Making an Abyssinian well with your own hands: how to make a needle well on a site

It is very often impossible to connect a small country estate to a central water supply due to the remoteness of the water supply main. Digging a well or drilling a well is sometimes unaffordable, and to build an autonomous system you need your own source of water.

In such cases, you can equip an Abyssinian well with your own hands - the technology for organizing such a source of water intake is quite simple. Agree, before starting to implement the idea, it is necessary to understand the design and operating principle of the system.

We will tell you how to plan an Abyssinian well, what equipment you will need and how to make an igloo well yourself. Particular attention should be paid to the type of soil on the site.

The content of the article:

Operating principles of the Abyssinian well

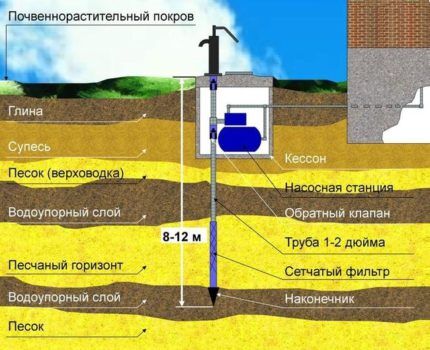

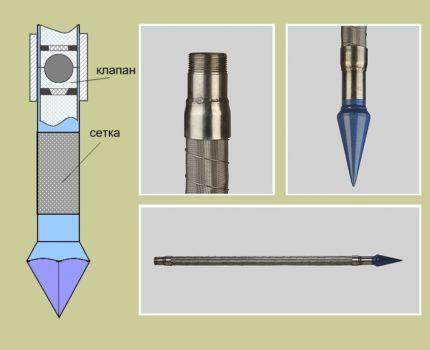

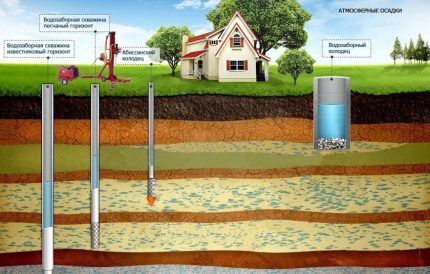

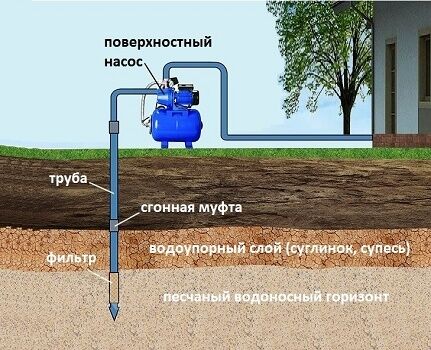

An Abyssinian well is a simplified version of a well that allows you to obtain water from the first or second aquifer lying on top. Its design is extremely simple. It is a column of interconnected gas-supply steel pipes with a primitive filter and a metal tip at the bottom.

The thin trunk of the excavation looks like an ancient sewing device. Hence the second name: needle well.

The classic method of immersing an Abyssinian well into the ground is done by banal driving - the simplest method, actively used among independent craftsmen. They hammer until the lower pipe with the tip opens the aquifer.

Sometimes the column is partially buried by auger drilling, but renting a manual or mechanical drilling rig significantly increases the work budget.

The Abyssinian well was invented and tested during the war between colonial England and Ethiopia in 1867-68. The design proposed by the American engineer Norton tirelessly provided the British troops with water during their movements across the desert.

The device for extracting life-giving liquid from underground layers of soil was quickly installed, dismantled and used again at the next stop.

Such priorities as mobility, low cost and simplicity of construction were appreciated by the military and attracted travelers and researchers.

In Russia, they became acquainted with a wonderful invention a year after the end of the English campaign. A device for lifting water from a shallow depth was described by K.I. Maslyannikov in a book dedicated to the effective drilling equipment that was in use at that time.

Of the five Abyssinian wells built in the Tsarskoe Selo area, two turned out to be quite suitable for obtaining fresh water. Three were unable to reach the aquifer due to limestone lying close to the surface.

