Heating in a wooden house: a comparative review of suitable systems for a wooden house

Until recently, heating in a wooden house was organized using a brick stove. It was this that was the main source of heat and was almost the main place inside the building.

Today everything has changed a lot. Thanks to the active development of technology, any owner of a wooden house will be able to implement a heating system that will satisfy all his needs. The main thing is to know what to choose and what nuances to pay attention to.

The content of the article:

Types of heating systems

First of all, the house can be heated using an autonomous structure with forced or gravitational (natural) coolant circulation. Each of these methods has its own advantages and disadvantages. In addition, there are situations when it is better to use one or another variety.

Advantages and disadvantages of natural circulation

Gravity pumping is entirely based on the laws of physics. More precisely, the coolant moves through the pipeline due to the difference in weight between cooled and heated water.

A hot liquid has a much larger volume, but much less mass.Accordingly, it rises up the riser, moves further through pipes that are laid at an angle, and is pumped into heating radiators, where it is cooled.

The list of advantages of such a solution should include ease of installation. A system with natural circulation lasts much longer and is stable. At the same time, the absence of a pump allows you to get rid of excess noise and ensure independence from the availability of electricity.

As for the disadvantages, this kind of solution can only be used when heating a small house. In addition, the system requires laying large-diameter pipes, which significantly increases the cost of organizing a home heating system.

Distinctive features of pumping systems

To make water move faster through the pipes, the heating system is cut into circulation pump. With its help, you can move the media with virtually no loss of temperature. As a result, a wooden building warms up much faster, which saves a considerable amount of fuel.

The main advantage of forced circulation is that the area of the heated house can be practically unlimited. At the same time, the owner is given the opportunity to control the amount of heat and the speed of the pump. The disadvantages of this solution are the dependence of the system on the availability of electricity and the high noise level of the equipment.

Types of thermal media

To transfer heat from the generator to the heated room, water is most often used, which has been heated to a certain temperature and circulates through a pipeline.

Today this is the most affordable and simple solution. Right calculating the number of radiators And boiler power, you can organize a high-performance system that does not require any special care.

In addition to water heating, in a private wooden house the following is used:

A combination option is also often used. A well-designed scheme makes it possible, without spending a lot of money, to build a system that will completely warm up the house in a matter of hours.

Criteria for choosing a heat generator

There is simply a huge selection on the market - domestic and foreign manufacturers offer a wide variety of models. From such an assortment, a buyer with any income level will be able to choose something for himself.

In order not to make a mistake when buying a boiler, you need to check what type of fuel is most available in the region. It is also important to correctly calculate the power of the equipment.

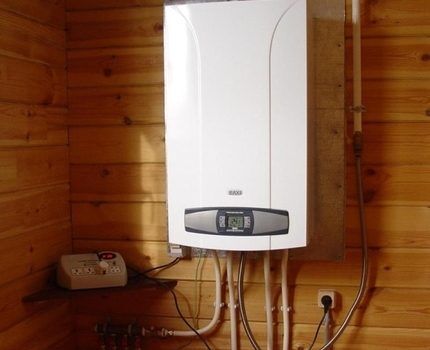

Advantages of gas units

The vast majority of owners of wooden houses opt for gas equipment.

Popularity of wall and floor-standing gas boilers This is due to the fact that such fuel is one of the cheapest in many countries.In addition, with its help you can organize a completely autonomous and maintenance-free heating system.

The list of advantages of gas boilers needs to be supplemented:

- High efficiency. Even a low-power device generates more heat than its counterparts running on other types of fuel.

- Easy to use. No need to worry about where the fuel will be stored. At the same time, using such equipment is easy - you only need to set it up once.

- Durability. A high-quality gas unit will last at least 15 years.

The main disadvantage is the need to obtain special permission to install it. All other disadvantages are completely offset by advantages.

Diesel component in the system

Diesel-powered equipment has become increasingly popular over the past few years. First of all, liquid fuel boilers cheap to maintain and easy to install.

