Supply and exhaust ventilation units: a comparative review of various types of equipment

The natural air circulation system often malfunctions - its performance depends on natural factors and the use of sealed double-glazed windows. Forced ventilation does not have these disadvantages.

To normalize air exchange, a supply and exhaust unit is used - a practical and effective solution. The variety of climate control equipment allows you to choose a model for specific operating conditions. However, deciding on a suitable device is sometimes problematic, don’t you agree?

We will help you resolve this issue. The article provides information on the operating principles and operating features of different types of air handling units. To make the choice easier, we have outlined the main characteristics and parameters of the devices that should definitely be taken into account when purchasing.

The content of the article:

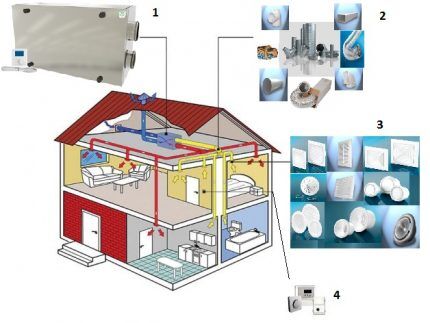

Components of forced ventilation

The supply and exhaust module is the main component of a forced-air ventilation system. The installation ensures normalized air circulation in a confined space - supply of clean flows and removal of waste materials.

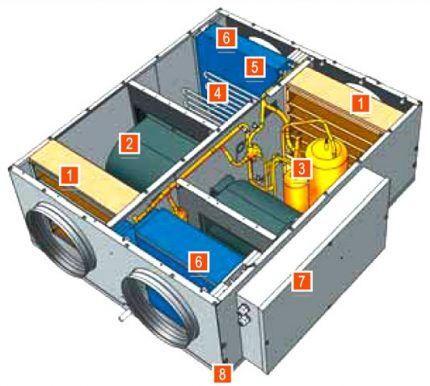

The ventilation module is a complex of equipment enclosed in a single housing (monoblock unit) or assembled from prefabricated elements.

The design of the supply and exhaust unit necessarily includes the following elements:

- Fan. Basic component for the operation of an artificial air exchange system. In PVU with an extensive network of air ducts, radial fans are installed to maintain high air pressure. In portable PES, the use of axial models is acceptable.

- Air valve. Installed behind the external grille and prevents the entry of air from outside when the system is turned off. If it is absent, cold streams will seep into the room in winter.

- Air duct main. The system uses two lines of channels: one is the supply, and the second is the exhaust of air. Both networks pass through the PES. The supply fan is connected to the first air duct, and the exhaust fan is connected to the second, respectively.

- Automation. The operation of the installation is regulated by a built-in automation system that responds to sensor readings and user-specified parameters.

- Filters. Complex filtration is used to clean the incoming masses. A coarse filter is placed at the inlet of the supply air duct; its task is to retain fluff, insects and dust particles.

The main purpose of primary cleaning is to protect the internal components of the system. For more “fine” filtration, a photocatalytic, carbon or other type of barrier is installed in front of the air distributors.

Some complexes are equipped with additional functionality: cooling, air conditioning, humidification, multi-stage air purification and ionization system.

The principle of operation of the supply and exhaust complex

The operating cycle of the PES is based on a double-circuit transportation scheme.

The entire ventilation process can be divided into several stages:

- Air intake from the street, its cleaning and supply to the distributors through the air duct.

- The entry of contaminated masses into the exhaust duct and their subsequent transportation to the outlet grille.

- Discharge of waste jets outside.

The circulation scheme can be supplemented with stages of thermal energy transfer between two flows, additional heating of incoming air, etc.

The operation of a forced system provides a set of advantages compared to natural air exchange:

- maintaining specified indicators – sensors react to changes in the atmosphere and adjust the operating mode of the PES;

- incoming stream filtering and the possibility of its processing - heating, cooling, humidification;

- savings on heating costs – relevant for devices with recuperation.

The disadvantages of using PVU include: the high cost of the ventilation complex, the complexity of installation after completion of repair and construction work, and the noise effect. In monoblock installations, the last disadvantage is eliminated thanks to the use of a sound-insulated housing.

Types of installations: features of design and operation

Cost, performance, and energy consumption depend on the functionality of the PES. The variety of models is conventionally divided into the following groups: units with recovery, units with heating and air conditioning. A separate category is “mobile” devices.

Supply and exhaust module with recuperator

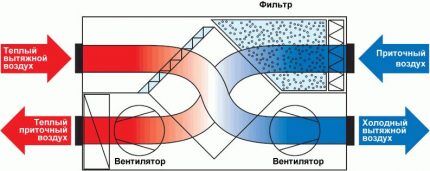

In addition to the advantages described above, the forced ventilation system also has a significant drawback - a significant increase in heat losses. Together with the exhaust air, the heat generated by the heating system “evaporates.”

