Plastic air ducts for ventilation: varieties, recommendations for selection + rules for arranging the ventilation duct

There is a lot of talk about how all plastic products pollute the environment. Why is this happening? This is because plastic is a very “long-lasting” material. It does not decompose easily: products made from it are very durable and reliable. Plastic air ducts for ventilation will last much longer than galvanized ones. But how to choose them?

You will learn everything about the types of plastic air ducts and how to assemble them from the article we presented. We will tell you in what order the installation of plastic ventilation ducts is carried out. We will explain how to assemble the individual parts into one flawlessly working network and how to secure it.

The content of the article:

Tips for choosing plastic air ducts

Ducts are nothing more than pipes through which air circulates, providing ventilation to rooms. They can be metal, in some cases, for example, in risers, asbestos-cement or plastic.

Nowadays plastic is the most popular. Given its comparative cheapness, it lasts much longer than metal, which is susceptible to corrosion, or asbestos cement, which is eaten away by dampness, excessive dryness and other external factors.

What to consider when choosing plastic air ducts:

- The inside of plastic pipes must be extremely smooth. In this case, there will be absolutely no air friction against the walls, and air flows will circulate in such a structure with the greatest efficiency.

- In case of installation of natural ventilation, not reinforced by fans, it is better to avoid corrugated pipelines. The corrugated walls of the ventilation ducts, especially at turns, will delay air flow and ventilation will not be carried out at full capacity.

- Preference should be given to the manufacturer whose joints of the plastic segments of the air duct are carried out with the best tightness.

Plastic that is too hard is a bad sign. When pressed, the pipe should give slightly. Excessively dense and rough material will last less than soft material. Most likely, it will begin to crumble and crumble during the first decade of using the ventilation system.

If the owner decides to install ventilation system made of such pipes, he can be sure that it will last no less than one mounted from pipes specially designed for assembling air duct systems.

The only disadvantage of sewer pipes is their exclusively round volumetric profile, which is not always convenient.

Main types of air ducts

All plastic air ducts can be divided into three categories:

- Round. In demand for laying ventilation system routes. The most common diameters of these are 100, 125 and 150 mm.

- Rectangular. They are used when it is necessary to install air ducts above a suspended ceiling. The most popular sizes are 60x120 and 60x204 mm. Although narrower modifications can be purchased.

- Flexible. They can be either round or square.

The flexibility of the material is ensured by a spiral reinforced outer “frame” that envelops an inner pipe made of PVC material - vinylurethane.

Often, along with the above, polymer sewer pipes are also used when installing plastic pipelines.

Technical advantages of plastic

As already mentioned, service life is one of the most important criteria by which people prefer plastic.

Along with a long service life, air ducts made of this material:

- They are lighter in weight than other materials from which the ventilation system segments are made.

- They are not afraid of slight sagging - up to 4% is acceptable.

- They are easy to install because they can be easily cut with a hacksaw or grinder.

- Reinforced thermal insulation is not required in the roof area.

- The inside has very smooth walls, which makes air circulation through such pipes more active and easier.

You can often see that the owner installs ventilation from the most ordinary PVC sewer pipes. They are cheaper, provide excellent sealing, and a wide range of fittings, tees, revisions, etc. gives them the opportunity to install a ventilation system of any degree of complexity.

But whatever the shape of the air duct pipes, the ventilation system must always fit within the framework of SNiP, which stipulates how any ventilation system should be equipped.

Basic rules for arranging a ventilation duct

Next we will talk about how to properly design a ventilation duct and what to pay attention to when developing a project.

In addition, recommendations from experts on arrangement of the ventilation system. Let's start by drawing up a diagram of the future ventilation system.

Main requirements of SNiP

Not everyone today resorts to the services of specialists. Many people design the ventilation system themselves. But with benefits SNiP 2.04.02-84 And 2.04.01-85 a must read.

They spell out the conditions for the correct installation of ventilation systems in private homes.

