Maintenance of gas boilers: routine maintenance and major repairs

Operating boilers around the clock leads to increased wear and tear.Do you agree that the operation of heating and water heating equipment should be safe? Why periodic inspections and repairs of gas units are carried out.

Prevention with the identification of existing defects allows you to prevent the occurrence of emergency situations. Who should carry out maintenance of gas boilers and what set of measures does it include? It is these questions that we will consider in detail in the article.

Our material contains a description of the main stages of service activities and step-by-step photos of maintenance. In addition, we have selected videos on maintenance of the boiler and its components.

The content of the article:

Service tasks

Every user of a gas boiler expects its long-term operation. But the durability of equipment depends on many factors.

Uninterrupted operation of the boiler leads to rapid wear of its working elements and components, and an unstable supply of natural gas leads to premature failure of an expensive device.

According to the rules, the first maintenance must be carried out six months after the end of the warranty period.

The frequency of technical inspections and troubleshooting is established on the basis of an agreement concluded between a representative of the technical department and the owner of the equipment.

During a routine inspection, a gas industry representative pays attention to the following points:

Malfunctions of gas units identified during the period between ongoing maintenance activities are eliminated at the request of the owners of gas boilers by employees of the organization with which the contract was concluded.

Boiler maintenance is designed to solve three problems at once:

- Control devices automatic regulation.

- Check that the burners are functioning correctly.

- Determine the current state of the internal heating elements of the equipment in use.

Each of the listed aspects is of primary importance in maintaining efficiency at the initial level and extending the “life” of the boiler system as a whole.

In addition, a gas worker performing maintenance on a gas boiler is required to inspect the condition of the taps and connections of metal pipelines. He must evaluate the performance of ventilation and smoke channels, tightness of units.

During the routine inspection, gas combustion is visually monitored and, if necessary, the burners are adjusted. The tightness of connections is assessed using a soap solution or gas detectors.

All identified violations must be corrected immediately upon discovery. The operability of parts and mechanisms is restored; if repair is impossible, replacement is carried out.

If necessary, parts and components of gas heating equipment are repaired in a gas workshop, with which a service agreement has been concluded.

Professional solution to the issue

At first glance, there is nothing complicated in carrying out preventive maintenance measures for boiler units. But you shouldn’t set up and clean a gas boiler yourself. And it's not just a matter of experience.

Such a critical procedure should only be performed by a qualified specialist who has the precise equipment necessary to diagnose faults.

The quality of boiler equipment maintenance directly depends on the professionalism of the technician. Therefore, such work should be entrusted only to professionals with special permission.

According to paragraph 6.2 of the current SNiP, servicing of boiler equipment must be carried out by licensed organizations that have their own emergency dispatch service.

Leading manufacturers of gas boilers, in order not to open branded service centers in every region of the country, issue licenses to organizations specializing in the field of maintenance.

You may be interested in information on how to choose a good and reliable gas boiler, discussed in our other article.

In addition to a certificate for performing a specified range of work, such organizations receive full access to technical documentation for equipment produced by the manufacturer, as well as the opportunity to receive new boiler components for warranty replacement. A list of certified companies is usually listed on the manufacturer's website.

When choosing a service organization and drawing up a contract, you should focus on two parameters:

- Certification of the boiler manufacturer, confirmed by the presence of a license to carry out work.

- The location of the service center in the same city or region, which will reduce the response time of the field technician.

In most cases, a service contract is signed before the boiler is fully put into operation. It clearly states the list of future works and the deadlines for their completion.

The work offered by service organizations is divided into three types:

- Routine maintenance – regular preventive maintenance carried out to assess the technical condition of the unit, identify and eliminate impending breakdowns, to prepare the unit for the heating season and after its completion before summer inactivity.

- Service upon subscriber's request – includes measures to identify violations and damage to the system, diagnose the performance of the gas apparatus or its individual parts, and eliminate breakdowns and malfunctions.

- Major renovation – a set of measures in the event of a unit breakdown, carried out in the event of emergency situations triggered by external factors or as a result of equipment failure.

The frequency of preventive maintenance of equipment depends on purpose of the installed unit and its design.

On average, routine inspections are recommended to be performed 2 times a year. They are carried out both for devices included in the heating circuit and for DHW system units.

Failure to meet the deadlines for such an important event can lead to serious consequences. Thus, a clogged pipeline can cause a failure of the heating system, and gas pipeline depressurization – cause of explosion and fire.

Basic steps of the current service

To fully control the situation, you should understand what work is performed when servicing various parts and components. Routine maintenance of a boiler generator includes three main types of work: cleaning, checking and adjustment.

Before servicing gas equipment, it is mandatory to turn off the system and gas supplies. The disconnected system should cool down slightly.

