How to cut a thread on a pipe: a detailed overview of the main methods

Do you like to do home improvement work yourself, without involving various craftsmen? Self-installation or repair not only allows you to save money on calling specialists, but also greatly increases your self-esteem, right?

During the installation of communications, it is often necessary to prepare threads on pipes. We have to find ways not to spoil the product.

We will tell you how to cut threads using different tools, which method is preferable to use in a given situation. The article discusses methods available for implementation by an unqualified performer. The features of cutting different types of threads and the equipment used for this are covered.

The presented material is provided with visual photographs depicting tools for performing the work. A video with recommendations will help you understand in detail all the intricacies of this process.

The content of the article:

Pipe thread classification

The term “pipe” has a privileged position in the plumbing industry. This term is classified with an eye to a group of standards that define the criteria for connections of various elements of plumbing structures.

For example, a pipe thread size is designated by a numerical value indicating the standard bore diameter of the pipe, but not the physical thread diameter.

In practice, pipe threads are used:

- cylindrical (G/BSPP),

- conical (R/BSPT),

- round for shut-off sanitary fittings (Kr),

- inch cylindrical (American standard NPSM),

- inch cone (American standard NPT).

A mechanic whose main work area is household work is recommended to take as a basis the conditional division of pipe threads into two main types:

- cylindrical (G),

- conical (R).

It is these two types that the home plumber most often encounters when servicing household plumbing equipment and installing water supply pipes or heating.

Pipe cutting is carried out in the following cases:

Basic cutting methods

You can cut threads on pipes in one of two ways:

- automatic - on machines, power tools;

- manually - using hand tools.

For living conditions, of course, manual technology is more relevant. Cutting threads on water pipes or other pipes by hand is often done using a die.

A die is a simple device for cutting threads on pipes at home. The same tool is successfully used on industrial machines.

The device looks like a disk with several axial holes drilled along its inner diameter. The edges of these holes form several incisors (usually 8-10). The material for the dies is alloy steel or other hard alloys.

There are several types of such devices:

- solid;

- spring loaded (split);

- Kluppovye (sliding).

According to the design, the die is produced in the form of a circle, square, hexagon, or prism. The most common are disc (round) instruments. They are used for threading water pipes up to a diameter of 36 mm.

For ease of working with dies, use:

- simple gates with fixing screws - hand tools;

- threading chucks on lathes.

Cutting threads (metric, conical) of the best quality on pipes manually or on machines is provided by solid dies.

However, this type of tool, due to the rigidity of its own design, has its negative sides.The cutters wear out quickly.

Spring-loaded (split) dies have a less rigid design, which makes it possible to cut threads on pipes and at the same time change the thread diameter in the range of 0.1-0.3 mm.

Such devices are characterized by increased wear resistance of the cutters, but do not provide high accuracy and cleanliness of thread cutting.

Sliding dies consist of two working parts. They are designed for installation in a fastening module - a clamp.

Fastening in the clamp is carried out by a mechanism consisting of a cracker and an adjusting screw. The screw adjusts the diameter size for thread cutting. Usually the die is equipped with a set of dies for several different diameters.

Method #1 - making pipe threads with dies

The process of creating a thread on a pipe with a die or die requires the mechanic to perform some preliminary actions:

- The surface of the pipe in the cutting area must be thoroughly cleaned.

- The end part of the pipe should be processed with a file (make an entrance chamfer).

- Apply lubricant to the surface to be treated to reduce resistance.

If possible, it is advisable to secure the pipe vertically, for example, in a bench vice, leaving free access to the upper part - the cutting area. The fastening force must be correctly calculated so as not to deform the pipe body.

Then take a pre-prepared driver with a roughing die (No. 1) of the required diameter and suitable thread characteristics.

The tool is held horizontally - perpendicular to the end area of the pipe. Place the roughing die onto the chamfer of the edge using the internal hole. Light pressure and successive short turns of 25-30° make the initial cut.

