Drilling a well with a bailer: a complete overview of drilling technology using the percussion-rope method

How to provide your own plot and home with enough clean water? Sometimes the simplest answer to this question is the construction of a well.If hiring a crew is expensive, but you have the skills and desire to work hard, you can drill it yourself. The methods by which you can extract water from the depths of Mother Earth vary.

Among them, drilling a well with a bailer takes a very worthy place. Most often, jelling is used in combination with the rotary core method to extract loose, incoherent rocks: sands, gravel deposits. It happens that without using a bailer it is completely impossible to lift destroyed soil from the face.

We will talk about how drilling operations are carried out using a bailer. Here you will learn how to competently drill a water intake well on a suburban area using the simplest homemade drilling tool. Taking into account our recommendations, you will arrange a water source at minimal cost.

The content of the article:

General concepts about the drilling process

Drilling with a bailer is a so-called percussion-rope drilling method. A bailer is used as a drilling tool - a heavy, hollow, long and narrow projectile, which is dropped into the well shaft from a height of several meters.

Under the weight of the bailer, the layers of soil are destroyed and fall into the cavity of the projectile. The bailer is removed, cleared of soil, and then thrown back into the mine.

The process is repeated again and again until the aquifer is reached and passed through. Although the process seems simple when described, it can be long and labor-intensive.

However, cable percussion drilling has many advantages over other methods. For example, when drilling by hand with a bailer, water is usually not introduced into the barrel, as is often done when using auger or rotary drilling.

As a result, the soil in the well does not get wet, and this reduces the risk of weakening or destruction of its walls. Another plus is the accurate determination of the aquifer.

With “wet” drilling, it is not always easy to understand that the long-awaited water has finally appeared. Even experienced drillers sometimes do not immediately recognize this moment and continue drilling. In addition, it is believed that the flow rate of “dry” wells is higher than that of “wet” ones.

When choosing between a bailer and an auger, some craftsmen are guided by the following considerations. Screw installations with flushing, which are produced by modern industry, have limitations on drilling depth.

And the power of such installations is 12 kW. It is difficult to find a gearmotor that provides such power in domestic conditions.

But a gearbox with a power of only 2.2 kW lifts a load weighing about one ton. Such a mechanism will lift even a very heavy bailer without difficulty. All that remains is to throw the bailer down to get a strong enough blow that can destroy fairly dense rocks. Thus, with less energy consumption, a more effective effect is obtained.

In addition, collect bailer made from improvised means will be simpler and faster than a screw, the design of which is noticeably more complex.There are cases when, with the help of a homemade bailer, tripod and motor, it was possible to drill a hole more than 40 meters deep, although it took several months to complete this work.

What do you need to consider when working?

To begin with, it doesn’t hurt to anticipate possible problems. Of course, each well has individual characteristics.

Drilling at a distance of just a couple of tens of meters can take place according to different scenarios. But knowing the approximate composition of the soil and the layers it includes will allow you to draw up a preliminary plan, stock up on the necessary tools, etc.

The heavier and more viscous the substance needs to be brought to the surface, the more difficult it will be to work with the bailer. The easiest way to deal with dry sand. But on quicksand, work can last indefinitely, while the well hardly gets deeper.In this case, some experts recommend drilling with simultaneous flushing, plunging the casing as quickly as possible forward of the bailer.

It is almost impossible to overcome layers of heavy clay using a bailer. On soils of this type, drilling is more effective using other methods.

To select a layer of loam, use a glass: a narrow, long tool with a sharp bottom edge and without a valve. He is also thrown into the mine from a height of several meters. The glass is then removed and cleaned through a narrow vertical hole made in its side. Sometimes such a hole is made in the bailer.

This kind of work on loam is progressing hard and slowly. It is worth assessing the cost of labor and time; it may make sense to prefer auger drilling to the percussion method. To assess the composition of the soil on which drilling will be performed, there are two ways. The cheapest one is to ask neighbors who already have a well, and the expensive one is to order drilling work from specialists.

Usually, a place is chosen for a well where the relief is lowered; it is believed that this will be closer to the aquifer. Some craftsmen, using a bailer, managed to drill a quite decent well right in the basement of their house, since a machine or tripod for a bailer is a relatively compact structure.

It should be remembered that such work can only be carried out in a fairly spacious basement with a high ceiling. In this space it is necessary not only to place the drilling rig, but also to extend the casing pipe.

If there is no floor or ceiling yet, the winch can be secured to the rafters. In addition, you should take into account the large amount of dirty water that will come from the well during drilling and can flood everything around. It is wiser to carry out drilling in the dry season.

Most often this is done in the summer. Drilling operations are also quite effective in winter, although it may not be easy to overcome the layer of frozen soil. But in the spring, during floods, drilling wells is not recommended. Wet soil is more difficult to remove, and it will be more difficult to determine when water appears in the well. In the fall, work usually occurs in November.

