Installing a floor-standing gas boiler with your own hands: technical standards and work algorithm

An autonomous heating system is the dream of many homeowners.Most of them choose gas heating, a significant disadvantage of which is the mandatory installation of equipment by certified specialists. However, control over the actions of invited workers is still necessary, don’t you agree?

Here you will learn how, according to building regulations, a floor-standing gas boiler should be installed. We will tell you how to prepare a room for installing a heat generator, and how to properly organize the removal of combustion products. Our advice will help you build a safe and effective system.

The information presented for review is based on regulatory documents. To optimize the perception of a difficult topic, the text is supplemented with useful illustrations and video instructions.

The content of the article:

Preparation for installation of gas equipment

Those who are sure that the installation gas heating device starts with its purchase, they are very mistaken.

We start with collecting permits. Simultaneously with obtaining the necessary papers, you should begin to select and prepare a site for installing the heating unit, while taking into account the following regulatory requirements:

In order to obtain permission to install heating equipment, you need to go through several stages:

Step No. 1: Obtaining Technical Specifications and Permits.

It is necessary to find out whether it is in principle possible to install a gas boiler in a particular apartment or house. To do this, an application is submitted to the gas service with a request to carry out such a procedure. It must indicate the estimated annual volume of gas consumption.

The document will be reviewed and as a result the applicant will receive permission to install along with the Technical Specifications or a justified refusal.

Step #2: Creating a project for the future installation.

To begin with, it is advisable to decide on the brand of meter and boiler, but you should not purchase them yet. After which an installation project is ordered. It is carried out on the basis of a previously obtained permit for specific equipment.

The document must indicate equipment connection diagrams and the laying of the main line inside the building from the gas communications connection point. Only a licensed company has the right to engage in the project.

Step No. 3: Obtaining approval from the gas service.

The new project must be agreed upon with the gas service that services the area on which the house is located. The procedure usually takes a maximum of three months and a minimum of a week.

At this stage, you can already purchase gas equipment, because in addition to the project, you must provide the following documents for approval:

- technical passport of the gas boiler;

- certificates of conformity and sanitary-hygienic;

- operating instructions for the heating device;

- expert opinion on the device’s compliance with all technical requirements.

It is very easy to obtain these documents. The manufacturer must include them with its products. At the end of the verification procedure, the applicant receives an approved project, which in this case will be stamped with a special stamp.

If the document is not agreed upon, a list of activities must be drawn up to adjust the project. After they are completed, re-approval is carried out.

Rules for arranging a combustion room

According to current SNiPs, a gas boiler is installed only in a specially equipped room called a furnace room.

This rule cannot be ignored, because a gas boiler This is classified as potentially dangerous equipment and should be handled with extreme care. Otherwise, penalties will inevitably follow and emergency situations may arise.

First you need to calculate gas boiler power, then determine the location for installing the boiler.The instructions allow the placement of single-circuit heating devices with a power of no more than 60 kW in any room of the building. Most floor-standing gas units are single-circuit, because... Designed for servicing heating systems only.

Dual-circuit models of any power cannot be installed in the kitchen. These are miniature boiler rooms with a built-in safety group and their own expansion tank. A furnace room is set up for them. If the total power of the equipment does not exceed 150 kW, it can be installed on any floor.

More powerful installations or groups of devices can only be installed on the ground floor or in the basement. In any case, gas heating boilers are prohibited from being installed in living rooms, bathrooms and toilets.

The room intended for the furnace must have certain dimensions. Its minimum volume can be calculated by the formula: 0.2 m³ multiplied by 1 kW of device power, but not less than 15 m³.

