How to make a ventilation passage through the roof: arranging a roof penetration

Bringing the pipe to the roof - this task at first glance does not seem particularly difficult.But in practice, everything is much more complicated: the ventilation passage through the roof must be carried out very carefully and in compliance with all technical requirements. After all, the integrity of the roofing pie must be preserved and sealing must be ensured.

We will tell you how to install a roof penetration in accordance with building codes. In the article we presented, two options are discussed: for a hard and soft type of coating. With our advice, you can do the job perfectly with your own hands.

The content of the article:

Passage requirements

Of course, in the place where a ventilation or any other pipe passes through the roof, it is necessary to ensure sufficient tightness so that moisture does not enter the building. At the same time, this unit should not prevent precipitation from draining from the roof surface. Another important point is the presence of reliable thermal insulation.

The top of the pipe should be protected from moisture penetration using a deflector. There are certain requirements for the length of the ventilation pipe to ensure sufficient draft inside the structure, although they are not as strict as the standards for chimneys.

Air exchange through ventilation is often provided forcibly, using an exhaust fan, which is also installed near the transition unit. This mechanism should also be reliably protected from the effects of precipitation and other natural factors. In addition, it is imperative to ensure that the electrical appliance is grounded.

Improper installation of this unit often causes poor removal of sediment from the surface, which can quickly lead to damage to the roofing material. The ventilation duct of an apartment building can cause a lot of trouble if it opens onto the roof across the slope.

It is much better if the knot is located along the slope, so it will create fewer obstacles to the flow of water. The optimal position is considered to be the location of a large transition unit along the ridge. This option eliminates the need to install additional elements that reduce the resistance of the ventilation pipe to the convergence of precipitation.

A serious installation error is considered to be the position in which the front apron ends up under the roofing sheet. An apron is a structure that ensures a tight fit of the roof to the walls of the pipe. If the lower part of the apron is placed under the roof, water will flow into the gap, entering the roofing pie and then into the attic space.

The absence of a thermal insulation layer contributes to the appearance of a temperature difference, which contributes to the formation of condensation on the surface of ventilation pipes. Over time, this situation can lead to damage to the construction material, the formation of mold, oxides, rusty deposits, etc.

Older ventilation ducts usually have what's known as a “drip,” a thickening that allows heated air to cool slightly before escaping onto the roof. As a result, the temperature difference between the air and roof communications will be smaller, which will reduce the likelihood of condensation.

In modern houses, aprons are used, with the help of which the gap between the pipe and the roof is completely sealed. The cuts for installing aprons are formed using a grinder. Insulation of metal and plastic pipes can be done using mineral wool or other suitable material.

Sometimes a wooden or metal box is used for these purposes. Designing ventilation system, you should immediately consider the option of arranging a passage through the roof. Experts note that it is much easier to remove a pipe with a rectangular or square cross-section than a round structure.

To ensure a sufficiently tight connection of the ventilation pipe to the roofing material, a square sleeve is usually used, which is placed on top of the pipe. It is filled with non-flammable material, mainly sand or fine expanded clay, which is why this structure is called a “sandbox”.

Ventilation above the roof should be installed to a height equal to the height chimney pipes. This is necessary to ensure stable traction. This value depends on the distance of the chimney from the ridge fin.

The passage unit must be securely fastened to all roof elements. It is worth paying attention to the distance between the edge of the pipe and the one fixed above it. deflector. It should be so large that the air masses passing through the ventilation duct can move freely.

Carrying out work on hard roofing

To arrange the passage of a ventilation duct through a roof covered with rigid roofing materials (tiles, slate, corrugated sheets, etc.), a square sandbox-type structure is used, the gaps around which are filled with non-flammable heat-insulating material.

A small flange should be made on it to protect the thermal insulation from contact with moisture that gets directly onto the pipe. Around the metal rectangular sleeve it is necessary to install four apron parts, which will ultimately cover the line where the pipe joins the roof on all sides.

First, install the bottom part, then install the side parts, after which you can place the apron element on top. The horizontal part of the apron part, located above the rest, should be placed under the roofing material. The rest, i.e. side and bottom elements are mounted on top of the roof.

A tie is a long roofing gutter that must be provided by the roof structure.Quite often, when installing a ventilation passage assembly, it is possible to do without such an element. To clarify this point, it is recommended to consult an experienced roofer.