At the same time, there is no need to organize a complex chimney design - many models run on light heating oil. The only thing required is to organize the pipe outlet in the form of a sandwich. It has a special turbine that pushes out air.

If you have decided to install a diesel boiler, you need to understand that this heating method will be expensive. After all, the efficiency of this equipment varies from 75 to 85%, which is a rather low figure.

Also, a diesel-powered unit requires constant monitoring. If it is left for at least a week, it will lead to problems.Indeed, due to the low quality of fuel, the equipment may stop. As a result, the water in the pipes will freeze and burst.

Solid fuel boiler

This type of equipment is as popular as gas equipment. Great demand is due to the efficiency and environmental friendliness of solid fuel boilers. After all, such a device is the cheapest device to operate. At the same time, it burns renewable fuel and is highly energy efficient.

There is an impressive selection on the market solid fuel boilers. Savings in this matter are not always justified - if you decide to buy the cheapest model, you need to be prepared for the appearance of soot, soot and come to terms with the need for frequent cleaning.

Electric heat generator

Equipment that uses current in its operation is the only solution for those regions where centralized communication systems are not installed. Most often it is used as an additional option.

Today manufacturers offer a wide range of electric boilers. Models with power from 6 to 30 kW are available on the market. Such a wide range of performance allows you to order the device for a wooden house of any size.

Advantages of the equipment:

- small dimensions;

- operational safety;

- complete autonomy;

- cheapness;

- Efficiency approaching 100%.

But keep in mind that electricity is the most expensive energy carrier. Therefore, even despite the low cost of the unit, operating such a system will be expensive.

Power calculation rules

To determine the optimal performance of the boiler, it is not at all necessary to seek help from a specialist. To do this, you only need to determine the amount of heat loss. Knowing this value, it must be multiplied by the area of the house and the resulting number will be the required power.

If the building is not insulated in any way, then heating one square meter will require from 130 to 200 W. For buildings with old windows and a facade that is covered with material that does not allow cold to pass through, the optimal value would be 90-120 W/m2.

As for houses with good thermal insulation of attic and basement floors, plastic double-glazed windows, insulated doorways, properly arranged air exchange, then 50-80 W/m will be enough to heat them2.

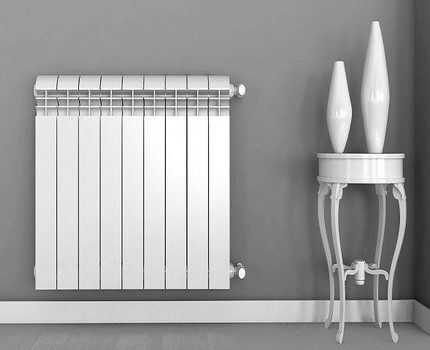

Subtleties of radiator selection

Radiators are one of the most important components of the system. After all, they distribute heat throughout the living area. Therefore, their choice should be taken with full responsibility, and not buy the first product you come across.

Batteries are divided into categories depending on their design and the material from which they are made. Since a wide assortment can drive an unprepared buyer into a dead end, before going to the store it is necessary to understand the advantages and disadvantages of each type.

Aesthetics of aluminum structures

Such products appeared in Italy more than 35 years ago. Since its invention aluminum radiators heating systems immediately became popular and won the recognition of professionals.

And this is not at all surprising, because these structures are distinguished by their lightness, high heat transfer, and attractive design. But they are poorly resistant to corrosion and are susceptible to airing.

Aluminum batteries can be cast or extruded. The first type is a monolithic structure, and the second is a blank formed by a press, from which finished products are subsequently cut.

Cast structures are considered more reliable and durable. In other respects, their analogues are in no way inferior to them.

Panel steel radiators

Steel is an excellent heat conductor. Therefore, batteries made from it are considered the most effective and are recommended for installation by all specialists. In addition, they are a monolithic structure, which greatly simplifies installation.

