Manual drilling of water wells: how to drill a water intake by hand

Not all owners of suburban areas are ready to shell out large sums of money to hire drillers to install a water intake well.However, the convenience of using your own water intake is difficult to overestimate. You can save money by building a water source with your own hands. How to make it?

You will learn everything about how to manually drill water wells from our article. We will tell you how and how the work is carried out, and what novice drillers will need to implement the idea. Taking into account our recommendations, you can drill and equip a mine without any problems.

For independent craftsmen, we have presented and analyzed all the techniques of manual drilling, and explained in what cases they should be used. Attached are diagrams of drilling rigs and projectiles available for self-production, and posted photo selections and video instructions.

The content of the article:

Types of wells and their features

Your own source of water is an excellent opportunity to provide yourself and your loved ones with clean, life-giving water and satisfy your household needs. By drilling and well construction The water supply problem can be solved several decades in advance.

The choice of drilling method and the amount of work to equip the well depends on the type of hydraulic structure.

Abyssinian type well

If the water on the site is supposedly located at a depth of 10-15 meters, then it is more profitable and easier to install an Abyssinian well. This type of hydraulic structure uses an aquifer located above a waterproof clay layer. The aquifer is fed by infiltration of precipitation and water from nearby reservoirs.

A relatively shallow narrow well is a column of thick-walled VGP pipes with a diameter of 50 - 80 mm. In the lower, very first link of the column, a special filter is installed by drilling holes in the walls of the pipe.

The pipes serve as a trunk; the Abyssinian needle well does not require additional casing. It is not drilled, but immersed in the ground by driving it.

Compact dimensions Abyssinian type water intake allow you to place it on almost any free space in the local area. The most common method of breaking through this type of hydraulic structure is impact drilling.

Features of sand wells

When the depth of the aquifer is up to 30 - 40 meters, widespread in loose, incoherent sediments, a sandy reservoir is constructed water-bearing well. It is called so because it extracts water from saturated sands.

The aquifer of a sand well is located only three to four tens of meters from the surface. And to reach it you don’t have to go through hard rocks and semi-rocky rocks.Therefore, drilling a sand well manually will not be difficult if you use one of the methods described below.

Deep artesian well

But when planning to drill an artesian well, you cannot do it on your own. Artesian water is distributed through cracks in impenetrable rock and semi-rock at a depth of about 40-200 meters.

To determine the depth of water, they should rely on the data of hydraulic structures of this kind, drilled not far from the upcoming work site.

Since an artesian well can provide water to several areas at once, it is convenient to order drilling services together. This will allow you to significantly save on drilling and arrangement of a water supply source.

Self-drilling methods

In order to choose the best one for you personally drilling method, you must first study their specifics and understand what tool is needed and whether it will be possible to drill with your own hands.

Manual screw method

Drilling using an auger is one of the most common and accessible methods. It is effective when constructing wells whose depth does not exceed 40 m.

The essence of the method is that the auger, like a corkscrew, is screwed into the ground.As it penetrates deeper into the soil, the helical rod destroys the layers, and its metal blades bring waste soil to the surface.

Augers used for manual drilling are of two types:

- Rods to which the cutting blades are welded at right angles.

- Structures to which the blades are welded at an angle of 30-60°.

The designs of the second version are more convenient to use. Due to the location of the blades at an angle, the crushed soil does not fall into the well, but is completely removed to the surface.

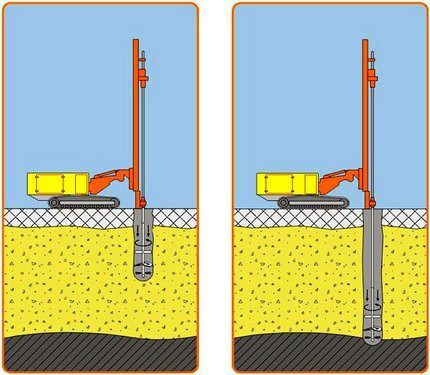

To facilitate manual labor and speed up the process, you can use small-sized screw installations.

