Do-it-yourself water well: construction rules + analysis of 4 popular drilling methods

Providing a site with water is the first task of its owner.The more ambitious the plans for improving your territory, the more acutely the lack of water supply will be felt. Water is needed for construction work, for the garden you are planning to create, and for your own daily needs.

If you make a water well with your own hands, your dream of water supply will not only come true, but will also allow you to save significantly. We will tell you the best way to drill and what kind of equipment independent craftsmen will need. Taking into account our advice, you will easily arrange your own water source on the site.

The content of the article:

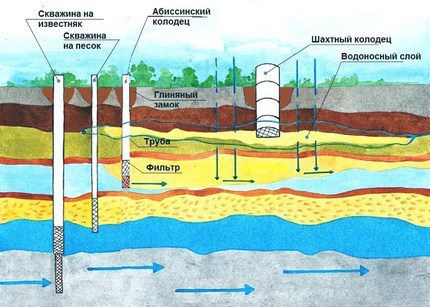

Main types of water wells

There are several real ways to obtain life-giving moisture, which we will tell you about. There are several technologies that can be used to independently extract water in a suburban area.

You will have to choose the appropriate option yourself, since it depends on the landscape of the area, as well as on the technical equipment, finances and skills that you possess. Let's look at the main well structures.

Abyssinian tube well

If there is a spring on your site, then installing a well is an excellent option for extracting water. The shaft of this structure will act as a liquid storage tank. If the source is active enough, up to 2 cubic meters of water will always be at your disposal.

The Abyssinian well is essentially the same well, but narrow and long. Due to the fact that its length can be approximately 8-12 meters, no pollution from the soil surface gets into the water that fills it.

The following video will introduce you to the technology of punching and constructing a needle well, otherwise known as an Abyssinian well:

Sand well (filter)

The deepening of this structure to 15-30 meters is carried out by any method: auger, shock-rope, core. The walls of the well are formed using a pipe with an average diameter of 100 - 180 mm.

The buried end of the wellbore is equipped with a filter. A stainless steel mesh is used as a filter, which is welded or soldered to the first link of the pipe string before immersing it in coarse sand mixed with pebbles.

This design can satisfy the water needs of a small country house with two water points. If the operation of the structure is seasonal, it will last about five years. With constant use, you can count on 15 years of water supply.

When the well does silt up, you can try to wash it out. If resuscitation measures do not give the desired effect, a new shaft will have to be drilled. Place it next to the previous one.

Artesian well without filter

This structure does not require a filter. Such a well can reach a depth of 100 meters or more. The water produced using such a structure is contained in limestone cracks. The liquid accumulated in them due to condensation can be not only crystal clear, but also mineralized.

Light mineralization is acceptable for everyday use. If the extracted water is classified as mineral water in its composition, then it cannot be used for domestic purposes.

It is difficult to determine in advance the depth of the well that will have to be drilled in search of water. You can only roughly get your bearings by talking with neighbors on the site and finding out from them what parameters similar structures have on their territories.

The soil layers are uneven, so the information obtained still cannot be considered accurate for your area. For this reason, casing pipes are purchased taking into account the correction of the obtained data.

How is a typical well constructed?

If you don’t focus on the nuances, the essence of installing a water well for a country house is the same: it is a long narrow vertical shaft that reaches the depth of the water. The walls of the mine are reinforced with casing pipes. Wells differ from each other in width, depth and additional devices that increase their productivity and reliability.

In addition to casing, wells are equipped with equipment for forced lifting of liquid and its distribution. To choose the right pumping equipment and storage tank, you need to know the characteristics of the well, the most important of which is its depth and flow rate.

The flow rate of a well is an indicator of its productivity: the maximum volume of liquid obtained per unit of time. It is calculated in cubic meters or liters per hour or day.

Functions of casing pipes

Casing pipes are the main element of the well. The casing is carried out using separate sections, soldered, welded or screwed together.Particular attention should be paid to their equal diameter: the entire structure should create a straight, even column.

