Water well maintenance: rules for proper operation of the excavation

Constructing a water intake well on the site is not the last task of the owner who has decided to install an autonomous water supply on the site.To be able to use the structure for decades, you need to regularly maintain the water well. For optimal results, you need to know how it is produced. Do you agree?

We will tell you what points to consider when operating a hydraulic structure. The article presented for consideration describes in detail how to carry out these activities on your own. Taking into account our recommendations, your water source will work for a long time and flawlessly.

The content of the article:

Rules for putting a well into operation

The constructed water intake system, which has a circular cross-section of small diameter, needs preparation before putting it into operation. Upon completion of installation, a test run of water-lifting equipment is carried out. Subsequently, the necessary repairs to the structure are carried out.

Repair operations are based on the data from the passport attached to the drilled well.

It is recommended to put the well into operation immediately after completing the flushing and test pumping procedure.If this event has to be postponed for any reason, then the wellhead is temporarily closed with a metal cover, previously welded to the casing. Such measures help prevent foreign objects from entering the structure.

Definition of static level

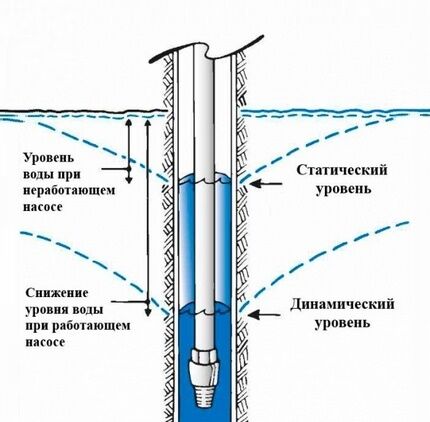

When equipping a hydraulic structure, it is important to know its static and dynamic levels. Both indicators are determined by simple measurements of the water surface using a hydrogeological cracker or a conventional polymer pipe replacing it.

When the ring-shaped edge of a pipe or firecracker comes into contact with the water surface, a kind of cotton is heard.

To determine the static level, you should not pump water out of the excavation for about a day before measurement. The static indicator should give us the distance between the day surface and the groundwater surface at rest.

The dynamic level is determined vice versa after pumping.This indicator is also necessary to determine the exact installation depth submersible pump. In addition, the difference between the static and dynamic values will allow you to determine the flow rate of your personal water source. It is necessary for selecting pumping equipment.

The pump is located 3-5 meters below the dynamic level mark. During operation of the equipment, it is important to control the height of the water column below it.

For example, when using vibration type submersible pumps, it is recommended that there be at least 1 - 1.5 m between the bottom of the excavation and the bottom of the device. A number of centrifugal pumping systems can be located at a distance of 0.5 m from the bottom.

The permissible installation depth of pumps is indicated by manufacturers. Their recommendations should be carefully studied and followed. In the case of an unstable and slowly recovering level in a water intake well, it is recommended to purchase pumps with sensors that detect a drop in the surface below the permissible limit.

The automatic device will automatically stop the pump if the water column is not enough for normal pumping of water.

If the operating water well has a low static level, test pumping is performed at low pump capacity. And subsequent operation begins with a minimum flow rate, increasing it over and over again until the calculated productivity specified in the passport is achieved.

Performance of a hydraulic structure

The first water sampling procedure should last at least one and a half to two hours. To determine the amount of water supplied from a well, use a ten-liter bucket.

When filling the container, you need to record the time using a stopwatch. To determine the flow rate, all that remains is to divide the resulting volume of 10 liters by the time spent.

Performance is considered normal:

- for sand wells – 1.5 cubic meters/hour;

- for artesian - 3 cubic meters/hour.

Having compared the obtained indicator with the norm, the operation of the pump is adjusted if necessary. In case of large discrepancies in measurements, before proceeding with the installation of the pump, it is still worth consulting with specialists from the relevant organizations.

Preparation of pumping equipment

The first step is to check the internal diameter of the installed casing pipes. This parameter should be 2 - 4 cm larger than that of the installed unit. Measurement work is carried out to a depth of 10 meters within the mark where the pumping equipment is supposed to be located.

Pumping devices should only be installed in the well of those design types that are recommended in the data sheet attached to it. Installation of the equipment must also be carried out in strict accordance with the passport and the operating instructions attached to it.

When starting the pump for the first time, the installed equipment should be turned on as smoothly as possible, first with a productivity of 40-50% of the design productivity, and gradually increasing to the recommended water intake value.

In the next few starts at the initial stage of operation, the pump should also be started “increasingly”. In this case, it is advisable to avoid short-term and frequent shutdowns of the unit.

