Plastic ventilation pipes for hoods: types, their characteristics, application

Organizing effective ventilation in a house is not a whim of the owner, but a necessity dictated by sanitary standards. To install such a system, plastic ventilation pipes for exhaust hoods are increasingly being chosen as the simplest, most productive and relatively inexpensive option.

The article we present is devoted to the construction of air channels from plastic ventilation parts. We will tell you how to select components to assemble the system and how to assemble it flawlessly. Here you will learn what devices should be equipped with ventilation for stable operation.

The content of the article:

Advantages and types of plastic pipes

These lightweight products, in addition to ease of installation, are distinguished by a host of other advantages: environmental friendliness, resistance to the negative effects of ultraviolet radiation, durability, low specific gravity, high resistance to aggressive environments, a large range of sizes and a relatively low cost.

The disadvantage is the low threshold of temperature stability, which does not allow their use in industrial conditions. They are ideal for a private home.

There are products of different lengths and diameters on the construction market. There is a length limit for PVC pipelines - 3 m minimum and 12 m maximum. Their diameter ranges from 1.6 to 160 cm. For a cottage, the optimal cross-section of the exhaust pipe is 15 x 15 cm.

An important fact is that the inner surface of PVC pipes is treated with an antistatic agent, which is why almost no dust settles in them, thereby extending the frequency of air duct maintenance.

Based on the type of section, there are 2 types of plastic pipes:

- round;

- rectangular.

Round pipes also include corrugated varieties, with the help of which air duct turns are conveniently, quickly and efficiently.

From an aesthetic point of view, a rectangular cross-section is preferable, but when the room has a small area, a pipe with a circular cross-section is more suitable, because in this case there are no protruding parts.

The markings on the square pipe make it possible to determine whether the rectangular cross-section corresponds to a similar round air channel.

In a country house with gas heating, the combustion products of the boiler are removed through an exhaust pipe exiting through the roof. The main enemy of the structure is condensation, which appears when the temperature drops in the autumn-winter period.

It does not destroy the plastic pipe itself. However, moisture flowing along its walls can cause significant damage to the building, so the plastic air duct at the outlet must be insulated.

Plastic pipes are contraindicated for hoods installed in baths and saunas, for chimneys and fireplaces, and solid fuel boilers. If you still use them in these places, then you need to lay pipes from this material only outside. In this case, they will have to be well insulated from the cold.

Details about choosing exhaust pipes, made of polymer materials, is described in the article we recommend.

Rigid polymer products

By choosing a plastic pipe to install the hood, you don’t have to worry about the harmful effects of corrosion and internal cleaning of the ventilation system. Passing through a smooth surface, the air flow does not encounter obstacles in its path and does not create much noise. To ensure that the air duct does not stand out against the background of the wall, the PVC pipe for the hood in the kitchen is laid above the cabinets.

In a pipe with a smooth inner surface, there are no stepped bulges or relief differences that accumulate fatty deposits and dirt. This greatly facilitates the maintenance of the exhaust structure. During installation, L-shaped adapters and sealant are used.

Corrugated flexible options

Pave corrugated plastic pipe for exhaust can be used in places where other pipes cannot be used. Thanks to its exceptional plasticity, it can be bent as conditions require.If access to the ventilation shaft is at a certain distance from the slab, then using a corrugated air duct is the most rational solution.

Their installation does not require any welding equipment, a large number of connecting elements, or special supporting structures. The disadvantages are the same as those of flat plastic pipes - complete unsuitability in high-temperature conditions. You can add to the list of disadvantages increased noise during operation of the exhaust system.

There are several types of corrugated pipes, but the most commonly used for hood devices are:

- Single-layer, with increased flexibility and low weight.

- Two-layer with high strength characteristics. They are also mechanically and chemically stable.

They are made from the same raw materials as other types of plastic pipes. The products have recesses on their surface located at equal intervals from each other. Corrugated 2-layer polypropylene pipes have a smooth inner surface and a diameter from 16 to 63 cm.

To produce them, manufacturers use the method of screw extrusion with the formation of corrugations over the entire outer surface. In places of depressions, the layer located inside the pipe is welded.

The strength of corrugated pipes is several times higher than that of smooth pipes. They produce corrugated elements for the construction of hoods with varying degrees of rigidity. This parameter depends on the presence of thickening on individual rings.

Brief overview of materials

The range of pipes, both flexible and rigid, is very large, it is not difficult to work with them, so they are highly appreciated by consumers. They are confidently displacing steel analogues from the sphere of private construction.

