Do-it-yourself well cleaning: a review of common causes of blockages and the best cleaning methods

One fine day you discovered that the well is not able to operate as usual? It’s a pity that there are no “eternal” sources for water supply, isn’t it? Do you suspect that it has become mechanically clogged over time and want to fix the problem on your own, but don’t know where to start or which option to choose?

We will help you cope with the problem that has arisen and settle on the most optimal option. Let us tell you what other methods of self-cleaning there are - the article discusses the best methods applicable at home, both for clearing blockages in an equipped well and in a mine.

After all, troubles can lurk at the drilling stage. Until the casing pipe (work string) is installed, soil can fall into the excavation, clogging it.

We have also selected photographs demonstrating the procedure and tools for doing the cleaning yourself. For clarity, expert video recommendations are attached - so cleaning the well with your own hands will be within your power.

The content of the article:

How to prevent clogging of a well?

"Eternals" wells for water supply can not be.Unfortunately, sooner or later, the owner of an individual water source will face problems. It’s bad if the aquifer has dried up, you’ll have to drill again or deepen the existing excavation. This is difficult and very expensive.

It’s a different matter if a well becomes clogged—it’s easier and cheaper to prevent it than to “treat it.”

Extending the service life of the source is facilitated by compliance with several operating rules:

- Strictly adhere to the selected drilling technology. Carefully monitor the tightness of the casing pipe and the integrity of the filter.

- Immediately after completion of drilling work, flush the source until clean water appears.

- Protect the well from penetration of surface water and pollution, installing a caisson, head. As a temporary solution, simply seal the top of the casing.

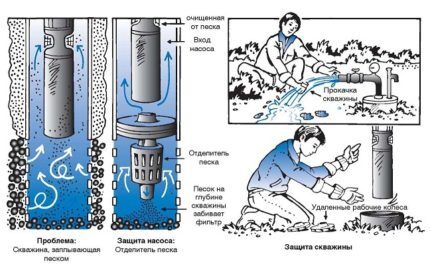

- Before starting operation, select the correct submersible pump and install it at the required height., necessarily taking into account the flow rate of the well.

- It is advisable not to use a vibration pump to supply water.. Vibrating in the casing, depending on the type of soil, it, to a greater or lesser extent, provokes the penetration of sand into the well or contributes to siltation of the adjacent soil. A cheap and simple vibration generator can be used for a short time; for continuous operation it is needed centrifugal pump.

- The well should not stand idle without drawing water. The ideal operating mode is daily pumping of several tens or hundreds of liters of water. It is provided if people live in the house permanently. If this is not possible, you should regularly, at least once every 2 months, pump out at least 100 liters of water from the well.

Following these recommendations, of course, will not avoid clogging of the well in the future.However, it will delay this trouble by ensuring the maximum possible resource for efficient operation for a given source.

Possible causes of blockage

It is worth mentioning the types of well clogging; this will help identify the causes of problems and determine how to properly clean the well yourself.

No. 1 - penetration of sand into the casing pipe

“Sanding” is a problem encountered in shallow sand wells where the aquifer is located in a sand and gravel layer. In a well-constructed well, sand penetrates into the casing in small quantities.

If the productivity of the source decreases, and grains of sand appear in the water, one of the following happens:

- Sand penetrates from the surface - the head and caisson are not sealed.

- The filter is not chosen rationally; the cells are too large.

- The integrity of the filter is compromised.

- The tightness between the casing sections is broken. The thread is not fully tightened, the welding is performed poorly, corrosion has “eaten” a hole in the steel casing pipe, mechanical damage to the plastic one.

It is not possible to eliminate leaks that appear inside the well. Fine sand constantly makes its way through the filter, but it is easier to remove it; it is partially washed out when the water rises.

Worse, if coarse sand penetrates into the well, over time the source may “float.” That is why you should pay special attention to the quality of installation casing elements and filter selection.

