Chimney for a gas boiler: types of structures, design tips, standards and installation requirements

If gas is chosen for heating the house, care should be taken to remove combustion products.This means that you need to select and correctly install a chimney for a gas boiler. Compliance with the rules and regulations in this matter absolutely cannot be neglected, since this can call into question not only the health, but also the life of the residents of the house.

We are ready to share with you useful information about the rules for installing and connecting a chimney for a gas unit, and about the specifics of selecting the optimal design. The information is complemented by visual illustrations and video instructions.

The content of the article:

- Why do you need a chimney at all?

- Selection of materials for chimney construction

- Subtleties of designing a smoke channel

- Rule #1 - compliance with channel cross-section standards

- Rule #2 - ensuring condensation control

- Rule #3 - choosing the cross-sectional shape of the structure

- Rule #4 - performing slopes, turns, ledges

- Rule #5 - correct pipe connection

- Rule #6 - subtleties of pipe placement on the roof

- Rule #7 - compliance with fire safety standards

- Choosing a chimney depending on the type of boiler

- Preliminary calculations of chimney parameters

- Installation options for chimneys

- How to remodel an old chimney?

- Conclusions and useful video on the topic

Why do you need a chimney at all?

One of the most dangerous products formed during almost all types of combustion is carbon monoxide. This is an insidious and very dangerous substance, the inhalation of which can lead to severe forms of poisoning.

When a gas boiler operates during fuel combustion, in addition to other combustion products, carbon monoxide is also formed.

If the chimney that removes combustion products is installed incorrectly or damaged, this can lead to poisoning.

The danger should not be underestimated. Carbon monoxide (also known as carbon monoxide) is odorless and colorless, so poisoning can occur completely unnoticed by anyone in the house.

Once in the human body, carbon monoxide molecules interact with hemoglobin. As a result, the so-called carboxyhemoglobin is formed, which prevents the entry of oxygen molecules into the tissues of the human body.

In addition, carbon monoxide can have a very bad effect on other biochemical processes in the body. There have been cases when carbon monoxide poisoning was discovered too late, and the person simply could not be saved.

To avoid such problems, it is recommended to pay close attention to the correct design and installation of the chimney, as well as its further maintenance.

Selection of materials for chimney construction

The gases discharged through the chimney of a boiler operating on this fuel have a low temperature - about 150⁰, therefore the requirements for the chimney material are somewhat different.

When it burns, steam is formed with an admixture of carbon dioxide - neutral substances that do not contribute to the occurrence of destructive processes, but, in addition to them, aggressive sulfuric acid is also present in the combustion products.

At gas heating device For a country house and a chimney for a gas boiler, only very durable materials that are resistant to many external factors should be used.They must be fire-resistant, capable of contact with moisture and acids released during gas combustion and deposited on the walls of the chimney in the form of condensation.

When choosing a material, you need to pay attention to such a parameter as the gas permeability of the material. It must be null. In addition, the material should not be too heavy, since such a design creates additional stress on the walls and foundation of the house.

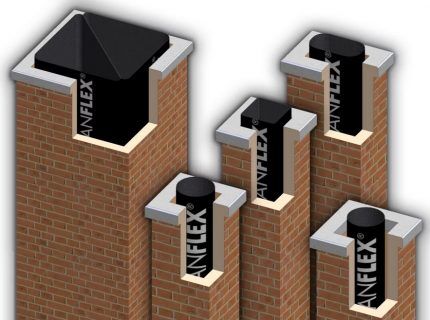

Homeowners are increasingly choosing lightweight pipes made of acid-resistant stainless steel, using furanflex, protective sleeves, and ceramic modules.

Stainless steel chimneys

Such designs are considered the optimal choice. They are exceptionally resistant to many types of corrosion, are relatively lightweight and provide excellent traction. The service life of a steel chimney is usually about 15 years.

Galvanized steel copes much worse with removing combustion products than stainless steel. Humid and hot fumes with high acidity quickly destroy this material. A galvanized chimney will have to be replaced after five years.

Ceramic chimneys

They have an exceptionally long service life - they can last up to 30 years. Particularly popular and convenient are European-made models with an external steel contour.

But this option also has a number of serious disadvantages:

- High weight of the structure, which should be correlated with the bearing capacity of the foundation and walls of the house.

- Increased installation requirements. It is believed that to obtain maximum traction ceramic chimney must be positioned strictly vertically, and such a configuration is not convenient everywhere.

