Self-regulating heating cable: overview of types and features of use

Low winter temperatures can bring a lot of trouble if you do not take care of the insulation of drainage and sewer pipes, roofing elements and soil in the greenhouse in a timely manner. Frozen water turns into meter-long ice plugs and disables the water supply system, and ice on the roof is completely life-threatening.

A self-regulating heating cable laid through pipes, roofs and trays helps to change this unpleasant situation.

In this material we will describe in detail how to choose the right heating cable, describe its design features and operating principle. In addition, the article provides two options for installing self-regulating systems.

The content of the article:

Design differences of self-regulating systems

Samregi (abbreviated) should not be confused with resistive analogues - the first modifications of heating cables.

In short, the disadvantages of the resistive type, due to which it is used less and less, are the following:

- certain length, impossibility of extension or shortening;

- constant resistance along the entire length, which makes it impossible to regulate the temperature in individual areas;

- connection at both ends, causing installation difficulties;

- risk of overheating at intersections;

- There is no repair as such; the entire system has to be replaced.

A positive feature of the resistive type is its low cost, so it is used where small protected areas need heating.

There are fundamental differences in the design of a self-regulating heating cable:

- Two high resistance copper cores. The greater the resistance, the greater the possibility of temperature regulation.

- Semiconductor matrix. This is a significant element of the cable, which makes it self-regulating. The matrix is sensitive to ambient temperature. As the temperature drops, the resistance of the material rises and it begins to generate more heat.

- Internal insulation. High-quality material has a uniform structure and maximum thermal conductivity.

- Shielding braid. Most often it is a copper mesh or aluminum screen. To protect the cable, the power must be connected via an RCD.

- External insulation. Its function is to protect all cable elements. The service life of the product depends on the characteristics of the external insulation.

The ability of samreg to change its own resistance (and therefore power) from temperature fluctuations frees you from the purchase of additional equipment - various kinds of thermostats with sensors.

The cable can be cut, and the length of the finished product can be shortened or increased if necessary.

But the main advantage of samreg is its “selectivity”. The matrix independently detects cold areas and brings their temperature to the optimal value.

In sufficiently heated areas, it simply maintains the required parameters (usually + 3-5 ºС). This is very convenient when it is necessary to protect a cable from freezing that has different heating conditions along its entire length (for example, it passes through both a heated room and cold ground).

At the end of the cold season, there is no need to heat the pipes, soil or roof, so the cable is disconnected from the power supply. When there is a possibility of severe night frosts, you can use a thermostat that automatically turns on the system.

Where are heating systems used?

The scope of application of heating cables for pipes (and not only) is quite large. They are installed in places where controlled heating of adjacent (surrounding) surfaces or materials is required.

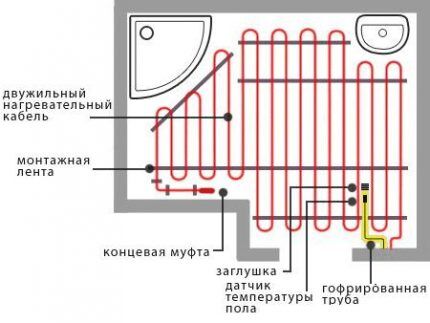

Some types of cable are specifically designed for underfloor heating systems. They are laid under ceramic tiles, boards, laminate, carpet, and sometimes filled with concrete screed.

The last option is the least effective, since the screed “steals” heat, and only part of it passes through the finishing coating.

Cable heating is common in water supply and sewerage systems. Communications buried in the ground or passing above the ground in the northern regions of Russia are at risk of complete freezing for six months - from October to April.

If the pipeline is laid above the freezing level of the soil and is not insulated enough, it will quickly lose its functionality. Therefore, we recommend that you learn more about the types of heating cables for heating water supply.

If the pipes are already buried in trenches and dismantling is impossible or undesirable, the cable is installed inside the water (sewer) pipe through a tee cut into the most convenient place.

The following application of self-regulating cable is roof heating systems and gutters.

Under the influence of high temperature, snow and ice gradually turn into water, which flows down through trays and pipes. Roofs become safe for people and vehicles in the yard.

