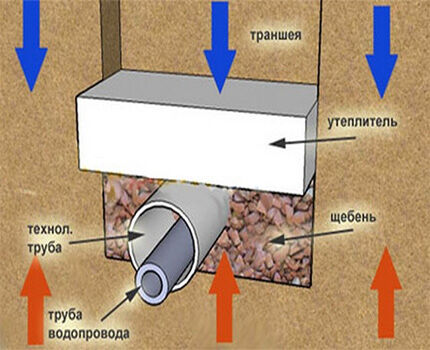

Insulation of underground pipe system

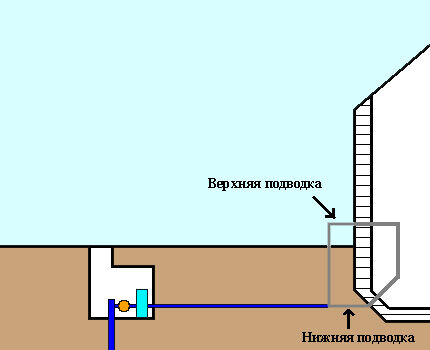

Insulation of the water supply branch leading to the house may not be necessary if it is located below the freezing level of the soil. However, the deeper the water supply system is located, the more complex its installation and repair.

In this case, pipe insulation can be cheaper in cost thermal insulation material and be simpler in terms of the level of work required.

Application of modern thermal insulation materials

The oldest and most proven method of insulating pipes is filling the trench with expanded clay. Mineral wool without a waterproofing outer shell is not used for underground communications.

Now the number of different types of thermal insulation offered for sale allows us to solve this problem for any temperature conditions. To install underground lines in areas above the freezing level, a “shell” of polyurethane foam and expanded polystyrene with a foil waterproofing shell is produced.

Let's look at the main types of material that are most often used when insulating underground water pipes:

- mineral wool or glass wool is compressed under the weight of the earth, so if it is used, additional work is required in the form of creating a durable casing;

- basalt fiber covered with aluminum foil for waterproofing is a rather expensive material, but it is easy to work with;

- polystyrene foam and polystyrene foam are easy to cut, retain heat well, but protection from rodents is necessary;

- polyurethane foam retains heat well and is moisture resistant.

There are special shaped shells for knots and turns, which is convenient for installing insulation. They allow you to install thermal insulation on pipeline sections of any degree of complexity without any problems.

You can quickly and reliably insulate a water line using sprayed polyurethane foam. In such cases, the pipe must be laid on an expanded clay cushion, because the bottom of the pipeline may not be covered with thermal insulation material.

For hard-to-reach places where the use of bulk materials is problematic, you can use thermal paint - a modern universal liquid heat insulator. This paint can be applied either with an ordinary brush or roller, or by spraying. In addition to its main function, it protects metal pipes well from corrosion.

Using a heating cable

The principle of operation of thermal insulation materials comes down to the so-called “passive protection”. Thanks to its proximity, the water in the pipes will not cool while it flows to the heated room.

It must be understood that in a closed system without an external heat source, the insulation system does not prevent freezing, but only increases the period until water crystallizes under the influence of negative temperatures.

If water from a well is used infrequently, such insulation for the winter may not be enough.In case of interruptions in work for more than a day, it is necessary to heat the pipes, with the water drained from them, using special electrical cable.

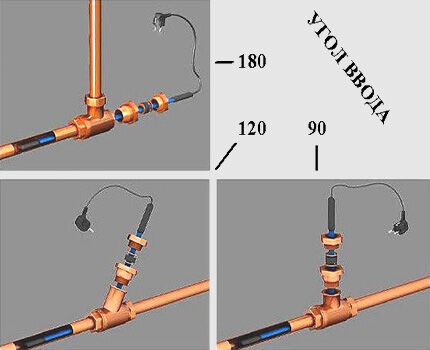

There are two ways to place the heating cable: inside the heated pipe and outside.

For indoor installation, special cables are used. They are non-toxic and meet increased electrical protection requirements (although experts recommend connection via RCD) and are sold complete with a sealed end coupling. Installation of such a cable is simple and is carried out through an ordinary tee.

The main advantage of the indoor installation option is the high efficiency of the heating system and, as a result, reduced energy costs. The main disadvantage is the difficulty of running the cable through curved sections of the water supply.