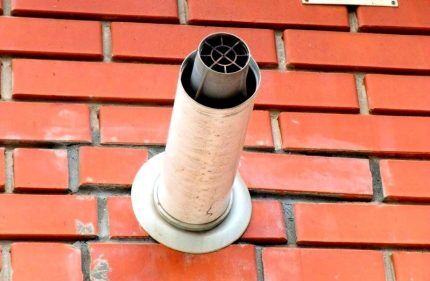

Coaxial chimney

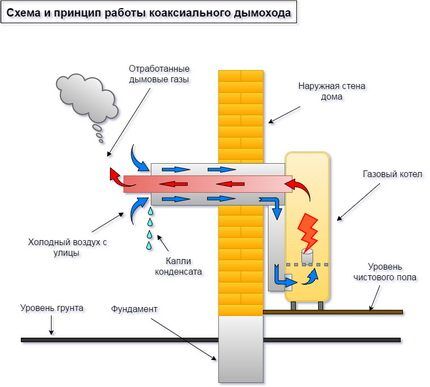

A coaxial chimney is a highly efficient, modern, but expensive choice. The design of such a chimney consists of two pipes nested inside each other. Combustion products are removed through the inner pipe, and the outer pipe is used to supply air.

The coaxial chimney is also supplied in the form of modules, which facilitates its assembly and installation. Another advantage is an increased level of security. This is, of course, if during the installation process the installation standards for a coaxial chimney and building regulations were observed.

Brick chimney

This is not the best option for a gas boiler. A massive design usually does not have good traction, weighs too much, and does not last long. Such a chimney needs to be cleaned frequently; a lot of condensation accumulates on its surface, so its service life when used with gas equipment is short.

A brick channel is also dangerous because, due to the unevenness of the internal walls, the effect may appear at low outside temperatures. reverse thrust or a water plug will form, which will lead to the cessation of the combustion process.

But if the house already has an old brick chimney, it can be used. A special stainless steel liner is inserted inside the structure, and the brickwork becomes a protective case. Of course, the diameter of the liner and its configuration must comply with the standards described above.

Chimneys made of asbestos cement pipes

Such designs are quite rare. They are being replaced by more efficient materials. If you buy a relatively inexpensive asbestos-cement pipe, its installation is complicated by the fact that it has a large mass and must occupy a strictly vertical position.

Due to its disadvantages, arrangement of this option is strictly not recommended. This is budgetary, of course, but can your health be assessed with money? The service life of an asbestos-cement chimney does not exceed five years.

It is recommended to equip all chimney options for gas equipment traction enhancers.

Subtleties of designing a smoke channel

At chimney design everything matters: its size, configuration, cross-section, slope, and other parameters. When installing a smoke exhaust from a gas boiler, it is necessary to strictly adhere to the requirements of regulatory documents: SNiP 2.04.05-91 and DBN V.2.5-20-2001.

Rule #1 - compliance with channel cross-section standards

The cross-section of the chimney duct must be no smaller in area than the cross-section of the gas boiler pipe through which the device is connected to the chimney.

When constructing and connecting chimneys for gas boilers along their entire length, narrowing of the channel, curvature and the use of modules that are not suitable for the cross-section are unacceptable.

When simultaneously connecting two devices to the chimney, the cross-section should be increased, taking into account the likelihood of simultaneous operation of two devices. Those. the cross-section of the channel must be equal to the total dimensions of the pipes of both units of equipment.

Rule #2 - ensuring condensation control

Modern gas boilers are designed in such a way that the maximum amount of heat is supplied to the heat exchanger. Such a high efficiency contributes to the production of combustion products with a relatively low temperature.

As a result, moisture forms on the walls of the chimney. An increased amount of condensate, including aggressive substances, can have a destructive effect on the integrity of the walls of chimneys.

At the bottom of the chimney, there must be a condensate collector in the form of a removable container made of plastic or stainless steel. A glass made of galvanized steel is also not prohibited from use, but it will have to be changed frequently.

To protect the structure, it is recommended not only to lay the chimney out of brick, but also to line it, i.e. insert a special stainless steel pipe inside. Such pipes are durable and well resistant to corrosion.

An alternative solution to combat condensate can be lining, i.e. installation of a special flexible chimney. A special container is used to collect condensate. It is installed just below the place where the boiler pipe connects to the chimney.

Rule #3 - choosing the cross-sectional shape of the structure

The traditional cylindrical shape of the chimney is considered optimal for efficient removal of combustion products. In addition, it is easier to carry out preventive cleaning in such a chimney.

Chimneys with a cross-section in the form of an oval are considered quite acceptable, although not so convenient. Square designs also have a right to exist, but their traction indicators are usually reduced.

Rule #4 - performing slopes, turns, ledges

A vertical chimney without ledges is considered optimal for a floor-standing gas boiler. In practice, it is not always possible to achieve such a design arrangement.

Deviation from the vertical is allowed no more than 30 degrees. In this case, you should make sure that the cross-sectional dimensions of the inclined section comply with regulatory requirements.