Tools and materials used

First, you will need the bailer itself, as well as the installation to which it needs to be hung. The drill bit is quite heavy.

If you really want to, you can, of course, pull the filled device out of the shaft manually, but this will require a lot of effort and time. To make work easier, a tripod tower.

It can be made of metal or wood. A block is fixed at the top through which a metal cable is passed. The bailer is suspended from this cable. This will require less effort to pull it out.

Lifting is carried out using a gear motor with a clutch, on the shaft of which a cable is wound. To prevent the drum from spinning due to inertia after hitting the bailer, you can install a special braking device.

For commercial use, the use of a brake is quite justified, but for your own needs you can do without it. Using the clutch, you can regulate the force supplied to the device, taking into account the moment of impact. During the operation of the device, the ability to determine this moment quickly comes with experience.

You can do the installation, the bailer, and the glass yourself or purchase it at hardware stores. How to make a drilling tool for manual drilling is written in detail. In this article.

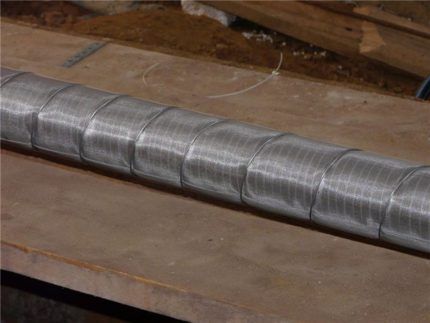

To make a bailer you will need a piece of metal pipe several meters long. The outer diameter of such a pipe should be approximately 20 mm less than the inner diameter of the casing pipe. For example, if a 133 mm steel casing pipe is used, a pipe with a diameter of 108 mm will be suitable for the wave bailer.

The wall thickness of the bailer pipe can reach 10 mm. In this case, you should compare the size and weight of the device. It must be heavy enough to effectively loosen and grip the ground when it hits the ground.

But it should be remembered that the power of the gearbox must be sufficient to pull out the filled bailer. A weight of 30-40 kg is considered quite sufficient. When the pipe is selected, it is necessary to weld or screw a shoe with a reed valve at the bottom.

A protective grille and a handle are welded at the top, to which a metal cable should be attached. The lower part can be sharpened inward to improve soil loosening. Instead of sharpening the edge, you can weld pointed rods or sharp pieces of metal at the bottom.

In approximately the same way, a glass for drilling a well in loam is made from a piece of pipe. Only in this case, a valve is not needed, and vertical holes are made along the length of the pipe so that the glass can be cleaned of viscous soil.

In addition to installation and bailer, you will need a number of materials and accessories:

- casing pipes in the required quantity;

- clamps to secure pipes during welding or soldering;

- garden auger;

- a place for collecting waste soil;

- a container or place for draining contaminated water;

- welding machine or soldering iron for PVC pipes.

Both metal and plastic can be used in the formation of well bores. casing. The lower part of the first plastic pipe must be equipped with a special shoe, which facilitates the process of lowering the pipe into the well shaft. Plastic pipes are soldered using a soldering iron designed for this purpose.

It is not difficult to master the use of this tool, but before starting work it is better to take several lessons from more experienced craftsmen or practice on sections of unnecessary pipes. Metal pipes are a little easier to work with because they are stronger than plastic structures.

Often such a pipe is simply driven into the shaft in order to lower it to the required depth. To weld metal pipes, a welding machine is used; if you do not have the skills to work with such equipment, you will have to master them. Most often, pipes with threaded connections are used for wells, but welding is considered more reliable.

Description of drilling technology

If all materials and tools are prepared, you can begin work. A tripod is installed above the selected location for the well. A metal bailer cable is placed on the block and wound around the gearbox shaft. In the ground under the bailer, using a garden drill, make a hole of such a diameter that the bailer fits into it.

Drilling can begin. The bailer raised above the hole is simply thrown down. The impact loosens the soil, the valve opens, and the bailer cavity is filled with soil.

Usually they make not one, but three or four blows so that the bailer is filled as much as possible with soil. Then it is lifted up from the shaft, the valve is opened and the captured soil is poured out of the device.

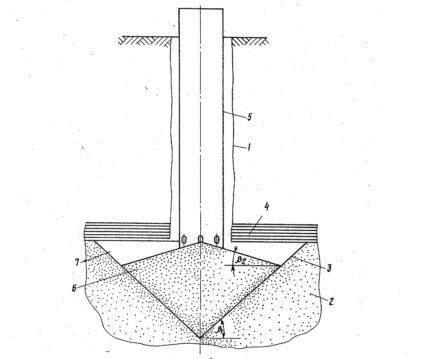

The empty bailer is thrown back into the shaft several times, etc. Gradually the mine becomes deeper. To protect its walls from collapse, you need to lower the first casing pipe inside.

The pipe is held in place using special clamps to prevent it from sinking too deep. As necessary, the length of the casing pipe is increased by welding, screwing or soldering the pipes to each other.