In addition, there are a number of requirements for the premises:

- the minimum width of the doorway should be 80 cm;

- minimum ceiling height – 2.5 m;

- degree of fire resistance is not less than 0.75 hours;

- the presence of natural light, which is calculated as follows: 0.03 sq. m of window area for every 1 cubic meter of combustion volume;

- the presence of a gas analyzer connected to an automatic valve that will shut off the gas supply in the event of a leak;

- arrangement of effective ventilation;

- the door or wall leading to the next room must be equipped with a ventilation grille, the area of which is determined by the formula: for every kilowatt of power of the heating device there are 8 square meters. see designs;

- ensuring free access to the heating device and auxiliary equipment for repair and maintenance work.

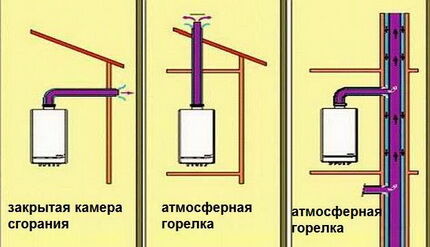

These requirements are strictly required to be met in the case of arranging a combustion room for a boiler with an open combustion chamber. For units with a closed chamber, the area of the room is not important and the ventilation requirements are less stringent, since for their operation they do not use air from the room, but take it from the street.

A gas duct is installed in the combustion room. Its horizontal section within the premises should not exceed 3 m.

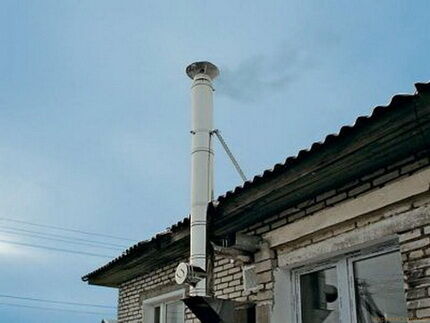

In this case, the number of turns cannot be more than three. The vertical outlet of the chimney is raised above the level of a flat roof or a pitched ridge by at least a meter. The materials from which the structure is made must be resistant to aggressive thermal and chemical influences.

Multilayer materials, for example, asbestos-cement pipes, can only be used in areas more than 5 m from the exhaust pipe.

There should be no cavities or niches formed by horizontal surfaces in the combustion room. Combustion products can accumulate here, which is very dangerous for humans.

The space in front of the heating device must be free. The floor in front of it is covered with a metal sheet, the minimum size of which is 1x1 m.It is prohibited to use asbestos cement for these purposes, since it wears out quickly and is harmful to human health.

Preparing the premises for installation

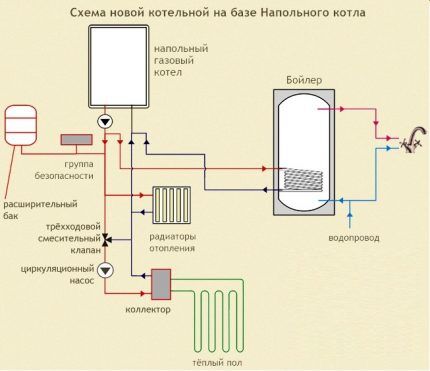

Before starting the installation of the heating device, you need to complete all work related to the arrangement of the heating system, installation of radiators, distribution of water supply and warm water floors, if present. In addition, electrical and plumbing must be fully installed.

The boiler room should also be ready. A strong floor based on cement screed is laid under the gas boiler or a separate foundation is prepared.

The last option is considered not the best. Ceilings, floors and walls, if they are decorated with flammable coatings, must be additionally protected from possible fire.

For this purpose, non-combustible linings are used, made of roofing sheet steel laid on a fire-resistant layer, for example, asbestos. The thickness of the latter sheet cannot be less than 3 mm.

In this case, the insulation must protrude beyond the dimensions of the device body along the entire perimeter by at least 100 mm. The minimum distance from the heating device to a wall made of non-combustible materials must be 100 mm.

The distance from protruding pieces of fittings, burners and automatic control devices to the opposite wall is also regulated.It must be at least 1 m.