Costs are about 60%. The solution to the problem is the transfer of energy from the exhaust air flow to the supply air flow.

Today, most air handling units are manufactured with recuperators. Despite the high cost of equipment, the feasibility regenerative system economically justified.

Efficiency values of the “heat exchanger”:

- 30-60% — low level of thermal compensation;

- 60-80% — a good indicator of efficiency;

- over 80% — high-quality heat transfer.

It is interesting that even the presence of a recuperator with an efficiency of 30% is more economical than a basic unit without a heat exchanger. The average payback period for a recuperative ventilation unit is up to 5 years.

The efficiency of the air flow unit, the air flow pattern, power consumption and the price of the module depend on the design of the recuperator.

There are several types of heat exchangers:

- rotary;

- lamellar;

- heat pipes;

- chamber module;

- gleycol aggregate.

The first two models have become widespread.

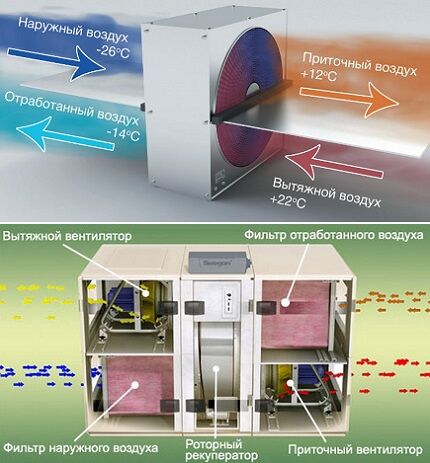

Rotary recuperator

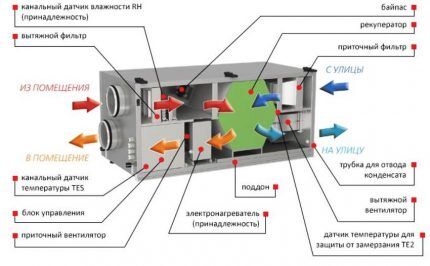

The PVU housing houses a cylindrical rotating heat exchanger with corrugated metal plates. As work progresses, the compartments are alternately filled with multidirectional air flows.

Heat recovery is 60-90%.

Additional benefits:

- partial return of moisture;

- economical energy consumption.

The rotation speed of the drum can be adjusted, thereby choosing the intensity of air exchange and the level of efficiency.

Arguments against drum modification:

- mixing of “working off” to the fresh flow – 3-8%;

- partial transfer of odors back into the room;

- acoustic pressure from a rotating rotor;

- the need for regular maintenance of moving elements;

- large dimensions.

Due to the complexity of the mechanism, PVUs with a rotary recuperator are more expensive than plate modifications.

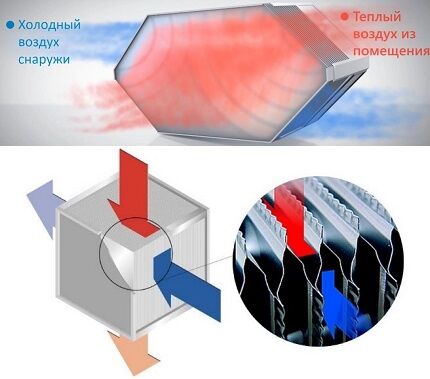

Plate heat exchanger

The ducts “meet” in a sealed unit with multiple channels. The compartments are separated by heat-conducting partitions.

Arguments for":

- supply of clean air without “exhaust” impurities;

- affordable price;

- ease of setup and reliability of the module - there are no moving elements.

The efficiency of the plate converter is up to 70%. The main disadvantage is the formation of condensation and the appearance of ice in the exhaust duct in winter.Operating in the “defrost” mode (redirecting the warm flow bypassing the cassette) reduces the efficiency of the system by 20%.

Nowadays there are quite a lot of supply and exhaust ventilation systems with heat recovery from various manufacturers on the market. Possessing a similar set of characteristics, they differ in price, quality, service area and many other criteria.

So, we recommend taking a closer look at the supply and exhaust ventilation unit with a plate heat exchanger and integrated automation from Naveka, which has recently proven itself in the market due to its reliability and fairly quiet operation. Integrated control using a remote control, monitoring on an external LCD display, setting a work schedule and much more is already built into this unit.

Among other brands, we recommend paying attention to recuperation systems from Mitsubishi, Maico and VENTO.

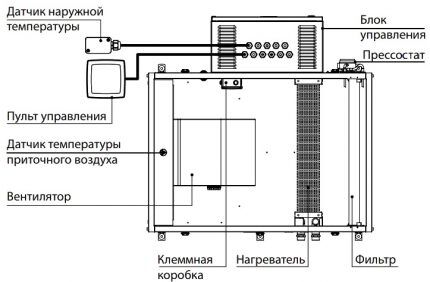

Energy-saving heated units

Recuperation alone is often not enough to fully compensate for the temperature difference of oncoming flows. This function is performed by the built-in heater. In addition, the element protects the heat exchanger from freezing.