For their production, polymers such as polypropylene (PN), polyvinyl chloride (PVC), polyurethane (PPU), fluoroplastic (PVDF) are used. PVC pipes are in greatest demand.

Dismantling PVC pipes

This inert polymer has sufficient rigidity. Its elasticity is increased by introducing plasticizers into the composition. Its glass transition temperature is quite high - 75⁰С.

Under normal conditions, the decomposition of the material takes decades, but at temperatures from 160 to 180⁰ C it begins to deteriorate very quickly. Because of this, it cannot be used for ventilation in rooms such as saunas, where the steam temperature sometimes reaches 200⁰.

When the material decomposes, carbon monoxide (CO) is released, the inhalation of which is accompanied by suffocation, hydrogen chloride (HCl), which in an environment with high humidity forms hydrochloric acid - an invisible liquid that makes itself known with a pungent odor.

The compound has a very negative effect on health, in particular on the condition of the respiratory tract. In severe cases, vision may deteriorate sharply.

From this we can conclude: PVC pipe is excellent for kitchen hood, but only in those places if the temperature threshold does not exceed +120⁰С. Negative temperatures are also contraindicated for these pipes.

Polypropylene ventilation pipes

Polypropylene is a durable polymer, the hardest of plastics and easily transformable. Its softening occurs at 140⁰С. Polypropylene does not withstand negative temperatures well - it immediately becomes brittle and brittle, therefore it is only suitable for internal use.

For the hood device take polypropylene pipes with designation PN10. This type is characterized by such dimensions as outer diameter - 2-11 cm, wall thickness - 0.19-1 cm.

Pipes made from polypropylene are single-layer and multi-layer.

The first include products marked:

- RPH - made of homopropylene;

- PPV - the material for production is a block copolymer of polypropylene;

- PPR - made from a statistical copolymer of polypropylene;

- PPs - low-flammable material was used in manufacturing.

Multilayer pipes are reinforced with foil and fiberglass. They have increased rigidity and a low coefficient of thermal expansion. Products made from polypropylene are less strong than PVC, so they have thicker walls and are more expensive.

Polyurethane ventilation pipes

The characteristics of polyurethane pipes are in many ways similar to those of PVC pipes. They are plastic and wear-resistant, they can be given any shape.

The main difference is the ability to remain unchanged until the temperature reaches 280⁰C. When this threshold value is exceeded, polyurethane becomes very hazardous to health because it releases nitrogen compounds.

They are used in areas with complex trajectories, many turns and shifts. The aerodynamic characteristics of these pipes are somewhat reduced by the presence of roughness on their inner surface. The cost of such pipes is quite high.

Characteristics of fluoroplastic pipes

Pipes made of this material have high strength characteristics. They have proven themselves well in the temperature range from -40 dl +140⁰С. Fluoroplastic is recognized as the most slippery polymer; this fact is even recorded in the Guinness Book.

They are resistant to aggressive alkaline and acidic vapors, therefore they are indispensable for exhaust systems in chemical industrial plants.The diameter of the products ranges from 15 to 60 cm.

Due to their high cost, it is irrational to use them in the private sector. Another limitation for their use is their increased gas permeability.

Plastic ventilation from sewer pipes

Experts often argue whether it is possible to make a plastic hood from sewer pipes. Opponents of this idea cite an argument such as the lack of antistatic coating in these products, as a result of which their internal surface is not protected from the deposition of dust and dirt. Proponents say the problem will be solved by doing the procedure yourself.

The undeniable advantage of pipes for sewerage installations is that their price compared to plastic air ducts is 3 times lower. The disadvantages of these pipes and special ventilation products are common - loss of rigidity at high temperatures.

When using pipes intended for sewer construction as a supply air duct, sometimes a characteristic plastic smell is felt, but after a while it disappears. The pipes also differ in their weight, which is slightly greater than that of air ducts. For them it is necessary to provide fastening.

Polymer air duct device

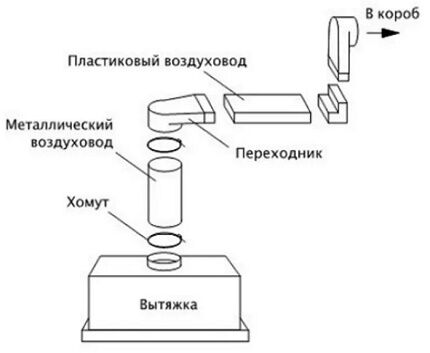

When installing an air duct, it is important to follow several rules:

- The length of the pipe should not exceed 3 m, otherwise the efficiency of the device will decrease.

