Do-it-yourself LED lamp repair: causes of breakdowns, when and how you can repair it yourself

Having problems with light sources, but you are in no hurry to buy new ones and do not want to call an electrician? It’s not a bad idea to try to repair LED lamps yourself, right? Moreover, it may not be so difficult. But you don't know where to start?

We will tell you how to detect the problem and repair the problem area - the article discusses the most common causes of breakdowns. The main thing is to correctly identify the area of the problem and, using specialized tools, carefully eliminate the problem. A correctly restored product will continue to function.

To help the home handyman, we selected photographic materials and provided repair instructions with informative videos. With their help, even a master who does not have extensive experience in work of this kind can cope with the task.

The content of the article:

Diode device design

Before you start repairing a damaged LED lamp, you need to find out what parts it consists of and where exactly to look for the fault.

The general structure of units of this type is approximately the same and includes such elements as:

- base;

- driver;

- circuit board;

- LEDs;

- radiator;

- optical elements.

Each part is very important and is responsible for a specific function. Having found the location of the problem, you can understand the level of its severity and begin to eliminate it.

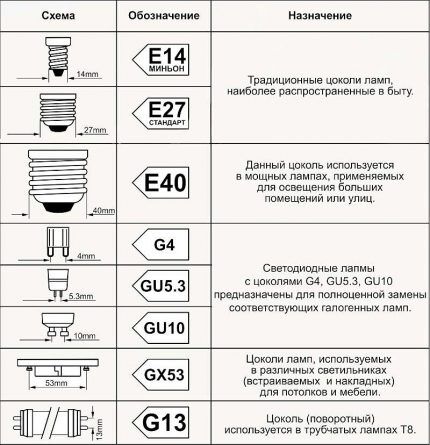

Purpose and types of socles

In LED devices plinth Made from metal, ceramic or advanced high-temperature plastic, renowned for its excellent heat resistance.

In products from branded manufacturers, soldering is not used when installing a part into a lamp. This completely eliminates oxidation or sticking of the base element to the lamp socket.

Most often, in LED devices intended for use in everyday life and industry, threaded and pin sockets are used.

Other types are considered rarer and are used in certain, specific cases. Myself the base has a good working life and almost never fails.

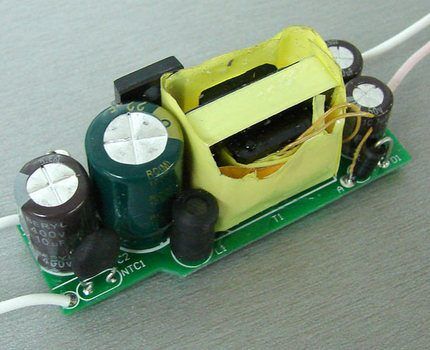

The role of the LED lamp driver

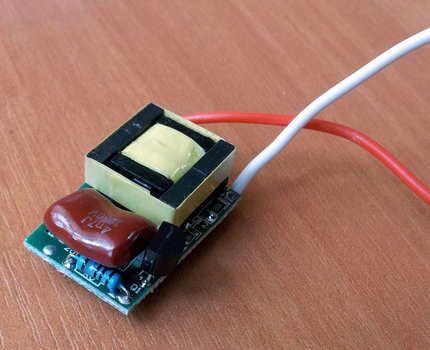

The driver in an LED device plays one of the key roles. This small part acts as a general power supply, neutralizes voltage surges, and directs direct current directly to diodes, which convert it into light visible to the human eye.

Drivers in modern lamps are electronic or capacitor. Each type has its own specific distinctive features and advantages.For more information about the types and selection of current converters for LED light bulbs, we talked here.

The first option is valued more expensively and is more often used in branded products in the mid-range and luxury segments; the second option is quite cheap for manufacturers and is used in budget series products.

Circuit Board Features

The circuit board serves as a springboard for the placement of LEDs and other operating elements. Manufacturers use different materials to create it. The most popular board now is one made of anodized aluminum alloy.

It exhibits maximum efficiency and absorbs up to 90% of thermal radiation arising during operation.