A practical use of heating cables for those who do not like foggy windows and mirrors is to mount the samreg on the back of the mirror, after which condensation will no longer bother you.

In production and during construction work, heating is often necessary to help “ripen” concrete solutions.

The situation is similar with liquids, for which samregs are also used to maintain a certain temperature. Instead of heating a reservoir with a technical liquid in the traditional way, a cable is lowered into it; as a result, the characteristics of chemical or food solutions do not change for some time.

Heating systems have not bypassed the agricultural industry either. The cable is placed directly into the soil, under the top nutrient layer, which protects the roots of the crops from freezing.

What characteristics should you pay attention to?

Before purchasing a cable, you must clarify the conditions in which it will be used. It is important to correctly calculate the power, set the length, take temperature readings, and determine the installation method - internal or external.

Characteristics that will be required when choosing

Power. The parameters of power/resistance and heat transfer are interrelated. Also, the properties of the cable depend on the cross-section of the core. You should also focus on it when choosing the length. Let's assume that a cable system with a cross-section of 1.1 mm² and a power of 25 W should not be longer than 80 m.

The average power of samregs that can be found on sale is from 5 W/m to 25 W/m. Systems with a minimum value are suitable for internal heating of pipes laid in the ground. For the same pipes, but with external heating, the cable should be a little more powerful - 10 W/m.The harshest conditions are above ground, so for above-ground placement the maximum power is suitable - from 25 W/m.

Temperature. It should be remembered that not all types of pipes tolerate heat equally well. Let's assume that plastic products (especially sewage and cold water) are not designed for strong heating.

In production there are cables that heat up to + 190 ºС (with a power of up to 90 W/m), but there is no use for them in everyday life.

Presence of grounding braid. This protective element is equally important for both the system and people - it guarantees the safety of installation. For the braid to function, it is connected through RCD. However, on sale you can find options without grounding - in some cases their use is understandable.

External insulation material. Various types of polymers act as external insulating materials. Some of them are thinner and more elastic, others are more rigid in bending. All types, without exception, protect the internal parts of the cable from damage, aggressive environments, and humidity.

External insulation affects the scope of use of the cable. Polyolefin protection (the most common material) is not suitable for all installation methods.

For example, for installation on the roof, a cable with fluoropolymer insulation (with protection from UV rays) is used, and for internal installation, systems with fluoroplastic insulation are used.

Self-regulating cable installation instructions

There are many options for cable laying - the choice depends on the location and installation conditions. When installing home autonomous communications, it is most often necessary to insulate pipes, so we will dwell in more detail on the description of the processes of internal and external installation of cables on the pipeline.

Option #1 - internal installation

Installation of a heating cable inside a water or sewer pipe is carried out for various reasons. The main one is the impossibility of fixation due to the fact that the pipeline is already in the trench and covered with a layer of soil.

Of course, this type of installation has some disadvantages:

- the use of an additional part - a tee;

- reduction in cable properties due to plaque that appears after some time (depending on the characteristics of the water);

- reducing the diameter of the pipe, an additional obstacle to the movement of water;

- limited length and preferred use on straight sections.

An important point: the samreg is connected only through a special tee; it is prohibited to use shut-off valves when connecting heating systems!

Instructions for using the finished kit:

- connecting all functionally important parts to the cable (design of the termination, connection of the power cable);

- insertion of a tee into the pipe with a free cable outlet;

- inserting the cable into the pipe to a certain length;

- sealing the assembly using feed-through elements or union nuts.

It is not recommended to insert Samreg into a pipe with a cross-section of less than 40 mm - this will affect the speed and volume of the liquid being moved.

How to prepare the cable and put on the termination can be seen in the following instructions:

Now the cable is completely ready for installation inside a water supply or sewer pipe.

Option #2 – outdoor installation

It is not recommended to insert more than one cable inside a pipe, especially a narrow one, but from 1 to 4 self-regulating cables can be placed on the outside. One is usually enough for a small diameter pipe (40-50 mm), and 2 to 4 pieces are used for large pipes located in low temperature areas.

For communications placed in the ground, a “golden mean” is often used - two cables running parallel along opposite sides.

