Pipes for internal sewerage in the house: a comparative overview of modern types of pipes

The uninterrupted operation of the sewer system depends on the competent selection of components and correct installation of the network.Often home craftsmen install engineering systems on their own and are faced with the primary question: which sewer pipes in the house are better technically and financially.

We will help you sort out this difficult issue. The article we have proposed describes all types of pipes used, listing their positive and negative sides. The material is systematized to make it easier to compare product characteristics, service life, cost and application practice.

The content of the article:

Requirements for internal sewerage pipes

The sewer system of a house is a network of engineering communications designed to drain household waste from private and multi-storey buildings. The movement of waste occurs spontaneously according to gravitational laws. The entire communication complex includes internal and external pipeline networks.

Internal sewerage consists of plumbing fixtures, filter units for preliminary cleaning of drains, pipelines, risers, collectors and branch lines located within the house, sanitary fittings.

Operating conditions, technical parameters, prices of pipes for external and internal installation differ from each other. The sewer network in the house is not under heavy load and is used in gentle conditions - the pipeline is laid inside the building and covered with decorative panels.

Basic requirements for the intra-house drainage main:

- Strength. Despite the “lighter” operating conditions, the pipes must withstand mechanical loads and pressure from waste fluid flows.

- Bio- and heat resistance. The manufacturing material must be chemically inert to aggressive components (cleaning agents, etc.) contained in the discharged masses. Equally important is resistance to high temperatures.

- Smoothness. The absence of gaps in the internal coating of the pipe ensures unhindered movement of waste. Even minor roughness over time causes a reduction in the flow area and clogging of the sewer.

- Ease of installation. Light weight and ease of connection of individual elements make it easier to assemble the waste line.

An additional requirement is the compatibility of the internal pipeline with the sanitary facilities of the premises and elements of the external sewer network.

When choosing pipes for internal sewerage Three main criteria should be taken into account: material of manufacture, cross-section diameter and manufacturer. Let's take a closer look at each of the parameters.

Technical and operational characteristics of different pipes

The most popular are two categories of pipelines: cast iron and plastic modifications. Over the past ten years, cast iron pipes have given way to their polymer counterparts due to their anti-corrosion resistance, reliability and lightness.

Cast iron – durability and strength

The basis for the manufacture of cast iron pipes is iron ore. Some characteristics of the material correspond to the properties of steel, but due to the high oxygen content, cast iron products are characterized by increased wear resistance.

In the manufacture of sewer pipes, centrifugal and semi-continuous casting techniques are used. The first method allows you to cast “reinforcement” of any diameter, length and thickness. According to GOST, all outlet pipes are equipped with sockets.

Advantages of cast iron systems:

- high strength if installation rules are followed;

- environmental Safety;

- good noise insulation;

- wear resistance;

- maintaining shape throughout the entire service life;

- fire resistance;

- resistance to different temperatures, atmospheric changes, chemical reagents and mechanical factors.

In order to prevent the appearance of corrosive “plaque”, pipes and fittings mounted on them are treated from the inside with petroleum bitumen or coated with enamel. In addition, this measure somewhat smoothes out the roughness of the cast iron surface.

Despite strong arguments in favor of the traditional material, the high cost and labor-intensive installation work have caused a decline in demand for cast iron pipes.

Additional disadvantages:

- the presence of roughness that contributes to the appearance of deposits and blockages;

- susceptibility to pinpoint impacts.

To ensure complete sealing of the line, it is necessary to accurately adjust the linear dimensions of the connecting parts.

Polyvinyl chloride - practicality of use

Polyvinyl chloride is a thermoplastic polymer that is resistant to acidic compounds, solvents, alkaline substances and mineral oils. The operating temperature range ranges from -15°C to +66°C. Due to its technical properties, the material is used in the production of pipes for laying internal non-pressure sewerage.

Experts consider unplasticized polyphenyl chloride (viniplast), a type of PVC that has a more rigid structure, to be the most promising raw material for the production of sewer and water pipes.

Distinctive features of uPVC pipes:

- Duration of operation.Thanks to its resistance to corrosion processes and “indifference” to chemical reagents, the service life is tens of years.

- Lightweight pipeline. Due to its low specific density, the material has little weight, which facilitates and speeds up the assembly of the sewer line.