Two types of heaters are used in PVU: water and electric. Let's look at each in more detail.

Water heating

The body of the forced ventilation unit contains a radiator with tubes through which the coolant circulates. The coil has fins to increase the contact area with passing air streams.

The liquid heating element comes into operation if the supplied air at the outlet of the recuperator is colder than the set temperature.

Electric heater

Installations with an electric heater are capable of heating the supplied air to higher temperatures than “water” modifications.

However, an electric heater is more demanding in terms of operating conditions:

- air flow speed – 2 m/s or more;

- supply air temperature is within 0-30°C, humidity – up to 80%;

- It is recommended to install an additional filter in front of the heating element.

Compared to water heating, the electric module is more expensive in terms of operation - electricity bills increase.

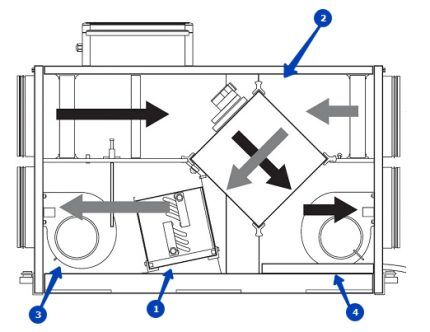

Complexes with air conditioning

Some models combine forced ventilation and air conditioning options. All elements are collected into a single thermal insulation complex. A striking example of multifunctional technology is a series of installations "Climate".

The circuit contains a reversible heat pump - a charged sealed freon circuit connected to heat exchangers on the exhaust and supply ducts.

The air conditioning unit operates in two modes:

- Cooling. The heat exchanger on the supply air duct acts as an evaporator and lowers the temperature of the incoming air. In turn, the heat exchanger-condenser is cooled by cool air coming from the room.

- Heat. The exhaust air duct recuperator transfers waste heat to fresh air masses. At the exit from the PVU, additional heating of the air is possible before supplying it to the house.

The operating mode is set automatically thanks to regulators and sensors that read atmospheric parameters.

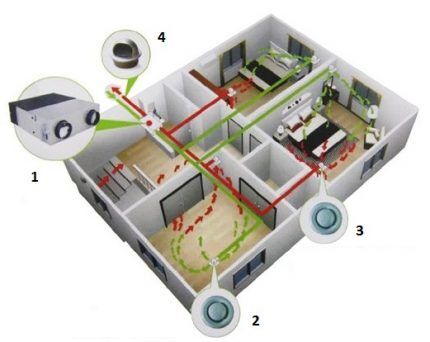

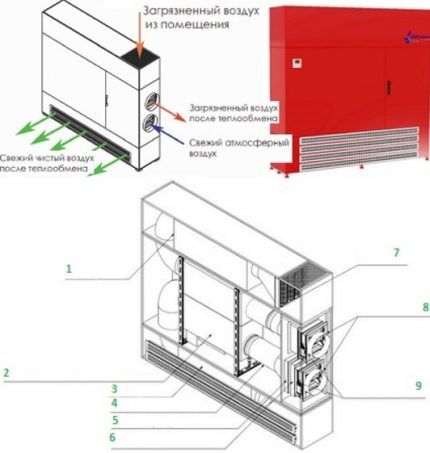

Portable ductless installation

An interesting solution for confined spaces is mobile air supply units with the ability to clean, heat, and cool air.

Distinctive features of portable modules:

- absence of bulky air ducts;

- installation inside a ventilated room;

- compact dimensions and the ability to install within 2-3 hours;

- multifunctionality: inflow, processing and removal of air masses;

- low noise level – within 35 dB;

- no drafts.

To arrange decentralized ventilation, it is necessary to install a portable PVU in each individual room.

Ductless ventilation units are used primarily in public buildings (lecture rooms, gyms, training rooms, etc.).

The rating of mobile climate equipment is given in this article.

Varieties according to installation method

There are three options for installing the ventilation module:

- floor;

- wall;

- "filmed".

Floor mounting is typical for high-performance and bulky ventilation units with an air flow rate of 8000 cubic meters per hour or more. Despite the presence of vibration insulation of the ventilation sections, installation of volumetric modules requires a solid foundation.

Wall-mounted models are characterized by low productivity - up to 1500 cubic meters per hour and compact dimensions. Installation is carried out by anchoring to the wall, connecting the air ducts from above. The unit can be placed in a technical room (balcony, bathroom, dressing room).

The main advantage of hanging models is hidden installation. However, to install the unit in the room being used, you will have to partially “use” the height of the ceilings.