Successful Abyssinian wells yielded a bucket per minute. At first there was a cloudy slurry, which after pumping for half an hour became quite transparent and clean.

A needle well penetrates only the first aquifers from the earth's surface, so the resulting water cannot be used for drinking purposes. It is suitable for watering, cleaning the area and similar household needs.

If desired and there is an impressive production flow rate, you can install a system for water purification coarse and fine filters, retaining mechanical inclusions and chemical impurities.

Structural specifics of the needle well

The Abyssinian drilling rig, developed a century and a half ago, has not undergone any fundamental design changes over the past years. For some time it was completely undeservedly forgotten.Although in terms of the pace and simplicity of construction it is noticeable, as well as the price of arrangement, it is ahead of widespread traditional wells.

There are two main components in the design of an Abyssinian well:

- drill bit, including a tip that cuts the soil and a barrel that is expanded during the process of penetration into the ground. The trunk also serves as a channel for lifting water from the depths. Therefore, it is assembled from pipe sections, and not from a steel circle or rod.

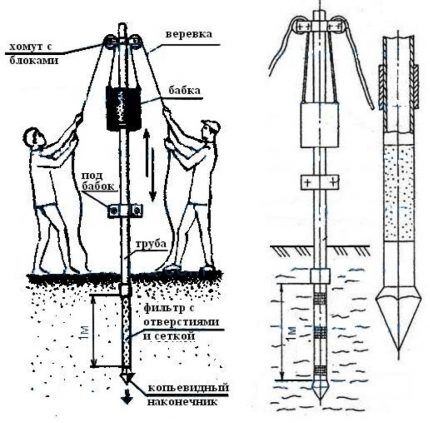

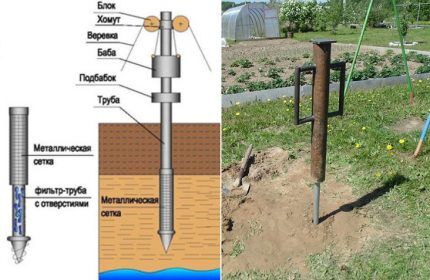

- Koper, consisting of a metal tripod and a heavy woman playing the role of a hammer. At the top of the tripod there are two blocks with ropes stretched through them, to which the woman is tied.

When the ropes are pulled, the woman rises to the top of the installation. When weakened, it rapidly falls onto the headstock, which is rigidly fixed on the section of the trunk being driven in. The latter performs the function of an anvil, thanks to which the trunk is consistently immersed in the ground.

The headstock is a kind of clamp, consisting of two symmetrical parts. The area of the headstock surface in contact with the headstock is slightly larger than the area of the bottom of the “hammer” falling on it.

After the section of the trunk being driven is almost completely immersed in the ground, the headstock is removed. The next section of the pipe is screwed to the buried section, on which the anvil clamp is once again fixed.

The steps to deepen the drill bit are repeated until the lower part of the do-it-yourself needle well reaches the aquifer. The water carrier must not only be opened, but also passed at least a meter.

According to the rules, the layer should be crossed at 2/3 of its thickness, but the actual dimensions of the water carrier are probably unknown to an independent driller. It is difficult to judge them without hydrogeological surveys.

The appearance of water in the workings must be periodically monitored. For the purpose of measuring the water level in a mine, professional drillers have a simple device that ideally determines the depth of the aquifer when it lies up to 15 m.

This is a hollow metal cylinder called a clapper. The device looks like an inverted thin glass attached through a loop to a tape measure.

When the edge of the firecracker comes into contact with the surface of the water, a pop is heard, indicating the appearance of the desired object in the well. You can make such a control device yourself by tying a large nut to a string so that it can come into flat contact with the surface of the water.

Instead of a nut, it would be nice to find a not too lightweight plastic or metal cone, open on one or both sides.