If the floor is made of flammable material, it should be protected from possible fire. For this purpose, a platform made of concrete blocks is used. Its height must be at least 100 mm.

The top of the elevation is covered with a steel sheet, the thickness of which is at least 0.8 mm. It is possible to arrange a site for installation of the device from special fire-resistant slabs.

In addition, it is advisable to install auxiliary equipment, otherwise the boiler will interfere with this. It is optimal to complete the layout of its placement in advance in order to think through all the nuances of the arrangement.

According to this diagram, mounting holes are marked on the walls and floor, after which the necessary devices are installed. The heating device is installed and connected last.

Chimney: requirements for arrangement

Before installing a floor-standing gas boiler with your own hands, you should prepare a chimney. It is advisable to place the heating device on the prepared base so that the distance between its body and the wall is sufficient for inspection and maintenance of the device. Then mark the location of the chimney.

You don’t have to install the boiler, but carry out the markings based on calculations. In this case, several nuances need to be taken into account.

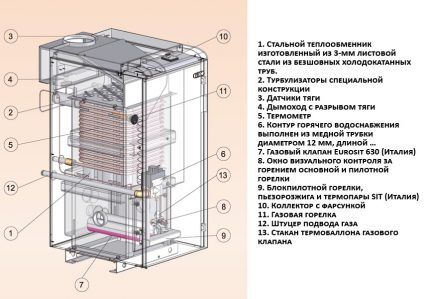

First of all, chimney of a gas unit and the hole for it must exactly match the type of floor-standing boiler. Thus, for modifications with an open combustion chamber, a separate type chimney with a cross-section corresponding to the power of the device is installed.

For example, for devices with a power below 30 kW, the pipe diameter must be at least 140 mm; for more powerful devices from 40 kW, a chimney with a cross-section of 160 mm is selected.

Devices with a closed combustion chamber are equipped with special coaxial type chimneys. In the technical documentation of the device, the manufacturer always indicates the required diameter of the chimney.

In addition, you need to remember that the pipe that will connect the heating boiler to the chimney should not be longer than 0.25 m. It is also mandatory to install a closing hole through which the structure will be cleaned.

The chimney from a boiler installed in one of the apartments of a multi-storey building must be diverted into a common chimney. If there is no such system, gas services will not issue permission to install the boiler. In a private house everything is much simpler. A chimney of almost any configuration can be installed here. It is important that it is safe and effective.

According to current regulations, the chimney pipe cannot be installed near a window opening. The minimum distance between them is 0.6 m. This is necessary to exclude the possibility of exhaust gases returning to the room.

In practice, sometimes supervisory services allow installation of equipment directly under the windows. In this case, it is necessary to ensure that the exhaust pipe is as far as possible from the vent or opening window sash.

The photo selection will introduce you to the features of using steel chimneys:

Installation technology for a floor-standing gas boiler

First of all, you should remove the device from the packaging and check its contents again. To know what should be in the box, you need to take the operating instructions, which the manufacturer must include in the packaging, and check everything according to it.

If a shortage is detected, you should immediately contact the seller. The same should be done if there are traces of repair work, dents, etc. on the device body.

Another important point is the verification of technical data. Those applied by the manufacturer to the device body must exactly match those included in the technical passport. If any discrepancy is found, please contact the seller.

All plugs are removed from the device, and the pipes are washed if necessary.This way you can make sure that there is no random debris that could have gotten inside during assembly.

Process installation of floor equipment may vary significantly depending on the type and modification of equipment. In general terms, it involves installing the device in its intended place, subsequent connection of communications and arrangement of a chimney. Let's look at each stage in detail.

#1. Heating installation work

First you need to place the equipment in the place prepared for it. This could be a concrete base, a small podium made of a fire-resistant slab, etc. A solid wooden floor is covered with a metal sheet, which should extend beyond the boiler body by approximately 30 cm around the entire perimeter.

For private houses, a different option is used. Here, a recess is prepared for heating devices, located 0.3 m below the floor level.