- The diameter of the hole through which the pipe is connected to the ventilation shaft cannot be larger than the diameter of the pipe.

- The pipe should not be bent more than 90⁰. This will disrupt the normal flow of air outflow.

4. Special valves must be used to prevent backdraft. - An adapter must be installed at the transition point from the hood to the ventilation shaft.

This option is not recommended for implementation when the stove and the hood above it are on the side opposite the exit to the ventilation shaft. At the same time, the length of the pipes and the number of turns will increase significantly, which will reduce the efficiency of the hood to a minimum.

An important parameter when installing a hood is the diameter of the pipe. If it turns out that it is smaller than the size of the outlet, the load on the motor of the hood itself will increase, and the noise level will increase to an uncomfortable level. This will be followed by breakdowns and additional repair costs.

Air ducts are always hidden.For this purpose, decorative boxes are installed and the structure is built into the furniture. An acceptable option is to install the pipeline above a suspended ceiling. The main thing is not to violate any of the safety rules.

If it is necessary to connect pipes having different sections, bends, special connectors, and adapters are used. The internal surface of these elements must correspond to the external parameters of the air duct. The pipe segment is inserted into the connector and the seal is ensured by using an appropriate sealant.

There is a socket type installation connection. It is used when joining pipes of different sections. A smaller diameter pipe is inserted into the wider end of the pipe. Fixation occurs using a thread or a special rubber seal.

Let's look at the standard sequence of assembling an exhaust air duct from plastic pipes:

The role of the check valve in the system

Presence in the system check valves will prevent air from entering the room from the ventilation duct. To avoid popping noises, it is necessary to install the valve axis perpendicular to the floor. The damper can only open when the hood is running.

Among the variety of similar products, 3 types of valves are most often chosen:

- Reverse petal. This is a series of blinds oriented vertically or horizontally when not in use. They open when the forced exhaust is turned on. Typically, walls with inlet openings are chosen for their installation.

- Turning. This is a simple mechanism that regulates the intensity of the flow or blocks it completely. It is made in the form of a block with a valve located on an axis and controlled using a system of counterweights and rods manually or using automation.

- Bivalve "butterfly". The body of this product contains an axis on which there are two dampers. When the fan is turned on, the dampers open; when the fan is turned off, they return to their original position.

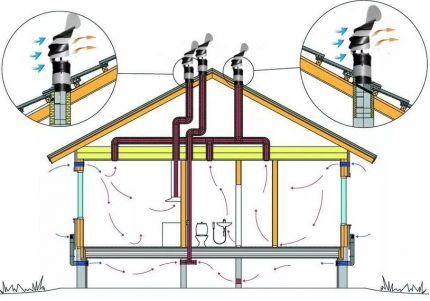

Often, by connecting the exhaust structure to the ventilation duct, they completely block the path of clean outside air entering the building. Then, when the hood is not working, the room is not ventilated at all.

To prevent this from happening, a special grill must be installed on the opening of the ventilation shaft. At the top of it there is a pipe for connecting the exhaust pipe and at the bottom there are holes through which air flows naturally.

Plastic ventilation pipes for hoods for both geysers and stoves are sometimes sold complete with the hood itself. The components of such a system are selected according to color and texture, so you don’t have to think about how to disguise or refine the pipes.

Conclusions and useful video on the topic

Video #1. A well-thought-out kitchen hood option:

Video #2. Here's everything about installing plastic air ducts with a rectangular cross-section:

Video #3. About the advantages of plastic air ducts and their installation:

The best type of pipes for inhalation are long plastic round products.Although the rectangular profile looks more aesthetically pleasing, it provokes increased resistance in the ventilation system, leading to equipment overload.

Please write comments in the block below. Express your own opinion, share your impressions of the information we offer. Perhaps you assembled a plastic air duct with your own hands? Tell us about it, post a photo of the process. Report new options for installing ventilation ducts.

Such a duct system and hood were ordered from a specialized company. They also ordered installation work there, the workers installed it quite successfully, it turned out quite beautiful and stylish. And most importantly, environmentally friendly! I believe that such ventilation options can be recommended to everyone, without any doubt about their reliability. By the way, at first they wanted to buy from stainless steel, but the price turned out to be very, very high.

Our kitchen is not in the house, but in a summer extension. When installing the ventilation duct from the hood, I installed corrugated pipes. Of course, it was risky, since everyone advised installing ordinary plastic round pipes. But I didn't regret it. Ventilation works well. There is no overload on the operation of the hood and the system. But if I spent it in the house, I don’t know, would the air be sucked in as well as in the summer kitchen?