Installing a surface pump for a summer residence: rules for connection and operation

To choose the best pump option for water intake, owners of summer cottages have to take into account many factors. Agree, you don’t want to find yourself in a situation where, after purchasing expensive equipment, it turns out that its performance is not enough.

We will help resolve this issue. We will tell you by what criteria we select surface pumps for a summer residence. Here you will learn how to connect a pumping unit, what equipment you will need if you decide to automate the pumping of water from a well or well.

The article presented for review describes in detail the design features of surface pumps and the specifics of operation. The material is accompanied by thematic photographs and videos that will help you do everything right.

The content of the article:

Features of operation of surface pumps

Surface pumps, as the name implies, are installed on the surface. These are relatively inexpensive and quite reliable devices, although they are not suitable for very deep wells.

Rare to find surface pump, which can supply water from a depth of more than 10 meters. And this is only with an ejector; without it, the performance is even lower.

If your dacha has a well or a well of suitable depth, you can safely choose a surface pump for the site.

You can take a model with a relatively low productivity for irrigation or a more powerful device that will effectively provide water to a private home. The convenience of surface pumps is obvious: first of all, it is easy access for adjustment, maintenance and repair.

In addition, the installation of such a pump at first glance looks very simple. The pump must be installed in a suitable location, lower the hose into the water, and then connect the device to the power supply. If the pump is needed only for irrigation, you can purchase and install it without any additional elements.

To optimize the operation of the device, it is recommended to take care of an automated control device. Such systems can turn off the pump if a dangerous situation arises, for example, if water does not flow into it.

“Dry run” not recommended for almost all models of surface pumps.You can also automate the pump shutdown if the watering time has expired, the required volume has been filled, etc.

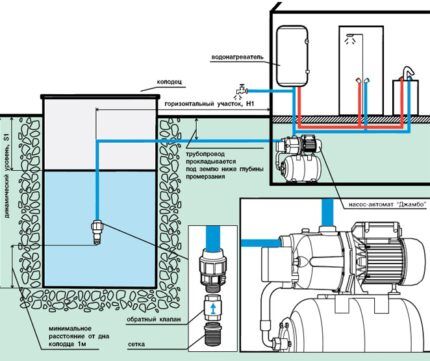

How is the pumping station constructed?

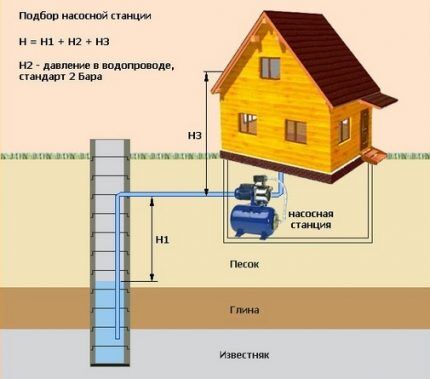

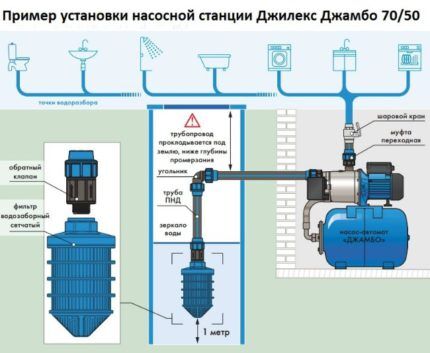

To organize an autonomous water supply to a house from a well or well, it is worth purchasing additional elements and combining them into a full-fledged pumping station. In addition to the pump, you will need a hydraulic tank, as well as a pressure switch. This relay turns the pump on and off, depending on whether the hydraulic tank is empty or full.

As a result, there will always be a certain supply of water in the house, and running the pump idle is completely eliminated. This significantly extends its service life. Besides, presence of a hydraulic tank compensates for possible water hammer, which has a positive effect on the condition of the water supply system as a whole.

Additionally, it is also recommended to purchase a pressure gauge (if the hydraulic tank is not equipped with one). Of course, you can purchase a pumping station equipped with all the necessary components. The installation procedure for an industrially produced station and a self-assembled one are not too different.

A hydraulic accumulator or hydraulic tank is a container equipped with a special rubber membrane. As the tank fills, this membrane stretches, and when it is empty, it contracts. This device is considered highly effective for autonomous water supply.

System with storage tank

As an alternative to a hydraulic accumulator, you can consider a regular tank, for example, made of plastic. It can be any suitable container that will meet the family's water needs. Typically, such a storage tank is installed as high as possible to ensure sufficient water pressure in the home's plumbing system.

It must be taken into account that the load on the walls and ceilings will increase. For calculations, you should remember not only the weight of the accumulated liquid (the weight of water in a 200-liter tank will, of course, be 200 kg).

You also need to take into account the weight of the tank itself. The total weight is related to the load-bearing capacity of the house. If in doubt in this regard, it is best to seek advice from an experienced engineer.

