Floor-standing gas heating boilers: types, how to choose, review of the best brands

Russia is one of the countries with a very harsh climate. In most of its territory, winters are very cold.Having heating in homes is vital. Practice shows that one of the best options for organizing heating of a building is the use of gas as fuel, and the most popular are floor-standing gas units.

We will talk about what floor-standing gas heating boilers are. From the article we present, you will learn how the equipment operates and what it needs for stable, trouble-free operation. In order to facilitate the selection of the optimal model, we analyze the main criteria and characteristics of the best options.

The content of the article:

Why choose floor-standing boilers?

Manufacturers of gas boilers produce a variety of modifications of heating devices. All of them can be divided into floor and wall devices.

The latter are compact and have good performance characteristics. And yet, many people prefer floor-standing equipment, which is explained by its significant advantages.

The advantages of floor-standing boilers include:

- More power. The design of the devices is such that they are capable of delivering much more power than their wall-mounted counterparts.

- Availability of non-volatile models capable of permanently or temporarily working with coolant moving without the use of a pump.

- Durability and reliability of equipment. A properly selected and installed boiler, subject to proper operation, can operate for 50 years or more.

- Cost-effective and easy to use. Floor-standing boilers, unlike wall-mounted ones, are most often produced without built-in automation and additional equipment. This significantly simplifies the maintenance of devices, their repair and extends their service life.

Of course, the use of floor-standing equipment also involves some inconveniences and limitations. These include the mandatory presence of a separate room - equipped boiler room, in which the boiler should be placed.

There are a number of requirements for such premises, each of them must be strictly observed. Otherwise, it will not be possible to obtain permission to install and launch gas equipment.

The dimensions of the furnace or boiler room are selected so that not only the boiler, but also all the necessary additional equipment can fit freely. SNiP requirements are also taken into account.

The need for combustion equipment increases the cost of installing the boiler. In addition, you will also need to install a chimney, prepare the floor, etc. Accordingly, the cost of installing a floor-standing boiler will be much higher than a wall-mounted one.

Types of floor heating devices

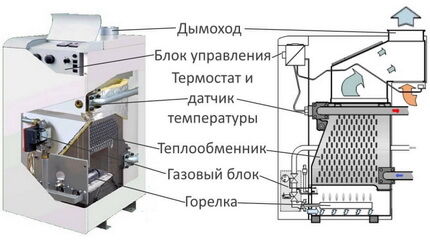

Boilers can be classified according to a variety of criteria. Let's look at the main characteristics that affect the quality of operation of devices.

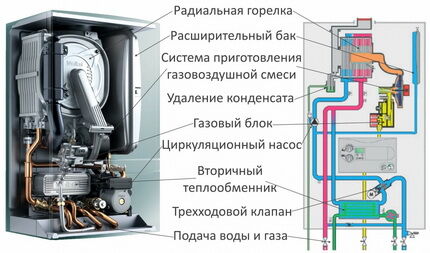

Number of circuits in the device

The boiler can have one or two operating circuits built into it. In the first case, the device will only heat the coolant, that is, function as a heating device.

Such equipment is equipped with one heat exchanger, which significantly simplifies its design and reduces its size. True, the latter also depends on the power of the device. If single-circuit equipment is installed, you will need to purchase an additional unit to heat the water.

In this case, you can add additional indirect heating boiler, for example, or any other device. Single-circuit boilers are chosen for heating objects that do not require hot water supply or for large houses, where all the power of the device will be used to heat the building.

Double-circuit models are capable of simultaneously heating the coolant and heating water for domestic needs. IN double-circuit boilers two heat exchangers are built in, which significantly complicates the design.

There are models with a so-called bithermic heat exchanger, which is divided into segments. The coolant moves through one of them, and the heating water moves through the other. Such devices are as compact as possible, but less reliable and easy to use.

The best option can be considered units with two completely separate heat exchangers. They form less scale. In addition, the circuits are separated, so there is no need to shut off the heating segment when distributing hot water. Whereas in boilers with a bithermic heat exchanger this is exactly what happens.

Double-circuit boilers are optimally used for small residential buildings. In large areas, mandatory separation of circuits is required, which is due to safety requirements, lack of total power, etc.