There is another ingenious tool that serves as a control device.It is trivial to monitor the appearance of water in an Abyssinian well by lowering an ordinary polymer pipe into the shaft. A characteristic clap will signal contact with the groundwater table.

Barrel manufacturing technology

There are no Abyssinian wells in industrial production. The production of the installation is ordered in a workshop or done with your own hands.

In order to make a needle well you will need:

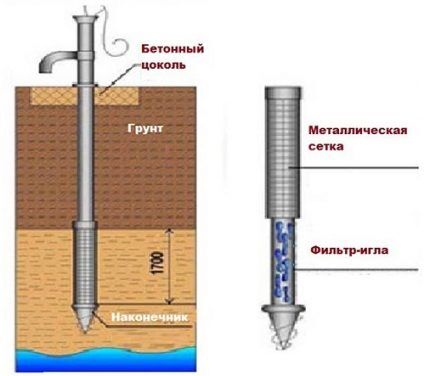

- Thick-walled VGP pipes, the labeling of which indicates “reinforced”. The optimal size of the outer diameter of rolled pipe is from 25 to 40 mm. It should be remembered that the thicker the trunk, the more difficult it is to drive it into the ground, and the thickness of the pipe will not affect the flow rate of the well.

- Steel tip, turned on a lathe. The length of the part is 10-12 cm, the Ø is 1-2 cm larger than the Ø of the pipe, so that the friction of the soil against the trunk does not slow down the driving process. The tip can be conical or pyramidal, but not welded from wedge-shaped pipe scraps.

- Steel mesh of dense galloon weaving, necessary for installing an additional filter. It will prevent the ingress of small grains of sand and even clay suspension.

To make a barrel, it is better to purchase seamless pipe, which will definitely not crack when driven in. The pipe must be cut into pieces of approximately 1.2 - 1.5 m. In drilling, they are called rods.

The indicated sizes are recommended based on the greatest ease of use. The specific length of the segments in the designated interval depends on the expected excavation depth.It is desirable that one of them be 1 m for final penetration into the aquifer.

The barrel is built up as the projectile is deepened, and is done by sequentially winding sections of the VGP pipe.

To make connections along the edges of the segments, 7 turns of plumbing thread are cut and steel couplings are used. The connections are made hermetically, and plumbing tow is placed in the threads.

A tip is welded to the first section of the future column and equipped with a primitive filter - this is the water receiving part. In the starting section of the pipe, holes Ø 8 - 10 mm are drilled so that the elements of the specified perforation are arranged in a kind of checkerboard pattern.

There should be approximately 5 cm between the conventional horizontal rows of holes: you should not make them any closer, so as not to weaken the pipe.

They begin to drill holes by stepping back about 15 cm from the bottom edge with the same goal of maintaining strength indicators. At the junction of the first link of the column with the next rod, a check valve pumping system.

Most often it is a ball that allows water to pass only towards the pump.

Improvement of the filtration element

The described filter will protect against the ingress of gravel and small pebbles, but will not get rid of smaller inclusions. Therefore it needs modernization. To turn a perforated piece of pipe into a filter with a higher degree of protection, it needs to be modified.

Procedure:

- Turns of stainless wire are wound over the pipe. They are needed to increase the area of the filtering organ.The distance between the turns is 3 – 5 mm.

- The resulting workpiece is tightly wrapped in a piece of stainless mesh, which is soldered to the walls of the pipe. They use exclusively tin solder, because the use of an alloy with lead will negatively affect the quality characteristics of the water.

There is an opinion that to make it even more important, the upgraded filter should be wrapped on the outside with stainless steel wire rod. Let us allow ourselves to doubt the reliability of such a fortification. We believe that when immersed in the ground, the outer coils of a homemade filter will certainly come loose, increase friction and make plugging noticeably more difficult.

Refining the filter is a good thing, helping not only to optimize water quality, but also preventing silting of the needle well.

True, with all the prostate of the device, strict adherence to the rules is required:

- A mesh made of brass or other non-ferrous metals is not suitable for a mesh filter. In union with steel, with strong soldering, they will form a galvanic couple, quickly and easily corroded by corrosion.