- Smoothness of the coating. An absolutely smooth inner surface, without any roughness, reduces the risk of pipeline clogging.

- Arrangement of complex paths. A wide selection of mounting elements simplifies the design and installation of intricate drainage lines.

- Affordable price compared to metal counterparts.

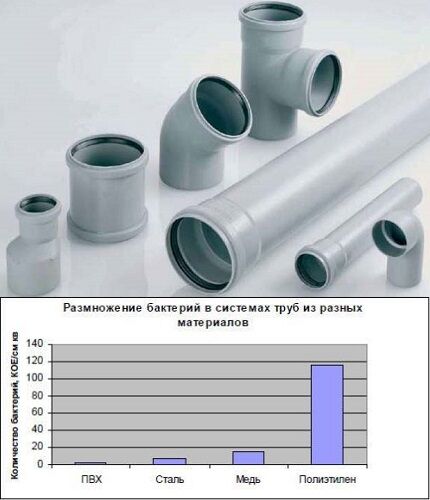

Compared to steel, copper and polyethylene pipes, PVC products are characterized by high physical and biological inertness.

It is convenient to reconstruct the PVC system if it is necessary to install additional plumbing and “tie in” the outlet pipe to the common riser.

When giving preference to PVC highways, you should take into account the following nuances:

- with prolonged exposure to high temperatures (70° and above), the plastic becomes brittle;

- concentrated organic solvents can “corrode” and change the structure of PVC.

PVC and UPVC fittings contain chlorine. When burned, plastic smokes and releases caustic toxic substances.

Polypropylene – resistance to negative influences

Polypropylene pipes are superior to polyvinyl chloride pipes in some respects. Advantages of PP products:

- The elasticity of the material explains the resistance of pipes to mechanical shocks - polypropylene is slightly deformed, maintaining integrity, and is restored to its original state.

- Contact with an acidic environment is acceptable. This quality increases their wear resistance and allows us to talk about the safe disposal of PP waste.

- High heat resistance. The permissible exposure temperature is up to +90°C; with a short-term increase to +100°C, the PP-main retains its declared qualities.

Frost resistance depends on raw material additives and the quality of pipe products. The range of indicators is within 10-50°C below zero.

The above characteristics are characteristic of products manufactured in accordance with GOST. Here the question of choosing a manufacturer will play a primary role.

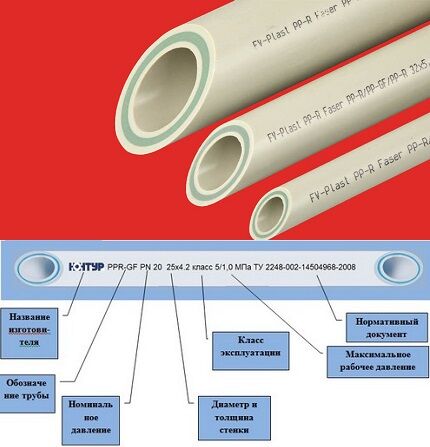

Basic information about the characteristics of a PP pipe can be found from its markings. The entire length of the product is knurled at intervals of 2-4 m.

The marking shows:

- brand name;

- type of raw material (B – block polymer, R – random copolymer, PP – polypropylene, H – homopolymer);

- outer diameter (10-1200 mm), wall thickness;

- permissible operating pressure.

It should be remembered that a thicker wall of the PP pipe must correspond to a high nominal pressure.

Polyethylene - flexibility and availability of the product

When wondering which pipe to use for indoor or apartment sewerage, you should pay attention to products made of polyethylene (PE). The material is formed during the polymerization of ethylene with the addition of catalysts.

Performance characteristics depend on the qualitative composition and reaction conditions (pressure and temperature). HDPE pipes are used for the sewer main.

Polyethylene obtained by polymerization of hydrocarbons under low pressure has the following characteristics:

- recommended operating temperature – no more than +40°С, short-term jumps up to +60°С are acceptable;

- the ability to expand by 5-7% of the original state explains the material’s flexibility and impact resistance;

- low thermal conductivity – the formation of condensate on the pipes is minimal;

- lack of reaction upon contact with transported waste of various origins (organic matter, chemical reagents).