Subject to use steel radiators in a house or country house with an autonomous heating system they have no disadvantages. If all recommendations are followed, the service life can reach 30 years.

Good old cast iron

Cast iron radiators were first used more than a century ago.But even today they have not lost their relevance and are actively installed in heating systems.

The reason for this is its ease of maintenance and simply enormous service life - cast iron will faithfully last for about 50 years. At the same time, it retains heat well. The products take a long time to heat up, but after turning off the heating they will heat the room for a long time.

Taking into account all its advantages cast iron appliances They have only one minor drawback - they are heavy. Thus, the weight of one section can reach 6 kg, and the weight of the entire battery can be 36 kg.

Tubular radiators made of steel

Tubular batteries, as a rule, are classified as products in the highest price segment. They fully comply with all quality standards and have a number of advantages over their analogues.

First of all, such structures can easily withstand sudden changes in pressure, and in the event of a heat cut, the battery will not become air-filled.

Also, tubular radiators have a smooth surface both outside and inside. Thanks to this, they have an attractive appearance, due to which they will harmoniously fit into any interior.

Modern bimetallic structures

These types of batteries are made from an alloy of aluminum and steel. These metals have completely different characteristics, and as a result of their combination, a material with excellent performance is obtained.

More precisely, these radiators show high thermal conductivity and can easily withstand water hammer.Provided quality assembly bimetallic products serve for about 50 years. But they are quite expensive.

Built-in floor convectors

This heating device is a tube made of copper and aluminum through which the coolant moves. Main advantage floor convectors - this is an opportunity to build them directly into the floor.

In this case, the structure does not take up precious residential square meters, but at the same time warms the building well. The only thing that comes out is the decorative grille or panel.

If installation is carried out incorrectly, drafts may form inside the room. In addition, you need to carefully monitor the cleanliness of the heating element - air flows carry dust well.

Heating system piping

The main task of the pipes is to transfer the coolant from the boiler to the radiators. There are many types of them - they are divided into categories depending on the material.

Pipelines are:

- polymer;

- steel;

- copper.

The latter variety is resistant to high temperatures and high pressure. Currently, copper pipes are the most reliable and safe. Thanks to this, they can be hidden in the wall. But they are quite expensive.

Nowadays, heating pipelines are most often assembled from metal-plastic or polypropylene products. They are characterized by ease of installation and resistance to corrosion.The elements are connected to each other using soldering. Their disadvantage is their low hydraulic resistance.

Drawing up a heating scheme

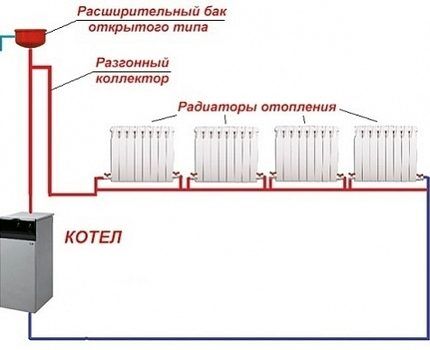

Since water is predominantly used as a heat carrier, the schemes discussed below will be based on this factor. The essence of this kind of heating system for a wooden house is that the liquid is heated in a boiler and passes through pipes into radiators, where it is cooled. Next, the water returns to the heat source.

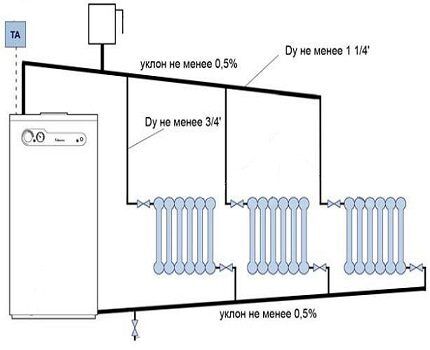

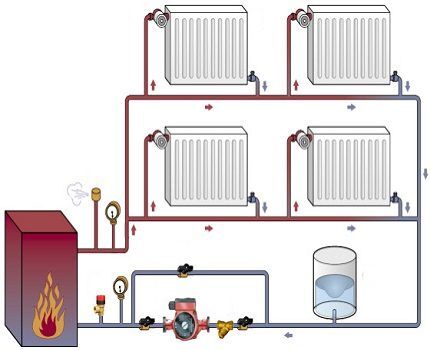

Installation of a one-pipe system

The choice of scheme largely depends on whether a system with gravity or forced coolant pumping is used. In addition, when drawing up a project, you need to take into account the number of circuits.

