How to make a filter for a well with your own hands: a review of the best homemade options

Installing a well on a suburban area will provide its owners with water.But without proper preparation, it cannot be used for cooking and drinking purposes. To perform pre-cleaning, you can make a well filter with your own hands. A practical homemade product will cost much less than the sales offer. And this is a lot, don’t you agree?

You can get acquainted with noteworthy information based on regulatory requirements by reading the presented article. The information contained in it will be useful both to independent craftsmen and to customers of drilling services. Knowledge of the design of the filter device and the specifics of its care will also serve during operation.

The article describes the types of well filters, which will help you decide on the best option. The construction technology is carefully analyzed, and the technical details of the manufacturing and installation process are listed. For a better perception of the impressive information material, photos, diagrams and videos are provided.

The content of the article:

Design and purpose of a well filter

All well filters have a similar structure. They work in single and multi-level water purification systems. They are responsible for mechanical cleaning, preventing soil particles, grains of sand and other relatively large contaminants from getting inside the casing.

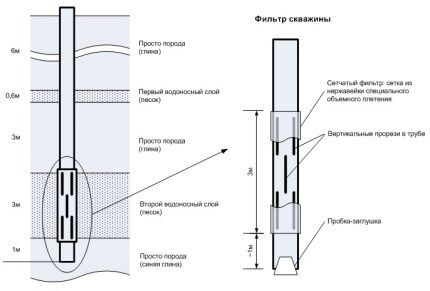

Filters consist of three main elements, arranged from top to bottom:

- Above-filter area. A part that acts as a kind of fitting when attaching the device to the casing pipe.

- Filter element. A partition with holes that prevents contaminant particles from penetrating into the filter.

- Sump. A container for collecting large particles that have managed to penetrate inside the casing.

To improve cleaning, a multi-level system can be used, which involves the presence of additional flow filters, which are installed in front of the tap.

Devices used for primary cleaning are divided into two groups:

- With pre-filtration. A layer of marble chips or gravel is placed between the outer wall of the well and the surface of the casing pipe, which “collects” contaminants and prevents rapid silting of the filter.

- No pre-filtering.

The filter element of the option without preliminary filtration is in direct contact with the aquifer.

The main purpose of a well filter is to purify water from unnecessary impurities. However, the device only removes large contaminants; additional cleaning after it is required. This is the only way to reduce mineralization and hardness levels, reduce the concentration of fluorine, manganese and iron.

The choice of the type of additional filtration system depends on the chemical composition of the water coming from the well. In addition to the main task, the well filter performs secondary functions.

A selection of photos will familiarize you with the arguments in favor of using well filters:

It ensures long service life for the well and the equipment immersed in it, since it protects them from impurities that can very quickly fill the wellbore. In this case, the well will silt up, become inoperable and will need cleaning.

It is important to understand that pump equipment It is not intended for long-term operation with increased load, which is inevitable when water rises with solid particles of contaminants dissolved in it.

Under such conditions, the pump experiences overload and fails very quickly. In addition, the filter supports the walls of the well, protecting them from collapse and rock shedding.

Materials for filtration equipment

The materials used are stainless steel, plastic and ferrous metals.Let's take a closer look at the features and characteristics of each of them.

The nuances of using stainless steel

The best material for making well filters is stainless steel. It is able to withstand high crushing and bending forces, and alloying makes it immune to oxidation.

Stainless steel pipes have a long service life, but their cost is quite high.

All the performance characteristics of stainless steel are also characteristic of the filter mesh and wire made from it, which is used for winding onto the part.

Features of the use of plastic

Plastic is another material that is widely used to make filters. Plastic is absolutely inert, therefore it is not subject to oxidation processes. It is very easy to process and has a long service life.

The cost of plastic parts is low, which is very attractive to well owners.

The main disadvantage of plastic is its low strength. As a result, it is not able to withstand the severe compressive loads that are characteristic of great depths.

