Circulation pump for heating: ten best models and tips for buyers

For heating small domestic premises and private houses, a time-tested autonomous water circuit is usually used.If the natural movement of liquid at the required speed is impossible, then a circulation pump is added to the system - the unit provides normal coolant pressure.

Among the many models, it is necessary to choose a device that is suitable in terms of technical parameters, which is also reliable and preferably at an adequate price.

We offer for consideration a review of the best models of household pumping equipment, which are in demand among consumers and have gained a reputation for quality units. To make the task of choosing easier, we have described the main characteristics and parameters that should be taken into account when purchasing.

Those who like to do everything with their own hands will find the advice of our experts on integrating the pump into the heating circuit useful.

The content of the article:

- Rating of the best household models

- 1st place - Grundfos Alpha2 25-60 180

- 2nd place - Wilo Star-RS 25/4 180

- 3rd place - Grundfos UPS 32-80 180

- 4th place - Gilex Compass 32-60

- 5th place - Grundfos UPS 25-40 180

- 6th place - Wilo Top-S 25/10 DM

- 7th place - Wilo Star-RS 25/2

- 8th place - Wester WCP 25-60G (180 mm option)

- 9th place - Gilex Compass 32-40

- 10th place - Leberg GRS 25/4 180

- Basic criteria for choosing a pump

- Nuances of equipment installation

- Conclusions and useful video on the topic

Rating of the best household models

The rating of household heating pumps below includes devices in the price range from 2 to 17 thousand rubles. All presented models have 3 speed levels, a standard installation length of 180 mm and a working pressure limit of 10 bar.

1st place - Grundfos Alpha2 25-60 180

One of the new models of the famous Danish company, which has proven itself during operation in real conditions.

Specifications:

- pressure at maximum mode - 6 m;

- flow rate - up to 2.8 m3/h;

- thread diameter - 1 1/2″;

- declared noise - 43 dB.

Among the advantages of the model, they note the reliability, low noise level and efficiency already familiar to the company’s products. Therefore, it can be installed in a living room.

Also, in addition to the classic manual power control, the device is equipped with an intelligent system AutoAdapt to automatically adjust parameters to the conditions of the heating system. This allows you to quickly respond, for example, to connecting or disconnecting a circuit element and changing the coolant supply rate.

There are many additional options, such as night and summer modes.

The only disadvantage of this model is the relatively high price for pumps with such characteristics. However, given the long period of trouble-free service and the 5-year manufacturer's warranty, the overpayment does not seem unreasonable.

Newer generation Alpha3 was released recently and it is still difficult to assess the reliability of equipment in this line.

2nd place - Wilo Star-RS 25/4 180

Reliable and popular pumps from a well-known German manufacturer are also distinguished by high-quality assembly and practical noiselessness.

Specifications:

- pressure at maximum mode - 4 m;

- flow rate - up to 3.0 m3/h;

- thread diameter - 1 1/2″;

- declared noise - 44 dB.

This model has been produced for more than 10 years. Over such a long period of operation, it became clear that this is one of the most reliable devices on the market.

Differs in build quality and ease of installation. There is a very successful solution that simplifies electrical installation: 4 terminal box positions and a removable cable.

3rd place - Grundfos UPS 32-80 180

Not very new, but a well-proven and quite powerful model for a household pump.

Specifications:

- pressure at maximum mode - 8 m;

- flow rate up to - 11.0 m3/h;

- thread diameter - 2″;

- declared noise - 43 dB.

It is characterized by quiet operation and durability. Users note its resistance to extreme situations, such as low voltage or stopping the flow of coolant.

Unlike many cheap analogues, it exactly corresponds to the declared pressure characteristics.

4th place - Gilex Compass 32-60

A Russian model with popular parameters among users and a fairly low cost compared to its competitors.

Specifications:

- pressure at maximum mode - 6 m;

- flow rate - up to 3.8 m3/h;

- thread diameter - 1 1/4″;

- declared noise - 65 dB.

The device is equipped with a simple mechanical flow rate control system. It has increased operating noise, especially at the third (highest) speed.

5th place - Grundfos UPS 25-40 180

A popular model that is often used for one-story buildings.

