Do-it-yourself well without equipment: how to arrange a water source yourself

To organize a source of your own drinking water on your site, you can invite a team and pay for the services.But for a skilled craftsman, drilling a well with your own hands without equipment is a completely feasible task.

The process will take a lot of time and effort, but it will save a lot of money. Where to start and what tools may be useful for drilling? We'll talk about all this in our article. We will also consider the types of wells that can be built on your own without special equipment.

The content of the article:

Types of water intake workings

Depending on the depth of water, there are three types of wells:

- on limestone, it is often pressure, i.e. artesian;

- for sand, it is also non-pressure or filter;

- Abyssinian well or needle well is a simplified type of sand well.

Artesian structures are considered inaccessible for independent drilling. They run deep, more than 40 meters, and there is a high probability that you will have to go through fairly hard layers. You can’t do this without a powerful drilling rig and equipment. Such wells provide a lot of water; they are often ordered together for several areas at once.

Filter wells - the most common option. The aquifer lies in sandy horizons. The drilling depth will be about 20-40 meters. Such a structure usually provides enough water to cover the needs of an average family and provide for the household.

Abyssinian wells - this is an option for those who are lucky with an aquifer that lies close to the surface. A long pipe with a sharp tip is driven into the ground. They put it on top pump or column.

Such a structure does not provide too much water, so sometimes two or three wells are made.

Preparing the site and equipment

Before starting work you need to select:

- location and type of well;

- drilling method;

- casing diameter;

- pump equipment;

- tools for performing work.

The best place to start is by interviewing your closest neighbors who have already built a well. From them you can find out the approximate depth of water, soil features, etc. It doesn't hurt to ask if they have any drilling tools left that you can borrow.

The type of well will become obvious after such a conversation. Most likely, this will be the “on the sand” option. The location is determined by sanitary standards. It is necessary to make a water source closer to the house and as far as possible from the cesspool, septic tank, livestock buildings, etc. An Abyssinian well is sometimes even placed in the basement of a house.

Casing pipe diameter and pump equipment need to be selected at the same time. Submersible pumps are considered the most efficient. The difference between the diameter of the device and the walls of the casing pipe should be at least 5-10 mm.

Drilling Tools and Methods

To select soil from a shaft intended for constructing a well, use an auger drill or bailer. The drill is rotated and the bailer is thrown from top to bottom. Sometimes these methods are alternated in order to pass through rocks of different composition and properties.

Cohesive soils, which include loams and sandy loams, are drilled with an auger or a hollow pipe - a glass; non-cohesive soils - sand, gravel, pebbles - are drilled with a bailer, because They cannot be removed with a screw.

The auger drill is rotated, deepening it by about half a meter, then removed to the surface, freed from the soil and lowered into the shaft again. The bailer is thrown down onto the face several times so that its internal space is filled with soil, removed, cleaned, and then percussion-rope drilling continues.

With a bailer you can also carry out so-called hydrodrilling. The principle of operation is the same, but a stream of water under pressure is supplied to the face. It erodes the soil, and the bailer forms a cylindrical shaft for the casing pipe to be installed simultaneously with drilling. The mixture of water and soil is pumped out by a pump.

Water can also be used for auger drilling when difficult areas have to be navigated. Water is poured into the mine, the soil becomes softer, easier to drill and extract. When hydrodrilling, there is a danger of introducing contaminants into the well. This point must be taken into account when the time comes flushing and rocking of the structure.

Different types of drills are used, for example:

- coil, especially effective on clay soils;

- spoon drill, suitable for both sand and clay;

- drill bit, useful for hard layers.

You can buy a ready-made drill, garden or fishing, the main thing is that it is strong enough and matches the size of the casing pipe. Industrial products usually allow you to make holes of 40-50 mm.

If this is not enough, you can make the tool yourself. To do this, parts of the steel disk are welded at a suitable angle to the steel rod. The edges of the disc should be sharpened. A spoon tool is made from a rolled steel sheet or a piece of pipe.

There are different types of bailers: with a valve in the form of a ball, with a pressure valve and without a valve at all. The latter are appropriate on dense layers.

The soil is packed inside the “glass” and does not fall out of it, so the valve is not needed here; the sharp edge at the bottom is more relevant.

Narrow slits are made along such a tool. It is convenient to insert a rod into them to free the cavity from viscous contents.