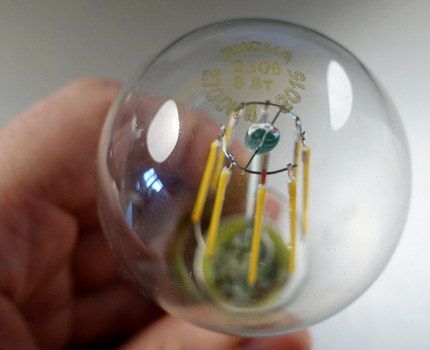

Nuances of the design of LED elements

Diodes that regenerate light flux come in several types. Most often in lamps there are SMD And COB chips. The more of them are located on the board, the more powerful the device is and the greater the amount of heat generated during operation.

For normal operation and long service, it is necessary to ensure correct heat dissipation, and the radiator installed on the case is responsible for this.

Specifics of radiator operation

Excessive heating has a detrimental effect on the functioning of LEDs. The lack of a high-quality heat sink significantly reduces the period of operation of the lamp and ultimately leads to its combustion.

Some manufacturers save money and equip the device with several transverse or longitudinal holes, placing them throughout the body.

Budget manufacturers supply cheap plastic, glass and composite parts. Advanced brands go further and equip their LED devices with radiators made of metal with an anodized anti-corrosion coating.

Therefore, it is better to buy initially reliable lamps from the best materials. Although they will cost more, the user will protect himself from constant breakdowns.

Some brands, mainly of Chinese origin, supply light bulbs with ceramic radiator elements.

Such products receive high-quality cooling, but, along with it, they partially lose structural strength and become more fragile compared to their metal counterparts.

A few words about optics

The bulk of LED lamps are necessarily equipped with a diffuser made of matte plastic. It helps concentrate the light flux at a certain angle and makes it more uniform.

Some models use lenses made from various modern and practical materials instead of diffusers. There are no breakdowns in these elements and they are not subject to repair.

Common causes of malfunctions

Failure of an LED lamp is often caused by incorrect operation and sudden voltage changes in the central power grid. In this case, the diode elements themselves remain operational, but the driver may deteriorate.

If the lamp itself does not provide high-quality ventilation, the driver will overheat. As a result, this will have a bad effect on its functioning and cause breakdown.

The lamp will begin to flicker and blink sensitively, irritating the eye, when the current-limiting resistor deteriorates, and will completely stop burning if the capacitor fails.

All these moments are unpleasant, but there is no need to panic. You can fix the problem without much effort at home with your own hands.

An incorrectly organized electrical system in a house or apartment will have a bad effect on the LED element and will lead to its failure.

Plus, it will increase the load on the wiring and, possibly, create additional problems in the near future. Therefore, it is better to entrust its arrangement to professionals.

During operation, a violation of the basic crystal structure of semiconductor diodes may occur in the lamp.

This problem is provoked by a reaction to an increase in the level of injected current density from the material from which the semiconductor is made.

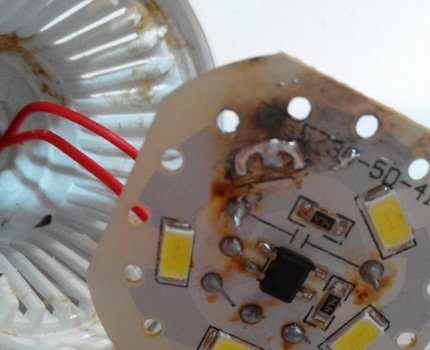

When the soldering of the edges is carried out poorly, heat removal loses the necessary intensity and weakens. The conductor overheats, an overload occurs in the system and a short circuit disables the lamp.

All these little things are not fatal and can be repaired without costing time and money.

Preliminary device diagnostics

The LED module usually does not light up due to breaks in the general wiring, malfunctions in the switch system, lack of contact in the socket, or problems with the lamp itself.

To understand the issue, you need to conduct a preliminary diagnosis and understand where the problem is located.

When the lamp does not light up when the switch is activated, you need to unscrew it from the socket and screw in another one, not necessarily a diode one.

If the situation has changed and the light appears, then the lamp itself is faulty. No light coming in means there is a problem with the wiring.