If fluctuations in the water level are detected during the pumping process, or its supply is intermittent, you need to turn off the pump for a while. This phenomenon can occur if the device is not assembled correctly. The problem can only be solved by carrying out repair work.

The equipment should also be turned off if clay and sand impurities are detected in the pumped water. But before this, you need to reduce the flow of water using a valve installed on the discharge pipeline. Otherwise, small parts that get into the pump housing will settle in its flow part, causing the mechanism to fail.

Carrying out chemical analysis of water

Upon completion of the selection, it is advisable to conduct chemical water analysis. This will allow you to determine whether it meets the standards, and, if necessary, select the best option for the water purification system.

It is recommended to carry out a chemical analysis of water no earlier than three weeks after the launch of the hydraulic structure. By this point, the static position of the water level will stabilize and the overall picture will become clearer.

Maintenance of water intake structure

To ensure long and trouble-free operation of a hydraulic structure, it is important to provide qualified service. Ideally, it is better to entrust this work to an experienced specialist who has studied geological documentation and knows all the nuances and subtleties of well operation.

But in the absence of the opportunity to use the services of a master, the operation of a water well can be carried out on your own.

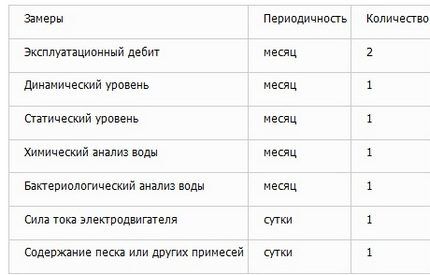

Monitoring the operation of a structure includes a number of main types of work.

Well performance measurements

Regular measurements of well productivity should be carried out during operation. They are carried out using the same technology that was used when the hydraulic structure was first launched.

If two measurements taken at a certain time interval show different filling rates, this indicates flow instability. This means that pumping equipment should be selected according to the highest value.

Please note that exceeding operating parameters will result in premature failure of the pumping unit.

An excessively powerful pump in workings with a small flow rate can cause a water shortage and will not create sufficient pressure. However, its productivity should be sufficient to provide water to all water intake points available on site.

Checking the pump's functionality

Pumping equipment, even if functioning properly, must be checked at least once every six months.

The check is performed in the following sequence:

- Visually inspect the equipment to determine the integrity of the housing and the tightness of all types of connections.

- Turn off the unit, after which the water intake valve is opened and the pressure in the system is measured. This parameter should drop to “0”.

- Check the pressure in the hydraulic tank. This is done using a car pressure gauge, which is connected to the tank nipple. The difference in values when the pump is turned on and after it is turned off should not exceed 10%. If necessary, air is pumped through the same nipple using a conventional compressor.

- Turn on the pump and observe its operation. When the pressure parameter you set on the device relay is reached, the pump should turn off.

- Recheck the pressure in the system, but already in the absence of consumption. When the equipment is operating correctly, the relay indicator should be on the red arrow, which corresponds to the maximum pressure mark.

- To check the correct operation of the pump, open the water tap for a while.. If the pressure in the system drops, the pump should turn on automatically. Then the tap is turned off, the pressure level is rechecked and the unit is turned off.

The frequency of preventive inspection of pumping equipment is usually indicated in the product passport.

The results and notes on preventive inspections of the well should be entered in a special journal, indicating the date of the inspection and the name of the employee who carried out the control. These readings will help diagnose possible problems with both pumping equipment and the well as a whole.

Preventative repairs of pumping equipment with replacement of worn parts should be carried out at least once every six months. For equipment operated irregularly, the interval between preventive measures can be increased to 9 months.

Control of water properties

You should also monitor the physical properties of water every day:

- smell – normal natural water should not smell.

- color – the color change depends on the substances that are dissolved in it, for example, iron colors it yellowish, and clay red-brown;

- turbidity – this indicator manifests itself at an increased concentration of pollutants in water;

- taste – deterioration in taste indicates the presence of a high concentration of manganese, magnesium or iron in the water.

Standard complex analysis for microbiological and chemical research can be ordered from government agencies or private laboratories.

To obtain the most accurate result, it is important to use only a clean, sterile plastic or glass container with a capacity of up to 2 liters when sampling. Bottles must be filled so that no air bubbles form.

The sampled water must be delivered to the laboratory within 72 hours. Water samples delivered later lose their properties and therefore do not provide a clear picture.

Pumping and preventative flushing

The drilled well must be pumped, clearing it of sediment that fell during drilling.

The work can be done using:

- special installation for washing;

- compressor with a capacity of 12 atmospheres;

- submersible pump.

Any of these methods is based on the fact that air or water under pressure will push dirty water along with inclusions to the surface.