Tripod, winch, drill rods

Most often, a tripod is used for independent drilling work. Such a structure can be purchased or made from metal beams, wooden beams, etc.

It must be large enough for two people to move freely under it, and strong enough to support the load of equipment loaded with broken rock.

At the top point of the tripod, a block is placed through which a cable attached to a winch is passed. With the help of such equipment, it will be much easier to remove equipment from the mine to free it from the ground. It is better to use a winch with an electric motor.

Drill rods are attached to the drill and gradually increased. Use elements with a locking or threaded connection. It must be reliable so that the rods do not break when removing soil to the surface.

A tripod is also needed for the auger; you will also need a guide structure made of casing pipes so that the tool moves strictly vertically. To extend the rods and disassemble the drill string to remove the drill bit, you will also need a tripod or metal frame.

It is better to carry out the work with two or three people; drilling a well alone is more difficult. To speed up the auger drilling process, some use an electric drill with a power of 1 kW or more.

An interesting option could be the use of a small-sized drilling rig. Such a device is expensive, but you can rent it if you wish. We have detailed instructions on our website drilling rig manufacturing with your own hands.

Instructions for constructing a well

Let's look at how to build a free-flow well and an igloo well, having only available materials at hand.

Option #1 - drilling a well “into sand”

To drill a well, the following basic operations are performed:

- Dig a hole about a meter or one and a half in size.

- Install the tripod.

- Secure the winch.

- Place a drill and deepen it about half a meter.

- Remove the tool and clean it of soil.

- Continue drilling, gradually adding drill rods.

- If necessary, change the drill to a chisel or bailer.

- Work continues until the aquifer is discovered.

- Drilling continues until a water-resistant layer appears.

- The well is pumped up, flushed with a pump.

- Lower the pumping equipment and arrange the head.

A spacious hole is dug at the first stage if it is planned to arrange a caisson. In other cases, you can simply drill a hole about a meter deep to set the direction of the structure. After this, you can continue working with both the drill and the bailer.

The auger is best rotated under load. Two people do this: the first turns the bar, holding it with an adjustable wrench, the second strikes the bar with a sledgehammer. Markings should be applied to the drill rods; this will help you understand how much soil has already been covered when it is time to take the tool to the surface.

When the soil becomes wet, you need to continue drilling to achieve a more dense waterproof layer. But the casing pipe should not rest against it; if it has dropped too low, it must be raised so that the edge is approximately in the center of the aquifer.

To ensure effective drilling, you should use the right tool:

- for clay soils it is better to take a coil drill; a glass or spoon tool is also suitable;

- on sand, a bailer and a spoon-shaped drill are preferable; the work will go faster if you add water to it;

- hard layers are broken with a chisel, flat or cross-shaped;

- on quicksand, a good solution would be to use a bailer with a valve;

- It is convenient to break pebble layers with a chisel and then remove them with a bailer; here, too, the use of drilling fluid may be appropriate.

After the casing is installed, the filter column should be lowered down.You can buy such a design or make it yourself. A piece of casing pipe is perforated, and this part is covered with a filter mesh on top. The filter protects the water and pump from sand.

The casing pipe is installed simultaneously with the excavation, regardless of the type of drill used to drill the soil. At the same time, the well is washed: a stream of water is supplied inside and the slurry returned from the face is drained into a sump dug next to the well.

Now they are carrying out well pumping, i.e. pump out a large amount of water from it until you get a clean stream. The procedure can be performed with a pump, having first cleaned the face with a bailer.

You should not take a submersible model designed for clean water for swinging. It is necessary to use equipment capable of pumping water with a large admixture of sand and clay particles.

An alternative is an inexpensive pump that is easy to repair, e.g. "Baby" or “Stream”. Sometimes it is necessary to use several pumps, because due to the increased load the device may simply burn out. If there is no electricity in the area, you can use a hand pump.

After this, all that remains is to lower the pumping equipment, arrange the head and connect the hose to the water supply.