This work should be done carefully, slowly, constantly monitoring the right angle between the horizon of the ram and the vertical of the pipe.

Using this technique, the first two or three threads are carefully cut. Usually, after cutting the first two or three threads, the tool is firmly in its working position. Further, the right angle can no longer be controlled.

But the technology of cutting with short (without particularly strong traction) circular movements should be maintained until the end of the cut. It is recommended to periodically add lubricant at the cutting point.

After the first pass, twist the device and then repeat one or two more times with a finishing die (No. 2).

It's good for you! Rating of the best bench and machine vices: characteristics, pros, cons, price.

Method #2 - clump cutting technique

The die is a variation of the same die for cutting threads, including on pipes. A distinctive feature of the die is the ability to adjust the cutters.

There are clamps for manual use, as well as similar devices with an electric drive.

Option #1 - cutting with a hand clamp. Manual cutting of pipes is usually done with a clamp, which is installed in a ratchet holder. This holder makes the work of cutting pipe threads convenient and less complicated.

Of course, depending on the conditions of plumbing work, you can use other types of hand holders. For example, a standard locking knob with two handles.

The principle of creating a thread with a die is almost the same as the method of working with traditional dies:

- Clean the working surface of the pipe and make sure there are no defects.

- Sand the cut area until it has a distinct metallic sheen.

- Process the outer working part of the end edge at an angle of 45-60º (chamfer).

- Lubricate the prepared surface with technical petroleum jelly.

- Secure the pipe in a mechanical vice or hold it with a gas wrench.

After these procedures, the cutting tool (blank) is placed with the internal hole on the pipe chamfer and, with moderate, uniform pressure, they begin to rotate it with short reciprocating movements.

If a ratchet clamp is used as a holder, only forward cutting is carried out. It should be noted that the ratchet clamp is convenient to use when working in cramped conditions.

For example, when it is necessary to process a pipe laid in close proximity to a wall.

Option #2 - cutting with an electric clamp. Along with hand tools, electrically driven devices are widely used. The obvious advantage for the mechanic is a significant reduction in labor intensity.

But on the other hand, not all electric machines are capable of performing work in cramped conditions. In addition, when working with hand tools, it is possible to obtain a better result.

To obtain a similar result from electrical plugs, extensive experience with this tool is required.

Working with an electric clamp:

- Preparation of the pipe surface in the cutting area - cleaning, chamfering, lubrication.

- Fastening the pipe with devices capable of providing rigid fixation.

- Fixation at the starting point of the die holder with the clamp included in the kit.

- Checking the stroke and direction of rotation of the die.

- Cutting the first two or three turns in the jog mode.

Next, pipe threads are cut automatically. The cutting length is considered optimal when the upper edge of the die cutting heads reaches the leading edge of the pipe.

At this point, the operation of the device is stopped, the reverse rotation function is turned on, and the bug is twisted from the pipe with a push feed. Be sure to periodically moisten the cut area with oil throughout the process.

Method #3 - using lathes

Large-scale construction and repair work, as a rule, excludes the use of hand tools. Here, lathes are usually used to process the pipes accordingly.

Threading functions are supported by many universal lathes.

Using the machines, both internal and external pipe threads are made efficiently and easily. The pneumatic (or mechanical) fastening module of the lathe ensures high-quality reliable fastening of the pipe and precise supply of the workpiece to the cutter.

To perform thread-cutting functions, different types of cutters are used:

- rod,

- lamellar,

- intercalary

Work on lathes is carried out by specialists trained in this field and having the appropriate qualifications.Without experience and professional skills, trying to cut threads with your own hands on a machine is not recommended.

For home craftsmen who decide to take up plumbing and carve metal workpieces, the following tips will help them in their work:

A few words about GOST for pipe threads

In conditions of work with gaseous and liquid media, according to GOST 6111, if it is necessary to introduce detachable connections into pipeline diagrams, it is allowed to manufacture such connections on a threaded basis.

