Self-repair of a well: a review of the best methods of restoration and resuscitation

The trunk and equipment of a private water source tend to gradually wear out.To restore the technical condition, it is not necessary to resort to the services of hired workers; the well owner can repair the well with his own hands. But first you should familiarize yourself with the methods of resuscitating the source. Isn't it true?

Here you will find valuable recommendations and descriptions of important nuances that ensure success in correcting the condition of the workings. We have described in detail the options for carrying out repair work and the technologies for their implementation. The information we provide is based on building regulations and the experience of owners of sites with wells.

The article examines in detail all possible causes of violations in the operation of an autonomous water intake structure. Methods for cleaning the source are described and a method for replacing the casing is outlined. Photo and video applications are provided as excellent additions to illustrate the topic.

The content of the article:

Signs and prerequisites for repairs

The owner of a water well must constantly monitor the performance of the source. This is in his own interests, because the sooner the breakdown is detected and corrected, the cheaper and easier the repair will be. Sometimes it's enough timely cleaningso that the hydraulic structure works normally again and the problem does not get worse.

It is worth diagnosing the breakdown and eliminating the malfunction if the quality of the water has deteriorated or the productivity of the well has decreased. As for changes in water quality, they are best seen from the results of chemical and microbiological analyses.

A decrease in productivity becomes obvious when there is no longer enough water for usual needs or it disappears altogether.

Change in water quality

Ideally, every owner of any hydraulic structure should regularly submit water samples to a local laboratory to determine its suitability. However, in practice, few people carefully monitor wells, so one has to rely on subjective assessment.

The following changes in water should alert you:

- turbidity;

- the appearance of sediment during settling;

- change in taste;

- appearance of foreign odor.

A tan sediment and an unpleasant aftertaste may indicate high iron levels. Most often, the problem is not in the well itself, but in the erosion of iron-containing rocks by water. In this case, there is no need to repair the structure; it is enough to install filters with iron-removing cartridges.

If the water becomes cloudy and has a putrid odor, then the problem may be bacteriological contamination. The water should not be drunk, much less given to children, until the well is cleaned.

After cleaning you will need submit a sample for analysisto obtain confirmation from laboratory specialists that the water is suitable for drinking and safe for health.

Decrease in well productivity

The decline in well productivity can occur gradually or abruptly.

There may be several reasons for this:

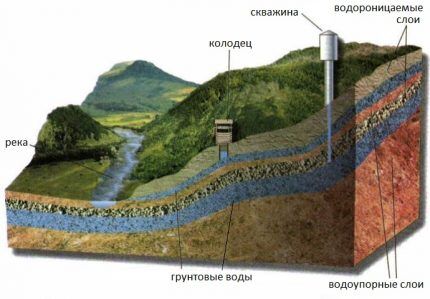

- Clogging. As a rule, owners of sand wells face this problem. Artesian springs usually do not silt up. Solid particles first enter the primary filters, and later the fine filters. The decline in well production occurs gradually. In this case, you need to clean the structure.

- Pump malfunction. There is no such thing as eternal technology, and pumping equipment breaks down in the same way and needs replacement. In some cases, cleaning the device and preventative maintenance is enough, and sometimes you have to buy a new pump. If the productivity of a well has decreased, the pump should be inspected first.

- Wear of production string pipes. If malfunctions in the operation of the well arose several years after construction, then the problem may be in the pipes. They rust over time. The lower the quality of the materials from which the production casing is made, the sooner the structure has to be repaired. Leaks often occur at pipe joints due to rust.

- Errors in well design and installation. If the source is initially poorly designed, then it will be very difficult to get it working. It is worth contacting professional drillers to understand why the difficulties arose and solve the problem. Often the only reasonable way out of the situation is to build a new well.

It is very important for future trouble-free operation to correctly arrange a water source immediately after drilling. It is necessary to protect the mouth of the excavation with a cap or arrange a caisson for maintenance and placement of equipment, install a filter and lay a pipeline taking into account construction requirements.

It is worth noting that sometimes the water level in the aquifer simply decreases. This means that as a result of prolonged use of the water supply source, the water supply may be reduced.

It is impossible to influence this, but you can contact the company involved in drilling in the area and consult with specialists on ways to solve the problem.

Flushing as a preventive measure against breakdowns

You can often find a recommendation to flush the well to prevent siltation. This advice is usually given by drilling specialists. Many well owners have a suspicion that they are simply tied to a certain company that will take care of their water supply system even after installation.

Are preventative flushes really necessary or is it still a gimmick? If the well operates constantly, then there is no particular need for such an event. But for a structure that is used only seasonally or temporarily, it is advisable to periodically wash it to avoid settling of sand and silt.