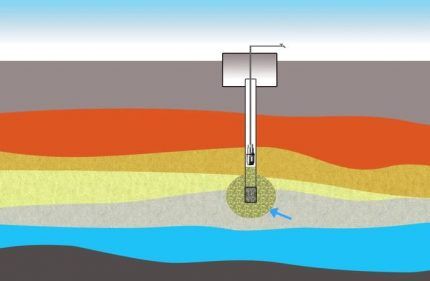

No. 2 - silting of an unexploited well

Over time, tiny particles of clay, rust, calcium deposits, and sediment accumulate in the soil in the filter area.

When their number becomes too large, the pores in the aquifer and the cells of the mesh (perforated, slotted) filter become clogged, and it becomes more difficult for water to penetrate through the mine shaft.

The well's flow rate drops, and it becomes “silted” until the water completely disappears. In a source that is used regularly, the process occurs slowly, stretching over decades. Without regular pumping, a well can become silted in a year or two.

If the well is cleared of silt in a timely manner, without waiting for it to completely dry up, there is a high probability of giving the source a “second life”. Water will be supplied in a volume sufficient to supply water to a private home.

Methods for cleaning a well yourself

How to independently clean a well in which sand or siltation has occurred?

There are three principles of cleaning: pump, rinse with circulating liquid or blow with compressed air. There are more cleaning methods used based on the above principles:

Method #1 - pumping with a vibration pump

A not always effective, but very simple way to restore well productivity is pumping with a vibration pump.

A vibration generator, which is not recommended for use for a long time during operation of the source, is just better suited for cleaning sand from a circulation pump.

Mainly due to the undemanding quality of water. It more easily tolerates contamination of the pumped liquid with sand and “swallows” even small stones.

An abrasive can quickly damage the check valve, but the part is cheap and you can replace it yourself in a few minutes.

A vibration pump costs several times less than a productive, but more sensitive to abrasives circulation pump. Even if the vibration pump “burns out” during extreme pumping, the financial damage will not be that great.

Suitable pumps for pumping a well: "Stream", "Baby".

Cleaning the well by pumping with a vibration pump will not help cope with serious siltation of the soil, but it can remove a large amount of sand that has penetrated into the casing.

True, provided that the well is shallow. When rising above 30-50 m, the performance of the vibration pump drops noticeably, depending on the model. Please note: only a pump with a bottom water intake is suitable for us.

In order for the vibrating device to actively suck in contaminants, it should be lowered almost onto sandy deposits, raising it only a few centimeters above the bottom. As sand is removed, its level will decrease, and the pump must also be lowered.

The time of continuous operation should not exceed half an hour; periodically the pump should be turned off for 10-15 minutes to allow it to cool.

If the sand contains pebbles exceeding 3-5 mm in diameter, they will be pushed under the membrane, preventing the flow of water. The membrane can only be released by lifting the pump to the surface.

The cleaning method with a vibration pump is not always effective and is quite lengthy. But it is simple and requires almost no physical human participation.

Method #2 - pwashing with a pump from the surface

Fine sand, rust and turbidity can be effectively removed from the casing by supplying water into the well from the surface.

In order not to turn the area into a swamp, it is better to organize washing in a closed cycle. Especially if there is no source of clean water nearby (we do not recommend rinsing the source with water from an open reservoir).

To do this, you should stock up on containers that can hold a volume of liquid equal to the total (from bottom to top) capacity of the casing pipe.

The flushing liquid will circulate between the well and the tank using a pump. Contaminants will accumulate at the bottom of the container and will have to be removed periodically. You will need a powerful pump; you can add chemicals to the solution.

For example, orthophosphoric acid, which dissolves layers of rust and calcium deposits.

Do not forget that the acid is extinguished with baking soda, and after using chemicals, the restored well should be pumped for at least 6 hours.

Instead of a well head, a nozzle should be installed at the wellhead that directs backwash into the reservoir. You can carry out flushing not in a closed cycle, pumping water into the well from a neighbor’s water supply.

In this case, there is no need to “bother” with tanks, but you should provide a drain for dirty water and make sure that it does not fall back into the casing.

Water is supplied downwards with a hose, the length of which should be sufficient for it to lie directly at the bottom. The surface washing method cleans the filter quite effectively.

