Well bailer: device, options and do-it-yourself manufacturing schemes

The lack of a centralized water supply pushes residents of private houses to drill wells on their own plots.Agree, without water in the house it is difficult to call staying in it comfortable. But well drilling services are quite expensive. It’s good that at least there are devices that allow you to drill a well on your own site.

One such device is a bailer. This is an effective and relatively simple drilling tool for cleaning private water sources from bottom contaminants. With its help, you can even drill a fully usable well yourself. Such a hydraulic structure will require a minimum of funds. And if it is done with your own hands, then the costs will not shake the family budget at all.

In this material we will talk about the structure and operating principle of the bailer. Let us dwell in detail on what tools and materials are required for its manufacture. In the article you will find step-by-step instructions for assembling the bailer, as well as videos that clearly demonstrate the structure and principle of operation of the bailer.

The content of the article:

Design and principle of operation of the bailer

The bailer is a rather heavy piece of pipe approximately 1 - 2 m long. It is equipped with a valve at the bottom, and sometimes special pointed elements such as teeth are attached.

Pointed edge during drilling loosens soil, silt, sand and other well contents, depending on the type of work.Eyelets are welded to the top of the pipe, in which a metal cable is secured.

The upper cut of the pipe is protected with a thick wire mesh. It will prevent the release of gravel, crushed stone or bailer valve elements when they are torn off.

Most often, bailers are used for well cleaning from serious pollution. If well pump did not turn on for a long time, for example, several months during the winter, a significant amount of silt or sand may accumulate in the well, depending on the soil.

As a result of such silting or sanding, the well flow rate is significantly reduced. In some cases, the pump even sucks into a layer of sludge, and it is not always possible to release it without damaging the well.

After the pump will be removed from the barrel, the well can be cleaned using a bailer.

The operation of the device is based on the gravitational principle. A heavy bailer is abruptly thrown into the well shaft from a great height. The sharpened edges loosen the mass of contaminants accumulated at the bottom. The valve opens and sand fills the interior space of the bailer. The valve closes and the filled bailer is lifted up.

To increase the efficiency of the device, the bailer is raised and thrown down several times. Thanks to the valve, the contents captured by it will remain inside.

Then the bailer is pulled out of the well and freed from contamination. The cycle is repeated again and again until the well is completely cleaned.

Bailers are quite successfully used for well drilling in loose, non-cohesive soils.

As a result of gelling, the well turns out to be quite decent and suitable for effective operation. Of course, working with a bailer requires significant physical effort.

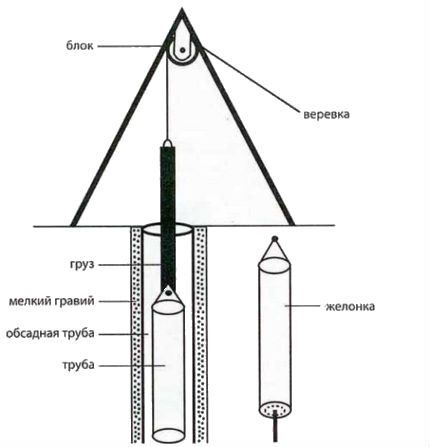

They can be shortened slightly, for example by using a pulley or an electric winch to lift the filled bailer to the top.

Pipe for making the body

So, to make a bailer you will need:

- Pipe of suitable diameter.

- Valve.

- Welding machine.

- Metal cable.

- Thick wire.

- Pieces of metal, etc.

To make a bailer yourself, you first need to select a pipe of the appropriate diameter. In this case, you need to focus on the internal dimensions of the casing pipe.

The distance between the outer wall of the bailer and the walls of the shaft should be two centimeters. This means that you need to subtract 40 mm from the internal diameter of the casing pipe. This will be the outer diameter of the pipe from which the bailer will be made.

The size of the gap between the bailer and the well can vary, but only to certain limits.

Too much clearance will reduce work efficiency. But if the gap is too narrow, the bailer may scratch or damage the barrel walls.

It’s even worse if, due to the large diameter of the pipe, the bailer gets stuck in the well, especially if the casing pipe is slightly skewed.It will not be easy to remove it; you can completely ruin the well and lose it.

The length of the pipe should also not be too short or long. A short device will more often touch the walls when moving up and down. And an element that is too long may turn out to be excessively heavy and difficult to reach, especially when the bailer is filled with a heavy blade.