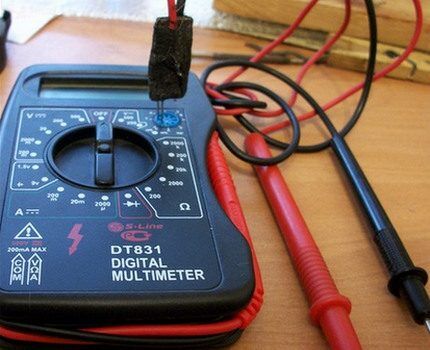

The next step is to use a multimeter to find out whether there is voltage in the electrical circuit.

To do this, just lean the device against the cartridge part with the switch activated and look at the indicators. They must be on par 220 V. If the numbers are different, then a fault zone has been detected.

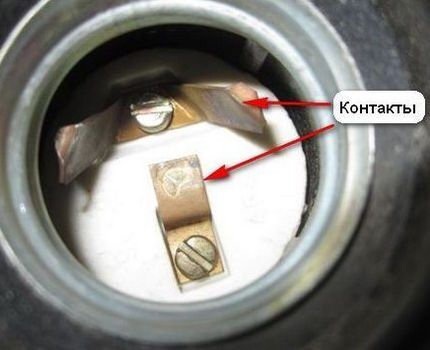

When the presence of the correct voltage is confirmed, but the lamp still does not light, you should check whether there is contact between the base and the socket antennae.If disturbances occur in this area, an arc occurs and carbon deposits form on the antenna elements.

To remove it, you need to turn off the voltage, clean off the incorrect formations, and carefully bend the antennae themselves. After all these activities, you can screw it into cartridge work lamp and check the result.

If there is no voltage at the contacts of the cartridge, it must be removed and checked to see if there is a phase on the wiring itself. If it is present when the switch is activated, the cartridge must be replaced.

When it is not there, you should pay close attention to the switch and look for the problem there.

If all the above-described elements, components and parts have confirmed their serviceability as a result of the test, it becomes absolutely clear that the problem is in the LED lamp.

How to disassemble the LED module?

To carry out repairs, the LED lamp will have to be disassembled. This procedure is not very difficult, but it requires accuracy, attention and some skill.

If you wish, you can film the entire process in step-by-step mode on your phone, so as not to confuse the order of actions later.

It is advisable to proceed with extreme caution. Not all internal elements of the device can be replaced, so it is extremely important not to damage them and keep them safe and sound.

This is especially true for such a vulnerable, but extremely important part as a printed circuit board.

Method #1 - unscrewing

An LED lamp is a rather fragile device that must be disassembled with extreme care and precision.. This does not require any significant effort, and there is no need to use sharp tools where there is a chance to do it manually.

To remove the diffuser dome, simply grab the light bulb by the edges with both hands and, using gentle rotational movements, separate the upper part from the body.

Usually this can be done easily, since the layer of fastening sealant is extremely thin and immediately reacts to movement and damage to integrity.

Then you will have to solve the most difficult task - to separate the plate carrying the LEDs from the rest of the body. To do this, you will have to unscrew all the mounting bolts.

Since their heads are tiny, you will have to use special precision screwdrivers.

The next step is to remove the mounting plate from the radiator unit. An object with a flat, sharp edge, such as jewelry tweezers, will help you do this. They will be able to carefully pry the edge of the board and carefully remove it entirely.

Then you will have to carefully unsolder the contact areas of the power wire and finally separate the plate with diodes from the accompanying parts.

You will need to separate the radiator and base using delicate rotational movements and lay out all the components of the lamp on the table in front of you. After this, you can proceed directly to the repair.

Method #2 - heating with a hairdryer

The second option is most suitable for products with thick glass that are not suitable for direct contact with a tool such as a screwdriver. Here you will have to use a hair dryer and use it to heat the lamp body.

This is the only way to remove a glass fragment glued with a special compound from the cylindrical base.

Intense exposure to hot air will cause the objects being processed to expand, and the adhesive layer holding the glass will become elastic.

After these manipulations, the lamp will disintegrate into its component parts, even if the master does not make any effort to do so.