Combustion chamber type

Heating boilers can be equipped with an open or closed chamber. In the first option, only natural draft is used to operate the unit.

This assumes that the oxygen necessary for the combustion process enters the chamber from the room in which the device is installed. The boiler independently, without the help of any additional equipment, takes in the amount of air necessary for its operation.

Thus, the room must have effective ventilation. In addition, for normal operation of a boiler of this type, it is necessary to install full chimney vertical type, which will provide normal traction. The advantages of boilers with such a chamber include energy independence and relatively low cost, but they produce less power.

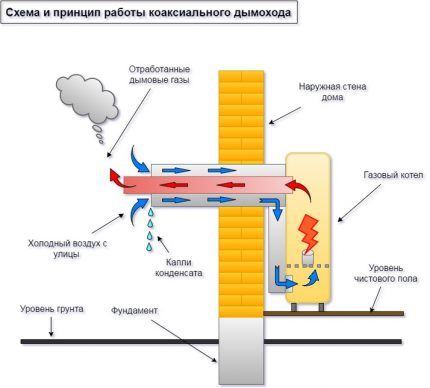

Devices with a closed chamber are distinguished by the presence of a fan that supplies air inside the device and removes flue gases from it. Therefore, the boiler does not take oxygen from the room.

The chimney in this case is also significantly different. Installed coaxial type system, where two pipes are nested one inside the other. The internal one is intended to remove combustion products, and the external one supplies street air.

The coaxial chimney can be installed not only vertically, but also horizontally at a certain angle. The presence of a fan guarantees stable draft.

A closed chamber increases the efficiency of the boiler. This is due to the fact that maximum afterburning of fuel occurs. Thus, the advantages of such boilers include higher efficiency, better efficiency, and lower fuel consumption.

In addition, they are safer due to the fact that the combustion cycle inside the device is completely isolated. Among the disadvantages, it is worth noting the energy dependence of the devices, which is extremely undesirable in areas where power outages are common. To ensure that the operation of the boiler is not affected by interruptions in the supply of electricity, it is recommended use UPS in the equipment connection diagram.

Due to the operation of the fan, such boilers are quite noisy and their cost is much higher compared to analogues with an open chamber.

Material from which the heat exchanger is made

Floor-standing boilers can be equipped with three types of heat exchangers. It’s difficult to say clearly which one is better, but let’s look at the features of each. The cast iron heat exchanger is not subject to corrosion. It is insensitive to heat shock and acid attacks.

With proper use, such a part can last 20-30 years. The main disadvantage of cast iron is its fragility, which is important to consider when transporting it and during operation.

Before installation, it is recommended to carefully check the heat exchanger for cracks.When using the boiler, it is very important to maintain the required temperature conditions and not allow a temperature difference between return and supply of 45° or more.

Otherwise, the heat exchanger may crack. Another disadvantage of cast iron is its heavy weight, which makes it difficult to install the part and its subsequent dismantling if necessary.

Heat exchangers made of steel are lighter and more durable. They are not prone to cracks and are not subject to deformation. Their main disadvantage is their susceptibility to corrosion and burnout.

Depending on the quality of the alloy steel, the average service life of a steel assembly will be 10-15 years. If operating conditions are violated, the part will fail much earlier.

Extending the life of a steel heat exchanger is quite simple. It is necessary to ensure that the temperature inside the boiler does not fall below the “dew point” value for the exhaust gases. If this happens, condensation will form on the walls of the part.

It is carbonic acid dissolved in water. The aggressive substance will damage the heat exchanger. Thus, it is necessary to constantly maintain a sufficiently high temperature inside the boiler, which leads to higher fuel consumption.

Heat exchangers made of copper are characterized by excellent thermal conductivity, corrosion resistance and low weight. However, they are installed extremely rarely in floor-standing boilers. This is due to the high cost and “capriciousness” of the metal. During operation of a powerful floor-standing appliance, copper wears out very quickly. For low power wall mounted devices This option is more suitable.