- The diameter of the perforated pipe together with the additional filter should not be equal to or exceed the maximum diameter of the tip. Otherwise, important filter additives will separate from the pipe when driven into the ground.

- For the construction of the drill string and the first link, which is the water intake part of the shaft, fragile cast iron pipes are not suitable.

You should not save on couplings by buying handicrafts with low-quality cutting. If the connections come apart during driving, the needle will have to be dismantled and the hole must be drilled again.

Conditions for the construction of an Abyssinian well

To install an Abyssinian well, the ardent desire of the owner of the site, supported by knowledge of the design of the water intake installation, is not enough. Before starting work, it is necessary to find out whether the geological conditions are suitable for constructing a needle well.

The soils lying in the ground differ in physical and mechanical properties: density, structure, hardness parameters, etc. Drillers have a classification based on the so-called “drillability” of rocks.

For excavation of sandstone and sand, for example, different types of tools and drilling methods are used. Rocky sandstone is drilled with a core pipe with a carbide crown, and water-bearing sands are lifted using the shock-rope method using a bailer.

Based on the totality of physical and mechanical properties, together with drillability, rocks are conventionally divided into:

- Hard or rocky. They are capable of splitting, crushing, and are gradually destroyed when drilling at high speed and pressure. Hard rocks are represented in the upper part of the sediments by limestones, sandstones, marls, dolomites, etc.

- Plastic. They can be easily or relatively easily cut with a knife and a drilling tool, including the tip of an Abyssinian borehole. Plastic representatives include clays, loams, and sandy loams with a high plasticity number.

- Bulk. They don't keep their shape because... consist of particles that are not connected to each other. When saturated with water, some silty species can “float.”The loose variety includes sand of all sizes, gravel-pebble, gruss-crushed stone and similar deposits.

At the disposal of home craftsmen who want to construct an Abyssinian well, there is no drilling tool for drilling all of the listed types of soil. Independent drillers will be able to cross only plastic and granular categories. It is impossible to crush hard rock with the tip of an Abyssinian well.

You should not try to break a large boulder: it is better to move a little and start working there again. Moreover, dismantling the water intake device is many times faster than installation.

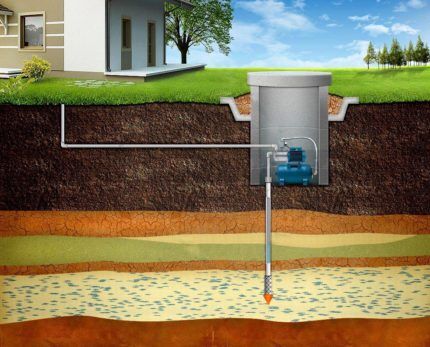

In addition to restrictions on drillability, the possibility of constructing a needle well is affected by the height of the water surface. The fact is that its extraction from a thin-bore mine can only be entrusted to surface pumping equipment. Most brands of surface pumps are ready to lift water from a depth of no more than 8 m.

Even if the technical data sheet indicates a suction depth of about 10 m, we must not forget about the standard pressure losses in the barrel and the fact that the pump usually also transports water along a horizontal section.

Every 10 m of horizontal movement takes away 1 m from the suction depth. In addition, surface pumps are strongly recommended to be located in enclosed spaces, and they are often remote from the water intake point.

If, apart from the Abyssinian well, there is absolutely no way out, and the depth of water in nearby wells is fixed at 12 - 15 m from the surface of the earth, then to raise the water you should stock up on an airlift or a hand pump capable of pumping water from the indicated depth.

Useful information on how to find water for a well on a site and assess the location of aquifers is presented in this article.

An alternative option for adapting the water intake needle to an unsuitable groundwater level is to construct a pit. Before driving the column into the ground, a hole is dug about a meter deep, the width of which is convenient for working with a shovel in it. Driving the rods then begins from the bottom of the hole. In such situations, the pump is installed in a pit.