Specifications:

- pressure at maximum mode - 4 m;

- flow rate - up to 2.9 m3/h;

- thread diameter - 1 1/2″;

- declared noise - 43 dB.

One of the most frequently purchased heating circulation pumps. We can say that this model is outdated, since its production in Serbia has been going on for more than 15 years. It features a mechanical adjustment system, simplicity and reliability.

Recently, sellers and consumers have noted an increased number of low-quality fake clones. Therefore, when purchasing, you need to check the serial number of the product against the database posted on the company’s official website.

6th place - Wilo Top-S 25/10 DM

The most powerful pump among the models presented in the rating.

Specifications:

- pressure at maximum mode - 10 m;

- flow rate - up to 11.2 m3/h;

- thread diameter - 1 1/2″;

- declared noise - 45 dB.

It is usually used when it is necessary to heat large two-story rooms. It has good reliability, a long service life and a very low noise level for such a powerful device.

7th place - Wilo Star-RS 25/2

The weakest in power and the most economical device in this rating.

Specifications:

- pressure at maximum mode - 2 m;

- flow rate - up to 2.2 m3/h;

- thread diameter - 1 1/2″;

- declared noise - 44 dB.

It is often used for short and simple geometric contours of one-story buildings. It is distinguished by reliability, low noise and efficiency.

The disadvantages include the high cost for such a low-power device, especially compared to devices made in Russia or China.

8th place - Wester WCP 25-60G (180 mm option)

A Chinese-made pump is very inexpensive for its stated characteristics.

Specifications:

- pressure at maximum mode - 6 m;

- flow rate - up to 2.7 m3/h;

- thread diameter - 1″;

- declared noise - 56 dB.

The pump has standard power consumption parameters. The noise level at first and second speed is quite low, and at third it is significant. Therefore, it is better not to place it near the bedrooms.

9th place - Gilex Compass 32-40

Inexpensive Russian pump with standard and popular parameters.

Specifications:

- pressure at maximum mode - 4 m;

- flow rate - up to 3 m3/h;

- thread diameter - 1 1/4″;

- declared noise - 65 dB.

A typical, ordinary pump with mechanical power control without any significant pros or cons. Users report noise at the highest third speed.

10th place - Leberg GRS 25/4 180

Circular model of Chinese production under a Norwegian brand.

Specifications:

- pressure at maximum mode - 4 m;

- flow rate - up to 3 m3/h;

- thread diameter - 1 1/2″;

- declared noise - 52 dB.

A fairly high-quality model with a ceramic shaft. The manufacturing company is not very well known, which, together with the pump being manufactured in China, determined its low price.

Basic criteria for choosing a pump

In order for a circulation pump to be used for heating a private home, you must first determine the required values of its main indicators. And only then choose the manufacturer and model based on parameters such as brand, quality and price.

Maximum pressure and flow

Each pump has two main characteristics:

- maximum pressure - how many meters the unit can lift a column of water;

- maximum flow rate - how many cubic meters per hour the pump will flow under the condition of a completely horizontal circuit without resistance.

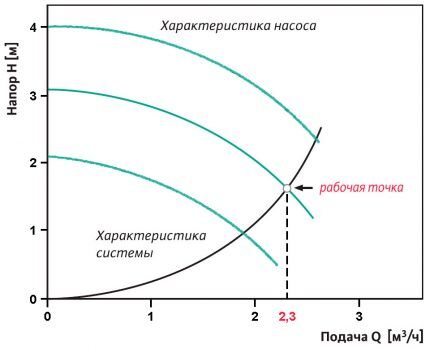

These two values are “ideal” and unattainable in real conditions. They serve as extreme points in the pressure-flow curve. This function in graphical form for different operating modes of the pump is in the user manual.

For the circuit through which the coolant flows, complex formulas are used to draw up a curve of the relationship between water flow and pressure loss due to the hydraulic resistance of network elements.

The intersection of these two curves is called the “pump operating point.”It will show the coolant flow that this device will provide for a specific hydraulic system.

Knowing this value and cross section heating pipes, you can calculate the speed of water movement through them. The optimal value is in the range from 0.3 to 0.7 m/s.

It is desirable that, according to calculations, operating the pump at the second (medium) speed would be sufficient.

This is due to the following reasons:

- Error in calculations. Actual heating circuit resistance values may differ from calculated values. In this case, to achieve normal speed, you may need to switch to a more or less powerful mode.