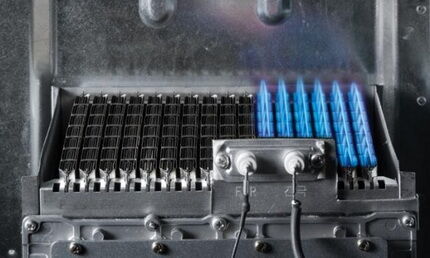

Device burner type

The burner of a floor-standing boiler can be single, two-stage or modulating. The first option assumes that the device always produces only one power level. Two-stage allows you to choose one of two levels.

Modulation involves smooth regulation (modulation) of the power output by the device. You must understand that the maximum power of a heating device is not always in demand.

According to experts, it is used from 15 to 30% of the time when the device is working. The rest of the time it produces less power.

Thus, modulating or at least two-stage burners are more economically profitable. They significantly increase the service life of the heating device, which is explained by a decrease in the number of switches on/off of the device.

The ability to operate at reduced power provides significant savings in energy resources. In addition, the amount of flue gases and other combustion products released into the air is reduced. Boilers with modulating and two-stage burners are suitable for use with boilers of various capacities.

Use of flue gases

Traditional boilers are convection-type devices and are designed in such a way that flue gases, along with water vapor, are immediately discharged outside. However, their temperature is high and this heat can be reused.

Condensing units collect steam released during the combustion of gaseous fuel, after which the heat is redirected to heating circuits.Due to more complete use of the energy obtained from gas processing, the productivity of both the boiler itself and the heating circuit as a whole increases significantly.

In this way, it is possible to achieve significant fuel savings and increase the boiler efficiency to a fantastic 100% -114%. The disadvantages of condensing boilers usually include a more complex design, which significantly increases the cost. Convection devices are simpler to make and much cheaper.

Choosing a floor-standing boiler: how not to make a mistake

Before you go to the store, you should carefully analyze the features of the heated object in order to clearly understand the operating conditions of the device. Based on this, the characteristics of the equipment are selected.

Gas unit power

One of the main factors determining the choice of boiler. Standard recommendations suggest determining the required power of the device from the following ratio: 10 sq.m of building will require 1 kW of power produced by the unit.

However, this is a very average figure. It does not take into account the heat loss of the building, the height of the ceilings in the room, the number of doors and windows, their thermal insulation and much more. If possible, produce calculation of the required boiler power must be a specialist.

One more thing. It is usually recommended to select a boiler with some power reserve. This is fair, but this reserve should not be large. Otherwise, this will lead to rapid wear of the equipment and constant excessive fuel consumption.For single-circuit boilers, the power reserve should not exceed 15%, for double-circuit boilers 25%.

Specifics of fuel consumption

If possible, it is advisable to choose the most economical boilers. These include all condensation models. Compared to traditional devices under similar conditions, they consume 15-30% less fuel. An electronic ignition system will also help you save money.

Standard piezo ignition requires constant operation of the pilot burner, which leads to excessive gas consumption. This is not necessary for an electronic system. Such boilers are more expensive, but during operation the investment quickly pays off.

Optimal number of circuits

It makes sense to think about purchasing a double-circuit boiler only if there is a need for hot water supply. In this case, it is worth installing a device with two circuits only in a building of small or medium size.

For large houses, installing double-circuit boilers is impractical, since the device’s power is often not enough for full operation. In addition, the security of the system suffers.

Priority heat exchanger material

Copper is not considered in this case. Only steel or cast iron. The first option is chosen if you want to save money. But you need to be prepared for the fact that in a few years you will have to change the heat exchanger. For long-term trouble-free operation of the boiler, a cast iron unit is chosen.

Design type and performance

For floor-standing gas boilers, efficiency is considered normal, varying in options from 80 to 98%.Condensing models differ in efficiency ranging from 104 to 116%. The higher this value, the more efficiently the boiler operates and uses less fuel.

For dual-circuit models, the performance of the DHW system can vary from 2.5 to 17 liters per minute. The performance and power of the unit affect its cost; the higher it is, the higher the price of the device.

Best control system

The most convenient and safe to use are boilers with automatic control. They are able to function autonomously, without constant control of the owner. These are expensive, complex systems.

It is also possible to use more budget-friendly manually controlled boilers, but in this case its operation will have to be controlled by turning the device on/off to obtain a comfortable temperature in the room.

An excellent option in the operation of a gas boiler is the presence of a built-in thermostatic sensor. If you don’t have it, it is recommended to purchase and install a thermostatto avoid wasting energy and overloading heating equipment.