In this case, the pipe itself connecting the chimney and the boiler must include a strictly vertical section with a height of half a meter or more. Of course, if necessary, some sections of the chimney can be made horizontal, but there should not be too many of them.

For example, if the height of the room in which the chimney is installed is about three meters, then the total length of the horizontal sections of the chimney should not exceed these dimensions.

Although, as mentioned earlier, the closer the chimney design is to the vertical, the better. It is not allowed that the slope of the chimney towards the boiler be more than 0.1 degrees. As for the turns of the chimney structure, their maximum number is three turns, no more.

Rule #5 - correct pipe connection

To connect individual parts of the chimney structure, special clamps are used. The slope of the chimney structure can be 15-90 degrees. A certain distance must be maintained between the connecting pipes and other surfaces.

It depends on what materials these surfaces are covered with. In places where flammable or even difficult-to-burn materials are used, it is recommended to maintain a distance of at least 25 cm.

The distance from surfaces coated with fire-resistant materials must be at least 5-10 cm. To protect the chimney from flammable materials, use asbestos cardboard, brickwork, etc.

Particular attention should be paid to the junctions of individual sections of the chimney structure. They must be made of durable materials that do not bend under external influence.

All chimney fastening elements must have the same characteristics. Horizontal or inclined sections of the chimney should not be under load.

The chimney elements are inserted into each other to a depth that is equal to half the diameter of the pipe or exceeds this figure. No gaps in these places are allowed; the connection must be tight and airtight.

If the tightness of the connection of individual chimney elements is broken, carbon monoxide can enter the room unnoticed. Therefore, the condition of the chimney should be periodically checked, and good ventilation should be organized in all rooms where chimney pipes are laid.

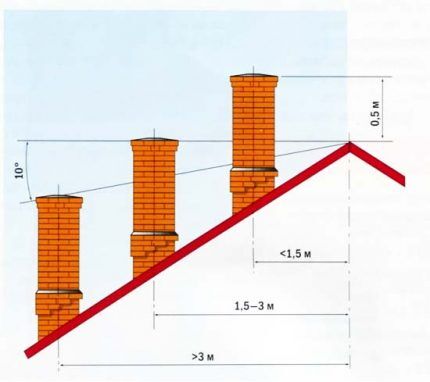

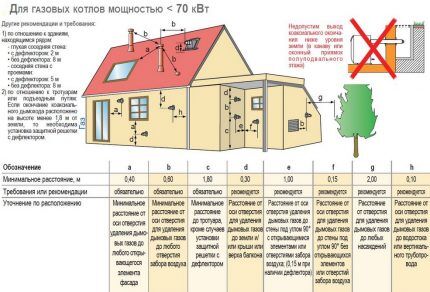

Rule #6 - subtleties of pipe placement on the roof

Chimney pipes should rise above the roof ridge by 50 cm or more, while the distance from the edge of the parapet to the chimney pipe should be no more than 150 cm. If the axis of the chimney pipe is located at a distance of 1-1.5 m from the roof ridge, then it should rise above the ridge level by 50 cm or more.

If the work is located even further from the ridge, then it can be made the same height as the ridge. The pipe can be even lower if it is separated from the ridge of the roof by a distance of more than three meters.

In this case, you need to draw a conditional line down from the ridge at an angle of 10 degrees to the horizon. The height of the chimney pipe must reach this mark. It turns out that the further the pipe is located from the ridge, the smaller its height should be relative to the roof ridge.

There is no chimney on a flat roof, so here, in accordance with the standards, a chimney pipe with a height of 100 cm is erected. On a combined roof, the height of the chimney pipe should be about two meters.

The outer part of the chimney must be insulated. If you neglect this point, condensation will accumulate on its surface. Moisture can penetrate inside the chimney, which will lead to the development of corrosion processes and damage to the structure.

The part of the chimney structure that is located on the outside of the house also needs insulation. Insufficient insulation can also reduce the efficiency of the chimney and reduce its draft.

If it is not possible to remove the chimney through the upper ceiling and roof, use coaxial chimneys. This option can be removed through the wall, while the intensity of removal of combustion products of blue fuel is not reduced at all.

Rule #7 - compliance with fire safety standards

At the chimney installation stage, it is necessary to take into account fire safety requirements. When the channel passes through walls made of different materials, they differ:

- if the wall is made of wood, insulation from a fire-resistant material is needed around it, and the pipe itself should be wrapped in asbestos;

- In a brick or concrete wall, foam insulation is sufficient.

The design of the chimney must comply with the requirements set out in the instructions attached to the boiler.