The advantage of creating one heating circuit is ease of installation. If you stick to the plan, you can quickly get the job done without involving a professional.

The single-pipe system allows you to save plumbing fittings. And in order to maximally equalize the temperature throughout the entire circuit, it is necessary to increase the number of radiator sections that are connected at the end. To speed up the water flow, it is recommended to install a pump.

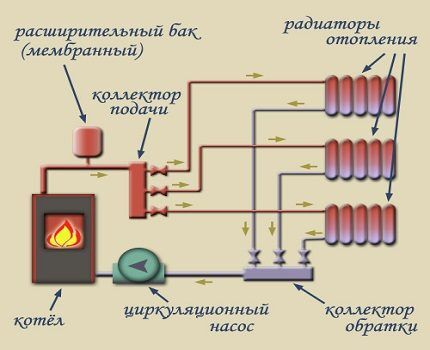

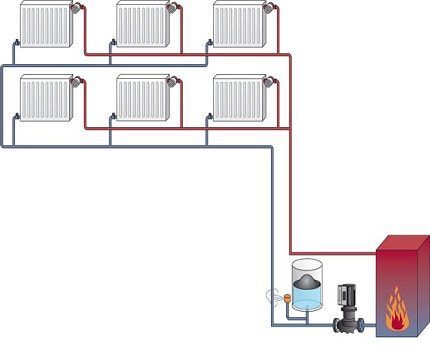

Subtleties of organizing two-pipe heating

A system with two circuits allows you to maintain the same temperature in all radiators, which will have a beneficial effect on heating efficiency. The disadvantage of this solution is the high consumption of materials.

When implementing a two-pipe project, each radiator must be equipped with shut-off valves. Such elements will allow you to adjust the temperature in each room.

If the boiler will be installed in the basement, then the best choice is a system with bottom wiring (the diagram is presented below). This solution is ideal for wooden houses where a gas boiler is used as a heat generator.

Conclusions and useful video on the topic

Video #1. Organization of a simple inexpensive boiler room:

Video #2. Heating a wooden house with an area of 120 m2:

Video #3. Nuances of pipeline laying:

The heating system is the heart of any home. Therefore, the owner of the building is faced with the task of competently designing and correctly installing such an important element. If you put in a little effort and take into account all the tips given above, then installing a heating system will not cause any connection difficulties or operational problems.

Tell us about how you built a heating circuit in your own wooden dacha or in your permanent home. Share useful information that may be useful to site visitors. Please write comments, post photos, ask questions in the block below.

My family and I live in a wooden house on the second floor.Naturally, there is no water or central heating. For a long time we warmed the apartment by heating the stove, then we purchased ordinary fan heaters, but since they only heat the air, and the floor remains cold, walking on it is not very pleasant. Overly complex heating systems, in my opinion, require huge financial costs, and will also add unnecessary problems with circuit development, installation and other inconveniences. I think the best option is a combination of underfloor heating and conventional heaters. If the apartment is small, I think this will be enough.

At my dacha (wooden house) there is a floor-standing gas boiler made by Czech Dakon, I don’t know any problems with it. It warms up 200 square meters calmly, with a reserve. And it wasn't that expensive. The radiators are ordinary, aluminum. Of course, it would be nice to also have a heated floor, but installation seems too complicated. At home you can still get confused, but for the dacha, perhaps not.