If the casing pipes have external threads, the links are connected with couplings, due to which the diameter of the penetration increases.

Casing pipes are needed to:

- When drilling the well, the shaft did not collapse;

- the barrel did not become clogged during its operation;

- the upper aquifers did not penetrate into the structure.

Casing pipes made of steel alloys and polymers (PVC, uPVC, HDPE) are widely used. Cast iron and obsolete asbestos-cement products are used less frequently. The space between the pipe and the ground around the mouth is filled with concrete if the excavation was drilled in loose soils or the aquifer lies at a considerable depth.

Only after this work is completed, all other equipment is installed. Sometimes during the operation of a well, a slight “squeezing” of the pipe to the surface may occur. This is a natural process that does not require any additional measures.

Inner pipe with filter

The wellbore, made according to the double casing scheme, is lowered pipe with filter. Through its perforated first link, filtered water will flow into the head and then be extracted by a pump to the surface.

After the pipe is installed to the desired depth, it is advisable to secure its mouth. For this purpose, a clamp is used to prevent spontaneous subsidence of the pipe.

Well head device

The upper part of the casing is equipped with head. The basic design of this device is the same for any type of head. It consists of a flange, a cover and a rubber ring.

Different types of heads differ from each other in the type of material from which they are made and additional options.

Due to the low pressure created by the pipe head, the water inflow increases and, as a result, the well flow rate.

Caisson, adapter, packer

To prevent high humidity from affecting the operation of instruments connected to the well, a special tank is provided for them - caisson. It is made of either metal or plastic.

Metal caissons, unlike plastic ones, can be repaired; they are better adapted to climates with significant temperature changes.In addition, a metal product can be assembled independently from parts that are sold separately. But plastic models are cheaper and do not rust.

Those who wish arrange a caisson for a well You will find detailed instructions for its construction on our website.

To tightly connect the ground water supply and the well, you will need borehole adapter. This device is usually placed in the place where all the equipment that needs protection from water is collected. Most often this is a technical room. One part of the adapter is attached to the casing, and the hose from the pump is screwed to the other part.

Sometimes there is a need to allocate a local section of a deep artesian well, where, for example, repair work will be carried out. For this purpose, packers are used - seals for wells.

The listed elements are part of the well design, having a great influence on its functionality.

Four types of drilling

You can drill a water well with your own hands different ways, for the implementation of which both exclusively muscular efforts and technical means are used.

Let's look at the most popular types of drilling:

- screw;

- rotary;

- core;

- shock-rope.

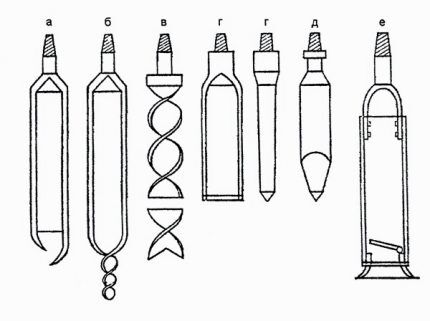

These technologies differ from each other in the methods of rock destruction during the construction of a well and in the methods of extracting soil from the shaft of a structure to the surface.To excavate workings using various drilling methods, different types of equipment are used, which affects the cost and quality of the finished structure.

Method #1 - manual drilling

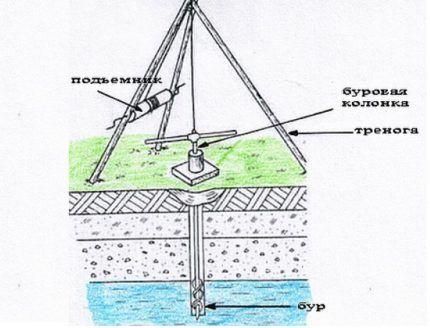

For manual drillingperformed using auger, shock-rope or combined technology, the following mechanisms and materials will be needed:

- Boer;

- winch;

- drilling rig;

- rods;

- casing.