The chimneys of boilers that convert gas into thermal energy are predominantly of the mounted type. According to the push-on design, the channel is installed directly on the floor slab of the heating unit. However, it is permissible to connect to wall chimneys using pipes no longer than 40 cm.

If connected to a wall chimney, there should be a gap of 14 cm between the bottom line of the pipe and the combustible ceiling.Between the top line of the pipe and the flammable ceiling, you must leave 50 cm if there is no fire protection, 40 cm if there is protection.

The area where the flammable floor intersects is equipped with a box of sand or a seal made of non-flammable insulation.

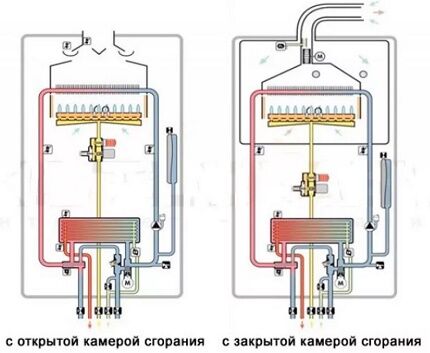

Choosing a chimney depending on the type of boiler

Gas boilers are equipped with one of two types of combustion chambers: open or closed. Externally, the heating units are no different, but their operating principles are different. The choice of chimney design depends on the type of combustion chamber.

The location of the chimney must also be determined in advance. It can be either internal or external. Projects for new houses usually include the installation of internal chimneys. When old houses are converted to gas heating, an external chimney is installed.

Chimney for a boiler with an open burner

A simpler device has an open chamber. It consists of the burner itself and the coil located under it. The latter consists of thin tubes through which coolant circulates. The device only works when air is present, which is why the burner is called atmospheric.

Such a boiler receives air from the room where it is installed, although there are models that are mounted on the wall and make an air intake hole in it.

For a boiler with an open chamber to work well, it needs a pipe going outside and excellent draft that occurs when air moves through the smoke exhaust channel. The unit is well suited when you need to heat a large house located outside the city limits.

There are 2 solutions:

- The straightest possible pipe, located horizontally, is passed through the wall, and from the outside it is directed up along the wall to the desired height. This type of chimney is called external.

- The pipe is pulled upward from the boiler. It must pass through the ceilings and exit above the roof surface. In such a chimney it is permissible to make 2 bends of 45⁰ each.

The first option is simpler in execution, but high-quality insulation will be required. This will reduce the amount of condensation, but get rid of it completely. At the outlet you definitely need a condensate collector and a tee.

The use of the second option is complicated by the fact that the chimney passes through the ceiling and roofing pie. Therefore, in these places, in accordance with fire safety requirements, installation of ceiling-passage units will be required.

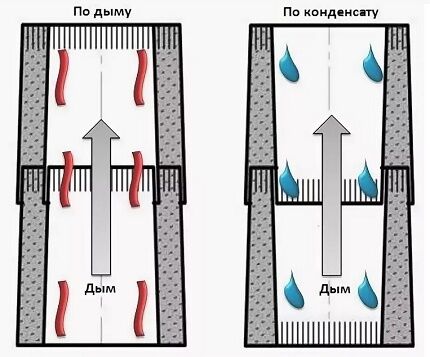

There are terms such as installing a chimney “through smoke” and “through condensate.” Assembly according to the first method is carried out when constructing an internal chimney, and according to the second - when an external chimney is being erected.

In the first case, the already installed lower element is inserted into the upper one, which will prevent gases from leaking into the room. In the second, they do everything the other way around.

If the pipe is led to the residential 2nd floor, it must be brought into an aesthetic appearance. For this purpose, special screens are used, which are attached to the floor with self-tapping screws. When the chimney opens into the attic, no additional work is required.

Chimneys for turbocharged boilers

Boilers with a forced-air burner are called turbocharged. This is a more progressive design with forced injection of oxygen into a closed chamber with a nozzle located in it. The air comes from an externally installed fan through a special channel.

The heating block has double walls with water between them. The liquid heats up when the gas burns, and the combustion products are forced out by the blower into the chimney.

A coaxial chimney is suitable for the turbocharged boiler.Through one of its pipes, exhaust gases are removed at a distance of up to 3 m, and through the other, the air necessary for the combustion process is supplied.

In terms of ecology, such a unit is safer; it controls the combustion process automation for gas boilers. The fuel in it burns almost 100%. The efficiency is greater due to the fact that the water is in contact with the walls of the chamber.

It is possible to use horizontal short chimneys. As a result of the use of a double pipe, the air coming from the street is heated due to heat transfer from the exhaust gases.