Subtleties of using ferrous metals

Ferrous metals can be used as filters only for wells that provide water for technical purposes. This is due to the fact that they are oxidized by water, as a result of which iron oxide appears in it. Doctors have not proven that it is harmful to the body.

However, when the concentration of this substance is more than 0.3 mg/l, the water will leave unpleasant yellow stains on plumbing fixtures, dishes and linen. Galvanized ferrous metals are also susceptible to oxidation.

As a result, not only iron oxide, but also zinc oxide appears in the water. The latter irritates the mucous membranes and leads to digestive upset.

Thus, experts strongly do not recommend using ferrous metals, including galvanized ones, for the manufacture of well filters.

This applies not only to the base, but also to the filter mesh, the lower sections of the casing pipes, as well as the wire that is used in fastening and manufacturing the structure. Otherwise, water obtained from a well with such a filter can only be used for technical purposes.

Thus, for deep wells it is best to use stainless steel parts, and for shallow depths or in the case of using an additional casing pipe, it is optimal to install plastic components.

Structural types of filters

There are several types of well filters, each of which is designed for use in certain conditions. The choice of design is determined by the geological characteristics of the aquifer.

Artesian wells are drilled in stable and hard calcareous rocks, which makes it possible to operate them without a filter. The trunk is simply left open.

Good water pressure, which is typical for such wells, allows you to install submersible pump at an impressive distance from the bottom, so the supplied water does not need rough cleaning.

There are almost no fine-grained impurities in limestone, and the ingress of large rock particles into it is practically excluded. If a well is drilled in unstable gravel, wood or pebble rocks, a filter is required to remove large and fine inclusions.

Accordingly, the pump must be installed fairly close to the water intake, which makes the presence of a filter mandatory. Most often this is a perforated or slot filter, which is designed only for rough cleaning. Provided there is no sand in the aquifer, the device will work effectively and last a very long time.

Wells made in sandy soils are considered the most “capricious”. They are the ones who cause the most trouble for their owners and drillers. Practice shows that they are the most common, since sandy water carriers are most often located closest to the surface.

Sand wells cannot be operated without a mesh type filter. Moreover, the service life of the well largely depends on the quality of its manufacture and the material from which it is made. Let's take a closer look at each type of well filter.

Option #1 - perforated filter

Perforated structures are also called perforated, because they are a pipe with holes arranged in a certain order.Such filters are able to withstand fairly high loads, since the ring rigidity of the pipe does not decrease.

That is why they are allowed to be used at great depths, even with a high probability of ground movements. Experts recommend installing perforated filters in wells with low pressure.

Over time, the performance of such a filter inevitably decreases as the holes in the pipe become silted.

You can make the device yourself. To do this you will need: a drill, sanding material, a plug made of moisture-resistant wood and a pipe of the required diameter. It is better if it is from the oil or geological exploration range.

If you choose plastic, make sure it is safe for humans. The size of the holes depends on the type of rock, so we select the diameter of the drill based on its granulometric characteristics. The holes on the pipe body can be located in a linear or staggered pattern.

Their number is selected in a ratio of 1:4, that is, a quarter of the entire pipe must have perforation. The holes are placed with a minimum increment of 2-3 cm.

Operations for the manufacture of a perforated filter are performed in the following sequence:

- We lay the pipe on a horizontal surface and begin marking. At one end we mark the length of the sump, approximately 50 cm. Directly behind it is the filter part, on which we mark the holes. Don't forget that it takes up ¼ of the entire pipe.

- Drill the first hole. We position the cutting tool relative to the pipe surface at an angle of 30 to 60°.We drill in the direction from bottom to top relative to the intended vertical placement. The result is oval holes of a larger area.

- Similarly, we make all the necessary holes in accordance with the markings.

- Using abrasive material, carefully clean all the resulting holes.

- We lift the pipe and install it vertically. We carefully free the internal cavity of the filter from chips that could remain in it and close the holes.

- We take a wooden plug and close the lower part of the pipe with it.

A homemade hole filter for a well is ready.