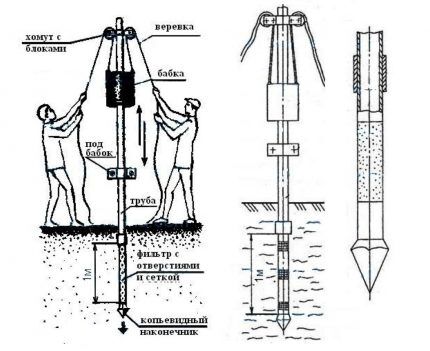

Option #2 - creating an Abyssinian well

The creation of such a structure is carried out in a fundamentally different way; there is no need to remove the soil.A narrow pipe, pre-equipped with a filter and a sharp tip, is simply driven into the ground until water appears. This pipe will become the casing.

You can buy a ready-made kit or make it yourself. The first pipe in the drill string is perforated and this part is wrapped with wire or covered with mesh. A check valve must be installed between the pipes following it and this filter.

It is simply made from a diaphragm and a steel ball. A cone should be welded to the bottom edge of the filter. Its diameter is made slightly larger than that of the pipe in order to protect the structure from damage while moving through the soil.

The finished pipe is driven into the ground, gradually increasing its length with drill rods. They are screwed or welded. The connection must be very reliable. Of course, you can’t hit it directly on the top of the pipe; it will damage it.

Therefore, after the pipe with the needle is installed vertically, a headstock is attached to it. A headstock is placed on this platform - a steel or concrete weight with a hole for the pipe. You need to place a block at the top of the pipe. Two cables are passed through it and attached to the headstock.

Now you need to lift the headstock using a winch and throw it down, repeating this operation until the headstock attached to the pipe reaches ground level.After this, attach the drill rod, rearrange the headstock and block, and then throw the headstock again.

When water appears in the pipe, it means that the filter has gone deep into the water carrier, the work can be considered completed. The pipe is cut, an electric or manual pump is installed. You can leave the headstock; it will come in handy when the Abyssinian well becomes clogged and you need to remove the needle from the ground for cleaning or repair.

We have detailed instructions on our website describing device technology needle wells.

Conclusions and useful video on the topic

Self-drilling with a bailer:

Creating a well manually using a drill with rods:

How to make an Abyssinian well:

Creating a well yourself is difficult, but it is possible. Each drilling case is individual; it is impossible to accurately predict how the structure will behave during work and during operation.

But if the technology is followed, it is possible to provide a site with a source of water that will last for several decades..

Do you have experience drilling a well yourself? Tell us what tools you used for this and how much time you spent? Write your recommendations, add a photo of the well in the block below this article.

If you are just thinking about building a well and you still have questions after reading our material, ask our experts.

Hiring professionals for such a task is indeed not a cheap pleasure. They quoted me a price of 40 dollars per meter. I saw how much it takes, and besides, I don’t know at all how to do it competently, so I decided it was better to save some money and, in fact, relieve myself of this headache and entrust it to those who understand it better.I don’t even have any idea where to get such a tool.

Please tell me how I can determine the type of potential well: an artesian structure, a filter well or an Abyssinian well? After all, before starting work, you need to decide whether the game is worth fixing? The fact is that there are no neighbors near my house from whom I could consult about the nature of the occurrence of water layers. What are the low-cost exploration methods?

The only adequate method of exploration, in my opinion, is drilling exploratory mines. If you do this using the screw method, you can do it inexpensively, or even do it yourself. Among the scientific ones, there is also seismic exploration, using instruments. But I have not personally encountered it and cannot speak about its effectiveness. All other methods give very approximate results and I do not recommend messing with them.

First of all, you will need to conduct reconnaissance, this can be done in several ways. It was already recommended above to drill using an auger method. I also recommend considering geological exploration with radar monitoring. With this method, you do not need to drill anything, but only specialists with experience and the necessary equipment can do this.

You can also drill test holes using a small diameter hand drill. But the disadvantage of this method is that the exploration depth is limited to 7-8 meters.

You can determine the type of structure for the well in advance, for example, if drinking water is needed, then you will definitely have to build an artesian structure.If the aquifer is at a shallow depth, then the best option would be Abyssinian well.

In general, you can conduct reconnaissance to the upper layers up to 8 meters on your own. Then we go to specialists who will conduct exploration and announce the price list for the implementation of a full-fledged well.

Good afternoon. Please tell me. They drilled a square well in the basement, lowered a hundred square meter sewer pipe, installed a pump, but the edges on the outside of the pipe were not sealed. Now it’s spring, the water has risen and I suspect from there, too, how to seal these edges? These specialists don't answer the phone.