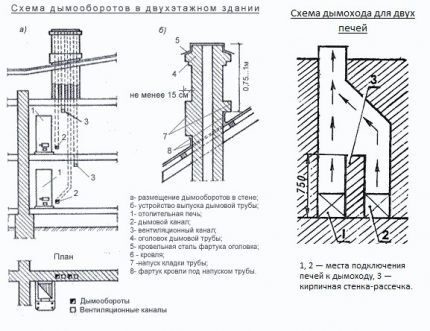

Specifics of chimney arrangement for two boilers

Each device using gas as fuel must have an individual chimney. In case of urgent need, as an exception, it is permissible to connect 2 units of simultaneously operating gas-consuming equipment. The main condition is to maintain a distance of at least 0.7 m between the points where pipes are inserted into the chimney.

If the house has not only a gas boiler, but also other heating or water heating equipment, the following standards should be taken into account:

- No more than two such devices, located on the same floor or on different floors, can be connected to one chimney.

- In this case, the openings for removing combustion products for these devices must be at different levels.

- The chimney entrances must be separated by a distance of 50 cm or more.

- Input of combustion products from two devices at the same level is allowed only if there is a special cutting insert inside the chimney.

- In this case, the height of the parallel inlets into the chimney, equipped with a divider, must be at least one meter.

Of course, the construction of several chimneys will cost more than just one structure, but you should not neglect the requirements of building codes and safety rules for the sake of dubious savings.

When creating a chimney, you should not use materials with low density and high porosity, which are characteristic of foam and slag concrete blocks. The chimney should not pass through living spaces.

Installation of such structures on closed loggias or balconies is also not allowed. In all rooms where there is a chimney, it is necessary to organize proper ventilation.

Preliminary calculations of chimney parameters

The selection of a chimney should begin only after purchasing the boiler, otherwise it is impossible to select its cross-section and calculate the dimensions. The best shape is round, although a rectangle is also acceptable.

Indicative list of chimney structural elements:

- adapter connecting the boiler pipe to the chimney structure;

- a tee with an inspection hole and a fitting designed to collect condensate;

- clamps for connecting individual elements of the chimney;

- brackets and other fasteners;

- conical tip;

- telescopic pipes;

- bends;

- feedthrough pipe, etc.

It should be remembered that it is usually recommended to install bends at a distance of no more than two meters from the gas boiler pipe. This will ensure the most effective traction.

For proper installation of the chimney, it is recommended to first calculate the cross-sectional area of the outlet.

The following formula is used:

F = (K ∙ Q) / (4.19 ∙ √ˉ N),

Where:

- K — constant coefficient, its value varies within 0.02–0.03;

- Q — gas boiler performance specified in the technical data sheet of the device;

- N - estimated height of the chimney.

After the cross-sectional area is calculated using this formula, it is necessary to compare the obtained data and correct them if necessary.

For example, according to the requirements for the chimney of a gas boiler, for round structures the recommended cross-section depends on the power of the boiler and can be:

- 120 mm for a 24 kW boiler;

- 130 mm - for 30 kW;

- 170 mm - for 45 kW;

- 190 mm - for 55 kW;

- 220 mm - for 80 kW;

- 230 mm - for 100 kW.

If a chimney with a rectangular cross-section is installed, the thermal power of the gas equipment is taken into account:

- for devices with a power of less than 3.5 kW - 140x140 mm;

- for devices with a power of 3.5-5.2 kW - 140x200 mm;

- for devices with a power of 5.2-7.3 kW - 140x270 mm, etc.

If asbestos-cement pipes are used, the cross-section of the chimney duct must be at least 100 mm. Vertical sections of the chimney are fixed to the wall in increments of 2.5 m, and in areas with a slope the increment should be more often - 1.5 m.

The height of the chimney is selected depending on its location in relation to the ridge of the roof.

If, during the calculation, it turns out that the condition under which the useful cross-section of the pipe should be greater than the internal area of the heating unit is not met, you should take a pipe of a smaller cross-section, but of greater length.

Installation options for chimneys

It is necessary to build a foundation under the internal chimney. If you also add a protective brick channel, this will minimize the amount of condensation. Sometimes chimneys are attached from the outside to the wall behind which the unit is located.

Internal design of the chimney

Before proceeding with the installation of the chimney, select a location for it. Then mark the places where it will pass through the ceiling and roof. Carefully check the accuracy of the markings and make openings. The next step is to connect the boiler pipe to the chimney, and then install the revision and tee.

A sheet of steel is fixed, the main bracket is installed, the pipe is extended, if necessary, “elbows” are used. In the area of contact with the ceiling, pipes are used. Take a sheet of galvanized steel with a hole such that a pipe can pass through it freely, and attach it to the ceiling. Clamps are used to strengthen joints. Every 2 m the chimney is secured with clamps, and every 4 m - with brackets.