Small-sized auger units work on the same principle as a hand drill, but are driven by an electric motor.

It is possible to drill a shallow well to collect water for watering the garden without drilling toolusing a garden auger. True, to line the walls, you will need pipes from which the mine shaft is assembled, and metal rod pipes required for extension.

Core drilling technology

Core drilling is performed using a special tool in the form of a pipe equipped with a crown. The specifics of drilling and the pipe diameter, which does not exceed 160 mm, allow us to work quite quickly. In a day of work, depending on the density of the rock, you can walk up to several tens of meters.

Using the fastening unit located in the upper part of the core pipe, one and a half meter rods are built up as the tool deepens.The build-up is carried out in stages, forming a technological column from a projectile with rods.

The crown is made of durable metal. The edges of the crown are sharpened so that its incisors can easily cope with dense rocks. The shape and size of the crowns used are determined by the physical and mechanical characteristics of the rock.

When dealing with super-hard rocks, a chisel is first used before plunging the pipe. Then a hole is drilled using a crown, and the slurry clogged in the core pipe shell is lifted to the surface.

In progress manual well drilling Using the core method, a column of casing pipes is installed into the shaft during drilling to strengthen the walls of the structure. To facilitate the penetration process, clean water or clay solution is periodically supplied inside the projectile.

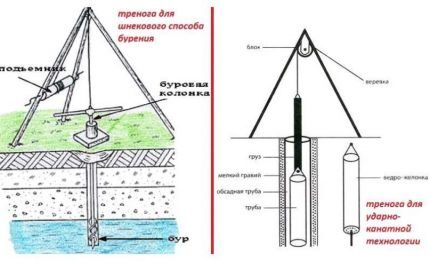

Shock-rope method

The method involves breaking up soil by lowering a heavy drilling tool from a two-meter height.

For this purpose, a drilling structure is used, the main elements of which are:

- a tripod, which is placed above the drilling site;

- block with winch and cable;

- a driving glass attached to the end of the cable.

The use of a winch allows you to reduce physical stress, and the use of a motor with a gearbox rotating the shaft automates the process.

The driving glass, made of a metal pipe, must have a well-sharpened cutting edge that is capable of breaking even hard rocks.To break up excessively dense soils, an additional steel rod is used as a weighting agent for the cup, fixing it just above the drilling structure. Loose rocks extracted with a bailer.

The glass is freed from the soil it has captured through its bottom, tapping the walls of the projectile with a sledgehammer. The bailer is cleaned through a technological hole located in its upper part.

The work is performed in the following sequence:

- In the selected location, dig a hole measuring 1x1 meter at a depth of 0.5 meters.

- A garden drill is installed in the center of the hole at a right angle. By rotating the tool around its axis, it is buried in the ground. As necessary, the screw rod is extended with a pipe, fixing it with a bolt connection.

- After wet sand appears, the drill is removed. Instead, a specially assembled structure of casing pipes is installed in the hole, which is driven in with a sledgehammer.

- The rock collapsed during installation of the casing is removed with a bailer. Each time a projectile penetrates into a rock formation, it captures and holds part of it.

- As the casing pipe deepens, it is extended with another section of the same diameter. The sections are screwed or welded together to obtain a single sealed barrel.

- To deepen the casing, carefully turn it and listen to the sounds produced. A grinding sound will occur during friction of coarse-grained sand, rustling - with fine-grained sand, silence - when passing through clay soil.

- For drilling loose rocks, such as loose sand, pebbles, gravel, a bailer is used. Clay rocks and dense sands pass through the glass.

- After performing a series of successive blows, the glass or bailer is raised to the surface, removing the soil from it. After this, the cycle of work is repeated.

As in previous methods, to facilitate the process of manual drilling of a well, a clay mixture or water is poured into the hole, and then removed back using a special bucket. If noise occurs during drilling, the well should be filled with water. If the water drains slowly, the pipe should be deepened another half a meter, but if it drains quickly - only 20-30 cm.