Polyethylene pipes have many of the advantages of a “plastic pipeline”: low cost, corrosion resistance, lightness of the material and ease of assembly of the drainage utility network.

PE products are inferior to PP and PVC pipes in terms of wear resistance - with regular abrasive effects of littered waste, the polyethylene surface quickly wears out.

Steel – “rigidity” of the sewer line

Steel pipes provide strength and rigidity to the utility network. The material maintains the slope angles of the system and withstands high temperature loads.

However, the disadvantages of steel sewerage are more serious:

- susceptibility to rotting - when used to drain gray waste, painting or treatment with bitumen is required; applying a waterproofing layer reduces resistance to temperature effects from 700°C to 60°C;

- Pipe joining is done by threaded connections or welding - both methods make the steel more vulnerable to corrosion.

Steel mains are characterized by a high frequency of blockages - the diameter of the pipeline narrows due to the appearance of rusty deposits.

Alternative materials: asbestos cement and ceramics

Asbestos-cement and ceramic pipelines are rarely installed in private households and apartments. However, it is worth noting their technical and operational nuances.

Asbestos cement pipes are made from Portland cement and asbestos fibers. Due to the complexity of installation, limited standard sizes and low strength, their use in sewer system not relevant.

The technical parameters of ceramics are somewhat superior to the quality of cast iron pipes:

- corrosion resistance – 100%;

- immunity to alkaline, acidic compounds and other aggressive components;

- temperature resistance – ceramics can withstand temperatures of 1000°C or more;

- Dimensions – 15-60 cm, wall thickness – 19 mm.

Ceramic pipes are in little demand due to the high cost and difficulties of self-assembling a utility network.

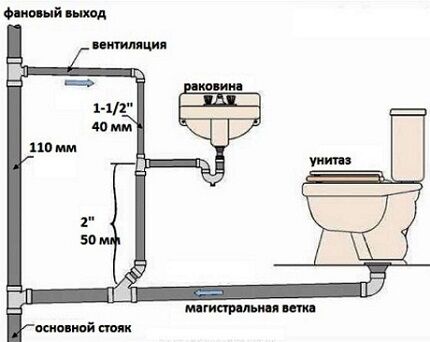

Choosing a diameter according to building codes

In contrast to cast iron products, a number of plastic shaped modifications are much richer. Manufacturers polymer pipes They produce products with a diameter from 16 mm to 6000 mm.

The need for a diverse range makes sense:

- the capabilities of pipeline engineering systems are expanding;

- The pipe size is selected taking into account certain tasks;

- it is possible to replace a section of the main line with a pipe with the smallest possible diameter - when laying a sewer system for a private house, this will reduce the budget for repair work.

The most popular standard sizes for the internal drainage network: 50/100/150 mm.

Scope of application of pipes based on the flow area:

- 16-25 mm – removal of uncontaminated liquid from ventilation units, air conditioners and dehumidifiers;

- from 32 mm – connection of a washbasin or sink used for washing conditionally clean dishes (glasses, wine glasses, etc.);

- from 40 mm – drain for a bathtub, shower, kitchen sink, dishwasher or washing machine;

- 50 mm or more – simultaneous connection of a shower and bathtub, laundry room;

- 60-75 mm – combined connection of three and five devices, respectively, with the exception of the toilet.

Dimensions are measured from the inside and reflect the nominal diameter of the line. Considering the wall thickness, the external size exceeds the internal size.

In addition to the diameter, when choosing polymer pipes you should pay attention to the following points:

Leading manufacturers of internal pipes

To determine which pipes are best to use for sewerage, you should compare the characteristics and prices of products from leading pipeline systems companies. The market leaders are the following companies: Rehay, Wavin, Ostendorf, Politek, Polytron and Corsis.

Rehay Raupiano – silent sewerage

The German company Rehay has developed multilayer pipes - Raupiano Plus.

Track record of merits:

- improved sound insulation – sound absorption efficiency increased by 30%;

- aesthetics - white pipes are suitable for various room designs;

- reliability - multi-layering provides protection against leaks, impacts and unpleasant odors;

- Flexibility – floor and wall installation possible.

Raupiano Plus - products for universal sewerage, compatible with adapters and pipe fittings from other manufacturers. To increase the heat resistance of polypropylene, the manufacturer suggests installing fire cuffs that block the spread of fire through the engineering system (sensor response temperature is 120°C).