The work is completed by checking the seams for leaks. To do this, take a soap solution and apply it to all joints. If everything is done efficiently, then when connecting the unit to the chimney, bubbles will not appear in these places.

External structure device

For an external chimney, a hole is made in a blank wall of such a diameter that a pipe with insulation can freely pass through it. Having installed the first element of the future chimney into the hole, secure it and wrap it with insulation.The next sections are added from the street side, controlling the verticality using a plumb line.

The pipe is fixed to the wall with brackets until it reaches the desired height. The process is completed by attaching the pipe to the boiler nozzle and sealing the joints. To ensure that the external chimney warms up quickly, it is insulated along its entire length with basalt wool.

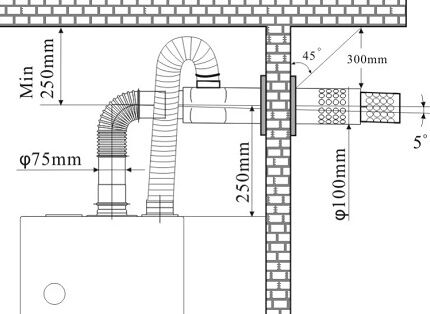

Installation of a coaxial chimney

This type of chimney removes combustion products outside and at the same time supplies the boiler burner with oxygen-rich air. With this design, no additional ventilation is needed.

The chimney is made of round pipes - an outer steel pipe with a cross-section of 10 cm and a wall thickness of 0.1 - 0.2 cm and an inner aluminum pipe with a diameter of 6 cm. The pipes do not touch because there are jumpers between them.

Coaxial chimneys are installed for boilers with a closed combustion chamber, designed for wall and floor installation, as well as for water heaters and other gas units.

This gas outlet has several advantages:

- Structurally, the pipe is designed so that simultaneously with the heating of the incoming air, the exhaust gases are cooled;

- the chimney increases the efficiency of the equipment;

- It has compact dimensions, so it is used not only in private houses, but also in city apartments;

- safe - the exhaust gases do not come into contact with the room air and do not exit through the ventilation duct but directly into the atmosphere;

- easy to install.

Install a coaxial chimney both horizontally and vertically. Regardless of the installation method, the maximum length of the chimney should not exceed 4 m.There are models with thorough parameters, created specifically for long-distance smoke exhaust.

Directly below installation of a coaxial chimney Manufacturers produce specially designed adapters used for vertical transitions through floors and roofs. To protect the system from precipitation and ensure tightness in the area where the pipe passes through the ceiling, there are special caps.

If a coaxial chimney is used for a boiler installed on a wall, it should be positioned horizontally. In this case, it is necessary to ensure a 3-5% slope, otherwise condensation will enter the boiler.

The standards regulate not only the dimensions of the chimney itself for a gas boiler, but also the location of the hole in the wall. It should be at least 50 cm away from the window next to it and at least 25 cm if it is located above the window.

How to remodel an old chimney?

If a gas boiler is included in a long-existing heating system instead of a conventional stove, the brick chimney does not have to be completely rebuilt. It can be upgraded by sleeving. There are two ways to do this.

Method number 1. Install a stainless steel pipe at the base of the existing chimney.

The pipe should be selected so that its height is equal to the height of the old chimney, and its diameter matches the boiler pipe. The gap between the walls of the existing chimney and the pipe is filled with heat-insulating material such as foam glass, expanded clay or perlite.

Method 2. Apply Furan-Flex technology.This option is more expensive than the first, but the diameter of the chimney remains unchanged. The material is frost-resistant, does not corrode, the diameter ranges from 6 to 100 cm.

The technology itself consists of placing an elastic pipe inside the chimney under pressure. The pipe takes the shape of a chimney, then hardens and becomes a continuous, seamless shell that does not allow smoke or condensation to pass through.

Conclusions and useful video on the topic

Video #1. A detailed overview of the installation of a coaxial chimney designed for a gas boiler can be seen in this video:

Video #2. Here is useful information on how to choose a chimney while avoiding common mistakes:

Video #3. Video about eliminating violations of chimney installation technology for a gas boiler:

Any household appliances, especially those running on such an unsafe energy source as gas, must be installed in compliance with all rules. The device for removing combustion products from gas boilers requires a competent approach. First, they carry out engineering calculations and only then implement the project, so it is better to entrust all this to specialists.

Do you have any questions about the design and installation of chimney pipes for a gas boiler? Do you have any comments on the material? Do you want to share your experience in arranging a smoke duct yourself? Please write comments in the block located below the text.

I agree with the author that coaxial and combined chimneys, which can be installed on the wall or adjusted to the structure of the house, are well suited for gas wall-mounted boilers.