Step #1 - inspection of heating circuits

At this stage, a general idea of the current state of the operating system is formed.

First of all, the technician checks the documents and the warranty seal, determining whether the installation of the gas appliance meets the requirements of two main regulatory documents:

- SNiP - sanitary building codes and regulations.

- “Rules of technical operation and safety requirements in the gas industry of the Russian Federation.”

Since a gas boiler is a set of equipment that uses both gas and electricity, electrical elements are also subject to visual testing.

Checking the condition of the boiler unit is intended to clarify the following points:

- integrity of the device structure;

- gas valve pressure;

- ignition electrodes, if available;

- condition of gas supply connections;

- electronics performance;

- serviceability of emergency machines.

At this stage, they control and perform swapping expansion tank, which is designed to protect the elements of the system and compensate for the pressure that is created during the expansion of the coolant.

The pressure level in cold water, depending on the type of boiler, is 1.1-1.3 bar. It is important to ensure that after heating the pressure does not exceed the recommended standard specified in the passport for the unit.

Step #2 - cleaning system elements

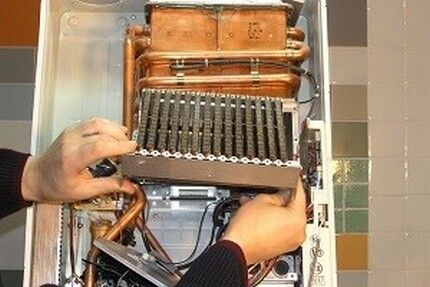

Before starting work, empty the boiler. After this, they begin to inspect the gas burner, determine the quality and direction of the flame.

To do this, remove and clean sequentially:

- retaining washer – a device that regulates the position of the burner torch relative to the installed heat exchanger;

- air sensor – it is designed to regulate the ratio of the mixture of air and gas;

- flame detector sensor – it generates a signal when traction indicators deteriorate;

- ignition device electrode – responsible for igniting gas-air mixtures;

All metal structures can become deformed over time under the influence of high temperatures and carbon deposits.

During normal operation of the burner, the flame has the shape of a cone, colored blue. A yellowish color indicates contamination.

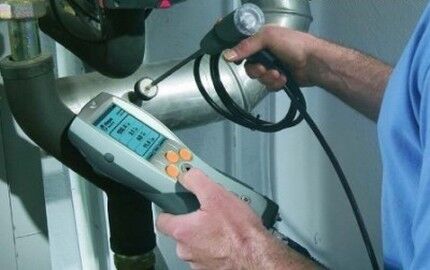

Measuring and analyzing the boiler exhaust gases will help check the operation of the key operating element of the boiler and assess the compliance of the burner settings with the composition of the supplied gas, as well as the completeness of its combustion.

The fire area on the fuel combustion chamber and all parts of the boiler that are in direct contact with the torch must be cleaned. This task can be easily accomplished using a soft brush and a vacuum cleaner.

When cleaning injectors, do not use a metal brush, the bristles of which can damage the surface.

Separately, unscrew and blow air through the gas channels of the boiler. The gas supply pipe to the burner is removed, disassembled and purged under pressure.

The heating system is equipped with two filter elements. The first is located in the hydraulic unit, and the second is located on the cold water tap. These filters also require periodic cleaning of salt deposits by washing.

As maintenance is carried out, all faults discovered by the technician must be eliminated, replacing failed parts and assemblies with new elements.

Step #3 - checking the control automation

Modern boilers are equipped with automatic control systems, the main purpose of which is to ensure the operation of the unit without constant human supervision. The degree of complexity of automation can be very different.

But regardless of the model, its main elements are:

- Thermostat – a regulating device responsible for maintaining the set parameters of the coolant temperature in the boiler.

- Gas valves - designed to open and shut off the gas supply.

- Gas fittings – an actuator designed to process commands from the boiler control circuit.

- Controller – an electronic device designed to implement a complex algorithm for controlling the unit depending on changing environmental conditions.

- Minimum and maximum pressure switch – membranes that act on groups of contacts, turning off the unit in the event of a drop/increase in pressure below/above the setting value.

This technique “painfully” endures a regular drop in tension. The master’s task is to promptly detect problems in the electronic system, possible problems with parts and correctly adjust automation.

To check the functionality of the boiler safety system and identify vulnerable areas of the equipment, the technician simulates the occurrence of an emergency situation. After starting the system, he monitors the speed of operation of the alarms, the tightness of the shut-off valve and other devices.

If the automation does not work correctly, the unit is disassembled and the failed membranes are replaced with new ones.

The inlet part of the gas pipe is also subject to inspection.It is examined for corrosion and other damage.

All connections of the gas path, including flanged, threaded and prefabricated, are tested for leaks. Measure the pressure in the gas pipeline. If necessary, adjust the gas fittings. Places where paint has peeled off from the surface of the pipe are repainted.

