Hood for the kitchen with an air duct: how to arrange a hood in the kitchen with and without a duct

The issue of arranging ventilation is relevant among owners of apartments and private households.After all, you immediately have to not only decide on the scheme, create a project, but also implement it by performing installation work. Agree, it would be nice to arrange everything yourself, saving on calling a specialist.

But you don't know where to start and how to act correctly? We will try to help - this article discusses the options for installing a hood and their features. So, one of the simplest solutions is a kitchen hood with an air duct. If you wish, it is easy to arrange it with your own hands, having studied in detail all the nuances given in this material before starting work.

The article is also supplemented with photo selections of step-by-step assembly, installation and connection of the exhaust device. For a better understanding of the material presented, videos on the manufacture of air ducts and connecting hoods have been selected.

The content of the article:

Features and rules for choosing a hood

In the kitchen, the hood serves not only as one of the elements of the ventilation system. Often it is an independent detail of the interior, a certain accent or the final chord of the chosen style solution for a particular room.

In order for it to function perfectly and delight you with its impeccable appearance, you have to choose the right option.

Types of kitchen designs

The variety of shapes, sizes, additional functions and significant price range makes it difficult to choose. First of all, you should understand that a hood is equipment designed to remove exhaust air from a room that contains particles of grease, dust and an unpleasant odor.

For example, when the owner of a home is frying chops and wants to protect the rest of the family from this overly intrusive smell, he will turn on the exhaust equipment. If the aroma of coffee is in the room, then you can do without it.

Model specifications

It is important that the hood is designed for such loads and can successfully remove pungent and unpleasant odors in full. This is provided by the purchase device of the required power.

When choosing equipment, you must carefully study the technical specifications specified by the manufacturer in the accompanying documentation.

A suitable option should remove exhaust air in a volume that is 3 times the volume of the kitchen. For example, if the room area is 12 m2, and the ceiling height is 2.7 m, then its volume is 12 * 2.7 = 32.4 m3.

To cope with its main function, the hood must remove at least 32.4*3+20%=117 m3. A margin of 20% is needed to ensure that the device does not constantly work at the limit of its strength. Otherwise, such work will quickly disable it.

Preferred installation type

According to the type of installation, all hoods can be divided into:

- built-in;

- open.

The first type of equipment is built-in hood - has a more modest appearance. They are installed inside cabinets or other kitchen furniture. When not in use they are practically invisible.

The second type - open hoods - can have the most intricate shapes and sizes. Their cost can be shocking, especially if it is a designer model that exists in a single copy.

Kitchen hood shape

Depending on the shape of the product, the following hoods are distinguished:

- corner;

- island;

- wall-mounted

The latter do not require installation of an air duct with subsequent connection to the ventilation shaft of the house. This is a hood option without venting.

Their design provides for the presence of several types of filters, including carbon filter, fat type filter device and others that provide local air purification rather than removing it from the room.

All other hood options require a ventilation duct. Based on the size, material used and cost of the product, you can always choose the most suitable option, taking into account the wishes and financial capabilities of the owner of the house/apartment.

Guidelines and nuances of choice

In order for the hood to be a beautiful and useful part of the kitchen interior, you need to choose a successful model. To do this, you need to choose a product from a manufacturer that has a good reputation.

The price does not have to be high, the main thing is that all quality documents, instructions for use and warranty are available from the seller.Otherwise, it is better to look at another option.

An ideal hood should perform the following functions:

- remove odors efficiently;

- create a minimum of noise;

- look aesthetically pleasing;

- fit harmoniously into the interior.

The main purpose of this element of the ventilation system is to remove exhaust air. No matter how beautiful and perfect its design is, failure to fulfill its main task makes such a hood a useless trinket. To prevent this from happening, when purchasing, special attention should be paid to power.

If the hood is correctly installed and connected, then it does not make loud noise. If errors were made during the installation process, the wrong parts were selected, and the power of the device itself does not meet the required standard, then you should prepare for a high noise level - 50 decibels or more.

The main problem is to harmoniously fit the purchased hood into the existing kitchen interior. Especially when the ventilation hole is located at a considerable distance from its location.

This is where it comes to the rescue box construction for laying an air duct from the hood to the entrance to the ventilation shaft of the house.

It is important to give the box and hood an aesthetic appearance upon completion of installation work. This applies to both purchased equipment and home-made structures.

Specifics of arranging a kitchen hood

To install a kitchen hood, in addition to the equipment itself, additional materials will be required - an air duct and fasteners for it, a box and fasteners for its installation.

It is advisable to immediately purchase other consumables necessary for connection. It is more convenient when all the components are of the same brand, this will ensure a complete match in color and size.