The bottom of such a pocket is filled with concrete, and the walls are finished with any non-combustible material. Mostly tiles. A floor-standing gas boiler is usually a fairly massive piece of equipment.

To transport it, use wheels, which the device is most often supplied by the manufacturer. The device is installed on the prepared base and carefully leveled.

You must understand that the uninterrupted operation of the device largely depends on the accuracy of its alignment. Therefore, the horizontal installation must be checked using a building level.

The equipment is leveled in place using adjustable feet. If they are not there, small pieces of any non-combustible material, for example, a metal sheet, are placed under the supports.

#2. Installation of a chimney

First you need to make holes for the chimney. Once again we check the diameter of the intended parts, it should be slightly larger than the cross-section of the chimney pipe. We make holes in the ceiling and roof.

Then we put an adapter on the boiler outlet pipe, which will be connected to the chimney. An important nuance. Corrugation, as when installing wall-mounted devices, is strictly prohibited in this case.

The adapter must be made of sheet metal only. After installing the part, we install a tee and a so-called inspection, through which the chimney will be inspected and cleaned.

Next, the remaining elements are attached: straight sections of pipe and elbow. Special parts are used to pass the chimney through the ceiling and roof. Particular attention should be paid here to fire safety.

Therefore, areas of passage through the ceilings must be equipped with non-combustible materials. The chimney must be installed at a slight slope towards the street. The exact amount of tilt can be found in the technical documentation for the boiler. This is necessary for the smooth removal of condensate, which inevitably accumulates in the pipe due to temperature differences.

The assembled structure is securely fixed to the wall or ceiling with clamps and brackets. The fastening step of the first is 2 m, the second is 4 m.It is recommended to strengthen the connections of the elements; to do this, they are tightened with clamps secured with bolts or wire.

The pipe placed on the roof or wall is raised to the required height, after which a tip is installed that will protect the chimney from precipitation, debris and wind.

You can familiarize yourself with the technology for assembling and installing a coaxial chimney in popular article our site.

#3. Heating system connection

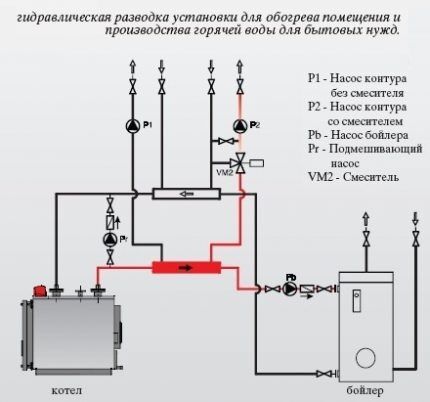

At this stage, you need to connect the boiler to the drain and supply pipelines of the heating system. For a single-circuit device, this is where the work ends. For double-circuit, you will also need to connect to the water supply.

First we connect the heating pipes. Depending on the current heating system, which can be either two or one pipe, the number of pipes for connection may be different.

In any case, experts strongly recommend installing a coarse mesh filter to protect the boiler from scale and dirt particles that may enter it from the heating main.

The heating device is not very sensitive to the quality of the coolant, but if its parameters differ greatly from those recommended by the manufacturer, additional cleaning equipment should be installed.

This could be, for example, a polyphosphate dispenser or another similar system. It is advisable to install shut-off valves on the return and supply lines, which will help prevent the radiators from airing and make it more convenient to repair the heating device.

All connections of elements are carried out strictly according to the rules with mandatory sealing. To seal the threads, you can use the usual tow and paint or more modern means.

Procedure boiler connections to the water main is carried out in almost the same way. It is also highly recommended to install a filter to prevent unnecessary contaminants from entering the device. It is also advisable to install shut-off valves on water pipes.

It is best to use so-called “American” ones with detachable connections, which allows you to quickly replace a worn-out unit if necessary and greatly facilitates installation.