Having adjusted all components of the boiler unit, the technician sets the parameters recommended by the manufacturer.

At the final stage, it carries out a final inspection of the boiler. The master fills out certification documents, confirming with his signature personal responsibility for the quality of the inspection performed. Finally, he makes a note indicating the period for the next service.

Carrying out major repairs

After the expiration of the operational period specified in the product passport, the gas boiler is subject to technical diagnostics. The main task of engineering and technical measures is to determine the possibility of further safe operation of the equipment.

Major repairs are carried out to restore the technical characteristics of gas heating equipment. As necessary, worn parts and functional units are replaced.

In addition to diagnostics, as part of a major service the following is performed:

- Flushing the heat exchanger.

- Comprehensive inspection and cleaning of all closed boiler components.

A properly carried out set of measures guarantees the proper operation of gas equipment during the subsequent period of operation.

The heat exchanger is cleaned from scale after the first five years from the date of commissioning of the boiler unit. Although most service organizations recommend carrying out preventive flushing once every two years.

A simple procedure for flushing the boiler heat exchanger can eliminate the problem at the stage of scale formation.

To carry out major cleaning, remove the device casing and disassemble all removable parts of the unit. Separately, dismantle the heat exchanger and, using a pumping station, thoroughly wash it with chemical reagents.

This flushing allows you to remove all the scale that has formed in the pipelines and fins of the heat exchanger over several years. After this, the boiler is assembled and the system is filled with coolant.

Cleaning of smoke channels, designed to remove combustion products from gas appliances and create draft, is not included in the list of activities required to be performed by the master.

He can do this work for an additional fee. If desired, you can clean the chimney yourself. It is advisable to wash it at least once a year.

Operation of the boiler during force majeure

In the event of an emergency, it is necessary to react to the problem as quickly as possible and try to return the boiler to working condition. Breakdowns, if they occur, occur only during the heating season.

And the reason for this is most often that the unit operates at maximum power without interruption for a long period.

Low-quality fuel, which is often supplied to the gas system, often leads to the same disastrous result.

Having a service agreement in hand, the owner can only call the organization. Having received the request, the repair team will arrive on site and fix the problem.

Since service centers always keep records of boilers, the visiting team’s specialists arrive on site with the necessary set of tools and spare parts that correspond to the specific model of the gas boiler installed in the house.

But there are situations when, during the peak of the heating season, repair crews are at a loss. And the masters may not satisfy the request as quickly as we would like. In this case, some owners resort to the services of “private owners”.

But it’s worth considering that calling the first gas worker you come across is not the best option. And it’s not even a tidy sum that the owner will have to pay. After all, no one guarantees that the master will be able to perform repairs at a high professional level in an emergency situation.

Therefore, in order to avoid such situations and save unnecessary costs, you should not neglect the opportunity to conduct a routine technical inspection before the onset of cold weather.

Conclusions and useful video on the topic

Video about the sequence of actions during maintenance of a gas boiler:

Video guide for cleaning the burner:

Regular maintenance of a gas boiler allows you to identify emerging problems at an early stage and not bring the situation to the point where the operation of the equipment begins to pose a threat to the health and life of household members.

Are you faced with the need to urgently call a technician to diagnose your gas boiler? Or did you have to pay for additional services during the maintenance process? Tell us about your situation - perhaps your experience will be useful to other owners of gas equipment. Leave your comments below the article.

We call our technician to check the gas boiler once every six months - this is both our safety and a guarantee of normal operation of the boiler. I don’t recommend doing this on your own, well, only if you have a special education. And it’s better to replace an outdated boiler right away than to risk repairing it or even being left without heat in the house during the heating season.

I fully support your opinion. This is gas, safety is very important here. We bought a cottage with a gas boiler already installed and the first maintenance is due next week. So I’m now studying the Internet to understand what the master is doing and to control so that he doesn’t mess around and check everything.

With our level of service, they only rip off money well, and provide services anyhow. We concluded an agreement before the launch. The foreman came to the launch, give me money. Then once a year he comes, with a smart look he opens the panel, looks through his glasses - that’s it, give him for the visit. I look in the book, I put notes that I cleaned it and checked it.

The other day I called them, I said, it’s time to clean the heat exchanger, because the hot water is not heating well. The dispatcher replies, you don’t have a deadline yet, everything is fine with you.

For your boiler room I also had to look for a normal office. And then a guy from the gas station came, did something for the sake of appearance and left - but they demanded money as if for a full-fledged maintenance.

Is it possible to repair an Ariston boiler like the one in the video with a malfunction - “it does not see the presence of a flame after ignition and turns off the gas supply”?

I don’t know what should be included in boiler maintenance, but in Zhabinka, let me tell you, the local gas workers don’t do anything...