Wavin – plastic piping systems

Wavin is a European leader (Netherlands) with forty years of experience in the manufacture of polymer pipes for water supply, sewerage, drainage and storm drainage, underground cable laying. The company has gained a reputation as an innovator and supplier of high-quality products.

Product Features:

- standard sizes – 32-110 mm;

- manufacturing raw materials – PP and PVC;

- thickness – 2.6 mm;

- pipes with a cross-section of 50 and 100 mm are produced in a double-socket design;

- temperature resistance: 75°C – constant contact, 95°C – short-term exposure;

- white and gray color.

Wavin Asto systems – premium segment sound-absorbing sewer. The wall thickness is 5.3 mm with a diameter of 110 mm. The thick pipe keeps noise out and suppresses acoustic vibrations. Thermal stability reaches 90-95°C.

Ostendorf HT – sound-absorbing polypropylene

Ostendorf (Germany) specializes in the production of pipes and fittings for sewerage installations.

Products with noise-reducing properties are made on the basis of polymer and mineral compounds.

Thanks to new technology, it was possible to improve acoustic qualities and strength. Product range - pipes with a cross-section of 50-200 mm, product length - up to 3 m.

Politek – domestically produced goods

The company specializes in the production of polymer pipeline components. The products meet European standards, each batch undergoes laboratory tests, the results of which are supported by a certificate.

Characteristics of internal sewage system Politek:

- increased ring strength due to the two-layer structure of the pipes;

- good temperature resistance – 70°C;

- models: pipes with and without socket;

- standard sizes: 32/40/50/110 mm, wall thickness – 1.8-2.7 mm.

Politek products are resistant to chemicals, therefore they are recommended for internal sewer lines in industrial sites, hospitals, laboratories and commercial buildings.

Conclusions and useful video on the topic

Video #1. Comparison of sewer pipes intended for the construction of external and internal sewage networks:

Video #2. Evaluation of the effectiveness of silent sewage systems Raupiano and Skolan:

From the point of view of financial benefit and practicality, polypropylene pipes are the optimal choice for organizing the internal part of the sewer system.The PP pipeline is affordable, easy to implement and guarantees uninterrupted long-term operation of the new engineering system.

Please write comments in the block below. Tell us about what pipes were used to repair the sewer system in an apartment or to install a system in a country house. Ask questions, share useful information, post photos related to the topic of the article.

The house was built about twelve years ago, and there wasn’t much variety then. The sewer system was made from whatever we found. We mainly have cast iron pipes, but since it took a long time to build, polypropylene products began to appear. That's why we have a hybrid sewer system. But sometimes you want to replace cast iron pipes with a polymer version. True, there have never been any failures or blockages. I decided that the best is the enemy of the good.

Several years ago I replaced the old Radian sewer system in the house with new pipes. Oh, and then I had to sweat. There was an option to connect old pipes with new ones, so as not to break everything and everyone, but I refused it. It’s better to do it once, but for many years. Moreover, the apartment is old; no one has changed anything in it since the times of the USSR. I installed polyethylene pipes because they are inexpensive and, in my opinion, of high quality. I am more than satisfied with the work done - there are no blockages, the water drains quickly and without problems.

For the production of HDPE pipes (low-density polyethylene), recycled materials are used, so the quality leaves much to be desired. In my opinion, it is better to choose other types of polymer. They are more reliable.

Hello! Why is a polyethylene pipeline more susceptible to bacterial colonies than PVC pipes?

Hello. It's all about the structure of the material itself. Ordinary polyethylene has average biological stability. This material itself is not susceptible to the influence of microorganisms, but exposure to UV radiation activates the proliferation of microorganisms in the pipeline. Therefore, it is necessary to protect the PE pipeline from direct sunlight.

As for polyvinyl chloride, its biological resistance is below average, this is caused by the rough structure of the pipeline, which contributes to the formation of deposits. In fact, this becomes a favorable environment in which microorganisms will develop. At the same time, PVC pipes show high resistance to ultraviolet radiation.

I am attaching a table with comparative characteristics of pipes made of different materials. Resistance to the effects of biological organisms below (B - high, C - medium, H - low).