Sequence of actions when rocking the well:

- Using a strong cable, a pump is immersed in the bottom of the well to pump out the liquid.

- A hose is attached to the outlet pipe of the unit and taken away from the well in order to prevent re-contamination of the structure.

- Start the unit and pump out the liquid until it becomes clear. The process can take several hours. During this period, a layer of coarse sand or fine gravel may accumulate in the area of the filter section of the casing pipe, which will subsequently act as a filter.

Some companies engaged in drilling wells recommend that during the operation of structures, from time to time they should be flushed and sand removal. The main argument is that this will prevent siltation of the lower part of the trunk.

Preventative flushing only makes sense if the well is used seasonally and with long break intervals. For constantly operating structures, such flushing is not necessary. After all, the well is already flushed with a pump every day.

Additional flushing may be required only if problems arise or the pumping equipment cannot cope with the task.

Frequent breakdowns and solutions

During the operation of a hydraulic structure, there is always the possibility of breakdowns.Some of them can be eliminated on your own, without resorting to the services of expensive specialists.

Sand getting into the water at the bottom of the well

This can happen due to a leak in the casing, or if the well head is periodically flooded with wastewater. This will be confirmed by the appearance of new impurities and turbidity in the water.

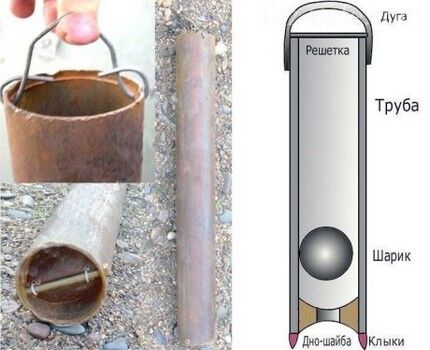

Cleaning the barrel using a cylindrical bailer helps solve the problem.

Scooping out the silt and sand drill bit, the well is pumped until clean water appears. In the future, in order to prevent a recurrence of the situation, the voids on the outside of the casing walls are filled with waterproof clay, covered with a layer of gravel or filled with cement mortar.

Filter obstruction

The reason for this is the same small particles of sand or gravel that clog the holes. Usually this problem occurs a couple of years after the commissioning of a sand well.

In case of integrity violation well filter or a critical drop in throughput, solve the problem by replacing it.

But this method is used quite rarely, only as a last resort, since it is not always possible to dismantle the casing without collapsing the walls of the structure.

Entry of foreign objects

It often happens that due to improper installation, the cables and hoses securing the pump break under the influence of load and vibration during equipment operation. Or a stone or bolt that accidentally fell into the well and got into the gap between the pump unit and the wall jams the equipment and causes the device to get stuck.

You can remove the pump and fasteners using hooks or a “cat” type device. The extraction operation should be carried out with the utmost care.

If during the lifting process the devices break off and remain in the column shaft, the task of removing the device will become several times more complicated.

If the unit is stuck tightly, the best solution is to call a team of specialists. Using an underwater video camera and other equipment, they will be able to diagnose the problem and fix it without damaging the structure.

Most often when jamming of the pumping device in the second or third link of the casing string from the top, it is partially removed from the excavation. Then the pipes are disconnected to the point of plugging from the barrel and the pump is taken out. If necessary, damaged links are replaced with new pipes of the same diameter.

Conclusions and useful video on the topic

Video #1. How to equip a well after drilling:

Video #2. Pumping sand from a well:

Video #3. How to determine the presence of heavy metals in water using improvised means:

Regular well maintenance is not a difficult task to perform, and any owner who has even the slightest idea about the operation of the system can cope with it.

You should not neglect preventive measures, since restoring a “neglected” well will cost many times more than carrying out minor regular repairs.

Please write comments in the block below. Tell us about your own experience in well maintenance, share the subtleties only you know. Leave posts with comments on the article and thematic photographs.

After constructing a well, it is necessary to pump it continuously or with short breaks for a month. If you made a well and did not use it, then it may silt up and then you will have to flush it not only with a pump, but possibly with a fire truck or something more serious. So you need to monitor the well and not start it, otherwise it may turn out to be completely unproductive after being idle.

Of course, having a well at your summer cottage is probably convenient. But it’s somehow a little scary that she needs constant attention in order for her to be productive. It’s good if someone in the family understands this matter and can solve current problems, of which, as I understand, there will be many. We are currently using a well and there are no problems with it.

We've had a well at our dacha for ten years, but the pump has never been removed. Spring has come, we plugged it in and started using it without any problems. And here it is written. And it’s the same with our friends too.

Constant attention, upgrades, etc.requires an abesin well, if you have a well for limestone, then there are no such problems.