For shallow excavations you can easily make a bailer with your own hands. To do this, you will need a pipe with a diameter of 100-120 mm, a metal earring and an eye for attaching a cable, which must be attached to the top of the pipe.

Impact-rotational method

The main difference between this method is that the drilling rig simultaneously performs both impact and rotational movements. This approach allows you to speed up the drilling process. This method is especially effective when it is necessary to arrange a hydraulic structure if the geological section in the area is heterogeneous.

Impact-rotary and percussion-rope drilling methods are effective when constructing wells in loose soils, the particles of which are not interconnected. Both methods are suitable for drilling and extracting clayey soils: sandy loam, loam.

When drilling in loose rocks, due to insufficient connection of soil particles with each other at the stage of well construction, there is a high probability of its walls collapsing. Therefore, sand wells must be equipped with casing and filters that prevent large inclusions from entering the extracted water.

Step-by-step auger drilling technology

Among all the listed methods, the auger method is rightfully considered the simplest. But it is worth considering that it is effective only when drilling loose and clayey soils.

Preparing the necessary tools

Before drilling a well manually, you need to prepare the following tools:

- drill or small-sized auger installation.

- drilling derrick with winch.

- set of 3-4 rods.

- casing.

If it is necessary to construct a well at a depth of more than 8 meters, to facilitate the immersion of the drill and its subsequent removal from the wellbore, the equipment is fixed to homemade drilling rig.

The size of the tripod should correspond in proportion to the height of the drill string section. To create the structure, the beams are laid in the form of a triangle and fixed using a bolted or welded connection.

Holes are made in them for inserting a metal pipe, which will serve as a support. The dimensions of the base are determined only by the stability of the structure.

In the upper part of the structure there will be an additional hole through which the rod will pass.

To protect the wellbore from destruction and shedding of the walls, a casing string of pipes is installed, which have a high bearing capacity for shear and compressive formation loads.For work, pipes made of metal, asbestos cement or polymers are used.

When assembling the structure, segments of such elements can be easily screwed into each other without the use of additional assembly units.

Making a screw from scrap materials

Material for production of drilling tools, in this case a helical rod, a d100mm pipe can protrude. For this purpose, it is better to use high-quality steel pipes with a wall thickness of at least 5 mm.

The upper part of the structure must have:

- at the upper end there is a screw thread on the outside for connection to the rod;

- at the lower end there is a screw auger with a number of turns of at least two.

To facilitate the process of turning the drill, a 1.5 meter long handle is welded to the upper section of the pipe. The transition element between the handle and the collapsible rods will be a tee equipped with an internal screw thread.

Rods 1.5 meters long are made from a pipe of the same diameter:

- a first rod with an external screw thread at the lower end for attaching a drill;

- all subsequent rods are threaded at both ends of the same size.

The couplings must have the same thread parameters. As the structure needs to be expanded, they are simply screwed to the auger, having first unscrewed the handle.

Some craftsmen use an ice drill as an auger.The knife of the tool in this case serves as the cutting blades of the auger. Extension rods are manufactured separately.

Trying to improve the tool, some craftsmen additionally weld reinforced cutters to the factory edges of an improvised auger.

Carrying out drilling operations

On well site dig a hole measuring 150x150 cm. It is necessary to ensure the stability of a vertically installed pipe. To prevent the walls of the recess from crumbling, they are reinforced with pieces of board or pieces of chipboard.

The drill is immersed in the hole and, holding the tool by the handle, they begin to gradually screw it into the soil in a clockwise direction. It is more convenient to do this work with two people: the first one will rotate the handle of the tool, and the second one will press on it from above.

After passing the first meter, they begin to form a structure trunk with a diameter of at least 12-15 cm. To do this, a casing pipe is lowered into the recess. The diameter of the pipe should be slightly larger than the size of the drill blades. Subsequently, the pipes are driven in parallel with the deepening of the well.