It is possible to make not only pipe threads, but also conical threads (GOST 3662).

Despite the rare use of tapered threads in pipe connections, they are considered more convenient in terms of screw-on/make-up characteristics.

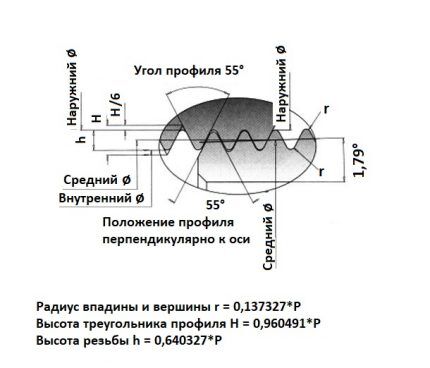

It should be recalled that the taper angle of a tapered thread is directly related to parameters such as pitch and diameter. The permissible value of this angle cannot be less than 26°. The standard value of the profile tip angle on a tapered thread is 60°.

Pipe threads are distinguished by a characteristic feature - they have a rounded profile top. Subject to cutting standards, the amount of rounding is 10% of the thread radius.

With this cutting technology, it is possible to achieve a significant reduction in internal stresses in the small area of metal occupied by the threaded profile.

Established tolerances GOST 6357, along with cylindrical and conical threads, metric threads are provided for pipes.

Here, the standard angle of inclination is 55°, which determines the increase in the number of turns in a section along a length equal to a section with a different type of thread.

The result is a connection with a higher degree of tightness, but the complexity of using such connections increases.

Existing GOST installations also provide for the possibility of making thrust and trapezoidal threads on pipes. But in practice, these types of cutting are not used due to their low operational strength.

In plumbing work, different methods of connecting pipes are used.The choice of method largely depends on the pipeline material and its “area of responsibility.” It is recommended to use threaded connections of parts in areas accessible for periodic inspection.

Information on alternative methods of connecting pipes is presented in the articles:

- Plumbing methods for connecting pipes: an overview of all possible options

- Connecting plastic pipes with metal ones: analysis of methods and examples of installation work

- Connecting copper pipes: instructions and comparison of various installation technologies

- Pipe insertion without welding: technology for insertion welding work

Conclusions and useful video on the topic

All the nuances of cutting pipe threads in one video:

Knowledge about the creation, operation, and maintenance of threaded connections on pipes is always relevant for every person who deals with housekeeping, plumbing, and other utilities..

Without this information, it is impossible to carry out quality repairs, modernize pipeline systems, or simply maintain the operation of household economic systems.

Do you have anything to add or have questions about cutting threads on pipes? Please leave comments on the publication and suggest your own methods and effective tools for creating carvings. The contact form is located in the lower block.

I carve pipes by hand using dies. I have them in one piece. There is nothing complicated about this. It's important to have skills. I clean the pipe, secure it in a vice and take a wrench with the required die. I gradually cut with rotational movements. It is important to cut the first 2 threads, then it will be easier. I don’t use this often, but on a large scale, of course, I need to cut it with a clamp.

Everything is extremely simple for me. Pipe, vice and die. I think that there is no point in paying for thread cutting, since everything is done in one or two minutes. If, of course, you don’t have the skills, then you can also buy pipes with cut threads, however, it is difficult to select such blanks “in place” in length, to be honest, almost impossible. So I advise everyone to buy a set of dies.

The quality of the cutting tool is important. When I bought the first die, I came across dies (as it turned out later) of disgusting quality. The thread was cut with great difficulty, I lubricated it with various types of lubricant (liquid, plastic) - it didn’t help much. And, oh happiness, one day the die broke. I quickly bought a new one... And it turned out that I had been tearing my belly button for several months.

A good teacher is experience, but it’s still better to first get a theory from a knowledgeable person. But I haven’t come across one like this.