Basic parameters for choosing a ventilation unit

Arrangement and installation of ventilation systems requires capital investment and considerable labor costs. Therefore, the approach to choosing the “heart” of the ventilation system is based on accurate calculations and analysis of a number of parameters.

Evaluation and calculation of technical characteristics

First of all, you need to decide on the appropriate capacity and static pressure values.

Performance

The calculation of the installation is based on air exchange standards according to SNiP, the purpose of the room, the service area and the number of residents.

It is necessary to perform two calculations (by the number of people and the air exchange rate), compare the indicators and select the largest value.

An example of determining productivity (L) for a house under given conditions:

- number of family members – 3 people;

- house area – 70 sq.m;

- ceiling height – 3 m.

Formula 1. Calculation based on the number of residents:

L=N*norm,

Where:

- N – number of residents;

- norm – air flow (not less than 40 cubic meters/h).

L=3*40=120 cubic meters/hour.

Formula 2. Calculation by air exchange rate:

L=S*H*n,

Where:

- S - square;

- H - height;

- n – normalized air exchange rate.

L=70*3*1.5=315 cubic meters/hour.

Conclusion: to ensure sufficient air circulation, an installation with a capacity of at least 315 cubic meters per hour is required.

Typical indicators of ventilation units:

- 100-500 cubic meters/h – apartments and separate premises;

- 500-2000 cubic m/h – private households, cottages;

- 1000-10000 cubic m/h – industrial buildings, workshops, offices.

Static pressure

The value indicates the pressure created by the fan to provide resistance to the air circulation path. Accurate calculation of static pressure requires taking into account the resistance of all network elements.

“Manual” calculations are difficult to perform without appropriate experience. Specialists use a software package such as MagiCad.

The given data is relevant specifically for modular ventilation units, and not for kit systems, where the pressure drop on the air valve, air heater, filter and other components must be taken into account.

In addition to the indicated parameters, you should evaluate:

- Energy efficiency. For each of the possible models, it is necessary to calculate the cost of electricity for 1 year, taking into account the operating mode in winter and summer. The energy consumption class indicates the ratio of energy expended to the volume of heat produced.

- Recuperator efficiency. It is necessary to compare the efficiency values in different operating modes of the PES. Heat exchangers with a double plate cassette and an intermediate zone have a high efficiency indicator - efficiency reaches 70-90%.

- Heater power. The typical figure for household ventilation units is 3-5 kW.

It is better to give preference to models with the ability to automatically reduce the fan speed to adjust the load on the network.

Noise level and degree of filtration

Acoustic power shows how “loud” the assembled installation will be.

The sound effect is determined by two quantities:

- LwA – degree of acoustic power;

- LpA – sound pressure level.

The real “noisiness” should be assessed based on the first indicator. Different manufacturers may measure acoustic power using different methods, so the same values sometimes have different results in practice.

The quality of the incoming air depends on the type of cleaning systems.

Possible filtration stages:

- barrier against coarse street dust, wool and fluff - rough cleaning with G4, G3 filters with an efficiency of 90%;

- protection against fine dust of 1 micron – filtration class F7-F9;

- absolute cleaning, providing a barrier against particles of 0.3 microns - HEPA filters (H10-H14), efficiency - 99.5%.

For residential buildings, the first two cleaning steps are sufficient. Highly efficient filtration is used in medical institutions, premises for the production of medicines, food, and electronics.

Ease of use: necessary functionality

Household PVUs are equipped with a built-in automation system, a control panel, and an LCD display displaying all air exchange parameters. In addition to basic options (adjusting fan speed, temperature), practical functions are welcome.

Timer. Scenario management will allow you to optimize the operating mode for a certain time of day or day of the week.

Restart. The ability to automatically turn on and save set parameters in the event of a power failure.

Filter clogging indicator. A convenient option is notification about replacing the filter element. High-tech models are equipped with pressure change sensors at the air filter inlet - when dirty, the pressure drop increases.

Self-diagnosis. Any equipment breaks down over time. It is useful if the automation “notifies” about a malfunction - this will help to identify and fix the problem in a timely manner.

Conclusions and useful video on the topic

Energy-saving ventilation system with recovery suspended type Daikin VAM/800FB:

Design, features and installation technology of the portable supply and exhaust module Vents Micro 60/A3:

PVU 400 from Ventrum with an electric heater and rotary heat exchanger:

Ventilation arrangement using a supply and exhaust module is used in rooms of different purposes and sizes.

Ensuring high-quality air exchange depends on proper calculation and selection of climate control equipment. If you have doubts about your own abilities, then it is better to turn to professionals to determine the parameters and develop the project.

Do you have anything to add or have questions about choosing an air handling unit? You can leave comments on the publication and participate in the discussion of the material - the contact form is in the lower block.