Water flow switch: device, principle of operation + instructions for connecting

Taking good care of the equipment that supplies water significantly extends its service life and guarantees uninterrupted operation of the system. This requires not only timely inspection and proper care, but also equipping the pumps with a full set of protection devices. Preventing the possibility of a serious breakdown is much cheaper than repairing or buying a new unit. Do you agree?

Installing a water flow switch will protect the motor of both surface and deep-well pumping equipment. After all, most often when the motor burns out, it is easier to buy a new pump than to change it. We will tell you how this important protective device works, how to choose it and include it in an autonomous water supply.

The article provides valuable recommendations for installing devices to protect pumps from operating in “dry running” conditions. The technology of customization for individual requirements has been analyzed. For a better understanding of the considerable amount of information, photographs, diagrams, video reviews and manuals are attached.

The content of the article:

Functional purpose of the flow switch

In household water supply systems, the action of a pumping station without water quite often occurs and threatens an accident. This problem is called “dry running”.

As a rule, the liquid cools and lubricates the elements of the system, thereby ensuring its normal operation.Even short-term dry operation leads to deformation of individual parts, overheating and failure of the equipment motor. Negative consequences apply to both surface and deep-well pump models.

Dry running occurs for various reasons:

- incorrect choice of pump capacity;

- unsuccessful installation;

- violation of the integrity of the water pipe;

- low fluid pressure and lack of control over its level, for which they use pressure switch;

- accumulated debris in the pumping pipe.

An automatic sensor is necessary in order to completely protect the device from the threats posed by a lack of water. It measures, controls and maintains constant water flow parameters.

The main purpose of the relay is to independently turn off the pumping station when the liquid flow is insufficient and turn it on after normalization of the indicators.

Design and operating principle

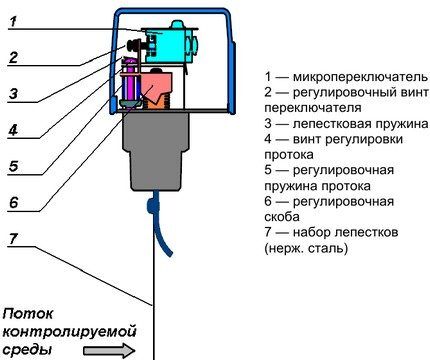

The sensor has a unique device, thanks to which it performs its direct functions. The most common modification is the paddle relay.

The classic building scheme includes the following important elements:

- an inlet pipe that passes water through the device;

- valve (petal) located on the wall of the inner chamber;

- an isolated reed switch that opens and closes the power supply circuit;

- springs of a certain diameter with varying degrees of compression.

While the chamber is filled with liquid, the force of the flow begins to act on the valve, moving it around its axis.

A magnet built into the back of the petal comes close to the reed switch. As a result, the contacts close, turning on the pump.

When the flow of fluid stops and the pressure in the system drops below normal, the compression of the spring weakens, returning the valve to its original position. Moving away, the magnetic element ceases to operate, the contacts open and the pumping station stops.

Some modifications are equipped with a return magnet instead of springs. Judging by user reviews, they are less susceptible to minor pressure surges in the system.

Depending on the design solution, several more types of relays are distinguished. These include rotary devices equipped with a paddle wheel rotating in a water flow. The speed of rotation of the blade in them is controlled by touch sensors. If there is liquid in the pipe, the mechanism deflects, closing the contacts.

There is also a thermal relay that operates according to thermodynamic principles.The device compares the temperature set on the sensors with the temperature of the working medium in the system.

If there is flow, a thermal change is detected, after which the electrical contacts are connected to the pump. If there is no water movement, the microswitch disconnects the contacts. Models thermal relays They are characterized by high sensitivity, but they are quite expensive.

Device selection criteria

When choosing equipment that controls the force of water flow, you should carefully study its technical characteristics.

Particular attention should be paid to the operating temperature and pressure range for which it is designed, the diameter of the threads and mounting holes, the protection class, and application nuances. It is also important to clarify what materials the product is made from.

When considering different modifications of the relay, it makes sense to purchase a version made of metal. The housing and working components of such devices are highly durable.

This fact allows the equipment to withstand for a long time serious loads arising due to significant pressure in the water supply from the side of the liquid passing through the sensor.

The pressure value at which the relay operates must correspond to the power of the installed pump. The parameters of the water flow circulating through the pipeline depend on this characteristic.

It is advisable to choose a device with two springs that controls the operation of the pumping station according to certain lower and upper pressure marks.

Another important criterion that deserves special mention is the climatic conditions necessary for the operation of the product. This refers to the recommended air temperature and humidity level that the device needs to provide in order for it to perform at its best.

The maximum permissible load for a particular device is determined by the protection class specified in the technical specifications.

When purchasing a flow sensor, you should check the thread diameter and the dimensions of the mounting holes in the equipment: they must fit perfectly with the pipeline elements. The correctness and accuracy of further installation, as well as the efficiency of the relay after installation, depend on this.

Trusted Instruments

Among the entire range of relays, the two models that are in approximately the same price category are in greatest demand - about $30. Let's take a closer look at their characteristics.