If the well to be constructed is deep enough, a drilling derrick will be needed. With the help of this design, the drill with rods is immersed and then raised.

If the well is shallow, you can do without a tower. In this case, work with the drill is performed manually.

The function of drill rods can be performed by narrow pipes that are connected to each other using threads or special keys. Drilling tool during the process of assembling the structure, it must be attached to the lowest rod.

The integrity of the soil is disrupted by the cutting attachments of the drill. They are made of durable three-millimeter steel. The edges of the nozzles must be sharpened, taking into account the fact that the drill will rotate clockwise and destroy soil as a result of the rotational-translational motion.

First, we choose a place to drill. We make a hole in the soil about two bayonets deep. This is how a guide for the drill is dug out. You need to install a tower above the drill entry point we have designated.

The height of the tower should correspond to the length of the drill rod: it should be slightly higher than this length.Only in this case can the rod be easily and simply pulled out after finishing the work.

Getting started won't seem difficult. The first turns of the drill penetrate the soil quite easily. One worker can handle this task. But with further immersion into the ground, with each turn the drill moves harder and slower.

At this stage of work it is no longer possible to do without an assistant. If it becomes difficult to lift the drill to the surface, you should turn it counterclockwise and then try again.

When subsequent penetration of the drill encounters significant resistance, there may be a risk of equipment failure. Therefore, you need to try to soften the soil using water for this purpose.

The work is going on, the drill is moving down, but do not forget that every half a meter of its advance it is necessary to free the tool from the ground, and for this it should be raised to the surface. When the tool is completely immersed in the soil up to the handle, it needs to be extended with the next rod.

The entire drilling process takes a lot of time, most of which has to be spent on lifting the drill to the surface and clearing it of soil. Therefore, it is worth using each cycle as efficiently as possible, trying to extract as much soil as possible.

If the layers that the tool passes through are characterized by increased flowability, then there is a danger of the well shaft collapsing at the most inopportune moment. To prevent this from happening, you should use casing pipes that will prevent the mine walls from collapsing.

But the condition of the land that comes to the surface has changed: the drill has reached the aquifer. There is very little left. Behind the aquifer there must be a water-resistant layer. The drill must be immersed to the waterproof layer so that the maximum amount of water enters the well. The maximum depth that can be achieved by manual drilling is from 10 to 20 meters. It is at this depth, most often, that the first aquifer is located.

Dirty water rises to the surface first and is pumped out manually or submersible pump. To flush the well, it is enough to remove just a few buckets of dirt. If there is no hurry to replace clean water with dirty water, you should drill another meter or two.

Like any other job, manual drilling can be upgraded by using a hydraulic pump and an electric drill. You can do this kind of work even without assistants. The entire drilling process can be seen in this video.

Method #2 - budget auger drilling

It is believed that auger drilling, and not rotary drilling, is the simplest and most affordable option for constructing a well under water. It is the use of the auger method that is incorporated in most modern small-sized drilling rigs.

The auger is the well-known Archimedes screw.Those who have ever seen how fishermen drill a hole for ice fishing can imagine what we are talking about. A shallow well, up to 10 meters, is created in a similar way. During the work, neither drilling fluid nor water is used, which is used to wash the tool in other cases.

If you turn to a specialized organization for help, then most likely they will use auger drilling equipment in their work, which is easily transported and widely used.

The peculiarity of this type of work is that it cannot be performed on all types of soil. Using an auger you cannot go through rocks or quicksand, but on dry and soft sedimentary soils this method has proven itself to be excellent. When performing this work, attention should be paid to protecting the mine from contaminated water from the soil surface.

Method #3 - rotary drilling (for rocks)

If the excavation is to be constructed in rocky soils, then a rotary drilling method is used to create it. It is based on the use of a special drill pipe, which resembles a thin glass turned upside down with a roller bit crushing soil along the lower edge.