The length of the bailer pipe is usually approximately 80 cm, but can vary between 60-150 cm. Longer and heavier devices are used for drilling.

The thickness of the pipe walls is also important, since the total weight of the product largely depends on it. The thicker it is, the more the pipe weighs, and the more effective the bailer will be.

But if drilling tool It will turn out too heavy, it will be difficult to work with it for the reasons already stated. A pipe thickness of 2-4 mm is considered sufficient, but it can reach 10 mm.

Thus, when choosing a pipe for a bailer, it is necessary to maintain a certain balance. The weight of the device and its dimensions must satisfy two conditions.

Firstly, it is necessary to ensure a sufficiently high penetration inertia so that contaminants are removed from the well quickly and efficiently. Secondly, The weight of the product with loading must be such that the bailer can be pulled out by hand or using a winch.

Valve systems for bailers

The most complex element of the bailer is the valve. There are two main options here: reed valve and ball valve. This element has one task: to let dirt or soil inside the pipe and not allow it to spill out.

If the valve fits tightly, the bailer will effectively capture not only dense dirt, but also water, which will increase cleaning efficiency.But on some light soils, drilling can be done without a valve at all.

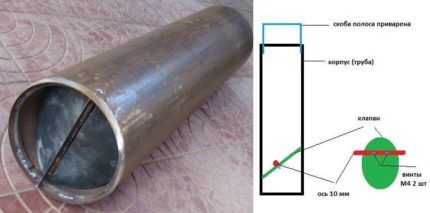

Option No. 1 - reed valve design

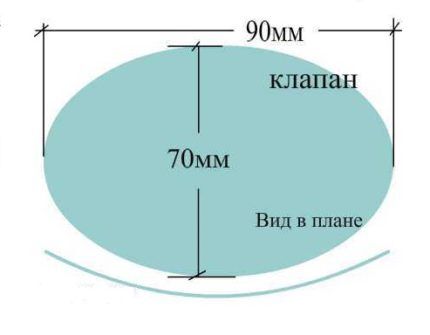

The reed valve is easy to make, but not very durable. It is an oval (ellipsoidal) plate made of a springy material: metal or polymer.

The valve is fixed in the center of the pipe. Under the influence of water flow, the edges of the ellipse open, allowing soil or silt to pass into the bailer. For a more effective fit of the valve to the walls of the bailer, a rubber or leather seal is used.

When lifting a bailer with a petal valve, its “petals” close. But constant movements wear out the valve quite quickly, it simply fails.

Another version of the reed valve is a spring-mounted valve, and it closes using a fairly powerful spring.

The design is not complicated; it can be used both when cleaning a well and when drilling with a bailer. Craftsmen also come up with their own, quite effective versions of valves for bailers.

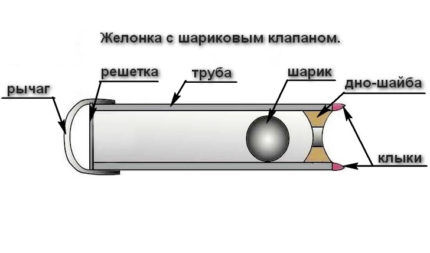

Option No. 2 - manufacturing a ball valve

A ball valve is a funnel, the mouth of which is tightly closed with a ball of the appropriate size.

The hardest part of making this valve is getting the right ball. It must cover a fairly large hole into which the contaminated water will flow and be heavy enough to drop down and close the valve securely and quickly.

There are three options to get such a ball:

- just find it among old scrap metal, for example, remove it from a large bearing;

- order the production of the required part from a turner, who will turn the ball on a machine;

- Make your own ball using available materials.

To make a ball yourself, you need to find a hollow plastic or rubber ball, these are sold in toy stores. You should buy a sufficient amount of lead shot from a hunting store. In addition, you will need epoxy or any other waterproof glue.

The toy ball is cut in half. Each half is filled with a mixture of shot and glue. After drying, the halves need to be glued and sanded, the ball is ready.

Instead of lead shot, any heavy metal balls, for example, taken out of old bearings, will do. You can cast a ball from molten lead, but the process is a little more complicated.

The ball dimensions should be approximately 60-75% of the diameter of the well casing. The second part of the ball valve is a thick metal washer in which a funnel-shaped seat for the ball is cut out. Usually, a ball is first found or made, and then a washer of a suitable configuration is made.

