Arranging a water supply system in a dacha from a well: diagrams, nuances, overview of the necessary equipment

An independent water supply system will allow you to forget about the main inconvenience of country life - the absence or lack of water. But it is quite simple to install a water supply system at a dacha from a well, especially since a water intake for one plot of land does not need to have a large flow rate. After all, you would like to get water on your own property, right?

After reviewing the information presented for consideration, you will be able to make an autonomous water supply yourself. It will reliably supply water to places convenient for use. Those who want to increase the level of dacha comfort with our help will cope with the arrangement of the system without any problems.

We described in detail the equipment required for assembly and installation, analyzed the operating principle and purpose of each device. The article we presented describes in detail the technology of carrying out work with step-by-step detailing. Valuable information and recommendations are supplemented with photo collections, diagrams and video reviews.

The content of the article:

Types of tube wells

The well is a circular opening, drilled without human access to the face. The diameter of such a mine is always much smaller than its depth. Two types of wells are used for water intake.

Filter or “sand wells”

The depth of such workings does not exceed 35 m. Filter wells are being drilled to a nearby aquifer, which is located in sandy soils.

Such a well is a casing assembled from pipes with a diameter of 127 to 133 mm. It is usually equipped with a wire mesh filter, but there may be other options. Filter wells have a small flow rate, most often it does not exceed one cubic meter of water per hour.

The advantage of such structures is the speed and relative cheapness of their drilling. Specialists will complete the job in just a day or two. The main disadvantage is the tendency to silt.

Therefore, it is very important to use such a well regularly, the service life of the structure depends on it. Depending on the thickness of the aquifer and the intensity of use of the well, it can last up to 15 years, in some cases longer.

Artesian or “limestone wells”

Deep structures that are drilled into an aquiferous area common in fractured limestone. It is about 20-130 m deep. Unlike sand wells, artesian wells have a higher flow rate. It can reach up to 100 cubic meters of water per hour.

Drilling wells on limestone is quite difficult, and the casing string is quite long. The drilling procedure lasts four or more days.

Accordingly, the cost of work and materials is significantly higher. The advantage of artesian wells is their long service life. They do not require a filter because the host rock does not contain fine clay and sand particles.

In this way, the well does not become silted, so it can last much longer than a filter well, five decades or even more.

Selecting a pump for pumping water

The pump is a kind of “heart” of the system. The uninterrupted operation of the future water supply system depends on its correct selection. You can find several types of submersible and surface pumps on sale.

Deep and surface units

The latter are called so because the pump itself is removed from the pumped liquid. The body of the unit is located on land, and water is drawn through a hose lowered into the well.

Surface pumps can extract water from an average depth of 8 - 10 meters, so they are used quite rarely for wells. Most often, submersible devices are installed to supply water. Their main difference from surface ones is complete immersion in water. Their design is specially designed for great depths, where they are used as rationally as possible.

Submersible well pumps are divided into two types. A shaft is mounted in the housing of centrifugal devices, on which paddle wheels with blades are mounted.

When the shaft begins to rotate, the movement of the blades creates a centrifugal force, which pumps the liquid that fills the internal space of the device.These pumps are reliable and versatile in use.

Besides, centrifugal mechanisms have an optimal price/quality ratio. Vortex pumps are considered the most practical option. In addition to their low cost, they are attractive due to their extreme simplicity of design and ease of operation and maintenance. The basis of the device is a membrane, on one side of which there is a liquid, on the other - a vibrator.

After switching on, the latter begins to move and causes the membrane to deform, thereby creating a pressure difference. Which, in turn, starts the process of pumping liquid.

The mechanism is devoid of rotating elements and bearings, which are especially vulnerable and require constant monitoring and lubrication. The absence of rotating elements significantly reduces the heating of the device and extends its service life.

For artesian wells, the best choice would be a high-performance deep well pump. They are specially designed to work at great depths, where surface pumps, even those equipped with an ejector, cannot function.

Installing a deep-well device into a well is quite complicated, as is its removal. A properly selected and installed high-quality device will work for decades.