Option #2 - slot models

Slot filters are very similar to perforated filters, but instead of holes they are equipped with slits.

Which can be located as follows:

- Horizontally staggered. A segment with slots is made, the block following it is cut with a rotation of 45°. This makes it possible to ensure the necessary strength of the structure without making special stiffeners.

- Vertical. The distance between the slots must be at least 10 mm. Such systems are similar to wire filters for sand wells.

- Horizontally with several segments of slots. The distance between the perforated areas, which is called the stiffening zone, should not be less than 20 mm, otherwise the pipe will lose the necessary strength. The slot pitch is at least 10 mm.

Slit filters are used in unstable soil where the percentage of pebbles, crushed stone or gravel is high. They can also be used in cases of high risk of rock collapse. A distinctive feature of the slot filter is a higher well flow rate.

This is due to the fact that the area of the slot located on the rod frame exceeds the area of the hole in the perforated filter by approximately one hundred times. The main disadvantage of the design is the high probability of clogging the cracks with fine-grained sand.

To make your own slot-type filter you will need: a pipe, metal or plastic, a wooden plug and a milling tool or gas cutter (torch). It all depends on how the slots will be made.

Operations are performed in the following sequence:

- We lay the pipe on a horizontal surface and mark it. We retreat from one edge about 50 cm, this will be a sump. Then we mark the location of the slots, not forgetting about the stiffening belt if the slots are located horizontally.

- Based on the markings, we make slots using any suitable method.

- We lift the pipe and free its inner part from chips and contaminants that could get there during the work.

- We install the plug.

The filter is ready for use.

A photo gallery will present the procedure for performing work on the construction of a well filter:

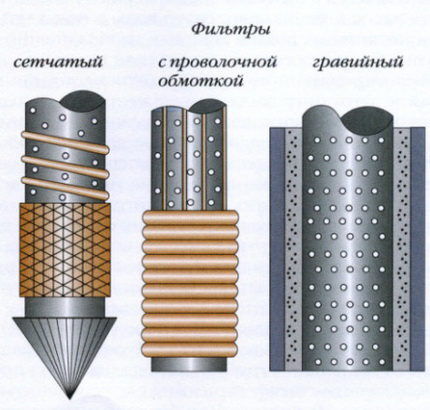

Option #3 - mesh filters

Such systems are designed for installation on clay-sand aquifers.

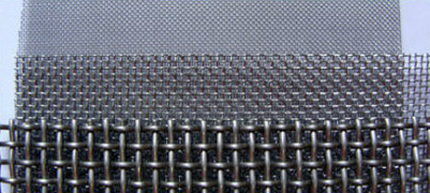

A mesh filter is a base in the form of a perforated or slotted structure, onto which a fine mesh mesh is attached to provide finer filtration. The size and shape of its cells may vary.

This system is considered quite durable and strong. Its main disadvantage is considered to be reduced productivity, since small holes in the mesh create quite strong resistance to flow.

In hard water, such filters quickly become clogged with particles of ferrous compounds.

The mesh that covers the structure can be:

- standard with square cells;

- keeper, consisting of several layers;

- galloon with cells of complex shape.

The type of soil determines the choice of grid. For gravel and coarse-grained sand, a keeper or standard mesh is selected, for fine and medium-grained rocks - a galloon mesh. Cell sizes can vary from 0.12 to 3 square meters. mm. To correctly determine the size, use the sample method.

Soil is collected from the well, then sifted through different mesh samples. The one that retains at least half of the soil particles can be considered suitable for the job. To determine the size of the cells and, accordingly, the soil particles, a handful of soil from the well is poured onto graph paper.

Filter meshes can be made of different materials:

- Metal - brass or stainless steel. Such products are durable, their cells can be easily cleaned if necessary. The main disadvantage of brass products is the high probability that during installation the mesh cells may be deformed, which will make it difficult for water to get inside the filter column.

- Fiberglass or carbon fibers. They do not deform during installation and have a long service life. The main difficulty during operation is cleaning the mesh.