When installing the cable externally, it is necessary, first of all, to ensure its tight fit on a well-cleaned surface. The cable is attached to the pipe using aluminum tape, then the tape is placed over the entire cable so that it does not come into contact with the thermal insulation material.

Plastic pipes are pre-covered with foil to ensure uniform heat distribution.

To increase heat transfer, you can secure several cables linearly or in a spiral. In the case of a spiral pitch of 5 cm, the length of the conductor will increase by 1.7 times relative to the length of the covered water pipe.

Installing a thermostat allows you to significantly save energy, because the heating is turned on only when the set temperature is reached. The optimal switching temperature is considered to be from 3 to 5 degrees Celsius.

The heating cable is always installed complete with thermal insulation, otherwise heating the environment will be very expensive.

Additional protection during installation

For the well option using submersible pump Before long-term downtime, the system is preserved.To do this, pipelines are laid with a slope towards the water source, and a check valve is installed at the outlet of the supply pipe from the shaft.

After turning off the pump, it, together with the supply pipes, is removed from the excavation, and the water is drained by gravity into the well. When using this method, it is desirable that there are no “pockets” where water could remain. The disadvantage of this method when using metal pipes is the increase in the rate of metal corrosion.

One of the rarely used methods is to create a “pipe-in-pipe” system, when a larger diameter pipe is placed on the water supply system, which is insulated from the outside. The air gap formed in this way serves as additional protection from the cold.

If you insert an external pipe into the basement of the house, ensuring air circulation between the layer and the basement, you can obtain additional heating of the underground water supply.

Another option is forced water circulation. To do this, it is necessary to install a second pipe leading from the basement to the well and a system of taps to switch the water supply to the house or to this pipe.

By turning on the pump according to a schedule, you can pump warm groundwater into the system, and pump cold water from the system into the well. This option is convenient when the owners are away from home for a long time and there is no water consumption.

There is a widespread opinion, including on the Internet, that you can prevent water from freezing by creating excess pressure in the system.However, the temperature at which water turns into ice decreases by only 1 degree for every 130 atmospheres of static pressure. It is unrealistic to build a water supply system that can withstand such pressure.

Conclusions and useful video on the topic

Video #1. Basic insulation of walls and caisson cover with foam plastic from the inside:

Video #2. Construction of a well using a caisson, covering the topic of insulation:

Freezing of the well and water supply system is fraught not only with the interruption of water supply, but also with damage to equipment and system elements, the repair of which will require money and considerable effort. It is better to carry out high-quality insulation work once and get constant access to water for many years.

Please write comments in the block below. We are waiting for your stories about your own experience in insulating an autonomous water source. Perhaps you have questions or have interesting information that you are willing to share with us and site visitors.

I use a heating cable complete with suitable thermal insulation. At the same time, there is no need to hide the pipes under a layer of non-freezing soil, which, in turn, significantly reduces installation costs and simplifies technical operation. Electricity consumption, provided that the cable is installed correctly and when using a thermostat, is small. In addition, the construction principle fully justifies itself when carrying out pipeline repair work if necessary.

Our winters in the south are not very frosty, and at my dacha I insulated a well without a caisson. I made a wooden box in the form of a house, and furnished it from the inside with the help of mineral wool. I made an opening lid on top.It’s convenient because you can open it at any time and check if everything is fine. And it adds aesthetics to the site, it looks very nice. Well, in regions with colder climates, it’s probably impossible to do without a caisson.

All this is good for clean water, when water from a well is supplied to the house and used immediately. There is no provision here for an option in which water from a well requires purification. Moreover, the water is first cloudy, then clear, and then cloudy again. There is a need to create an additional, external, outside the house, reservoir for settling water for preliminary rough cleaning of clay suspension, a reservoir that requires heating in winter.

So, I have never seen a design that combines cleaning and heating.

Filters at the water intake point, on the submersible pump, are not effective.

And further. Nowhere is it said or shown how to install a heating cable if a submersible pump with a flexible hose extending to the surface is lowered into the well. The cable cannot be attached to the wall of the well due to its small diameter (you can only climb into the well at arm's length). And how to attach the cable to the hose going outside (after all, it is this part of the hose that freezes in winter), and whether it is possible to attach it this way, is also not said anywhere.

Attach the cable to the hose with aluminum tape to the depth of soil freezing. The well itself does not need to be insulated; the water does not stand at its neck.