If you don't have a hairdryer at hand, you can go another way. To do this, you will need to take a solvent, an awl and a medical syringe with a needle. First, carefully and without pressing, run the awl along the edge of the dome diffuser.

Then inject the solvent with a syringe and wait a little. Just a couple of minutes will pass, the sealant will become pliable, and the dome will be able to be unscrewed without any physical effort. All further actions are no different from the method described above.

Are you having trouble taking the lamp apart? We have others on our website disassembly instructions different types of light bulbs. We recommend that you familiarize yourself with them.

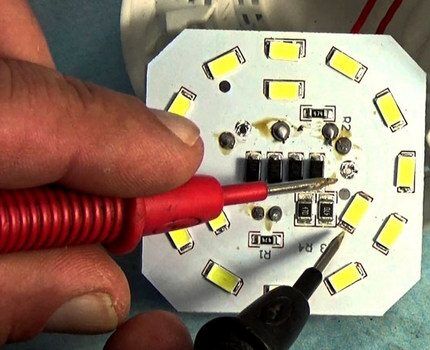

DIY LED replacement

Burnt-out LEDs are often the reason why a light bulb fails. Usually, after disassembly, you can immediately see which elements are damaged and require replacement. But there are often cases when at first glance all the diodes look normal.

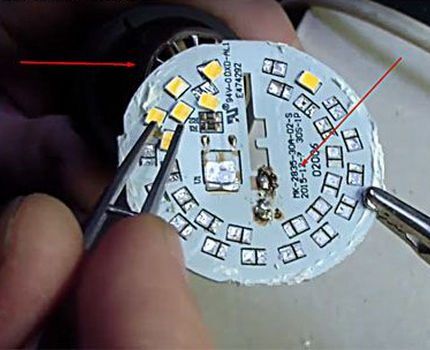

In this case, you will have to use a multimeter and ring each element separately to identify the faulty one. Or remove the elements that raise doubts from the board and test them using wires connected to a 12-volt power source.

When only one diode is damaged, you can simply short-circuit its outputs. If the luminaire uses a chain connection, this moment will not in any way affect the loss of functions of all other elements.

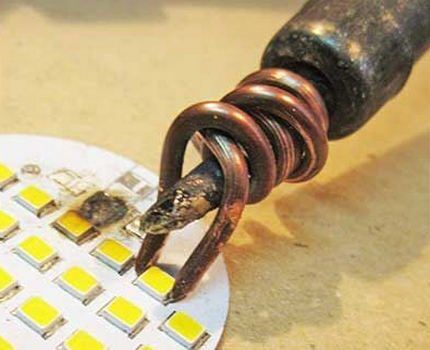

Old, faulty diodes will have to be unsoldered, then the board will have to be turned over and new chips soldered to the visible contact tracks.

In some cases, you can replace the LED without using a soldering iron. To do this, the board will need to be warmed up well with a hair dryer. The soldering area will become soft and pliable, and the diode can be easily removed using ordinary tweezers.

You will need to install a working light source in a place that has not yet cooled down. When the board cools down well, it will be firmly fixed and will not move anywhere.

The main thing is to clearly remember the location of the element relative to the smaller and larger contacts and place the correct one in compliance with the polarity.

Solving driver problems

Driver problems are a fairly common problem with LED lamps. Most often, a resistor or capacitor burns in the driver.

Using the measuring instruments available to the home craftsman, it is quite problematic to determine the level of performance of this element. Therefore, it is recommended to simply replace it with a working one with similar parameters.

It is not always possible to find a suitable part in lighting stores. It is better to immediately go to the radio market or to a place where radio electronics are sold and try to find the thing you need there.

When it is purchased, you will need to dismantle the faulty unit and put a working element in its place.

To correctly disassemble and repair LED light bulbs, you do not need complex, expensive equipment. A minimal set of simple tools will help you troubleshoot problems.

A multimeter will allow you to check the presence of voltage in the circuit, make it possible to detect the presence of breaks and show how efficient the remaining parts of the circuit are.

A soldering device with rosin and solder will be required to repair breaks found in the circuit and subsequently replace damaged parts and elements.