A cheaper counterfeit product is unlikely to cope with such a load and will require repairs.However, one must understand that in the case of a deep-well pump, the cost of dismantling it alone can be quite comparable to the cost of the device. Therefore, you need to purchase only a high-quality device.

Experts identify several criteria that must be taken into account when choosing a mechanism.

The total depth of the excavation and the water level in it

Key characteristics when choosing a pump. The technical documentation must indicate the optimal depth at which the device is intended to operate.

If this requirement is not observed, the device will not operate efficiently and may quickly fail. The well's passport must indicate both its depth and water level. They can only be compared with the characteristics of the pump.

If such data is not available, you can use a very simple method to measure the depth of the structure. We take a long dry rope, tie a weight to its end and lower it into the well. We lower the rope down until the weight touches the bottom.We remove the cable. We measure the dry part - this will be the distance from the top to the water level. The wet part is the height of the water column.

Approximate debit of the water intake source

This is the name of the mass of water that can be obtained from a well in a certain period of time. Drillers indicate this value in their passport, but if not, we make approximate calculations.

We completely pump out the water from the well and measure the time during which we did this. Then we measure the time it takes for the well to fill with water. We divide the second result by the first and get an approximate debit, which will be enough to select a pump.

The video will demonstrate how to determine the flow rate of a well and choose a pump:

Estimated water requirement

Different pumps can supply water at speeds from 20 to 200 liters per minute. In order not to overpay for a more powerful model, it is important to correctly calculate your own water needs.

On average, it is believed that one person needs about 200 liters of water per day, so for a family of three to four people, a pump with a capacity of 30 to 50 liters per minute is needed.

Some people prefer to take a device with a “reserve” of power, which will inevitably affect its cost. If it is planned that the pump will work not only to serve household needs, but also for irrigation, the increase in its power should be calculated.

It will depend on the size of the plot, but on average about 2000 liters per day should be enough. Thus, it is necessary to increase the water demand by 40-50 l/min.

Pressure required for operation of devices

The pump passport must indicate the pressure. To calculate the required pressure, we add another 30 to the depth of our well expressed in meters. This way we get the height of the water column.

We increase the result obtained by another 10% and obtain the desired value. Comparing it with the pump data, we select a model. If there is no exact match, we “move” in the direction of increase.

Diameter of drilled well

Another important quantity that determines the power of the pump. Like others, you can take it from the well’s passport or measure it yourself. It should be taken into account that the diameter of the well must be expressed in inches, where an inch is equal to 2.54 cm.

The vast majority of pumps are designed to work in 4-inch wells. For 3-inch ones, you will most likely have to order a pump from a catalog.

Equipment for autonomous water supply

For arrangement water supply from a well In addition to the pump, we will need other special equipment necessary for the normal functioning of the structure.

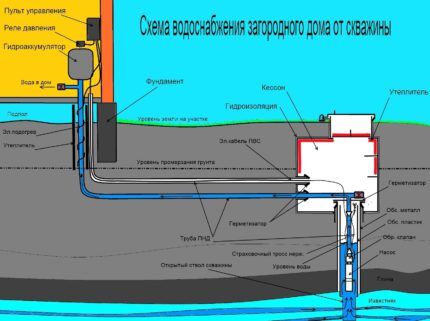

Sealed container to protect the head

An important structural element for well construction is caisson. This is a sealed chamber in which the well head is located. It protects the structure from freezing in the cold season and from the penetration of groundwater.

In addition, all the equipment necessary for the functioning of the well is located inside the tank. Therefore, the dimensions of the caisson must be sufficient to accommodate instruments and a person descending for maintenance or repair.

The sealed chamber can be made of different materials: plastic, concrete, metal, brick or polymer sand. Each option has its own advantages and disadvantages.

The container can be of any shape, but most often it has a round or quadrangular cross-section. The caisson can be purchased ready-made or made independently. In any case, the container must be equipped with a hatch with a tight-fitting lid.