But, purely my opinion, there is nothing better than a brick chimney with condensate drainage, both in construction and in operation.. Let me explain my point. Today everything is fine with your gas, but tomorrow a dozen more houses will be built on your ShRP, and the pressure will drop. Or maybe they’ll come up with something else that will make heating cheaper than gas.

With a brick chimney, you simply change the boiler; with other chimneys, you will have to change both them and the boiler itself, and that’s another story, as they say.

I want to lay a chimney from a gas boiler outside a one-story house with an attic. Is the issue with condensation solved differently for internal and external chimneys or in the same way? If such hot smoke enters the chimney that condensation forms even in summer at positive atmospheric temperatures, is it possible to somehow deal with it? Are there methods to reduce or eliminate condensation?

Condensation cannot be excluded, since water is released during the combustion process, but it can be reduced if you use sandwich pipes. It is better to drain condensate outside. Then you simply won’t notice it...

Not a comment, a question. The outlet diameter of the gas boiler is 115 mm, the existing chimney is 100 mm. What is your opinion - can it be connected using, for example, a smoke exhauster? Thank you.

Hello. SNiP 2.04.05-91 and DBN V.2.5-20-2001. The cross-section (diameter) of the chimney cannot be smaller than the outlet pipe on the boiler.

Is it possible to place a coaxial chimney of a 20 - 24 kW boiler vertically from the boiler room to the roof of the house? The house is one-story.

Hello. Yes, if it is provided in the instructions for the device itself.

Everything, of course, is clearly explained, but not all materials are always available in our city. It remains to install asbestos pipes the old fashioned way. Gas service workers do not allow these pipes to be insulated. Everyone wants this chimney to last longer, so they insulate it with mineral wool. Hence the question: is it possible to insulate chimneys in this way to avoid condensation?

Hello. Why don't the gas service workers allow it? We have the opposite situation, for example. We bought a house last year, when we were still importing things, and a specialist from the gas company showed up (the previous owners had not registered the new gas boiler).

So, he inspected all the equipment and the system, took the chimney seriously, saying that it was not insulated - “at least wrap it with basalt wool on the frame.” In terms of flammability, mineral wool is a fairly resistant material; there should be absolutely no problems.

In a two-story house, where initially there were wood boilers and later gas ones were installed, the boilers were turned off. The grounds are an act of firefighters, they do not see the sky in the mirror. When examined with a camera, it turned out that the chimney had ledges. But the traction is normal. Are firefighters legal?

Hello.

Firstly, firefighters could not dismantle and turn off anything without drawing up special official acts, which you could easily read and even make a copy of (go to the Criminal Code and ask for such an act). A strange thing is that we doubt the actions of authorized persons, although we can check the exact measurements and legal justification.Or did you see the act and not just hear about it? Then there should be no questions at all, the document is drawn up and officially signed.

Secondly, it is difficult to answer your question without knowing what kind of ledges there are. According to the norms and rules, chimneys must be vertical with a permissible horizontal offset of 30 degrees of no more than 1 meter with smooth outlets and a stable cross-section. At the same time, there should be no protrusions, overflows of solution, etc. inside the chimney.

It seems to me that the actions of firefighters are not only legal, but they also need to be thanked for caring about your safety.

For about 40 years, our two-story house was heated by gas stoves made of red brick based on a clay-sand mixture with burners of the UGOP-16 type.

A neighbor on the first floor installed a double-circuit wall-mounted boiler with a closed combustion chamber that discharges combustion products into the existing chimney of his old stove, which also passes through our stove on the second floor. Under the roof, the chimneys of our stoves were combined into a common asbestos-cement pipe.

From the very first year of operation of a gas boiler by a neighbor, problems with draft in my furnace began in winter. By February, the connecting pipe above the ceiling was completely frozen over with ice from condensation, and the boiler on the first floor continued to operate and push combustion products into my stove through the common pipe, and then into the living rooms.

I was forced to remove my chimney from the connecting pipe, making my own separate exit. But this turned out to be not enough. As a result of the erosion and destruction of the chimney channel by condensate from the boiler, the chimney became unsealed.And, consequently, in the winter the pipe will freeze again, and the turbine will push the combustion products through the leaky walls of the chimney into my stove and then into the living rooms.

All attempts to force the neighbor to line the chimney and insulate the pipe above the roof slab were unsuccessful. Moreover, in June, a representative of Vulcan successfully inspected his chimney - in 10 minutes he wrote out a certificate of suitability and serviceability. At this time, all I could achieve was that the gas in the house was turned off, and a letter was sent to Vulcan about re-inspecting the chimney.

Are there any standards that were initially violated when installing this boiler? Just by reading all the SNiPs and DBNs, not everything is completely clear, but the operating manuals for such boilers, the actions for lining and insulation are converted into recommendations...