- Probability of adding new elements, such as radiators, control devices, etc. In this case, resistance will increase, which will lead to a decrease in flow speed. To solve this problem, you may need to switch to third speed.

- Increased wear of equipment at maximum load. Operating at medium power significantly extends the trouble-free operation of mechanical devices. This rule also applies to pumps.

Nowadays, modern devices for forced circulation are equipped with automated systems for maintaining optimal operating parameters. With their use, it has become much easier to achieve the desired temperature in the premises.

Additional information on the calculation and selection of a heating pump is provided in this article.

Other important characteristics

The pump must be selected taking into account the “thread diameter” parameter. It must match the internal size of the heating pipes.

Another important parameter is the noise from the operation of the device. Since the task is often to choose a quiet circulation pump for a residential heating system, almost all manufacturers indicate this indicator along with technical data.

In order not to be mistaken about the purpose of the pump, it is necessary to pay attention to the permissible temperature range that is determined for the pumped liquid. The upper limit should be at least 110°C, since boiling of water in a closed system occurs at approximately this temperature.

If the lower value is less than 0°C, then it is permissible to turn on the pump at a negative temperature of the antifreeze circulating in the system. If the water is frozen, even if the circuit has retained its integrity, the device cannot be started. First you will need to defrost the system.

Nuances of equipment installation

Household devices for forced circulation of water do not consume very much electricity - conventional pumps require up to 200 W, but powerful ones, with a maximum pressure of more than 10 m, can take more than 1 kW of energy.

Therefore, their contribution to the total current of the circuit must be taken into account. It must be remembered that for such devices the rated power exceeds the active (consumed) power.

Also, large pumps can operate from 380 V. But usually they heat large areas to which three-phase power lines are connected and there are no problems with their connection.

Since the coolant, passing through the system, releases energy and cools, its temperature at the end of the circuit is lower than at the beginning. Therefore, it is better to integrate the pump into the pipes closer to the inlet of the heat exchanger, i.e. on the return line. This will increase the service life of the device, since very hot water is worse for metal parts than partially cooled water.

The insertion location must be selected in accordance with the rules installation of pumping equipmentwhich are given in the installation manual. For each model, there are permitted engine orientation options that must be adhered to.

The heating circuit, as a rule, is designed taking into account the physical laws that justify natural circulation, and the introduced pump must “help” the flow to reach the required speed. In order not to be mistaken with the orientation of the device, there is an arrow on its body showing the direction of pressure.

Sometimes unforeseen situations arise due to power outages. In this case, the pump will become an obstacle to the flow, and a sharp slowdown in speed or a complete stop will most likely lead to boiling and damage to the heating system. To prevent this from happening, a bypass pipe is installed at the pump insertion point.

Another way to avoid problems during a power outage is to purchase a backup power source for the pump.If the power of the device is small and is no more than 0.5 kW, then the best solution would be a set of battery and UPS with a built-in stabilizer.

With a battery capacity of 200 Ah, a device with a 100 W motor can operate autonomously for about 20 hours.

For more powerful pumps, if you need to maintain its operation for a long time in the absence of electricity, you will have to purchase a generator. If you need to automatically turn on a backup power system, then it must support the autostart function and work in conjunction with a backup selection machine.

Conclusions and useful video on the topic

Calculation of the required pump characteristics depending on the parameters of the heating circuit:

Detailed video instructions for assembling a bypass from polypropylene pipes:

For any hydraulic circuit, you can select a pump that helps achieve the required pressure. First of all, you need to pay attention to the pressure and flow characteristics of the device, and then to other technical data: efficiency, noise, reliability and connection method.

Share with readers your experience of using a circulation pump. Tell us what the choice of unit was based on, and whether you are satisfied with the purchase. Please leave comments on the article, ask questions and participate in discussions. The contact form is located below.

As for the Vilovsky pump, which took second place, I will say this. This is just a super pump, I’ve had it for more than 10 years in a warm field, namely a 4-meter one.

It has a wet rotor, which adds reliability. It works very quietly. If you don’t put your hand on the body to catch the vibrations of the engine, you won’t hear it in your ear.

Definitely, I have never done an audit of the thing in all the time.