For the ball, a special “saddle” is machined with a hole, which the ball closes. The valve hole should be large enough to allow a lot of soil to flow inside.

If this does not happen, the hole is bored as far as the diameter of the ball allows. If you decide to entrust the manufacture of the ball to a turner, then it makes sense to immediately order a saddle for it, i.e.the whole valve.

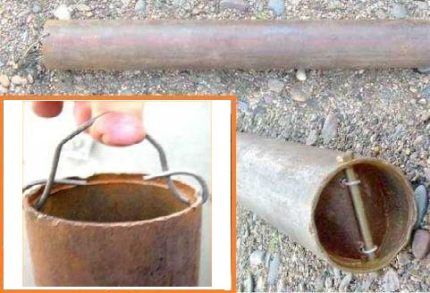

If you don't have a welding machine

To make a solid and durable bailer, you need several metal parts connect by weldingAnd. If this is not possible, a simple but fully functional bailer can be made without it.

To do this, you can take a regular pipe, about 0.6 m long and about 70 mm in diameter. Of course, it must be quite heavy. A handle made of thick wire should be attached to the top.

To do this, two holes are drilled in the pipe walls, the wire is threaded through them and fixed. A petal valve is installed at the bottom, which can be made from an ordinary plastic bottle. A two-liter container will do.

A valve of a suitable size in the shape of an ellipse is cut out from its wall.

The smaller diameter of the valve should be equal to the internal diameter of the bailer, and to determine the larger diameter of the ellipse, another 20 mm is added to the diameter of the pipe.

The valve is fixed with a bolt 6-8 mm thick. The length of the bolt must exceed the outer diameter of the pipe so that it can be inserted across the pipe and secured.

Those. The length of the bolt consists of the sum of the outer diameter of the bailer and the thickness of the nut. But the bolt should not be too long so that it does not touch the walls of the casing.

For the bolt, two holes are drilled in the bailer walls approximately 10 mm from the bottom end of the bailer. To connect the valve to the bolt, use 2-4 mm thick wire.

It is used to make two wire rings in the middle of the valve. The bolt should fit freely into these rings.

To assemble such a homemade bailer, you need to bend the valve and push it inside the bailer. The bolt is then threaded through the hole in the pipe wall, then through the valve wire rings, and through the pipe wall again. Secure the bolt with a nut.

The bolt must move freely into and out of the valve rings so that the bailer can be easily cleaned during operation.

Final assembly of the bailer

If the pipe has been selected and the valve is ready and welded, there are still a number of operations and recommendations left to complete to complete the manufacture of the bailer. The bottom edge of the pipe should be sharpened so that as it moves, it gently removes dirt from the walls of the shaft.

One-sided sharpening from the inside would be optimal.

It is recommended to heat-harden the sharpened edge so that it does not dull so quickly when interacting with solid contaminants.

Sometimes pointed rods or pieces of metal are welded to the edge of the bailer to loosen dirt or soil. A loop for attaching a metal cable is welded to the upper end of the pipe.

It can be made from pieces of thick metal wire. The loop must be welded in such a way that the bailer suspended on the cable maintains a vertical position.

This is very important, since distortions when the device moves inside the pipe are unacceptable.This can lead to jamming of the bailer or damage to the casing walls.

A reliable metal mesh is also welded at the top, which will prevent the ball from spontaneously flying out of the bailer as it moves down. And it’s better to let coarse soils remain in the device body. Instead of a metal mesh, you can make a wire grill. All that remains is to connect the metal cable to the bailer.

Sometimes a durable nylon cord is used instead. To make it easier to lower and raise the device, a slave with a block located directly above the well is installed above the well. The bailer cable is led onto this block.

As a result, the device is lowered into the well strictly vertically, and pulling it out is much more convenient than simply pulling the bailer up with your hands, like a bucket from a well.

Before lowering the assembled bailer into the well, it is recommended to inspect the walls of the shaft to take into account all the irregularities and deformations. This will avoid damage or jamming of the bailer.