For fixation, aluminum tape is used, designed to increase heat transfer and simultaneous protection. However, sometimes a more durable fastening is required - with ties.If direct sunlight falls on the pipe fragment, it is recommended to use black UV-resistant screeds.

The spiral method covers the maximum surface area of the pipe. The smaller the step between cable turns, the more efficient the heating. The average interval is 5-6 cm. The length of the spiral is approximately 1.7-1.8 times longer than a linearly laid cable. Mounting tape is used as fastening.

Installation instructions:

- Cable placement along the entire length of the pipe section requiring heating, in a linear or spiral manner.

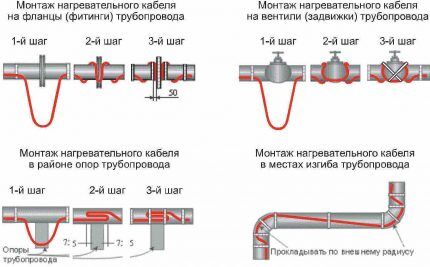

- Winding during installation of connecting units, valves and other shut-off valves.

- Fixation with mounting tape (aluminum tape, zip ties).

- Thermal insulation “in the sleeve”.

The last point is mandatory. Thanks to the insulation, the heat generated by the cable will remain in the pipeline area. The type and thickness of thermal insulation is selected based on the type of pipeline and external conditions.

Let’s assume that in order to lay a water pipeline in a trench, in addition to the heating cable, you will need insulation 25-30 mm thick - a foam “shell”, extruded polystyrene foam or basalt wool.

The nuances of roof heating

To create favorable conditions for the constant thawing of snow and ice on the roof and drainage system, the heating cable is installed in the following places:

- on the edge of the roof (preferably around the entire perimeter);

- in gutters under slopes;

- in drainpipes;

- in the valleys.

There are various options for designing a heating system: from a single cable stretched along the most critical location to a whole network of cables with a thermostat and sensors.

In open areas, the cable is secured with clamps and brackets; in pipes, it is suspended on a cable or chain.

Anti-ice system design option:

The final stage is carried out indoors. We install the electrical control cabinet and connect the heating system. Then we turn on the thermostat and check how the system works.

Conclusions and useful video on the topic

The following videos will show you how to choose and install a heating system correctly.

How to fix Samreg on a sewer pipe with a diameter of 110 mm:

Installation of the Deviflex cable system for heating gutters and roofing:

What does cable insulation of a concrete structure look like:

For the proper functioning of pipes or drains, samregs are often used, which create the most suitable temperature conditions. Installation requirements are reasonable if the cable is selected correctly.

Pay attention to brands Raychem, Heat Trace, Nelson, Lavita and strictly follow the instructions included with the cable. If any difficulties arise, contact company representatives, they will definitely help you.

Please write comments in the block below. Perhaps you have practical skills in laying a self-regulating heating cable and can give valuable advice to visitors to our site? Or if you have any questions about the topic of the article, ask them in the comments section, and we will try to answer them promptly.

Winter is an unpredictable time of year. It can be both warm and harsh. Last year, my parents took care of the installation of drainpipes in a timely manner. They laid a “heating” cable and also insulated it with basalt wool. Thanks to measures taken in advance, the snow melted, and there were no gusts in these places, as happened in their neighbors. Works great!

Tell me, what are the properties of external Teflon insulation for internal laying of a heating cable (devi dph-10)? Or is fluoroplastic required?

If you are directly interested in the self-regulating cable DEVIpipeheat 10 (DPH-10), then its outer insulation is made of Teflon (fluropolymer). PTFE is not used here, in which case you need to select a different cable.

As for the Teflon insulation itself, with internal laying you can count on the following indicators:

— maximum permissible water temperature 40*C;

— maximum permissible water pressure 10 bar;

— on the flat side, the minimum bending diameter is 2.5 cm;

— the strength of the cable itself corresponds to classes M2 IEC 60800:2009, IEC 60335-2-96.

Where does the information come from that fluoroplastic is required for laying a heating cable inside a pipe?

This model uses a cold connecting wire with a Euro plug and uses sealed heat-shrinkable transition and end sleeves.