With a small screwdriver you can carefully separate the control elements from the lamp body, and with a thin, durable stationery knife you can delicately detach the parts from the circuit board.

Users also often encounter problems such as blinking light bulbs and burning lamps when the switch is off. What causes these malfunctions and how to eliminate them we discussed in our other articles:

- Why LED lights blink: troubleshooting + how to fix

- Why LED lamps burn when the switch is off: reasons and solutions

Conclusions and useful video on the topic

How to eliminate typical failures of an LED light bulb with an E27 socket. Detailed instructions for disassembling the product, interesting practical tips on using available tools.

Tips on how to correctly remove the flask from the device without damaging it in the process.

2020-04/1585745834_remont-svetodiodnyh-lamp.mp4

An easy way to repair an ice-type light bulb without using a soldering iron. Instead of soldering, a special electrically conductive paste is used.

A complete description of the work on products of the Cosmos brand, which is owned by the KOSMOS Group, which controls about 25% of the domestic market for progressive and economical products for creating high-quality lighting.

How to fix an LED corn light bulb. Features of the disassembly process, design nuances and other educational points. A significant increase in the service life of the product after all work has been carried out.

An LED light bulb is a practical source of lighting. The only disadvantage of this product is the high price compared to other modules. True, LED devices are reliable and usually work out their lifespan completely..

And if breakdowns suddenly occur during operation, most of them can be fixed with your own hands. Any home craftsman will have the necessary tools, and finding time for repair work will also not be difficult.

Do you know how to repair LED lamps yourself and can supplement the material we have presented with valuable recommendations? Write tips in the comments to the article, add unique photos - many beginners who have no experience in repairing lighting products will be grateful to you.

We buy LED lamps only with a warranty, usually 2-3 years. Only once did a lamp break before the warranty period, and we replaced it without any problems. And after the end of its service life, we simply hand it over to the housing department and purchase a new one. After all, independent repairs do not know what consequences can lead to. Especially if you have never done this before, you shouldn’t take the risk. Better buy quality light bulbs with a guarantee!

“we hand over to the housing department”???

Are you not mistaken for crazy in the housing department? LED lamps do not contain mercury, lead, etc. substances requiring some special disposal.

What can a self-repair lead to? Either the light bulb will work or it won't. I have repaired these light bulbs so many times already. Mostly successful. Mostly I had to change the LEDs. Sometimes you can see which element has burned out, and sometimes you have to call.

The replacement was made either using a soldering iron or heated with a hair dryer. The only inconvenience is that the part is very small, you have to use tweezers. True, not all can be repaired.

After repair, they do not last long, especially those where the LED was not changed, but simply shorted the outputs. The load on the others is probably increasing, so they can’t handle it. The ones I repaired had their windows removed, I didn’t put them back, but it added brightness.Lately, the quality of lamps has improved and fewer breakdowns occur.

It’s simply interesting - “...and I just closed the outputs...” - how long do they last: an hour, two or more?

Statistics on the Feron LB-770, 11W lamp. The “repair” was carried out by shorting the LED terminals. The first - 07/13/19, the second - 07/17, the third - 08/05. Today it works fine. Apparently, I came across such a copy, because... similar lamps in the same chandelier work flawlessly.

Quote: “Since their heads are tiny in size, you will have to use special precision-type screwdrivers.” — What kind of screwdrivers are these CLAIM type? Is this the type of complaint someone is making? Or did the illiterate author mean precision (Comes from the French précision “precision”, further from the Latin praecīsus - see Wiktionary).

Or here’s another quote: “The heating temperature at the time of soldering should not exceed 2600. A simple soldering iron heats up more, so a piece of copper wire with a cross-section of no more than 4 mm must be wound onto its tip in a tight spiral.” - Very entertaining and informative! It turns out that the melting point of gold is only 1063 degrees Celsius, and the boiling point is 2660, but for copper these numbers are slightly different - melting 1083, boiling 2580 degrees Celsius! Just a little short of 2600! A clear dislike for illiteracy.

After 260, the ° sign means degrees. This is not 2600, but 260 degrees.

“Pretentious screwdrivers” have been corrected, thank you.