Subtleties of choosing and installing air ducts

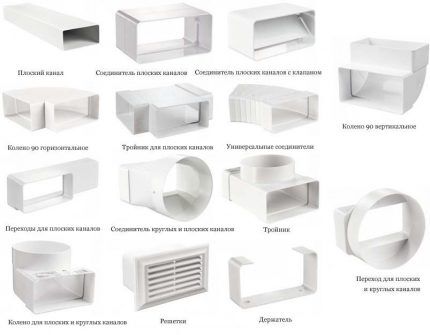

Among the air ducts offered in hardware stores, you can find the following:

- corrugated polymer;

- aluminum corrugation;

- corrugation made of stainless or galvanized steel;

- plastic round pipe;

- plastic rectangular air duct.

The most used for arranging household ventilation are: aluminum corrugation and plastic pipes of rectangular and round cross-section.

This is explained by the ease of installation, which even an inexperienced home craftsman can handle.

Some inexpensive models of hoods come complete with plastic corrugation. Whether to use it or not depends on the type and size of the slab over which the exhaust equipment will be installed.

If the kitchen has a gas stove, then craftsmen prefer to buy a good metal corrugation from a reliable manufacturer instead of the plastic included in the kit.

To install a household ventilation duct, you should choose a quality product. If the foil corrugation is too delicate and thin, it can tear due to careless handling during installation.

A metal corrugated pipe fits harmoniously into some interiors without the need to come up with options for its disguise.Although most often it has to be hidden in every possible way so as not to disturb the harmony of the kitchen space.

The corrugation is easy to install - you just need to attach one end to the pipe of the hood itself, and insert the other into the grille of the ventilation shaft.

For fastening, clamps, aluminum tape, and sealant are used.

Round and rectangular plastic pipes look more aesthetically pleasing. They do not bend in different directions. Their installation is also not difficult - all parts are attached to each other, like a construction set.

Special adapters are purchased for connection. It is inconvenient that the turns here will be sharper and not smooth, as is the case with a corrugated pipe.

For your kitchen, you should choose exactly the option that will fit more harmoniously into the interior. If your budget involves using a very small amount to purchase an air duct, then you can buy inexpensive aluminum corrugation and skillfully disguise it.

It is worth paying attention that the required footage of the corrugated pipe is measured in stretched form. And the required length of the plastic smooth pipe should be accurately measured at home, taking into account that the turns will be clear.

You should immediately buy all adapters for pipes and preferably from the same manufacturer.

Another important point when purchasing a ventilation duct is selecting the correct diameter recommended by the hood manufacturer. A smaller or larger pipe size will contribute to poor equipment performance. It is also best to purchase all fasteners from the same company.

Equipment installation options

When the hood and all additional parts have been purchased, all that remains is to install it and connect to the ventilation system.

There are 2 options for carrying out this type of work:

- with your own hands;

- by the hands of a professional.

Each option has its pros and cons.

The sequence of work on constructing a hood with a flexible air duct will be demonstrated by a selection of photos:

If you trust the masters, you will have to pay a decent amount for their services.

Moreover, it makes no sense to call a cheap team - they may turn out to be extremely bad specialists who can ruin expensive equipment.

The first option is more reliable if the home craftsman has some experience in repair or construction work. When the owner does everything with his own hands, he knows what is placed and where.

Also, no one will deceive himself - all work will be done efficiently. Just need to carefully study the instructions so as not to lose the warranty on the hood.

When performing work on your own, the following are important:

- safety;

- correct connection;

- great appearance.

To ensure the safety of the installed element of the ventilation system, it is necessary to strictly follow the instructions and recommendations of the manufacturer.After all, each hood model has its own characteristics.

The materials used in manufacturing also differ - stainless steel can withstand higher temperatures than plastic.

To connect the kitchen hood to the ventilation yourself, you must first attach it. For this, the manufacturer's recommendations contained in the instruction manual will be useful.

Each type of hood has its own installation features. For example, for built-in models you will have to cut a hole in the bottom of the kitchen cabinet, while dome models are attached to the wall with the fasteners included in the kit.

Having installed the hood, you will need to attach an air duct to it, the second end of which will be attached to the entrance to the ventilation shaft of the house. It wouldn’t hurt to install it right away and check valve.

The duration and complexity of subsequent work depends on the type of air duct used to connect the kitchen hood to the ventilation system.

If the selected ventilation duct does not fit the overall style composition, then it will have to be disguised. For these purposes, special boxes are used.

Such products can not only hide the air duct, but also decorate the kitchen space. But their installation may require significant strength and skills from the master.

Types and nuances of installation of ventilation ducts

To mask individual elements of ventilation equipment, you can purchase a special box.Most often, you need to hide an air duct that stands out from the overall picture.

It is for this component of kitchen ventilation that you can build a box with your own hands. Which option is appropriate in a particular room is up to its owner to decide.