The following video will introduce you to the arrangement of a caisson for an autonomous water source:

Hydraulic accumulator for pressure formation

The device is a container separated by an elastic membrane. One of the resulting compartments is filled with air, the second with water. The water entering the tank stretches the membrane, thereby reducing the volume of the first compartment.

The more water, the higher the pressure in the first chamber. After the consumer opens the tap, the amount of water decreases and the pressure in the air compartment decreases.

Hydraulic accumulator is complemented by a sensor that monitors the pressure in the chambers. When it drops below a predetermined level, the device sends a signal to turn on the pump and water from the well enters the system.

As soon as the pressure rises to a certain level, the pump turns off. The hydraulic accumulator is used to create pressure in the water supply system sufficient for the operation of household appliances.

Some of them, for example, instantaneous water heaters, dishwashers and washing machines, require a pressure of at least 0.5-0.7 atmospheres.

In addition, the device protects the pump from premature wear. Without a hydraulic accumulator, the equipment will turn on too often. And this is extremely undesirable for him, because turning on the pump more than 10 times a minute increases its wear by 40%.

Filter system for water purification

Filters necessary for wells of any type. Even deep artesian wells produce water with a high content of iron, heavy metals and other non-useful microelements. Therefore, purification of such water is necessary.

You can select the right type of filter only after water analysis. A complete cleaning system in its maximum configuration will look like this:

- Coarse strainer. Placed in front of the pump and in front of the hydraulic accumulator.

- Mechanical filter. The device delays inclusions with a size of 80-100 microns. It is a flask with replaceable fibrous filler.

- Aeration block. Saturates the water passing through it with oxygen.

- Set of special filters. Each of them eliminates excesses of a certain element: iron, potassium, sodium, salts, etc.

- Biological protection unit. It is a carbon filter or ultraviolet emitter that eliminates microorganisms from water.

- Fine filter. Stops inclusions up to 5 microns in size, which completely removes sediment and foreign impurities from the liquid.

As an option, a reverse osmosis filter can be installed, which allows you to obtain drinking water of the highest quality.

Technology for constructing a water supply system

After all the necessary equipment has been purchased and the well has been drilled, you can begin installing the water supply system.

Stage #1: laying pipes from the house to the well

We determine the area where the pipeline will be located and begin digging a trench. Its depth should be 20 - 30 cm greater than the level of soil freezing in this area. This is a very important requirement. Failure to do so threatens freezing and destruction of the system during the cold season.

We lay a sand cushion at the bottom of the dug trench, and on it a 32-mm water pipe made of cross-linked polyethylene or metal-plastic.

As an option, you can lay a PDN pipe, but it is destroyed by freezing, which cannot be excluded. Some “specialists”, instead of a pipeline, place a hose in the trench to supply water.

If you don’t want to get problems with the operation of your water supply, you shouldn’t do this. We pay special attention to the section where the pipeline rises to the house. Be sure to insulate the foundation and wrap the pipe with special material.

Can be used for insulation self-regulating heating cable, which is laid along the pipe in the lifting section. The same method is also used in the case when, for some reason, it is impossible to carry out excavation work on the site.

Then they dig a shallow trench under the pipes and lay them along with the heating cable. The elements are wrapped in thermal insulation material and placed in a pipe of larger diameter.

In addition, a storage tank for irrigation can be added to the resulting system. Because warm water has a beneficial effect on plants.

When laying a water pipe, do not forget to lay the cable that supplies electricity to the pump. It must be four-core and have a cross-section of at least 2.5. We place the ROM box in a specially designated place in a heated room.

Stage #2: caisson installation rules

Installation of the caisson depends on what material the container is made of. The easiest way to install plastic and polymer-sand containers. In any case, first we prepare a foundation pit, which should be larger than the chamber itself.

In some cases, we install a concrete platform at the bottom of the pit. Then installing a caisson into place and level. In the case of a plastic container, we also secure it.

Homemade concrete chambers are assembled from rings or poured into formwork assembled on site. Brick containers are laid out directly in the pit. Upon completion of the work, we insert water pipes and cables into the caisson, and reliably seal the entry areas. We lower and install the equipment for the well. If necessary, we backfill the installed caisson.