Rules adjustment of the automation unit gas equipment are given in the article, the contents of which we advise you to familiarize yourself with.

Acceptable design and dimensions

The dimensions of the boiler and its appearance are selected based on the area of the combustion room. Manufacturers offer a large selection of a wide variety of models of various designs and dimensions, which allows you to choose the device that is most suitable for a particular room.It is important to remember that the boiler and additional equipment must be provided with completely free access.

Best models gas boilers presented in the article, which sets out the selection criteria in detail and provides all the arguments on the basis of which you can make an informed purchase.

The best equipment: consumer opinion

According to the owners gas heating systems and specialists servicing the equipment among foreign manufacturers, the best can be considered the German brands Bosch, Wolf, Buderus, Vaillant, the Slovak brand Protherm, the Italian BAXI and the Korean Navien.

Among domestic manufacturers, the Conord Plant from Rostov-on-Don and the Zhukovsky ZhMZ have proven themselves well. Let's look at several models recognized as the best.

Bear 30 KLOM from Prothrem

Floor-standing single-circuit device with an open chamber and a cast iron heat exchanger. Equipped with a modulating burner made of stainless steel. It is possible to arrange forced removal of flue gases.

The heat exchanger is equipped with a condensation protection system; if necessary, its sections can be replaced. The boiler is compact in size, has a cooling circuit, an automatic control system and two operating modes “Summer-Winter”. Device power 26 kW.

EcoVIT VKK INT 366 from Vaillant

A single-circuit boiler operates using condensing technology. Capable of heating up to 340 sq. m, power – 34 kW. If it is necessary to provide domestic hot water, it is well compatible with an external storage boiler. The model has an efficiency of more than 100%, which makes it very economical.

Equipped with a multi-sensor control system and a closed-type modulating burner. An economical electronic ignition is used for ignition. The boiler can be connected to external control, which allows it to be integrated into Smart home system or control it remotely.

AOGV-23.2-3 Comfort N from Zhukovsky plant

Inexpensive domestic boiler with improved environmental performance. Fully adapted for operation in Russian conditions, capable of stable operation at low gas pressure.

Non-volatile, can be built into systems with gravitational or forced circulation. Equipped with a dial thermometer and piezo ignition. Extremely easy to operate and maintain. The burner is easy to clean and replace.

An overview of popular models of gas boilers operating on liquefied gas will be presented next articlededicated to this issue.

Conclusions and useful video on the topic

Video #1. Which boiler is better to choose: floor-mounted or wall-mounted, why is it recommended to prefer one type or another:

Video #2. Construction of a floor-standing gas boiler:

Video #3. What to consider when choosing a floor-standing boiler model:

Floor-standing boilers are the most practical choice for installing autonomous heating. If necessary, you can choose a dual-circuit model and provide not only heating of the house, but also the supply of heated water.

Among the variety of heating devices, it is important to choose the right device that is most suitable for specific operating conditions. You should not save money and purchase a clearly low-quality but cheap device. A good boiler will work for a long time and will pay for its cost many times over. With it, your home will always be warm.

Would you like to share your own experience gained during the selection, installation and operation of a floor-standing gas boiler? Do you have useful information that will be useful to site visitors? Please write comments in the block below, ask questions, post photos on the topic of the article.

For a long time I did not dare to install a gas boiler at the dacha. And yet, last spring my father-in-law persuaded me to buy it. We began to choose and settled on the Czech floor-standing boiler Dakon. The price is not that bad, and the quality is good. Yes, it looks a little cheap and clumsy, but we didn’t take it to admire it, but to keep it warm. And it heats up normally. A house of 200 square meters warms up calmly. It’s true that it’s inconvenient to light it - all the automation is at the bottom, you have to bend down. And that's a good thing.

Well, regarding the choice of a gas boiler: this must be approached with all responsibility. When they installed gas into the house, my father-in-law purchased a fairly cheap floor-standing boiler. You have to ignite it manually, which is not very convenient. In addition to all this, the ventilation system and exhaust hood were located incorrectly, on the windy side. When there is a gust of wind, the flame will blow out. Therefore, it is better to pay more for normal installation than to suffer like this.