Sometimes regular flushing can actually prevent repair or restoration of a well, but most often it is not necessary. Extra flushing will not hurt if there are difficulties in putting the well into operation after construction or a long period of downtime.

Subtleties of diagnostics

To eliminate a breakdown, you need to clearly understand its cause. If you plan to repair the well yourself, then if the diagnosis is incorrect, the owner will only lose time. If he turns to professionals, then he will also get money. Therefore, you should take your time and carefully consider the diagnosis.

First of all, you need to make sure that the problem is really in the hydraulic structure itself, and not in the water distribution system. To do this, the pump is disconnected from the water supply, connected to a regular hose and put into operation.

If the water flows with good pressure, then everything is fine with the well and pumping equipment. The source of trouble is worth looking for in the water distribution system. If the pressure is weak or the water does not flow at all, and the pump is running idle, you will really need to resuscitate the well yourself or call specialists.

To check the pump, you will have to remove it and temporarily connect another one.If no changes occur, then equipment failure can be ruled out. In this case, you will have to clean the well or deal with malfunctions of the production string.

In the case of self-diagnosis, you have to use the method of elimination, checking each node one by one. It is impossible to study the wellbore with special equipment; you will have to call the employees of the drilling company.

In order to clean the well, filter or replace the production pipe, you should also resort to the help of drillers. If it is simply silted, then it is possible to restore functionality. In serious cases, professionals should be hired. And even in this case, there is no complete guarantee that the productivity of the well will be restored.

Four ways to clean a well

If during diagnostics it turns out that the problems arose due to siltation, then you can clean the well yourself. To do this, it is washed with water or blown with a compressor.

The easiest option is to pump with water. The process requires a lot of time and effort, but the result is worth it. If the filter is not destroyed, but simply dirty, then it is quite possible to completely restore the productivity of the source.

Method #1 - flushing with a pump

You will have to stock up on clean water in advance.If your own well is not working well, this can become a whole problem; you will need to turn to your neighbors for help. Water will require a large container and a pump, and finding them may also be difficult.

If these issues are resolved, then you can start working. The hose is connected to the pump and lowered to the bottom of the well. It is important that it reaches not just to the surface of the water, but almost to the very bottom.

The pump is turned on to pump water, and it lifts silt and sand from the filter. The well bore quickly fills with water, and it begins to gush out uncontrollably. Pollutant particles are released along with the water.

[the_ad_placement id=”mobile-vstavka-v-tekste-5 “]This is one of the fastest and most reliable ways to clean up a silted source. If you can’t do the restoration of the well yourself, then you can turn to hydrogeologists and sewage disposal specialists. The former will calculate the required hydraulic shock power, and the latter will help with a large-volume tank for removing excess water.

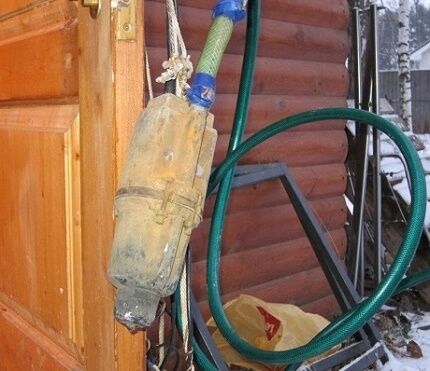

Method #2 – cleaning with a vibration pump

A shallow well can be cleared of silt and sand using vibration pump. Small-diameter equipment is often used, for example, Malysh brand devices. The pump is lowered into the mine shaft to the level of the filter, turned on and the well is gently rocked.

The device will lift solid particles, and they will come to the surface along with water. Such well flushing may take several days, but it will be effective only if the contamination is light.

When cleaning the well, the working parts of the pump may become clogged with dirt, and the electric motor may overheat. Therefore, it is advisable to take breaks and clean the device from dirt.

The advantage of this method is its simplicity and low cost. Everything can be done with your own hands; no complicated equipment is required.

Method #3 - using a bailer

This method is only suitable for shallow wells - no more than 30 m. For work you will need assistants, a winch and drilling rig - bailer. It is a piece of metal pipe with the upper part covered with a mesh and a washer bottom. The bailer is attached to a long, strong cable.

The device is lowered to the very bottom of the well, then raised about half a meter and sharply lowered again. After several such manipulations, the bailer is removed from the well and cleaned of sand. Usually it gains about 0.5 kg.

Not all well owners consider this cleaning method effective, but most still agree that the bailer helps cope with siltation. The main advantage of cleaning with a bailer is its low cost. If you make the device yourself, you can remove sand almost free of charge.