Conventional washing will not be enough; you will have to use more complex methods: chemical reagents, electrical discharges or hydrodynamic shock.

To make a mesh filter yourself, you will need: a plastic or metal pipe, a wooden plug, a mesh, wire with a cross-section of at least 3 mm, a soldering iron and a drill or milling tool, depending on the chosen perforation method.

Let's get started:

- Place the pipe on a flat horizontal surface and mark it for perforation.

- We make holes or slots in accordance with the markings.

- Place wire over the perforation. We wind it at an angle of 30-45°, while the distance between adjacent turns should be 2±0.5 cm. Every 5-10 cm we perform spot soldering, securing the wire to the base.

- We check the quality of the winding and, if necessary, repeat the soldering.

- We put a mesh on the wire and wrap it around the body of the pipe and secure it.

In the case of a metal mesh, we use soldering, soldering the fabric to the wire, and fasten the plastic parts with metal wire.

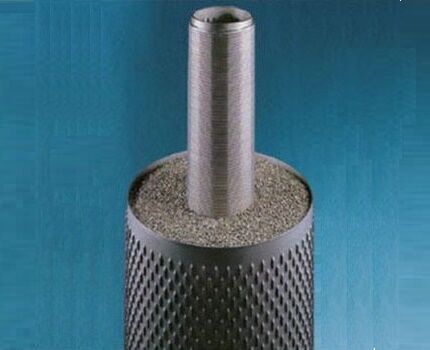

Option #4 - wire filter

Such a device can be considered a type of mesh filter with the difference that instead of a mesh, a special wedge-shaped wire is wound in a spiral on the base. The size of particles retained by such a filter is determined by the shape of the wire and the pitch of the winding.

Filters of this type compare favorably with mesh analogues in their high strength and long service life, which is due to the greater thickness of the wire compared to the mesh. It is clear that we are talking about high-quality frame-rod products, which are almost impossible to make on your own.

At the same time, mesh filters tolerate local damage more easily. If one or several mesh cells are destroyed at once, in this area it will allow larger particles of contaminants to pass into the column. However, the rest of the filter will retain its properties completely.

For wire filters the situation is different. If the winding is damaged, the product loses its filtering properties in the segment between two adjacent points where the winding is attached to the frame in the area of the break. In addition, the cost of mesh filters is much lower. This is due to the fact that they are easier to manufacture.

High-quality wire filters are almost impossible to make yourself. If you really want to try it, you will need a metal pipe of the required diameter, a plug, a milling tool or gas cutter, metal rods, a soldering iron and wedge-shaped wire.

First, a base is made in the form of a slot filter, the width of the slots of which should correspond to the average diameter of the rock particles. We lay 10 or 12 metal rods with a diameter of at least 5 mm on the prepared frame.

They will not allow the wire to lie directly on the frame and close its holes. The base is ready, you can start winding the wire. The peculiarity of manufacturing a wire filter is that it is wound onto a frame under tension. It will be easier to wind using a lathe.

If this is not possible, the operation is performed manually, which is very labor-intensive and requires special care and patience. During the winding process, turns of wire laid at the required pitch must be secured to the base by soldering.

Option #5 - gravel backfill

Small, smooth fragments of hard rock or gravel can be considered a natural filter with a fairly high cleaning effect.

It is capable of retaining even very small elements of contaminants and has the ability to self-clean. Based on this, fine gravel can be used as an additional filter.

For this purpose, it is placed in the water intake area of the well. The effectiveness of such a filter depends on the characteristics of the gravel and the height of its layer. The more particles of contaminants settle on the gravel, the fewer of them will enter the main filter, which will significantly prolong the operation of the well.

There are two types of gravel filters:

- Backfill. It is a layer of material poured directly into the well through the holes in the annulus.Can only be used for structures whose diameter does not exceed 10 cm in the filter section.

- Collected on the surface. The gravel mixture is packed into the cavity between two layers of filter material made of wire or mesh. After filling, such a circuit is lowered into the well. The width of its walls does not exceed 3 cm.