To automate the operation of a pump with a homemade storage tank, you can use a float sensor. This is a relatively simple device; many craftsmen make it themselves. A float is installed in the tank, with the help of which information about the water level is supplied to the automatic switch.

When the amount of water in the tank reaches the minimum level, the pump turns on and runs until the tank is full. After this, the pump automatically turns off. A storage tank is considered an economical option for water supply at home, since the cost of such a set of devices is lower than that of an industrial pumping station.

Where is the best place to install the pump?

The most important point when installing a surface pump or pumping station is choosing a suitable location.

Here are a few requirements that will help you find a suitable location for pumping equipment:

- the closer the device is to the water source, the more stable its collection will be;

- the device (or set of devices) should be protected from bad weather in a special room, head, bunker, etc.

- it is necessary to protect the pump from freezing during winter cold;

- the place in which the equipment is installed must be ventilated to avoid high levels of humidity that cause corrosive processes;

- care should be taken to ensure sufficient space not only to accommodate the pump or the entire station, but also to carry out the necessary maintenance, adjustment, repair, etc.;

- the place should either be remote from residential premises or additionally isolated from noise, since surface pumping equipment operates quite loudly.

It is not always possible to meet all these conditions, but this should be achieved with all our might. A surface pump is usually installed as close to the water source as possible.

To protect the device from external factors, it can be placed in such places as:

- special wooden box;

- well-maintained well head;

- a cavity dug into the ground;

- inside a spacious well;

- boiler room located next to a water source, etc.

Of course, each site is individual, the decision must be made depending on the situation. The pump is deepened into the ground if it is necessary to protect the device from frost, but there are no other options. You will have to dig a fairly spacious and deep hole; it should be below the freezing level of the soil.

Of course, if the cottage is used only in the warm season, the requirements for installing a pump may not be so severe. The problem of freezing automatically disappears.

But the pump should still be securely hidden from precipitation. When preserving a dacha for the winter, of course, the surface pump must be removed, cleaned and stored in suitable conditions.

If the source of water is a well made of concrete rings large enough in diameter, you can place the pump directly in it. In this case, there is no need to dig anything; you will need a small, durable raft that can support the weight of the pump. The raft is lowered directly onto the surface of the water surface, and a pump is fixed on top of it.

The advantage of this solution is that the depth of immersion of the hose will be slightly increased, i.e. the fence will be made from a greater depth. But possible problems should also be taken into account.

To service and repair the equipment, it will have to be removed to the surface. The risk of contact of an electrical appliance with water increases. But in general, this option is quite acceptable.

If it is necessary to install a surface pump as part of a pumping station, the requirements for choosing a suitable location will be approximately the same. Although it should be remembered that the dimensions of the whole complex of devices are somewhat larger than those of a conventional pump. Most often, the station is installed in an equipped area near the mouth wells caisson.

The ideal place is considered to be a boiler room, already equipped for the operation of heating equipment. Pumping stations are also installed in the basement of a residential building, but such a room will have to be carefully prepared: insulated and provided with heating to prevent water from freezing, etc.

It is possible to install the station inside a well, but this will cause an additional problem. To adjust pressure switch the equipment will have to be removed to the surface. Indicators obtained when the pump is operating on the surface may change when it is lowered down. This makes it difficult to adjust the pressure switch.

For lack of anything better, surface pumps are sometimes installed directly in living spaces: in the hallway, closet, bathroom, etc. This way the equipment will not get wet or freeze, but the noise from its operation will definitely disturb the residents of the house.

This option should only be considered temporary; the pump or station should be installed in a more suitable location as soon as possible.

You should choose a location for a surface pump before purchasing it. When installing such equipment, you should adhere to the “1:4” rule. This is exactly the ratio of the depth from which water is drawn to the horizontal distance to the pump.

If water comes from a depth of two meters, then the horizontal distance to the equipment should be no more than eight meters.If this ratio is not met, for example, the distance to the pump is greater, it is recommended to use pipes a quarter of an inch wider than the manufacturer's recommended dimensions.

Pump connection procedure

Although it is believed that installing surface pumps is less hassle than installing submersible modelsHowever, you should not take this matter lightly. A number of important points taken into account when installing the pump will help improve its efficiency and prevent possible breakdowns.

Step 1. Preparation of materials and tools

To connect surface pump, first you should stock up on the appropriate materials.

Here is a sample list of required elements:

- connecting fitting, which is installed between the pump and the hose;

- hose for collecting water from a source;

- hose or pipes for connecting the pump to the storage tank;

- watering hose;

- check valve with strainer;

- special adapter for the second output;

- connecting fittings;

- fasteners, etc.

If a system with a hydraulic accumulator is installed, you will also need a pressure switch and a pressure gauge. If you decide to use only a storage tank, you should purchase or make a float sensor.

Tools may require various keys, as well as devices for working with fasteners. A tape measure, a building level, materials for insulating threaded connections, a soldering iron for polypropylene water pipes, etc. will come in handy.