Communications used in drilling pass through the pipe cavity. The hydraulic installation creates a load on the bit, which makes its way through the rock. The load is supplemented by the mass of the pipe string.

The soil from the well is washed out using drilling fluid fed into the pipe using one of two possible methods:

- Direct flush. The solution is pumped into the pipe using a pump, after which it flows out through the annulus along with the rock.

- Backwash.The solution enters the pipe by gravity, and is pumped out of the annulus along with the rock by pump.

It is believed that reverse flushing is more effective than direct flushing: with its help, a higher well flow rate is achieved due to the highest quality opening of the aquifer. But to implement this washing method, it is necessary to use expensive equipment, which affects the increase in the cost of work. Direct flushing will cost less than reverse flushing.

Method #4 - percussion-rope drilling

If you want to get a well that will last you up to 50 years, and you have a sufficient supply of time, effort and nerves to implement your plan, then choose the percussion-rope drilling method. It will take a long time to work. You will slowly but surely make your way to your cherished goal.

The process is based on the use of specific drilling tool - bailer. This is a section of thick-walled pipe 1 to 2 m long with a ball or reed valve at the bottom. A “window” is cut out in the upper part of the pipe for extracting soil, and the top is equipped with an eye for the torso.

Tied to a cable thrown over a block, the bailer is freely thrown onto the face. Falling down, it loosens the soil and captures it with the valve. The process is repeated several times before removing the bailer from the barrel. The bailer removed from the well is freed from the soil: it is turned over and shaken out through the hole.

This method of breaking through a shaft is considered very labor-intensive, but effective.In addition, water-saturated sands and loose sedimentary rocks can only be extracted from a well using the shock-rope method. When gelatinizing, no drilling fluid is used, so the groundwater that appears in the well cannot be confused with it.

Due to its high labor intensity, this method is more expensive than the rotary method. In addition, if the goal is to go beyond the first aquifer, there will be costs to isolate the mine from the aquifers that are located above.

For this purpose, additional casing pipes are used. In addition to the increase in material consumption, the volume of work performed by specialists is also growing. Therefore, such a structure will not be cheap.

More information on how to drill water well without equipment, you can get by reading the article we presented.

Conclusions and useful video on the topic

The video will clearly present the process of drilling a well manually with the installation of casing and a filter in the casing pipe:

Each type of water well has its own advantages and disadvantages.

Now that you have an idea of the type of wells, their design and construction methods, it will be easier for you to make a choice in favor of one design or another, based on the characteristics of your site and your own financial capabilities.

If you have ever drilled a well with your own hands, tell us how difficult or simple the process was. Please write comments in the block below. Ask questions, share your impressions, post pictures related to the topic of the article.

To begin with, before drilling, it would be nice to find out at what depth the aquifers lie and decide what you need the well for: for irrigation, for swimming or drinking. And from here we can start from choosing the depth of the excavation and the method of its arrangement.

For casing pipes, take metal or PVC pipes specially designed for this purpose, but not those used in laying communications. Take the water that comes out of the well to the SES for analysis to check its suitability for drinking purposes.

Can two men drill an artesian well? Marvelous. My current task is to drill a well on my site after dividing the general territory into two parts.

If the excavation is located at a distance of 5-10 meters from the existing water intake point, does this mean that the flow rate in it will be equal and the water will be of the same quality? Will it be necessary to submit water samples for analysis in this case?

What's surprising? It’s better, of course, at least three of us, it’s more convenient, but if there are no more people, then the two of us can cope. Of course, the number of drillers varies depending on the method.

If you are going to drill a well next to the old one, into the same aquifer, then you probably don’t need to do a new water analysis. But by making a well so close, you risk clogging the old well with drilling products, or even completely collapsing the aquifer. In general, a well should be made at least 15 meters from the neighboring one.

As for the well's flow rate, it should not fall, it will be approximately the same level as in the first one.

Hello. Please explain how the water of the first aquifer is separated from the second.