Genyo Lowara Genyo 8A

Development of a Polish company engaged in the production of electronic equipment for control systems. Designed for use in domestic water supply systems.

The main purpose is to control the pump and control the pressure in the pipes during operation.This sensor starts the pump when the water flow exceeds 1.6 liters per minute. It consumes 2.4 kW of electricity. Operating temperature range – from 5 to 60 degrees.

Grundfos UPA 120

Manufactured in factories in Romania and China. Maintains stable water supply in premises equipped with individual water supply systems. Prevents pumping units from idling.

The device’s automation starts at a liquid flow rate of 1.5 liters in one minute. The limit parameter of the temperature range covered is 60 degrees. The unit is manufactured in compact linear dimensions, which greatly facilitates the installation process.

Recommendations for installation and configuration

Liquid flow relays are installed for devices that require constant control and compliance with a certain operating mode. Often they are equipped with equipment at the production stage. However, there are also circumstances when a separate installation of the sensor is required.

Rules for installing relays in the system

Installing a safety device that detects the presence or absence of water flow in the system is a reasonable step in cases where it is not possible to be present while the pumping equipment is operating.

It is not required only in two cases:

- Water is pumped from a large well with unlimited resources by a low-power pump.

- It is possible to independently turn off the installation when the water level drops below the designated norm.

The device is installed on horizontal sections of the pipeline.In this case, you need to ensure that the membrane assumes a stable vertical position.

The device is mounted to the drain pipeline using a threaded coupling. Usually a special socket is provided for this.

Before you start directly screwing the device, it is advisable to seal the threads well with flax or thread, sold in specialized departments.

It is better to wind it clockwise towards the end. This method of fastening increases the reliability of fixation.

When installing a factory sensor, you need to focus on the arrow shown on the body. The direction indicated on it must coincide with the direction of flow of the liquid passing through the device.

If contaminated water is transported through the pipeline, it is recommended to install cleaning filters, placing them near the sensor. Such a move will ensure the correct operation of the product.

At the final stage of installation work, the dry-running relay is connected to the electrical network:

- a wire core is screwed to the free ends of the two groups of contacts;

- a ground connection is attached to the sensor screw;

- the device is connected to the pump by connecting two devices with a regular wire in compliance with colors veins.

After connecting to the network, all that remains is to check the functionality of the system.The fact that the device is ready for full operation will be indicated by an increase in pressure marks on the pressure gauge and the automatic shutdown of the pump when the limit value is exceeded.

Self-adjustment procedure

For adjustment, the sensor has special bolts. By loosening or tightening them, you can reduce or increase the compression force of the spring.

This sets the pressure level at which the device will operate.

In most cases, setting up automatic equipment is not difficult.

It is advisable to adhere to the following algorithm:

- drain the liquid from the system until the pressure mark reaches zero;

- turn on the pumping unit and slowly let the water back in;

- record the flow pressure indicator when the pump is turned off with a sensor;

- start draining again and remember the indicators at which the pumping equipment will start working;

- open the relay and use the adjusting bolt to set the minimum level of compression of the larger spring required to activate the device and start the pump (more compression increases the degree of pressure, less - reduces it);

- in a similar way, adjust the compression force of a smaller spring mechanism, setting the limits of the maximum pressure, upon reaching which the relay measuring the water flow will turn off the pump.

Having completed all the described manipulations, you should make sure that the adjustments made are correct.To do this, the pipeline is filled with liquid and then drained, assessing the sensor’s response when the set values are reached.

If the test result is unsatisfactory, the procedure is repeated.

To ensure that the pipeline through which the liquid passes works properly and stably, regular annual checks of the flow sensors are carried out. If necessary, the operating parameters are adjusted.

Conclusions and useful video on the topic

Structure, components and operating principles:

The process of connecting a device in stages:

Learn more about how to adjust the trigger level in a relay:

A relay that controls the flow of water in the pipeline will significantly increase the ease of use of pumps and will extend their service life for a long time. It is highly undesirable to neglect the installation of a safety device, since it not only automates the operation of the equipment, but also protects it to the maximum from possible problems that occur due to idling.

Do you want to install the flow switch yourself, but are a little confused about the instructions? Please ask your questions, and we and our website visitors will try to help you.

Or maybe you have successfully completed the installation and configuration of the device and want to give useful recommendations to other beginners? Write your comments in the block below, add photos of the installation or setup process - your experience will be useful to many home craftsmen.

There is a well in the garden, a vibration pump “Typhoon” and a hose. For now I’m thinking of adapting this only for watering. But which model to choose a flow switch, and is there a need for it at all in this case? Is it believed that the best option is a spade type relay with a reed switch? Or maybe it’s easier to buy a pump with a float switch and not complicate the whole thing?

We installed a pump in the well and placed a water flow relay near the pump in the house, although in principle the additional booster pump in the house has its own similar device. We think it’s in vain, but we decided that it wouldn’t hurt. The foreman who supervised the installation of our water supply and heating systems was not against it either. We had sewerage before and it was done simply. The wastewater is discharged directly into the sewer well.