Your own hydrogeologist: soil assessment

No matter how simple the process of driving a needle hole may be, careful preparation for the work is still necessary. It is not enough to stock up on rods and a starting unit with a filter, rent or make your own pile driver. We need information about the geological and hydrogeological situation in the area where the Abyssinian well was constructed.

Where and how to get them? We can literally get information about the groundwater level from a neighbor’s well or borehole.

We will measure it ourselves with a clapper or ask the owner of the source about the depth from which he pumps water.At the same time, we will find out what kind of soil was lifted from the face when they drilled or dug a working.

In flat areas, rock layers lie almost horizontally with a slight bend or slight slope. The groundwater table is approximately at the same absolute level. The difference in the depth of the existing and planned well can only be expressed due to differences in relief.

Do not forget that the Abyssinian well reveals the perched water or the following aquifer, covered by clay or loam, but not rock aquifer. Those. The water level in the mine will definitely be unstable - depending on the volume of precipitation.

During the period of snowmelt and rainy season, the groundwater table will be higher than in the dry weather season. You should find out from the owner of the existing water intake point what the maximum and minimum differences in water level are, so that during a dry summer the Abyssinian well does not turn out to be empty.

The question about the breeds being developed is not at all idle. For example, in the Leningrad region, water is extracted from large sands with a significant number of massive boulders.

Often, due to the inability to crush and remove a huge stone, drillers displace the water well. It is worth doing the same if there are similar soils in the region where the Abyssinian well was constructed.

It makes no sense to carry out driving in high-lying rock and semi-rock massifs. If the neighboring area receives underground water, common in fractured dolomites, sandstones, limestones, then the idea of constructing a needle well will have to be mercilessly abandoned.

Detailed information on conducting geological surveys is presented in the article - Where and when is it better to drill a well on a site: general rules + advice from experienced drillers

For those who decide to make an Abyssinian well with a pit, information is needed about the structure and condition of the soil layers lying at the depth of the pit. If the section is composed of sandy loam, loam, or their alternating layers, it is not necessary to strengthen the walls of the pit.

If the pit is dripping in sand, the walls should be reinforced with boards or concrete. Sandy sides are unstable and can collapse and cover the water intake point along with the pumping equipment.

Questions about the upper layers of soil are also necessary for those who plan to go through the upper part of the excavation with an auger. Auger drilling will significantly speed up the process, but may not bring the planned result. For work, use a simple device - purchased or homemade drill.

In case of collapsing sand walls, installation will be required casing pipe, thanks to which the economic priorities of the Abyssinian well will be reduced.

Conclusions and useful video on the topic

Analysis of the pros and cons of the Abyssinian well against the background of a regular well:

Video about deepening with an auger and then plugging an Abyssinian well:

About the futility of searching for water using the traditional method using frames:

Installing and operating an Abyssinian well is the simplest and cheapest method of obtaining water from the upper aquifers. To construct a water intake shaft, no equipment is required; all stages of the work can be easily completed with your own hands.

The invested efforts and minor funds will quickly pay off; the Abyssinian well will last no less than traditional water sources. It is important to get excited and implement the idea, armed with the information we present.

Do you have practical skills in constructing a needle well on your site? Please share your accumulated knowledge or ask questions on the topic in the comments below.

Yes, everything is correct, but while reading the article I had a natural question. Does this mean that two wells will have to be made on the site? One for household needs, the second as a source of drinking water. But excuse me, why? Of course, you can install a cleaning system, but it will have to be maintained and changed periodically. In my opinion, it is better to drill one artesian well and use water for everything. I don’t know how it is in other regions, but in Khabarovsk the well water is of disgusting quality.

There are both advantages and disadvantages to such a well. The price is two or even four times less than if you make a conventional well with concrete rings. If done properly, the water rises from the depths, so it is clean and no water gets in. The water is usually soft, without iron content, and can be used for food without special purification. But there is a chance that the layer will slip through and the well will have to be raised.And this method will not work in every area: the aquifer can lie deeper than 15 m.