This year we decided to install a new gas boiler in the apartment. And as I understand it, it is also necessary to install a chimney. For some reason it seems to me that an external chimney might be suitable in this case. Who knows if this is true? And which of these types of chimneys is more suitable for an apartment located on the second floor? I just don’t want to take risks in this matter!

Just last year we installed a gas boiler in our house. I also spent a long time choosing between an asbestos-cement pipe and ceramics (I immediately excluded steel from the options). Made from ceramic - it is the most reliable and durable. I think this option is most suitable for an apartment on the 2nd floor. Of course, the chimney is external, since this is easiest to do in a high-rise building.

SP 402.1325800.2018 Residential buildings. Rules for designing gas consumption systems.Please read Appendix D.

I have two gas floor boilers, one 140 kW for heating, the second 38 kW for preparing hot water. I want to connect them to one chimney. Ceiling height 4 meters. One-story boiler room with a flat roof. Tell me how such a division is possible.

Good afternoon. When installing a boiler in an apartment on the 1st floor in a 5-story building, Gorgaz requires installing an atmospheric chimney, while I already have a turbo exhaust installed on the boiler. How legal is this requirement? Thank you.

Hello. Most likely, your boiler model is more modern, which requires the installation of an atmospheric chimney.

Is it possible to install a condensation trap in the attic?

In a Wooden House, a full-fledged basement with plastic windows, a wall-mounted gas boiler with a standard coaxial pipeline is installed, the distance of the pipe to the ground is 1 m 10 cm. The gas service requires an increase in the distance to 2 meters. Your pictures show the distance of the pipe to the ground is 0.3 meters. Where can I read about such a tolerance in installing a coaxial chimney for a gas boiler?

Hello. Please tell me, is it possible to seal pipe joints with metallized adhesive heat-resistant tape? Thank you.

In an apartment building, neighbors brought a horizontal chimney pipe out of the wall at the height of a person and about two meters from my front door and the windows of other neighbors; in addition, the pipe “breathes” 30 cm from the clotheslines (another place for them in the yard no) and on people passing by on the path.How dangerous is this for us? What standards exist for the installation of such a chimney and the safety of people? Photo 2 is my door.

Is a coaxial chimney suitable for boilers with an open combustion chamber?

Why refer to outdated documents? Instead of SNiP 2.04.05-91, SNiP 41-01-2003 is now in force.

In my private house, I had a chimney made from asbestos-cement pipes, and they have been in service for 26 years, and during this time the galvanized ones burned out, the simple publicly available stainless steel, which is sold everywhere, decomposed, and as a result, the supply pipes from the boilers had to be replaced with food-grade stainless steel. While I'm watching.

We installed a turbo nozzle from Proterm 30 on the Baxi Slim 1230 boiler. Sometimes the boiler turns on with an explosion. I don't understand what's going on

Good afternoon.

The old boiler was leaking. I called the repairman, he took the money and brought me the boiler. They called for service, put the boiler under warranty, although the boiler did not work, error 003 was displayed, the sensors were triggered. In my case, a boiler with a turbine would be suitable. Tell me, do I have the right to demand that the boiler be fixed and replaced by those who supplied it to me?

The photo is terrible, and in some cases, the recommended distances are less than those indicated in the construction standards..

The aesthetics in the photo are tin..

The installers would have to beat their hands...

I have a question: how high should the pipes be from the level of the slate on the nearest roof (see photo), if the neighbor’s house is 2 meters away from the pipes? Previously, the nearest house was two-story, but the neighbor’s house did not exist at all.Therefore, such a misunderstanding. :-) And if possible, with a link to the normative act. I couldn't find it unfortunately. Thank you very much in advance.

Hello! I have a floor-mounted atmospheric in the kitchen of a townhouse. Can I install a wall-mounted boiler with a closed combustion chamber (not a condensing one) and connect it to the old 150mm stainless steel chimney with a new pipe through an adapter, and take air from the room or through the wall. Or, as some say, you need to buy a new 12-meter pipe for pressure exhaust from a special stainless steel for a lot of money and thread it into the old chimney? (why is not clear). Thank you

Gas boiler Baxi boiler 24 kW, coaxial exit to the street 100/60, heights below 2 m, you need to make a sandwich upstairs.,

Is it possible to make a sandwich chimney with an internal diameter of 80 mm (the internal diameter of the coaxial is 60 mm)

Gas boiler Baxi boiler 24 kW, coaxial exit to the street 100/60, heights below 2 m, you need to make a sandwich upstairs.,

Is it possible to make a sandwich chimney with an internal diameter of 80 mm (the internal diameter of the coaxial is 60 mm)