Ventilation from plastic sewer pipes in a private house: the possibility of construction and the best options

Each living space must be equipped with a ventilation system, otherwise the owners will encounter mold, mildew, dust and dampness.The microclimate in the house is far from optimal, and with high humidity, finishing, building structures and furniture will quickly become unusable.

Is your budget so small that you can't afford employees? A good solution would be ventilation from plastic pipes in a private house - affordable and effective. The main thing is that it is not difficult to build air ducts from them with your own hands.

We will talk about how to organize ventilation from polymer pipes. Let's introduce them to their advantages, disadvantages, and installation rules. Our recommendations will help you assemble a flawlessly functioning system and operate it correctly.

The content of the article:

Advantages and disadvantages in comparison

There are no prohibitions on the use of plastic or other products used in sewer systems in the construction of ventilation pipelines. However, before planning and installing ventilation, you should definitely understand the characteristics of the material chosen for construction.

It would be good if their advantages over metal boxes and, of course, their disadvantages are known.

The advantages of plastic sewer pipes used in the arrangement of budget ventilation include:

- Low cost. PVC or PP pipe is several times cheaper than its galvanized tin counterpart.

- Easy to install. To install communications, the owner does not need to involve specialists - everything can be done with his own hands.

- Practicality. A variety of plastic parts allows you to create ventilation systems of any functionality.

- Electrical insulation. Plastic cannot become a conductor of electric current.

- Structural rigidity. Pipes made of PVC and PP do not require additional fastening; they excellently maintain their structural direction and shape without additional devices.

A strong plus plastic sewer pipesb is excellent resistance to biological and chemical influences. Colonies of mold fungus do not settle on their walls; they cannot be damaged by household chemicals during cleaning.

If we compare sewer plastic with specialized products, it clearly has disadvantages, these are:

- Poor resistance to elevated temperatures. The sewer pipe cannot be used at air temperatures above 50-60 degrees.

- Insufficiently high strength. Compared to metal, plastic is not reliable, durable and resistant to negative external mechanical influences. If you try, it can be damaged by a strong blow with a sharp object.

- Limited installation options. Plastic pipes cannot be laid next to units that generate heat (boilers, heaters, stoves, columns, radiators and heating pipelines). They should not be placed in areas freely illuminated by the sun.

You can build a ventilation system from plastic sewer pipes. It will be virtually as durable and stable as metal. In addition, it does not transport any aggressive media, and it does not experience pressure.

That is why PP and PVC pipes can be used almost everywhere: in the construction of fire ventilation systems, hoods over cooking surfaces, hidden air ducts laid behind false ceilings and walls.

A wide range of clips and brackets are produced for attaching polymer pipes to structures. Hanging from the ceiling can be done using metal mounting tape. Fasteners for metal systems of similar shape and size are also very useful.

Comparison of section sizes

Plastic air ducts, ventilation equipment (fans and diffusers), connecting

and sewer fastening products have the following diameters:

- 100 mm;

- 125 mm;

- 150 mm;

- 200 mm.

Less common sizes are also available. plastic pipes, intended for ventilation systems.

PVC sewer pipes, as well as fittings, have their standard diameters, mm:

- 110;

- 160;

- 200.

Comparing the parameters provided above, there is a noticeable discrepancy with the standard sizes of air ducts. When assembling a natural ventilation system from the components of a sewer system of appropriate sizes, there will be no problems.

When connecting to an existing ventilation channel, discrepancies appear. You won’t be able to buy an adapter - they don’t exist, and making it yourself in makeshift conditions is long and difficult.

Difficulties may arise when selecting fans and other equipment for installing a forced ventilation system made from sewer plastic pipes. All equipment has standard sizes and, of course, will not fit in diameter.

Priority air exchange volume

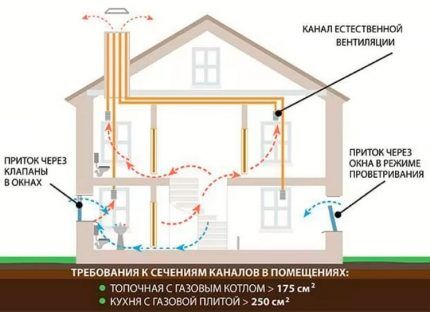

Regulatory documents are intended to determine the parameters of natural air circulation. For a living space of 30 m22 air exchange should be 4.5 m3 air at 1 m2. For a larger room, 30 m2 is required for each person3 fresh air per hour.

In the kitchen and bathroom the indicator should be within 110-140 m3/h. For forced ventilation the figures will be higher.

Plastic pipes with a diameter of 160 mm are perfect for arranging ventilation in your home. This parameter provides an air supply of about 30 cubic meters per hour with a duct height of 3 meters. With other indicators, the efficiency will be less.