Step #2. Installing the device on the base

Before connecting any elements to the pump, you must install it on a solid and level base. This is an important point.

Even slight instability or tilt can cause a significant reduction in instrument performance. The base can be made of concrete, brick or even solid wood.

The main thing is that it is strong and even. Anchor bolts are usually used to secure the pump in a stable position.

There are special holes in the device body for fastening. Sometimes a large rubber gasket is installed under the pump housing. It acts as a shock absorber and dampens vibration when the engine is running.

Step #3. Installation of the supply hose

After this, the supply hose should be installed. Attached to its lower part check valve, on which a mesh filter is placed. A coupling with an external threaded connection is used as fastening.

Pumps equipped with a check valve and a coarse filter are produced at industrial enterprises. In order not to bother with this part of the system installation, you can buy a ready-made hose.

But, according to reviews from experienced craftsmen, making a hose with a valve yourself will cost much less. If the installation technology for all elements is followed, such a device will be no less reliable than an industrial production model.Sometimes two check valves are installed: one at the end of the hose, the other next to the hydraulic accumulator.

The upper part of the hose is connected to the pump using a fitting. Instead of a hose, you can use a polypropylene water pipe with a diameter of 32 mm. After this, the hose is lowered into the water so that the check valve is immersed in it by at least 30 cm.

The check valve, as well as the filter protecting it, are necessary elements. The valve protects the pump from idling because it prevents water from flowing back after the pump is turned off. The filter is necessary to protect the device from contamination.

Step #4. Connection to the water supply system

Then connect the pump to a hydraulic accumulator or storage tank. It should be remembered that the horizontal part of the hose should have a slight slope. Often, a flexible connection to the tank and an adapter, as well as other elements of the system, are mounted on threaded connections. In this case, it is necessary to ensure proper sealing using FUM tape or other suitable sealants.

After this, the storage tank or station is connected to home plumbing system. When laying pipes, you should also remember the correct slope. An important point is the insulation of pipes laid in the ground. Today there is a wide selection of suitable insulation materials; all that remains is to choose and use the right one.

Only after all devices have been assembled into a common pipeline and connected to the internal part of the house water supply can the operation of the system be tested.

Improper starting of the surface pump can lead to its rapid failure. The details of this process are outlined in the manufacturer's instructions, which should be carefully studied.

Step #5. Checking the system operation

Usually, before starting, surface pumps are filled with water through a special hole. Water must fill not only the pump, but also parts of the line before and after the pump. Then the filler hole should be closed. It is recommended to immediately record pressure readings in the accumulator and in the system.

This information may be useful when further configuring the system. You may need to pump some air into the hydraulic tank or bleed it.

After this, the pump is connected to the electrical network and turned on so that the storage tank or accumulator is filled with water. Immediately check all connections for leaks and repair faults if necessary.

If you are using a homemade tank, it would not hurt to check its integrity. Water may begin to leak through previously undetected cracks. This problem should also be resolved immediately. If the system is assembled correctly and nothing is leaking anywhere, all that remains is to configure the control equipment.

After this, you need to check the operation of the automatic systems. To do this, you need to open the water and observe the process.When the tank is empty, the pump should turn on automatically and turn off again when the tank is filled to the set level.

Typically, the pump automatically turns off when the pressure in the system approaches three atmospheres. After this, the water is drained until the pump starts working again.

At this moment, you should record the real system pressure and compare it with the manufacturer's recommendations. If significant differences are found, the performance of all devices must be adjusted to an acceptable level. After setting, the check is repeated.

Conclusions and useful video on the topic

Details on how to properly connect a surface pump as part of a pumping station are presented in the following video:

Here is a visual representation of the procedure for connecting a surface pump for irrigation:

There are not many pitfalls in installing a surface pump. Of course, you shouldn’t rely on your own instincts or the famous “maybe”.

A careful study of the manufacturer's instructions, as well as a few short consultations with experienced craftsmen, will help even a beginner cope with this task quite satisfactorily.

Would you like to tell us how you use a surface pump in your dacha or installed a water supply system based on it? Do you have any rationalization suggestions or tricky questions? Please write comments in the block below.

I have a special hole dug for the pump (small cellar, pit). The pump is there all year round. In winter you have to insulate it additionally. For this I use an old cotton blanket.But there are no problems with forgetting to hide equipment when it suddenly started to rain, and other similar situations. There is noise coming from this pit, but it is less than if the pump was working somewhere on the surface. It’s dry in the cellar, I keep an eye on that too.

I have a Marina CAM 88/PA-HL on a well at my dacha. A good pump, easy to use and reliable. In the spring you will put it on the pipe and fill it with water to the brim. And he works all season and doesn’t complain. There is no need to do any swapping. In the fall, you dry it and put it somewhere in a dry room. The pump is made of stainless steel. Gives a pressure of about 4.5 atmospheres, pumps 60 liters/minute. Before this there was a domestic Agidel pump, there were more problems with it.

Installation of a surface pump at the dacha