It is believed that a shallow well can be drilled first and then the pipes can be installed, but it is much more reasonable to install the pipes right away. This will definitely protect the walls of the well from collapse.

It is very important to correctly install the first casing pipe in the mine. Its position is leveled and carefully fixed. The position of the remaining pipes is set according to the first pipe. If the pipe is placed skewed from the very beginning, this may complicate drilling, installation of a filter pump, well maintenance, etc.

The top layer of loamy soil is usually very dense due to the large number of clay inclusions. It is passed using a glass, the device of which is described above. They act in the same way as with a bailer: they throw it into the shaft, take it out, clean it, etc. Having passed this difficult section, you can use the bailer again.

Difficulties may also arise during the passage of quicksand if, during the drilling process, the trunk goes through this water-rich layer. Some craftsmen believe that to speed up the work, it makes sense to pump water into the casing and scoop out the liquid soil.

Typically, drilling with a bailer is performed “dry”.This makes it possible to accurately determine the appearance of water in the well, indicating that the aquifer has been reached.

Stopping drilling as soon as water appears in the mine is a common mistake made by new drillers. It is recommended to continue drilling and go deeper into the next layer of soil by about half a meter. In this way, the maximum flow rate of the well will be ensured. Then it remains pump the well, lower the pump into it, arrange the head, etc.

Choice: with or without filter?

To prevent contamination from entering the well, a second pipe with well filter. It is made from a long piece of pipe, the diameter of which should be smaller than the diameter of the casing. The upper part of the pipe is used for the seal, and many holes are made in the middle part.

The perforated area is covered with a galloon mesh, but in extreme cases, an ordinary fine mesh, for example, with parameters 0.2X0.13, will do. The mesh can be fixed with wire.

The lower part of the filter is a sump; perforation is not needed there. If a filter can be lowered into a well constructed using an auger method using rods connected to each other, then when performing percussion-rope drilling, the filter is delivered using a metal cable.

This does not allow the filter to be pressed with force to ensure the tightness of the structure when connected to the oil seal. In this case, you can effectively use PSUL - pre-compressed sealing tape. This material is widely used in the installation of PVC windows.

Such a tape should be wound around the edge of the filter and immediately lowered into the shaft, since the PSUL expands quite quickly. If the filter is lowered immediately after winding the tape, it will expand at the bottom and provide a good seal to the filter. After the filter is lowered down, the casing is carefully lifted up.

In this case, most of the filter should be below the level of the edge of the casing pipe. To lift the pipe, you can use two five-ton jacks. The part of the pipe brought to the surface is cut off or unscrewed. To prevent the clamp from slipping, pieces of reinforcement are welded to the protruding piece of pipe.

The percussion-rope drilling method allows you to create a filterless well. To equip it in this way, it is necessary to lower the casing pipe below the aquifer by about 0.5 meters. When using “wet” auger or core drilling, it can be difficult to extract the core from the well. The bailer easily removes loose, water-saturated clastic rocks.

After the casing is firmly installed, two hoses are lowered into the well. Through one of them, a flow of water is supplied into the well, and through the second, air is pumped in using a compressor. Thus, a so-called airlift is obtained, and the flow of water prevents the formation of a sand plug.

As a result, a mixture of water, sand and air will flow through the casing pipe, which must be drained into a separate container. When the mixture has settled, the volume of sand washed out of the well should be measured. According to reference books, each cubic meter of such sand is equal to approximately 4.5 cubic meters of flow rate.

He will introduce you to the core and auger methods of drilling a water intake well. another article, which we recommend that you familiarize yourself with.

Conclusions and useful video on the topic

Video #1. A visual demonstration of drilling a well with a bailer:

Video #2. A combination of auger drilling through hard ground and using a bailer to get through fine water-saturated sand:

Video #3. An interesting option for constructing a bailer and drilling cup:

Drilling using the percussion-rope method has many advantages over the more common auger method. It is easy to make a bailer and other devices from scrap materials. The drilling process is also simple, especially if possible problems are anticipated at the very beginning.

Do you have personal experience in hand drilling? Do you have any questions while familiarizing yourself with the material we presented? Do you want to share the subtleties that only you know? Please write comments in the block below, ask questions, leave photos on the topic.

The most difficult thing with this method of drilling a well is considered to be to break through the limestone, if it comes across, to clean water. The first 6-8 meters are quite easy to walk (loam, sand, sandy loam), but then the most interesting part. You can fight through limestone or shale all day, but in the end you will provide yourself with excellent quality water without turbidity and sand (which comes in a shallow sand layer).

With this and other similar methods, it is difficult to obtain drinking water, because water carriers with drinking water will certainly be contaminated with so-called dirt. high water and Mr. the nearest cesspool. These are not drillers, these are Mr. Nomes. This must be understood clearly!

The bailer doesn't take it dry. The casing sometimes rubs into the sand so that after 10 m it is impossible to turn it. The bailer requires sludge.