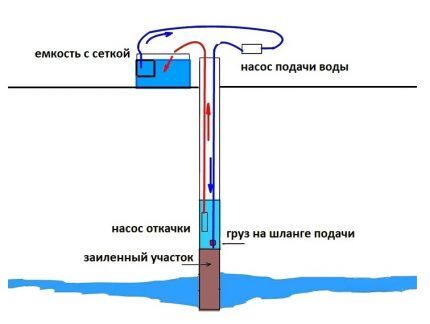

Method #3 - flushing the well with two pumps

It is difficult to flush a deep (over 50 m) well using a vibration pump or supplying water from the surface.

The power of the vibration generator is not enough, and when supplied from above, a significant part of the pollution will not be able to overcome a significant thickness of water and will sink to the bottom again.

You can significantly increase the efficiency of washing by using two pumps.

The second cleaning option involves the use of two different types of units: surface and deep well pump.

The first pump, located at the top, supplies flushing fluid to the bottom of the well, raising contaminants. The second, submersible centrifugal, pumps water with sand and silt to the surface.

To extract contaminants, you can use the pump that is installed in the well; you do not have to remove it or even lower it below the suspension point.

The main thing is to lower the water supply hose to the very bottom, passing it through a narrow casing pipe next to the submersible pump. You need to understand that if there is sand and small stones in the water, the pump will be subject to increased wear.

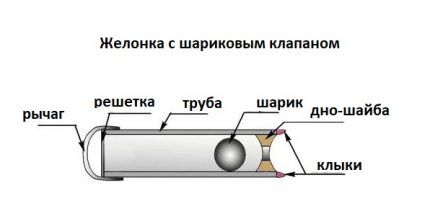

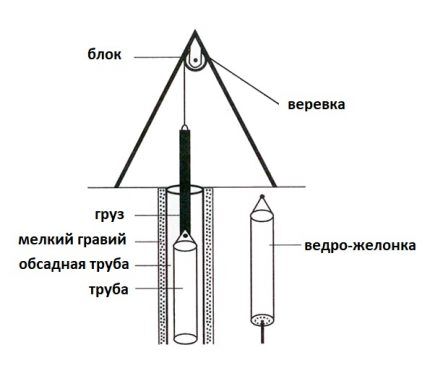

Method #4 - extracting sand using a bailer

The method of cleaning a well from sand using a bailer is very effective for removing large amounts of sand, stones and compacted sediments of small fractions from the casing pipe.

However, it is almost useless if you need to clean the filter and the surrounding soil from sludge. A bailer is a piece of steel pipe about a meter and a half long with a valve on one side and a lever-eye for a cable on the other. The design is quite simple - make a bailer you can do it yourself.

The valve is a heavy steel ball held in place by a washer that is attached to a threaded connection.

It is advisable to completely pump out the water from the casing. The bailer is sharply lowered to the bottom of the well. The valve, having crashed into the sand, opens and a certain amount of sand penetrates into the bailer.

The projectile is raised to the surface, the contaminants are shaken out. The process is repeated several times. You can operate the bailer manually, but it is difficult, even with two people.It is easier to lower and raise a heavy projectile and a steel cable using a tripod with a block or a winch.

You can buy a bailer of the required diameter from a specialized company, rent it, or make it yourself. When working with a projectile, you should be careful when approaching the filter: there is a possibility of damaging the thin mesh.

It is better to remove the last centimeters of dirt closer to the bottom using another method where there are no shock effects.

Method #5 - uRemoval of contaminants by water hammer

The water hammer method is effective in removing silt deposits from the filter and adjacent soil.

If the sand has been scooped out of the casing pipe (or it was not there in the first place), and after prolonged pumping or flushing water still does not flow into the well in sufficient quantities, severe siltation of the soil has probably occurred. A silt plug has formed.

In most cases, you can clean the well yourself using the water hammer method by “rocking” the plug.

To do this, you need to make a simple projectile: a heavy pipe with a diameter slightly smaller than the casing so that it fits inside with a small gap. The end of the projectile must be tightly welded, and at the opposite end there are eyes for attaching the cable.