If it is necessary to increase the throughput, you can increase the cross-section of the air duct and its length. To ensure maximum draft in each room, there should be the same length of ductwork on the same floor.

Recommendations for setting up the system

The normal operation of the system under construction and the thoughtful purchase of materials for its assembly should be preceded by a well-made project.

In order for the result to meet expectations and the system to cope with its responsibilities, the following must be taken into account:

- When designing a project, try to reduce the number of sharp turns and bends in the ventilation duct. The smoother the ventilation channel is, the more intense it will become air circulation.

- The following recommendation directly follows from the previous recommendation. The shorter the air path from inlet to outlet, the more effective ventilation will be.

- When thinking about and creating a project, stick to uncomplicated and simple schemes. Convenience in planning will lead to a decrease in efficiency.

When constructing a ventilation system from plastic pipes, pay attention to the height of the structure itself. If the air outlet pipe rises to a height of less than 5 meters from the lower level, then natural ventilation will not work. In this case, it will have to be reinforced with fans.

Natural and artificial type

According to the type of stimulation of the movement of air masses, ventilation systems are divided into natural and artificial:

- Natural, they are also gravitational. They operate due to the difference in density and temperature of the air mass outside the window and indoors. Warm exhaust air with a lower density rushes upward and is drawn out into the vents, and is replaced by a denser cold stream flowing from behind the window.

- Artificial, they are also mechanical. They work by continuously stimulating air flow with fans. They are installed on the exhaust or supply side; it happens that they are installed on both the supply and exhaust components, but only one direction is always involved.

The gravity type of ventilation directly depends on weather conditions. In the summer heat, its work spontaneously stops, because... the pressure between the air inside and outside is equalized. It happens that in hot weather the air flows in the opposite direction: from the house/apartment to the street.

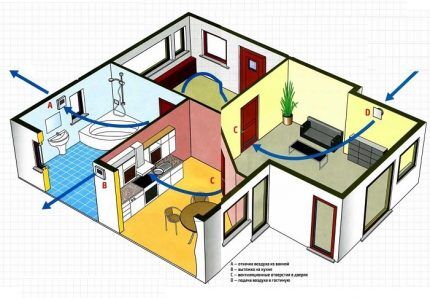

Fresh air enters naturally through leaks in window and door openings with frames, through open vents and periodically opened doors. Outflow is through barred ventilation openings located in kitchens and bathrooms.

Apartments in the old housing stock were ventilated according to a natural pattern. Nobody was going to mechanize it. Now in these apartments designed for natural influx, plastic sealed windows are installed. Because of them, normal air movement is disrupted, so it should be installed together with a plastic window in a high-rise building. supply wall valve.

Supply or exhaust valves into the wall should be used in private houses in which the construction of mechanical supply and exhaust ventilation is not planned.

Using a valve, inflow or outflow will be ensured in the cheapest but most effective way. In this case, the entire system will receive the status of combined - i.e. partially mechanized.

Mechanical ventilation is the most expensive and difficult type of system to implement, requiring the inclusion of a recuperator or heater, air handling unit. Its air ducts are laid behind false walls, suspended or suspended ceilings, and laid out in building structures during the construction of a house.

Naturally, if the owner decides to install supply and exhaust ventilation, he will not skimp on material for the ventilation ducts. It is unlikely that he will buy sewer pipes. It is better to purchase plastic air ducts that can be connected to ventilation equipment without problems and unnecessary tricks.

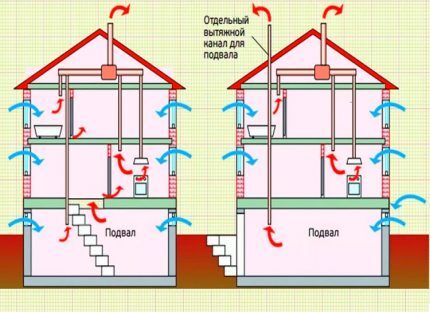

In private houses, exhaust ducts from bathrooms and kitchen hoods they are either taken out separately into the attic or brought into a common shaft located in the middle of the building. This reduces the loss of usable area and the shaft reaches the roof at the highest point, which provides excellent traction.

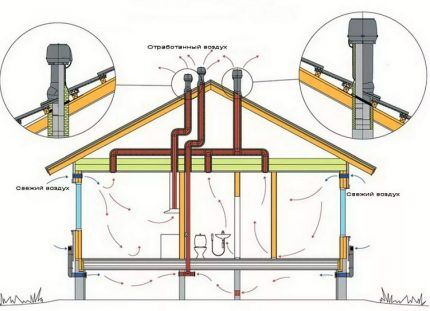

The plastic sewer pipe passing through the attic must be lined with insulation. Otherwise, the pipe will collapse due to temperature changes. Hotter air will always come out of the kitchen than in the environment, which means that due to unstable expansion, deformation or violation of the tightness of the channel is possible.