Where did you see 2600???

Andrey, look carefully and do not invent or distort the author of the article.He did not write about any 2600 degrees, there is 0 as a degree and, accordingly, this is a degree icon. The same goes for the names of screwdrivers - are you hitting the eyes? Re-read the article. Everything is fine there

Whoa... Where did you see 2600? It seems readable and visible - 260°. The author of the comment is obviously a troll or illiterate himself!

A precision screwdriver is not a precision screwdriver. Older people often become inattentive and irritable...

Lately it has become difficult to repair lamps: the diffuser is not on the thread or on the latches, heating with a hairdryer has also stopped helping - there is no sealant or glue on the seam. It is not possible to unsolder the LEDs: a soldering iron (even tweezers of soldering irons of different power!) and heating the aluminum board (with a hairdryer with a temperature display or in an oven for SMD mounting) does not produce results. Increasing the temperature above 260C does not help to remove the LED, even if it is already destroyed by heat (at approximately 380C)... Have they really started welding them?

I also repaired LED light bulbs. And I'll tell you what. In theory, LEDs should be almost eternal (about 30,000 hours). But this is in theory. In practice, manufacturers do not need this, otherwise who will buy new ones if the old ones work? Therefore, the main problem of these lamps is poor, insufficient heat dissipation. As a result, the LED crystal overheats and quickly fails. Not every lamp will last 1 year, and a rare one will last 2 years.

So my advice to you: buy LED lamps by weight - the heavier the better. As a rule, weight is directly related to the amount of aluminum in the heat sink.

Thank you. How many volts are the LEDs in these lamps?

“Most often, a resistor or capacitor burns in the driver.Using the measuring instruments available to the home craftsman, it is quite problematic to determine the level of performance of this element.” What? What kind of “philologist” posted this? If you don't know how to use a multimeter, don't write garbage!

Tell electronics engineers what can burn out on the T8 lamp driver? How to repair it? Where to begin? The LED strip is intact. Thank you.

Today I disassembled the LED bulb. Two LEDs burned out. Why two? — Because 14 LEDs are combined into 2 parallel chains of 7 pieces in series each. First, one LED burns out and one chain of LEDs stops consuming current. Accordingly, the driver passes double current through the second chain and it burns out.

Therefore, carefully study how the LEDs are connected in a particular lamp...

An attempt to test even one LED immediately failed. As it turned out, when applying voltage from a laboratory power supply, inside each LED there are actually 3 crystals in series! And only when 6-7 volts were applied a weak “three-point” glow appeared. Therefore, it is easier to evaluate the result of the repair by directly connecting the lamp to the network.

It’s easier to get a tester to check LEDs. Output voltage is 200V DC. You can measure a line of LEDs, a single one, or any combination. At the same time, it will show the opening voltage of the LEDs in the line or LED. Powered by 18650 battery. Spare parts are mainly from aliexpress.

Yes, LED lamps work due to the glow of diodes. I have been repairing them for a long time, removing the diodes with two soldering irons set at 300 degrees. I solder new elements instead of burnt ones with one soldering iron.

To replace it, it is better to take new diodes. A hundred pieces on Ali Express cost pennies. In addition, you can choose diodes for different voltages: 3,6,9,12,18, etc. I tried using old lamps as LED donors. It doesn’t help: they burn out again, so it’s better to solder new ones.

Is it possible to extend the life of an LED lamp by replacing the driver with a lower wattage lamp?

Manufacturers make lamps in such a way that LEDs operate at a current twice as high as their nominal value, which causes overheating of the lamp and lower (than it could be) light efficiency. You have to either buy proven light bulbs (which have a sufficient number of LEDs according to their power, or buy what you have, but powerful 15 watts, and immediately change the current-setting resistor in the driver, reducing the lamp power to 8 watts, or change them every year or two , or fight with the seller, because they have to change the lamp and reset the warranty period, but stores simply change the lamp without extending the period.

The 9W lamp blinks and shines dimly. One LED receives 120 volts. the rest are 15 volts. I replaced the diode with a 240 ohm one watt rfesistor. The lamp lit up normally.