The well should be filled with water several meters deep. It makes sense to add orthophosphoric acid to the water: it will dissolve calcium deposits and help get rid of rust flakes. The projectile is sharply dropped down into the water. They pick it up and drop it again.

After setting it up for a couple of hours, the casing is filled with liquid to the top, then pumped or washed.If the desired result is not achieved, the process is repeated.

It is often necessary to carry out dozens of such cycles to sufficiently remove silt and calcium deposits.

Method #6 - pwashing with gas-air mixture

Well cleaning is carried out using a gas-air mixture (bubbling).

Compressed air is constantly supplied to the bottom of the well through a sprayer located in the thickness of sand and silt (you need to try to literally stick it there) using a powerful compressor. Bubbles, rising to the surface, carry contaminants with them.

To ensure that dirty water flows out of the well, flushing liquid must be constantly added to it. This can be done either using a pump or manually.

You can organize water circulation in a closed circle between the well and a pre-prepared container.

The combined method of washing with simultaneous blowing with compressed air is not particularly productive. Cleaning is slow; the process can take several days, or even weeks, if the contamination is severe.

However, bubbling has certain advantages over alternative technologies, and in some cases it is the only reliable way to clean the well and filter from sand and silt if pumping with water does not give the desired result.

Alternative, very effective methods for removing sand by mechanical action (bailer) and silt deposits by water hammer create serious vibrations that can damage the filter if it is made of a fine mesh.

The likelihood of destroying or causing “collapse” of fragile plastic and even worn steel casing is even higher.This can completely destroy the water supply.

At the same time, flushing and purging with a gas-air mixture is the most gentle technology; it will not cause any damage to the well.

How to choose the right cleaning option?

It can be difficult even for a specialist to determine exactly why a well’s production rate has dropped. As a rule, pollution is complex. If the pump “drives” sand with water, this does not mean that the soil is not silted.

When cleaning a well with your own hands, you should be patient. You may have to apply several methods in succession and try hard before obtaining a satisfactory result.

We recommend starting with the simplest: pumping with a vibration pump. If pumping does not help, move on to flushing. We start with washing if the source has almost dried up. If there is a lot of sand at the bottom, a bailer will help to scoop out sand.

But it cannot be used for plastic casings, only for steel ones. For polymer barrels we use only bubbling. If there is neither sand nor water in the steel casing, we move on to water hammer technology.

This is, of course, if the aquifer itself has not dried up. Renting a washing machine, of course, costs a pretty penny, but the cleaning efficiency is noticeably higher than when using homemade methods.

Conclusions and useful video on the topic

In conclusion, here is a useful video that shows step by step the available method for flushing a clogged well:

Note that cleaning a well from sand and silt can be a very difficult task. And it’s not a fact that you can do this on your own.And by carelessly wielding mechanical projectiles, you can generally cause significant damage to a water source.

At the same time, there is a special technique that very effectively and to a large extent restores the characteristics of wells.

Do you have personal experience in cleaning wells on site? Do you want to share effective methods or ask questions on the topic? Please leave comments - the feedback form is located below.

These recommendations are more suitable for owners of sand wells with a depth of up to 18 meters. I also had a problem with cleaning the well and I couldn’t solve it myself, since it’s on limestone and 44 meters deep. We had to call a professional team, who arrived not only with a drilling rig, but also with a tank. I washed it, cleaned it, and now my water is wonderful!

The most effective method of cleaning wells is water hammer; no bailers or pumps will help, they just “smoke quietly on the sidelines.” Moreover, it is worth noting that before proceeding with direct impacts, it is necessary to pour into the well in advance, preferably special acids intended for cleansing. But on the other hand, it’s my fault, I let my well get to this point, my neighbor easily cleaned it with a vibration pump.

When using orthophosphoric acid, it is necessary to extinguish it with soda - how is this done? Can I use citric acid?

Yes, Vladimir, and not only is it possible, but it is also necessary. I myself used citric acid to clean my well. The well stopped working completely, literally. I thought I would have to stop using it. But I found an article on the Internet about citric acid, tried it and it worked. The water is now very clean and the pressure is like new.