Method #4 - flushing with two pumps

The method is similar to flushing with a pump, but has some differences. You will need two pumps - submersible and surface. Not far from the well, you should install a large water tank (from 200 cubic meters), and in it - a homemade filter made from a bucket with a mesh or a woman's stocking. A hole is made in the side and bottom of the tank through which water will be pumped using a surface pump.

Using a deep pump, contaminated water is pumped into the tank and passed through a filter. Surface pump takes purified water from the reservoir and pumps it back into the well. The bucket is periodically emptied of sand and silt. The procedure is carried out until clean water without impurities flows from the well.

Replacement of production string

One of the most unpleasant breakdowns is wear of the service pipe.Replacing it is a complex and time-consuming process that requires considerable financial investment. It is best to entrust the work to professional drillers. To do it yourself, it is advisable to have the appropriate skills, because... replacement borehole pipe even more difficult than installing a new one when drilling a well.

It is easiest to work if the casing and production structures consist of two pipes of different diameters. In this case, only the production pipe is changed without touching the casing. If everything is done carefully, the well’s performance will be restored.

It’s better not to even start repairing a well with asbestos-cement pipes, because... the material collapses under additional loads. This is the case when it is worth immediately starting the construction of a new hydraulic structure. But it is quite possible to replace a metal pipe, even if the material is heavily rusted.

To dismantle the pipe, grab it with a slip-on loop or a special clamp and pull it out using any available lifting mechanism - a railway jack, a truck crane, etc. The main thing is that the device provides the force necessary for lifting.

When the pipe is removed from the shaft, a new one is installed - metal or plastic. Do not use asbestos cement. The material is impractical and potentially hazardous to health. This is confirmed by data from the World Health Organization.

New pipes can be connected using threads or nipples. You should choose high-quality connecting elements with a special anti-corrosion coating. If plastic pipes are selected, a strong nippleless connection is provided here. When choosing pipes, you should not skimp. This is fraught with new breakdowns.

Important information about the well filter

When cleaning the well, it is important to be careful, otherwise you can accidentally destroy the filter, especially if water hammer is used. If the filter was cleaned with chemicals, the water quality will inevitably deteriorate. Don't worry. This is a temporary phenomenon.

Gradually, the well will be cleared of chemicals, and the water will again become of high quality. To prevent the reagents from having a negative impact on health, you should pump water from the well for 12 hours and stop using it for domestic purposes for a couple of days. You also need to put good filters in the house and do not use unfiltered water for drinking or cooking until it is purified.

When chemically cleaning a well filter, substances are used that are used in the food industry, so it is generally accepted that they are safe. However, you should always keep the quantity in mind. The concentration of chemicals in the water after cleaning is too high. Reasonable precautions must be taken to avoid poisoning.

In addition to chemical filter cleaning, you can use mechanical cleaning. This method is safe and does not affect water quality. To clean the filter from deposits, use a metal device that looks like a regular bottle brush, but is much larger.

Simultaneously with the brush, you can also use cleaning by pumping water. But you should always be aware of the risks. The filter may not withstand the additional pressure and may collapse. It's better not to experiment unless absolutely necessary.

Conclusions and useful video on the topic

Video #1. Demonstration of siltation of a well and presentation of the process of pumping it on your own:

Video #2. How to clean a well using a simple homemade bailer:

Unfortunately, you can never be sure that after restoration the well will work fully and uninterruptedly.

There are cases when resuscitation of a well is generally impossible, especially if it is placed on sand and the filter is not removable. Then it is easier to create a new source than to bring the old one back to life, because in the end the effort and money spent on this will be approximately the same.

If problems arise with a new well, it means that it was originally built incorrectly. The contract with the drilling company usually specifies a warranty period, so you can get its employees to determine the cause of the problem themselves and fix it, if possible.

Problems with the pump, filter, siltation - these can be solved. But replacing a completely destroyed filter or worn-out barrel pipes will lead to serious costs with an uncertain result. Here you will have to decide what is more profitable - restoring the operation of the old well or building a new one.

Tell us about your own experience gained during the restoration of the well, share only the nuances of the work known to you. Please write comments in the block below. Ask questions, post photos related to the topic of the article.

I bought a plot with an old well. It turned out that it was all clogged with silt and needed to be cleared. You can do this yourself, but the question still arises of where to get a fairly impressive volume of water for rinsing. So I hired workers, they had their own pump, and they also brought a water truck. I had to pay the normal amount, but in a few hours the problem was solved, and now the well is functioning normally.

Hello, what should you do if water flows along the pipe, that is, not only inside, but also outside (spout), depth 17.5 m? L.O. Gatchina district.