And this is what the main list of requirements looks like:

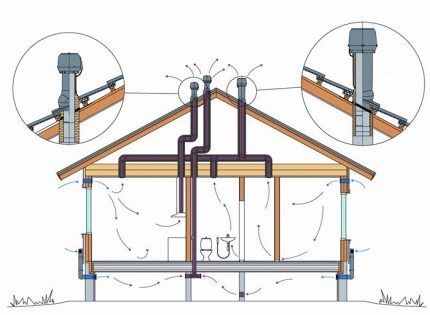

- It is imperative that in any private residential building the inflow and outflow of air masses must be ensured not only in the rooms where people directly live and spend most of their time (bedrooms, living rooms, kitchen), but also in utility rooms such as a bathtub, toilet, laundry, etc.

- Air exchange must be carried out through installation supply and exhaust channels, as well as slot ventilation.

- Air circulation in the home should be facilitated by the correct placement of doors. The gap between the floor and the lower end of the canvas is at least 20 mm.

It happens that the exhaust works much stronger than the inflow. The problem is solved by ventilating the room using open windows. Under these conditions, this point cannot be neglected.

It is desirable that the supply duct be located close to a heat source - a heating center, a heating radiator, etc., which will allow the air entering the home to be heated simultaneously in winter.

In principle, nothing difficult to develop ventilation schemes No. You can simply take a schematic drawing of the building and draw on it the layout of future air ducts, focusing on the set of listed rules and regulations.

About the calculation rules for determining the area of air ducts in detail written here We recommend that you read the useful information.

Recommendations for arranging ventilation

Let's move on to the assembly of the natural circulation ventilation duct.

The list of recommendations on this matter is as follows:

- If you are going to install a natural ventilation system, then in this case it is better to opt for straight plastic pipes rather than corrugated ones. Corrugation is more suitable for a supply and exhaust system, reinforced with axial fans, due to which air circulation occurs in a forced manner.

- In your projects, you should try to avoid a large number of sharp turns in the ventilation piping. The smoother the bends, the more intense the natural air circulation will occur.

- The next recommendation directly follows from the previous one. The shorter the path the air travels from the “input” to the “exit”, the more efficient the ventilation will be.

Therefore, when developing a project, preference should be given to the simplest and most uncomplicated schemes, without cluttering them with ornate routes that are convenient for planning but reduce the efficiency of the system.

When installing a ventilation system from plastic pipes You should definitely pay attention to the most important point - the height of the system itself.

If the exhaust pipes rise less than 5 meters above the lowest level, natural ventilation will be ineffective. Here, whatever one may say, you will have to strengthen the system with fans.

But for many it is much easier to build pipes above the roof.Extended air duct pipes in the case of low buildings do not always look attractive, but in terms of adding aesthetics, you can think of a kind of camouflage design for them. And in some cases, the solutions are the most aesthetic and attractive.

Strengthening the system with fans

The development and installation of a forced ventilation system also has its own nuances, the observance of which is mandatory. Otherwise, the system will either not work properly, or vice versa.

According to experts, the main thing that you should definitely pay attention to in the case of a forced ventilation system is:

- Differences in the operation of intake and exhaust fans. They should be adjusted so that the fan is slightly underworked on the inlet side, and overworked on the outlet side. Thus, there will always be a certain air deficit in the system, which will contribute to more efficient interchangeability of air in ventilated rooms.

- In the case of a forced ventilation system, it does not matter where the fresh air will be taken from - from above or from the level of the lower floors. The main thing is that the system follows the rule of the previous paragraph.

- The most optimal air exchange for both natural and forced plastic ventilation systems is air exchange with a room air renewal rate of 100% in 1 hour. For example, if the room has a total area of 40 sq. meters, the air exchange should be approximately 120 cubic meters of air per hour.

You should also keep in mind that the exhaust duct in the room should be installed at least 25 cm from the ceiling.

Networking of channels

Particular attention is drawn to the fact that it is unacceptable to combine air ducts coming from rooms of different directions. If the channel belongs to a utility room, for example, a laundry room, a bathroom, etc., it is under no circumstances recommended to combine it with a channel that circulates air in a living room - a bedroom, living room, or even in the hallway.