Stage #3: installation and connection of the pump

Before installing the mechanism, be sure to read the manufacturer's recommendations. We start with cleaning the well. We pump water out of it until sand and other particles of contaminants stop coming out.

To secure the pump in the well, we use a 4 mm steel cable of the required length or a 5 mm nylon cord. We securely fasten it to the body. In addition, we connect the pump to the water pipe.

We perform all operations very carefully so that the pump does not jam in the casing later. For normal operation of the system, a check valve is required for the pump, which will not allow water from the pipeline to return to the well.

Some models are already equipped with such a device; if not, we install the unit. We put the lower part of the head with the seal onto the well pipe.

Now you can carefully lower the pump into the well. We do this carefully, without jerking, and do not forget to fasten the electric cable feeding the pump to the water pipe every meter and a half.

The wire should lie freely, without tension. After the pump touches the bottom, raise it to a height of one to three meters and secure it. Now we install the upper part of the head in place.

We connect all the equipment located in the caisson to the water supply and electrical cable: water purification system, shut-off valves, automation, etc. During the work, we strictly follow all the recommendations of the device manufacturer. After connecting, we once again check the reliability and tightness of the connections of the water supply pipeline and the electrical safety of the newly assembled system.

Stage #4: installation and connection of the hydraulic accumulator

The volume of the hydraulic accumulator can be very different: from 10 to 200 liters. Depending on it, the location where the equipment will be installed is selected. This can be either a caisson or the basement of a house.

When choosing an installation location, it is necessary to take into account that it is necessary to ensure free access to the device for subsequent maintenance, repair or possible replacement of a failed container.

When installing a hydraulic accumulator, a check valve must be installed to prevent the flow of water from the plumbing system into the tank. It is placed in the direction of fluid movement. A drain valve is also installed for emergency drainage of water from the tank. To reduce the level of vibration from a working device, we mount it using a special rubber seal.

We connect the water supply pipe to the hydraulic accumulator. We assemble a starter that will supply electricity to the pumping equipment.We connect a sensor to the hydraulic accumulator, which will monitor the pressure in the compartments of the tank, and through it we power the starter. We connect the accumulator to the internal water supply system, directly or through a collector.

Step #5: Perform a test run of the system

After installation and connection of all elements of the system have been carried out, you can begin its test run. First, we activate the pump and, if necessary, debug its operation.

Then we fill the storage tank with water and check the accuracy of the automatic start and stop systems of the pump. Then we carefully inspect the entire pipeline.

We need to identify possible leaky areas. If any are present, we carry out repair work. In addition, we check the operation of all plumbing fixtures connected to the water supply.

We also pay attention to the performance of the system: the water pressure should be normal even with all taps open. If the test run was successful and the system works without failures, we dig a trench to supply water supply from the well to the house.

Conclusions and useful video on the topic

Practice-tested options for constructing an autonomous water supply are presented in the video:

Assembling a water supply system from a well yourself is a rather difficult task. It is important to choose the right equipment that matches the type of well, install it correctly and connect it.

If you have no experience in such work, you should entrust it to specialists who will quickly and correctly set up the system. The owner will only have to enjoy the comfort of his home, equipped with an autonomous water supply system.

We are waiting for your stories about your own installation of water supply at your summer cottage.You can leave them or comments in the block below. Please comment, ask questions, share information and knowledge.

In a dacha, without water it’s like being without hands; it can be difficult without the usual benefits of civilization. So, if possible, you need to immediately install a water supply system. This year I installed water supply at my summer cottage. Of course, not everything went as smoothly as I thought. There were problems with the well, as it turned out to be very deep and my pump, which I bought at first, did not justify itself. There was not enough power, it pumped water poorly. But then I found a solution. The information turned out to be useful for me, I received all the answers for myself.

I have a few clarifying questions. Firstly, please tell me whether such installations always provide good pressure or is it all individual and depends on the area? Secondly, even if the pressure is good, is it enough for a large household, say 300 m2? And thirdly, what are the energy costs of the installation? Will you end up paying a lot for electricity?