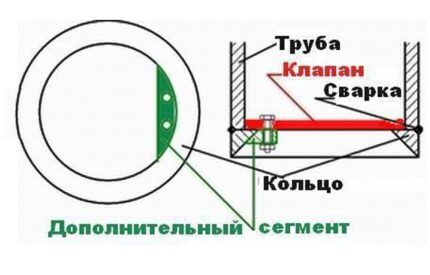

Gelonding scheme with pump

It is very difficult to remove the bailer to clean the well, even with the help of a winch. A significant amount of time is spent not on working in the well, but on raising, cleaning and lowering the bailer. A small upgrade will optimize the operation of the device. The reverse side of the pipe body should be tightly welded.

An outlet is made from it and a special fitting intended for the outlet hose is placed there. A pump is connected to the hose, which is designed to pump liquids with significant mechanical contamination.

This scheme allows you to avoid constantly raising the bailer to the surface and lowering it again.

In this case, contaminants from the bailer chamber will be removed using a pump. The bailer, equipped with a pump, simply needs to be raised and lowered to loosen and move the contaminated liquid into the chamber.

This cleaning method is effective in cases of heavy siltation or sand accumulation.For regular well cleaning, a bailer without a pump is suitable.

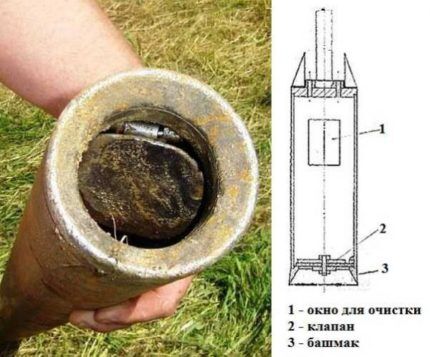

Features of drilling with a bailer

Drilling with a bailer is a popular, although rather labor-intensive, method of creating a well. Not every device of this type, suitable for cleaning a well, can cope with the excavation of a large amount of dense soil. For drilling, you should use a fairly long bailer - about four meters.

Here, a type of petal valve is more appropriate, which is a plate that is fixed with a special spring. With its help, a gap is created in the body, the area of which is almost equal to the cut area of the bailer. This allows you to pass the maximum amount of soil into the bailer body for each dive.

Removing dense soil from a long and narrow bailer is not always easy.To simplify this task, a special window is made in the upper part of the pipe, designed for more efficient and quick cleaning of the device. If you have to drill sandy rocks, it will be easier to release the bailer.

When drilling with a bailer, different types of rocks have their own characteristics. Here are some useful tips:

- On sandy soils, the bailer should not be immersed more than 10 cm without a casing. In general, the casing is supposed to be 10 cm ahead of the bailer.

- When drilling sandy soil, water is pumped into the shaft to further strengthen the walls.

- If wet sand is excessively compacted during the work and does not fall into the bailer, use a special chisel.

- The casing is immersed continuously during drilling.

- For quicksand, use a bailer two meters long or more with a reliable flat valve and a leather seal.

- When lifting the bailer on the quicksand, you need to not only lower the casing, but also turn it; this work is more convenient to do with two or three people.

- If the casing pipe does not fit into the shaft, it is lowered under pressure, for which a platform is placed on top on which a load is placed.

- When drilling layers of gravel and pebbles, sometimes alternate the use of a chisel, which breaks large inclusions, and a bailer for excavating broken soil.

- On dense sediments, the bailer is raised only 10-15 centimeters, and movements are made frequently.

- When drilling dense formations, the casing is deepened hydraulically or someone periodically stands on a platform mounted on the casing.

- Dry layers are softened by supplying water to the mine.

- On very soft plastic soils the valve is not always needed; the rock remains in the bailer even without it.

- The bailer must be raised after drilling every 0.5 - 0.7 m, so as not to tear when lifting the body filled to capacity.

As with other drilling methods, when using a bailer, you should take into account the individual characteristics of the soil on which the work is being carried out.

The correct strategy and timely casing of the borehole walls usually allows you to successfully create a working well.

You may also be interested in information about how flush the well after drilling.

Conclusions and useful video on the topic

One of the options for manufacturing a petal valve for a bailer is presented in the following video:

You can see the design and operating principle of a ball valve for a bailer in this video:

Here you can consider the design of a bailer intended for drilling:

Making your own bailer is not a particularly difficult task. This device can be made taking into account the specific needs of your site and the capabilities that are available. A simple design will ensure a long life of the bailer if it is made with high quality.

If you have experience in making and using a bailer yourself, please share it with our readers. Leave your comments in the block below.