These rules are mandatory regardless of what materials the air ducts will be installed from - be it plastic or galvanized.

In the case of the arrangement of some “specific” premises and heating/heat-generating devices, there are specific requirements. For example:

- The kitchen must be equipped own air duct, having no associations with others.

- If there is one in the building, the fireplace must also have its own chimney. Under no circumstances should any other ventilation ducts flow into it. You should also pay attention to the fact that it is strictly prohibited to use plastic pipes for a fireplace or stove.

- When designing an exhaust system oriented towards a kitchen stove, it should be borne in mind that in no case should it be combined with air ventilation of the kitchen area itself.

If the building has several bathrooms, then it is not forbidden to combine their plastic air ducts together.But at the same time, it is recommended to retrofit them with a valve that does not allow contaminated air to penetrate back into the room.

It should be remembered that flows coming from living rooms should in no case merge with flows coming from technical rooms.

Exiting channels through the roof

It is always recommended to raise the head of the plastic duct as high as possible. The minimum can be considered a height of 0.5 m above the ridge level if the ventilation pipe exits at a distance of no more than 1.5 m from it.

Otherwise, if the distance of the outlet part of the plastic air pipeline is more than one and a half meters from the ridge, it is allowed to make the upper head a little lower, but it must still rise above the ridge by at least 10% of its outer length.

To facilitate work on the device passage through the roof It is advisable to combine them using a shaft box. It can simultaneously include up to 6 plastic pipes coming from rooms of the same direction, for example, bedrooms, living rooms, halls, etc.

In this case, you will have to install only one hole in the roof for the air duct, and not 6, for each pipe. It is not forbidden to install plastic air ducts under the canopy, but only if the space under it is well ventilated.

The upper part of the plastic air duct head is not allowed to be located less than 3.5 m from the nearest windows or balconies. Ventilation risers must be equipped deflectors: conventional “fungi” or turbine-type devices.

Will familiarize you with the rules and formulas for calculating the speed of air mass movement through the air duct next article, which we strongly recommend reading.

Conclusions and useful video on the topic

The advantages of installing a ventilation system for a residential building with plastic pipes will be discussed in the following video:

How to install a simple natural ventilation system made of plastic pipes is shown in the following video:

From all of the above, it is clear that installing a home ventilation system from plastic pipes will be much easier and, most importantly, cheaper than from galvanized pipes.

And with all the variety of all kinds of connectors, adapters, etc., doing this will be no more difficult than assembling a house from a children's construction set.

Would you like to talk about how you selected a kit for installing a plastic air duct and assembled it with your own hands? Do you have information on the topic of the article that will be useful to site visitors? Please write comments, post photos, share information and ask questions in the block below.

The option is excellent and practical, but is more suitable for metalworking shops. Or for warehouses where wood, metal, and other materials are stored, because any moisture is destructive for them. The main thing is that the plastic is not very hard, which I completely agree with the author of the text.It is also desirable that the exhaust duct be close, or almost close, to the ceiling.

I have a ventilation project for my house. Can I replace metal ducts with plastic ones to save money?

Hello. You, of course, can replace metal air ducts with plastic ones, but this may result in incorrect operation of the entire ventilation system.

The fact is that the calculations used indicators such as the resistance of the material, but it is different for plastic and metal. Accordingly, other volumes will pass through the air ducts than were originally included in the project. Therefore there are two options:

1. Rework the project for plastic air ducts;

2. Leave everything as is.

The first point is advisable if the calculations are performed for you free of charge.

Is it permissible to reduce the height of the ventilation duct on a kitchen hood above a gas stove?

From the hood, the pipe goes up to the ceiling, then horizontally to the outer wall, then down 10-15cm to the passage through the wall, and then through it to the street.

It turns out that there are a total of 3 90-degree bends in the pipe and a decrease in the channel height by 10-15 cm.

I understand that this definitely reduces the efficiency of the hood (the hood itself is powerful, i.e. this will not be a problem), here I am wondering whether this is allowed according to the standards.