A cap must be installed on top of the pipe - a ventilation deflector that protects from precipitation.

System construction process

Exhaust device ventilation in the kitchen or in the bathroom it begins with marking the entire system. After this, materials are selected and calculated. Never rush into calculations. Everything needs to be done carefully and calmly.

When designing, remember that ventilation is important for its functionality with the ability to make maximum use of all conditions in each room. If you make a mistake, you will have to use mechanical air blowers, which will significantly increase the cost of the system.

Installation steps:

- Ventilation design.

- Purchase of equipment: sewer pipes, installation products, fasteners, fittings, mounting metal tapes.

- Installation of brackets and clamps at the locations of ventilation communications.

- A ventilation riser is assembled from large pipes.

- Assembly and installation of air ducts.

- Connecting all branches to each other.

- Sealing of connections. There is no particular need for this, but it won’t hurt.

- Installation of fans and valves, if provided.

- Installation of ventilation dampers.

The end of all types of installation work is testing the system for operability. All actions consist of checking traction. To do this, you need to attach a piece of paper or a napkin to the exhaust ducts.

Design or development of a circuit

Creating a ventilation project begins with basic calculations and collection of information, then:

- Calculate the air exchange rate throughout the entire house. This indicator depends on the volume of all premises, their purpose and the number of residents. In living rooms, the air should be completely changed once every 1 hour, and in technical rooms (toilet/bath) - at least 3 times in 1 hour. By adding up the resulting figures, we obtain a performance indicator, taking into account which the diameter and height of the ventilation equipment will be selected.

- Draw a diagram of the movement of air flows. Immediately estimate the position of the intake and supply channels.

- Draw a diagram of the air ducts. For now, ignore the detailing, stick to the rules and try to fit the system in without complicating the design. This is the most difficult stage of the work. Hiding ventilation from bulky plastic pipes is not so easy.

The sketches are ready. Take some time to think about what devices you will have installed in the system and where they will be located.

Detailing and assembly of the system

Having resolved all the issues regarding the diagram and given it its final form, it’s time to move on to detailing.

First, calculations are also carried out, system components and equipment are selected and the budget is reduced, then:

- The cross section is calculated and air duct area. The maximum speed of quiet air movement is taken into account - otherwise there will be a hum in the house.

- All dimensions are transferred to the diagram.

- Detailing. A list of all necessary elements is compiled, indicating the sections.

- The total cost of the ventilation system components is calculated. Reduce your desires to your available budget. At this stage, you will have to change the components several times, abandoning the desired in favor of the real.

- The final project is drawn. Do not forget about the passage of ventilation channels through the roof, ceiling, walls, insulating and consumable materials, ventilation grilles, fasteners and all other little things that will ultimately add up to a decent amount.

All that remains is to find, buy and install. Not much has been written, but it will take a lot of nerves, time and effort to implement the plan. Having installed the entire system, one cannot yet say that everything is ready.

The ventilation system made from plastic sewer pipes still needs to be tested and modified during operation. Achieving coordinated operation of each element of the system is also not so easy. If the natural ventilation option is not effective enough, it is worth upgrading by installing exhaust valves or their influent counterparts.

Analysis of rumors and speculation

Hearing: Plastic sewer pipes, when used in a supply ventilation system, will emit harmful and possibly toxic substances, poisoning the air. They have a different purpose and may use harmful chemicals during production. Therefore, when installing a ventilation system, it is better not to take risks.

All, without exception, manufacturers of sewer pipes have documentation confirming environmental safety. It is impossible to refute or confirm this, since the production technology is kept secret. The manufacturer can provide you with a quality certificate for their product.

Hearing: Sellers polymer air ducts disseminate information that sewer pipes quickly become electrified, which leads to the adhesion of dirt and dust on the inner surface of the pipes.

Air movement can actually cause an electrical static charge to form inside the pipe. It’s strange why everyone is talking about fan products, since tin pipes are also electrified. It's all about processing.

Manufacturers of plastic air ducts must treat them with antistatic agents. If you treat sewer plastic pipes with an antistatic agent before installation, the electrification property will disappear.

Conclusions and useful video on the topic

The following video will introduce you to errors in the construction of sewer pipe hoods and ways to correct deficiencies:

Effective ventilation in a private house from sewer pipes is a very real option. The advantages and disadvantages of such systems are not much different from specialized ones, as evidenced by the operational characteristics. However, they can only be made into gravity type.

It is worth mentioning the dimensions. All fastening and connecting fittings, bends and turns will be 2 times larger than those of ventilation competitors. The appearance is also not great. Conclusions have been made, and then it’s up to you to decide what is more important, the final cost of the product or its compactness and appearance.

You can share your own experience in installing ventilation from polymer sewer pipes in the block below. Please write comments, ask questions, post photographs related to the topic of the article. It is possible that your recommendations will be very useful to site visitors.