You can purchase a ready-made apron, but this design is easy to make yourself. For this purpose, galvanized roofing sheet 0.5 mm thick is used. It is not advisable to use thicker roofing material as it will be more difficult to bend to the desired shape.

But thin sheet metal should not be used for these purposes either, since it is not reliable enough. The size of the apron must correspond to the wave size of the material used for the roof.

To install the transition unit under metal tiles, the vertical part of the apron is made as long as two roofing waves, and the horizontal part is made as long as three times the wave length.

These dimensions are designed to create a sufficiently large overlap of the apron on the horizontal plane of the pipe and the inclined plane of the coating to prevent even accidental splashes from getting under the roofing material. Aprons are also mounted with an overlap of the element installed on top onto the part located below.

It is considered optimal to overlap elements equal to the width of one of them, but such a position is not always achievable. Thus, the overlap of the top and side elements of the apron will be hidden under the roofing material, making it difficult to install the parts in the correct position.

But with the overlap of the lower and side parts of the apron there is no such problem; it is recommended to accurately maintain the required dimensions.If necessary, the dimensions of the apron parts after installation can be adjusted using metal scissors.

Beading should only be done for the top and side elements. For the lower one, such adjustment is not necessary, since the moisture from it flows onto the roof slope and, possibly, onto the tie.

This element can be installed on top of the roof to optimize moisture removal. In such a situation, a slight bend should be made on the lower part of the apron towards the tie.

In addition, you will need a bottom flange. If the installation of a tie is not provided for by the design, then the lower flange on the apron is not needed, but the outlet for moisture should be made larger.

Arrangement of a transition on a soft roof

Roofing structures for soft roofing have some features that are reflected in the order of installation of the ventilation passage. The slopes on such a roof are usually made with a slope of 12º and above.

Piece roofing material is not suitable for low-slope structures, because differs in a large number of joints and seams. Arrangement of a passage unit in a pitched roof must be thought out at the stage ventilation designto choose the best option.

Before starting work on installing the ventilation passage, you should find out in which direction the roof is tilted.If a passage unit is installed on a hard roof before the roofing work begins, then in this situation you must first roll out the main area of the roofing carpet.

After this, a thermal unit is made and thermal insulation materials are installed. Further actions depend on the shape of the roof penetration assembly. For an element with a round cross-section, you will need to install only two parts, but a square configuration unit is mounted using four components.

Instead of the hard aprons that were described above, here you will need pieces of fused roofing material. They are fixed to the roof and to the passage unit. The fastening process begins from the bottom, then from the middle to the edges, after which the upper part of the lining is fastened.

The individual elements are installed in a similar way: first the bottom, then the side ones, and the installation is completed by securing the top plate. Of course, all these parts must have some overlap, but the requirements for its size are not as strict as when installing a passage under hard roofing material.

Flows of atmospheric water are removed from a pitched roof quickly and regularly, so significant overlap is not necessary in this situation. But the slow rate of winter precipitation on the roof can create another problem. At the joints, the roofing material may delaminate due to prolonged contact with moisture.

To prevent such a situation, you should pay special attention to the quality of installation of flexible roofing and strictly comply with all the requirements of the installation technology. To put it simply, the roofing sheet should be properly heated and pressed firmly. In this case, you can use the slamming technique or use a special roller for rolling the shingles.

Slam down the sheet using a mitten containing a leather insert. The roller is more suitable for working on thin roofing materials. If multilayer material is used, installation of a large assembly is usually performed using two-layer overlays.

For a small element, you can only use one layer. A round passage of small diameter is decorated with two large overlays with a horizontally bent “skirt”.

First, install the lower element, then the upper one. During the installation process, the sheet of heated material must be slightly pulled up to ensure reliable coverage of the ventilation communication and the necessary overlap.

Features of installation of a standard design

Units for penetration of ventilation communications of industrial production are carried out in accordance with the requirements of GOST-15150. It is believed that the air temperature inside the communication pipe should not exceed 80 degrees, and the humidity of the flow should be within 60%.

To calculate the passage unit, you should take into account such indicators as the slope angle of the slope and the distance from the element to the roof ridge.

A typical transition unit can be made in the following variations:

- with or without condensate ring;

- with insulated or regular valve or without valve;

- with manual or mechanical control for valve;

- with or without spark protection, etc.