Depending on the material of manufacture, you can buy the following box options:

- plastic;

- aluminum;

- stainless steel;

- wooden.

Next, let's look at the features of each of the options mentioned.

Features of the use of plastic

Plastic pipes used as an air duct are often called a duct. Due to their clear geometric shape, they do not require the use of any additional masking material.

Unless the desired shade is available for sale, they can be painted with moisture-proof and heat-resistant paint. This move will allow the ventilation duct to become inconspicuous.

Exhaust ducts made of metal

Metal boxes are an expensive solution. They are connected to each other in the same way as plastic ones, using adapters.

But due to their greater weight, they require more reliable fixation along the route of the ventilation duct.

Wooden box structure

A wooden exhaust duct gives a special atmosphere to the room. Such products should be used in wooden houses, where all pieces of furniture are simple and made from environmentally friendly materials.

For an apartment, the use of wooden boxes is also acceptable, the main thing is that the style of the kitchen design matches.

Making a plasterboard box

Another material used to make the box is drywall. It is used by craftsmen who prefer to make a structure for the ventilation duct with their own hands.

Typically, such a box is puttied, primed and painted in a suitable color. Lighting is immediately built into it at the installation stage.

This distracts attention, giving the room an unusual look due to the two-level ceiling and additional light sources.

Installation of a hood without a duct

A kitchen hood with an air duct can be installed without using a duct.

This happens in the following cases:

- the mine is located nearby;

- use of suspended ceiling;

- hood without duct;

- rectangular/round plastic pipes.

To disguise the hood itself, a kitchen cabinet is sometimes used.

The best location for the hood is under the hole in the ventilation shaft. In this case, the corrugation can be covered with a beautiful hood casing.

If a suspended ceiling is installed in the kitchen, then all the exhaust system structures will be well hidden under it.The main thing is to warn the craftsmen who will be working on the ceiling about this.

When a hood without a ventilation duct is installed in the kitchen, there is no need for a duct. In the case of using plastic pipes as an air duct with a rectangular or round cross-section, it is quite possible to do without a duct.

Conclusions and useful video on the topic

Step-by-step video on assembling an air duct for a kitchen hood from rectangular plastic pipes with a cross-section of 60x120:

A visual video tutorial on how to make a duct for an air duct that imitates a two-level ceiling. For greater effectiveness, it is equipped with decorative lighting:

A short video about the features of installing plastic air ducts:

Video instructions for installing the hood:

Having studied the features of installing a hood and its connection to the ventilation shaft of the house, you can choose the most suitable option for your kitchen.

In cases where the budget is limited, all work on installing the hood, air duct and duct can be done with your own hands. You can select all the components of a kitchen ventilation system in an inexpensive price range.

Have you installed a kitchen hood yourself and connected the air duct to the ventilation system? Or maybe you have experience in making an original air duct box? Share your knowledge with newcomers to this business - leave comments on this article.

If the hood is powerful, then when operating at full power, sound interference is inevitable. Even if the noise is small at first, it will increase over time.It is important to choose the correct area of the hood: it must cover at least 80% of the area of the stove. The distance between the hood and the electric stove should be within 65-75 cm. For a gas stove, the distance should be 70-85 cm. Do not forget to install a check valve in the hood duct, otherwise odors from neighbors will circulate through the ventilation and will inevitably enter your room.

We recently moved to a new house: a new building with 24 floors that has just been completed. We’ve already planned how we’ll design the hood, looked at the model... and then it turns out that in our house it’s supposedly impossible to vent the hood into the ventilation duct! This, it turns out, is not provided for by the design features, and the management company can even fine you for this! To be honest, I’m in slight shock - how can this be? Could it be that the ventilation shafts in the kitchen were not initially designed to connect hoods?

Good day, Natalia. You have provided too little input.

I can assume that you have a gas heater or boiler installed in your kitchen. Most likely the apartments come with autonomous heating. For safety reasons, in this case the ventilation hole must remain open. If carbon monoxide leaks, natural ventilation will remove it from the room.

One option is to choose a recirculating hood. You can find out more details here. The nuances of the operation of coal hoods in this article.

Of course, ventilation shafts are not intended for connecting hoods.

I deliberately refused to use a box hood in my kitchen.Firstly, this complicates the design, and secondly, such a hood, due to the presence of a ventilation duct in the design, collects a larger amount of carcinogen, which it draws in.

Arranging a hood without a duct was simpler from an engineering point of view. On my own behalf, I will add that, in fact, the best location of the hood is not at all important. Is it located directly under the hole in the ventilation shaft or is it offset relative to it? The modern design of the hood and its ventilation power make it possible to install the hood without rigidly binding its position relative to the position of the shaft ventilation hole.