#4. Connection to the gas main

You need to know that according to the standards for installing gas floor-standing boilers, only a qualified specialist can perform this operation. You can do the work yourself, but an invited professional will still check the assembly and do the first start-up.

Connection work is carried out extremely carefully and accurately. Start with gas pipe connections with the corresponding element of the heating boiler.

Only tow can be used as a sealant. No other material will provide the required tightness of the connection. It is necessary to install a shut-off valve, which is additionally equipped with a filter.

At the same time, gas workers strongly recommend installing a high-quality system here. An insufficiently efficient filter can cause boiler failure.

For connection it is recommended to use copper pipes, the diameter of which can vary from 1.5 to 3.2 cm, or special corrugated hoses.In any case, special attention should be paid to the quality of sealing of connections. Because gas tends to leak from loose connections and accumulate in the room, which can create an explosive situation.

There must be a flexible connection behind the filter, which can only be done using a corrugated hose. Rubber parts are strictly prohibited because over time they develop cracks, creating channels for gas leakage.

The corrugated parts are secured to the boiler pipe using a union nut. A mandatory element of such a connection is a paronite gasket.

#5. Conducting a trial run

At this point, the main work on connecting the gas boiler has been completed. The exception is appliances with a closed firebox. They require a connection to the electrical network. It is better to do this through a stabilizer.

After which the system can be filled with coolant. This is done as slowly as possible to displace most of the air present in it. The liquid is pumped until a pressure of 2 atm is reached.

All connections are carefully checked for possible leaks. After a gas service representative inspects the connection and allows gas to flow, you should also carefully inspect all connections on this pipeline. They need to be coated with soapy water and make sure there are no bubbles. Now you can carry out the first start-up of the equipment.

You should conclude with the representative of the gas company that installed the equipment service contracte, according to which the organization undertakes to conduct regular inspections to study the technical condition and repair of the unit as necessary.

Conclusions and useful video on the topic

Video #1. How to properly install a floor-standing boiler:

Video #2. How to avoid mistakes during installation of a floor-standing device:

Video #3. An example of installation and connection of a gas boiler:

Self-installation and connection of a floor-standing gas boiler is one of the extremely important operations, because the safety of all residents directly depends on the correctness of its implementation.

You should not get down to business if you have no experience in carrying out such work. It's better to invite specialists. Arrogance and frivolity can be very costly.

You can share your personal experience in the field of installation and connection of a gas boiler, ask questions to clarify controversial issues, and give useful advice in the block located under the text of the article. We are interested in your opinion on the information presented. Please comment.

A gas boiler was installed in the basement from the moment the foundation was laid (we built it ourselves). It was not possible to place it in the bathroom, as usually happens in private buildings built since Soviet times without lower levels. We have wooden floors. I will say right away that the house is large, so the first few years it was cold in winter. I solved this problem by installing an automatic pump and welding an additional pipe line in two places. Now it's on the wick and it's quite warm.

With the increase in heating prices, I decided to make an individual one in order to save money. I purchased a gas floor-mounted parapet boiler. I found out the price for installation and decided to install it myself, since money was tight. After reading a lot of literature, I began the editing itself. True, before this I visited all the services and paid all the receipts for permits. Everything worked out for me, I installed the unit, it has been working for three years now, there have been no problems. So installing a gas boiler yourself is realistic and, most importantly, economical.

The house was built 15 years ago, there is a project for gas, the gas service connected and equipped the boiler room, and every year they did regular maintenance. This year, a “smart guy” came to do maintenance and said that the ventilation duct was not made correctly (according to him, there should be a pipe on the outside and along the roof canopy), but I just have a natural air vent - I just punched a hole in the wall to the street and inserted a pipe - The gas service did the project. And for 15 years everything was OK, there are acceptance certificates for the boiler room.

I have no idea what to do... this pipe costs 100 thousand rubles. Who can, help with advice. Sue them?