After the drill is deepened by 1.5-2 meters, it will be quite difficult to rotate the tool on your own. Using pipe wrenches and other gripping devices will help make the job easier.

When the moment comes that the drilling tool will be buried to its full height during immersion, it should be “increased.” To do this, a rod is fixed to it using a threaded connection or a “pin-rod” extension.

At this stage, it is important to ensure the strength of the connection of the elements. To simplify the task of determining the depth traveled, it is advisable to mark the extended rods.

As the layers pass, they continue to form the casing, not forgetting to check the verticality of the trunk. Even minimal distortion can prevent the casing from descending freely. Therefore, if during work the drill begins to hit the walls of the casing, wooden wedges are driven between the soil and the casing to adjust the verticality of the trunk.

Work continues until the soil delivered to the surface is wet. This will indicate that the aquifer is already close. To overcome the aquifer, all that remains is to go a little deeper.

It is possible, but not advisable, to install the casing after completion of drilling. After installing the casing pipe into a completely drilled shaft, the collapsed soil will again need to be removed from the well, but this will have to be done using a bailer.

To temporarily fix the casing string installed in the drilled shaft, you should use a device in the form of a clamp equipped with handles. It will not allow the casing to descend into the excavation before the next section of casing pipe is connected.

But it is worth noting that this method is far from the most rational, since it requires a long time to clear the face of sludge. When forming a column, you should not lower the pipes to the bottom of the well. They should not reach the lowest point of the bottom by approximately half a meter.

To facilitate the drilling process using an auger, experts recommend flushing with water from time to time. The jet pumped into the cavity of the casing pipe will wash the dump to the surface.

Conclusions and useful video on the topic

Drilling a well using the percussion-rope method:

The subtleties of making a screw with your own hands:

For those who want to know how to correctly drill a water intake well by hand, we have provided methods proven in practice. You need to choose the optimal drilling method, take a serious approach to choosing the necessary equipment, and when drilling, strictly follow the advice of experienced professionals.

The result of the efforts will be a self-developed source of water supply, providing clean water to all households.

Would you like to tell us how you drilled a well on your own property? Do you have questions or interesting facts about the topic of the article? Please write comments in the block below.

I couldn’t manage to drill a well at my dacha on my own. I had to look for specialists in this matter with special equipment (for the sake of one well, you won’t buy everything you need). They arrived with a small auger unit, I helped. I bought the pipes in advance (made of plastic - they serve better than metal ones).After drilling, we had to pump out the water until it became clear.

I'm in a similar situation now. I need a well in my country house, drillers in my region ask for 1500-2000 rubles per meter. I’m even afraid to imagine how much the total amount will be. On the other hand, on the forums they are scared by the fact that drilling on your own takes a lot of effort, time and nerves. Is it worth trying or shelling out for professionals?

Hello, Alexey. If you need a well for the uppermost aquifer, then using the services of drillers is not at all necessary. You can drill a well in the sand yourself.

This can be done manually, i.e. with a hand drill. If the cut is predominantly sandy, then it is enough to stock up on an auger. Using this tool, it is quite possible to drill a well up to 30 meters on your own. No experience is needed at all. If the depth is within 15 meters, then you will break through in a couple of days, but do not forget to immediately install casing so that the trunk does not become covered with soil crumbling from the walls.

The difficulty in constructing a well on your own arises precisely when installing well filters and connecting pumping equipment. If you think you can handle all this, then get down to business.

I also strongly recommend that you read the article about do-it-yourself well construction. This material will be very useful to you.

To construct a well on limestone, it would still be more practical to order drilling work. Hand tools are not enough for digging rocks. More serious equipment will be required, and tens of times more effort is required.

There was one case related to drilling.I found specialists in my city on this issue, called, and made appointments. We arrived, everything was as it should be, and we started drilling. When we finally found the water, it turned out to be very dirty, and no matter how much we cleaned it there, it did not become cleaner in the well itself. And the guys from the company shook their heads, they say, this is their first time doing this, usually you clean it a little, and it’s crystal clear.