You can only make the first type of filter yourself. First of all, you need to prepare the gravel. The work should be taken with great responsibility, since the quality of the filter depends on the quality of the material.

First we select the diameter of the gravel. It should be on average 5-10 times smaller than the diameter of the well pipe.

We select all elements according to size and calibrate them. It is desirable that they be the same size. If the material is heavily soiled, it may need to be washed. When installing a gravel filter, preparatory work begins at the stage well drilling.

You may also be interested in information about ways well drilling and how rock her after drilling.

The hole for it is made taking into account the future sprinkling, that is, a slightly larger diameter than required. After the well is ready, prepared gravel is poured from the wellhead. The thickness of the coating is not less than 50 mm.

Practice shows that even a novice home craftsman can make a filter for a well on his own. Such designs are easy to manufacture and install. It is only important to correctly determine the type of filter device and correctly select the material from which it will be made.

Conclusions and useful video on the topic

Step-by-step instructions for making a mesh filter:

And this video will introduce you to the sequence of work on making a well filter from a plastic pipe:

If everything is done according to the rules, the filter will last a very long time, purifying the water supplied to the house from contaminants and protecting well equipment from overloads and premature failure.

Do you have a homemade filter in your well, made according to one of the instructions discussed in the article? Tell us if it was difficult for you to assemble it and what nuances you encountered.

Or did you have any questions during the process of building a filter device? Feel free to ask for advice by leaving your question in the comments section - we will try to help you.

My family and I live in a village; we have no running water and the entire population uses water from wells and wells. I also drilled a well, used stainless steel materials, the water comes out clean without any impurities. And the well has been in service for ten years now and no problems have arisen so far.

It’s interesting to know, how did you determine that the water is clean and without impurities? Well, clean, okay - by eye, but what about the presence of impurities to taste? Even if the water has a normal taste and is colorless, it is not a fact that it is clean in terms of chemical and bacterial composition. Therefore, the very first thing after drilling a well is to submit the water from it for laboratory analysis. Especially in your case, when the well is used as the main source of water, including drinking water. And based on the result of the analysis, you need to look at which filter should be chosen for the well, whether a simple homemade one will be enough or whether you will have to buy a more serious thing.

Very pressing issues that require priority attention when developing a well and ensuring subsequent water supply from it. There are impurities in any water, even if the well is three times artesian. If you plan to drink water from a well, then first of all a chemical analysis will show whether the water is suitable for this or whether the water will have to be filtered.

Further, for some reason, many people believe that borehole pumps will work in any water. This is wrong! For example, there are classes and series that are designed to work in water with a high iron content or with a high sand content. To protect against such factors, appropriate technologies and materials are used.

It is not uncommon for pumps that are used in wells with a high content of sand particles to be repaired when the models are not designed for this. At the same time, people are frankly surprised and indignant that the manufacturer refuses them warranty service.

Only six months ago they made a well at the dacha. The water tastes good, seems clean. But I noticed a fact: when I fill an enamel bucket with water and leave it in it for a while, a sandy sediment appears at the bottom. I was worried that such water would lead to kidney disease. I made a mesh filter from fiberglass. You have to clean it periodically, but the quality of the water has become much better.

Have you tried pumping the well normally? So that the amount of sand in the water is reduced to a minimum. Plus, the reason may be that the pump is too powerful for your well.

Filters are needed, but it wouldn’t hurt to fix the root cause either.

Hello! I read the article and realized that all this is good for a well, from which water is pumped to the surface of the earth. And we have a well in clay, an aquifer under a thick layer of clay, a submersible “Rucheyok” pump, the diameter of which barely fits into the well. And where to put the filter? You talk about how to make a filter out of a pipe, but don’t say anything about how to lower it into a well and then how to lift it for cleaning. We pump water with a “stream”, it is sometimes clean, sometimes muddy. We put it in barrels, where the water settles and becomes absolutely transparent. But it takes a long time to settle the water.

We need a filter, but which one? The one you are talking about is not good.