The options listed may vary depending on the situation. For example, there is no need to install a mechanical valve if the system is stable and does not need constant adjustment. It is also possible to manufacture a penetration unit to order.

Structures of this type are made of polymers, stainless steel with a thickness of 0.5-0.8 mm and black steel with a thickness of 1.5-2 mm. The cross-section of the finished transition unit can be round, oval, square or rectangular. The specific model is selected depending on the type of roofing material and the parameters of the ventilation pipe.

Although foreign-made passage units are usually of high quality, they are not always adapted for local climatic conditions, so it does not hurt to carefully study the proposals of domestic manufacturers.

They are usually labeled as follows:

- the letters UP with an index from 1 to 10 indicate a design without a capacitor ring and valve;

- indexes from 2 to 10 indicate devices with a manual valve, there is no ring;

- The designation UPZ is assigned to devices with a special platform for the actuator for the valve, which is provided for by the design.

Complete models of transition units include embedded bolts and nuts that are attached to wooden structures and reinforced concrete cups intended for installation.Mineral wool is successfully used for thermal insulation, which is recommended to be protected with a layer of fiberglass.

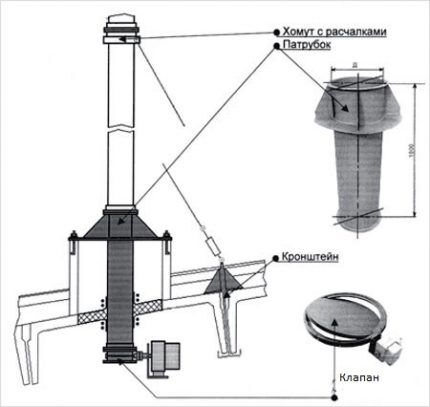

If it is necessary to install a ventilation unit with a safety valve, you should pay attention to the pipe intended for it. A valve must be attached to the bottom flange of this element. The upper flange is designed to fix the position of the air duct. Clamps and brackets are used as fasteners for braces.

To further protect the ventilation riser from moisture, you need to use a skirt. The condensate collector is welded to the pipe.

It is designed to remove moisture from air masses that move along the ventilation duct. To control the valve, a mechanical unit is used, which should be installed on the shelf intended for it.

This element should not be installed next to the condensate collection ring in order to maintain the integrity of all elements of the penetration. Typical models of units are usually installed before the start of roofing work: first, the air ducts of the ventilation system are installed, then the passage, and the roof is installed after that.

It is recommended that upon completion of the work, seal all joints, including the junction of the assembly elements with the roofing.

To do this you should:

- clean the surfaces of the pipe and roof from contamination;

- seal the lower part of the air duct and the adjacent area of the roof with foil paper;

- fill the holes with sealing compound.

These measures will help protect the penetration from moisture and create additional thermal insulation of the structure.

Our recommended specialist will familiarize you with the rules for installing the ventilation system itself. article, in which the nuances of design and organization are analyzed in detail.

Conclusions and useful video on the topic

A video demonstrating the installation of a ventilation pipe passage through a roofing system allows you to get an idea of the features of this type of work:

Installing this important element is not too difficult. But it is necessary to strictly comply with the requirements of the installation technology in order to prevent moisture retention on the roof surface and its penetration under the coating.

Tell us about how you arranged the passage of the ventilation pipe through the attic and the roofing pie with your own hands. It is possible that you know technological subtleties that will be useful to site visitors. Please write comments in the block below, post photos and ask questions on the topic.

From my experience I will say that it doesn’t seem difficult to arrange proper ventilation in your home. But when I installed the pipe and brought it outside, having previously sealed the passage through the roof, there was no effect. The neighbor advised to increase the length of the pipe as much as possible. I thought about it and realized that his statement was wrong. I started looking for literature on this issue. Found this information. Everything in it is described in detail and step by step. I started doing it based on the description. No pipe enlargement was required. I carefully carried out the sealing and installed the fan. Everything became normal. This is what a smart recommendation means.

I have a wave slate roof. Therefore, sealing the ventilation pipe is a big problem. In fact, some leaks are still detected periodically. Maybe someone can tell me a 100% way, if one exists. And another problem in winter is a large amount of snow on the roof.I have to clean it off closer to spring, otherwise I’m afraid the falling snow will break the pipe.