How to connect gas to a private house: input device + installation of the system

Do you want to connect your house to a centralized gas supply? But this desired event can take a lot of time, effort and money, right? Do you want the gasification of your household to take place without unnecessary stress and fines, but don’t know how to proceed correctly?

We will help you understand the procedure to connect gas to a private home in the shortest possible time and without problems. The article discusses all stages, starting with documentation and ending with putting the installed system into operation. Visual photographs and informative videos have been selected.

Understanding the features of this process will allow you to use your resources more profitably - after all, excavation work can be done on your own. But for the insertion, the participation of a gas service employee with special permission will be required. Knowing the specifics of installing gas communications won’t hurt either.

The content of the article:

Features of gasification of residential buildings

With the help of gas, you can successfully organize heating, hot water heating, and cooking in your home. Gas equipment is reliable and diverse, and the cost of blue fuel is usually lower than using electricity, solid or liquid fuel for the same purposes.

In addition, gas lines rarely fail, but power outages are a common occurrence.The reserves of firewood, coal, diesel fuel and other similar energy carriers have to be constantly replenished.

The main problem with natural gas is its danger to human health and its ability to explode. Even a small leak can lead to poisoning or an explosion. That is why the requirements for the installation of gas communications are very high; you should not even think about doing all the work yourself.

To begin with, experts do not recommend saving on materials or system elements. Laying pipes of questionable quality and unprofessional installation are unacceptable.

Gas pipes almost always need to be laid open (except for underground sections of the pipeline). They cannot be hidden under any decorative elements to improve the interior.

It is recommended to avoid installing detachable connections whenever possible. All places where pipes are connected must be located in such a way that the contact point can be inspected at any time and repaired if necessary.

Gas pipes must not be laid inside walls or deep into the foundation. This rule also applies to other elements, such as platbands, door frames, window frames, partitions, etc.

In some cases, it is permissible to lay a gas pipe in a wall niche, but this point must be clearly reflected and justified in the project.Special requirements are also imposed on the slope of the pipes. Horizontal deviation of the line position is allowed by only 3 mm towards gas appliances.

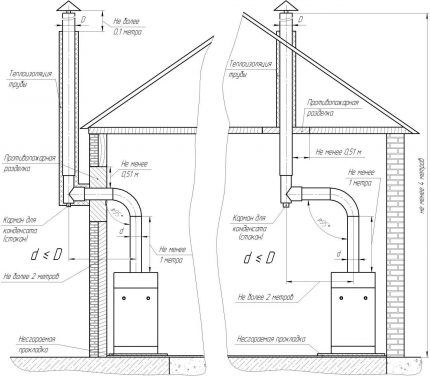

Vertically, no deviations are allowed, but the riser may have a slight slope: no more than 2 mm per meter. It should not pass through living areas, toilets or bathrooms. The gas riser should be located on the staircase; it is often routed through the kitchen.

You will also have to pay close attention to the installation of shut-off valves. Thus, the position of the central axis of the plug should be strictly parallel to the wall along which the pipe runs. When choosing the position of the tap, you should make sure that the position of the shut-off device is not blocked by the wall. The gas pipe should be located at a distance of 100 mm from the ceiling and from the walls.

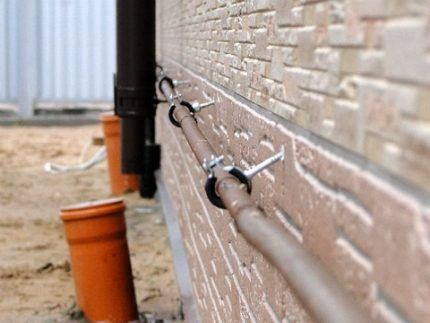

The gap between the wall and the pipe can vary from the radius of the pipe to a maximum value of 100 mm. This clearance is necessary so that the structure can be easily examined. A distance of 2.2 m should be maintained from the floor. Gas pipes are placed on special strong supports; sagging of the structure is unacceptable.

Therefore, you need to make sure that there are no gaps between the bracket and the pipe. All these important points are taken into account in gas supply system project, which must be previously compiled by specialist engineers.

Gas pipes should be laid no less than 30 cm from the electrical panel, and no less than 25 cm from open wiring. You should step back at least five centimeters from the hidden cable.

Gasification of households step by step

When figuring out how to connect natural gas to a private home, you should take into account the lengthy procedure for completing various documentation.

Stage #1 - documentation of gasification

First, the owner will have to submit an application with a request for gasification of the house, to which must be attached documents on ownership of both the house and the plot, as well as all available technical documentation in relation to these objects.

After this, specialists must examine the site and the house to draw up a document called technical specifications. At the same stage, it should be clarified whether it will be necessary to lay part of the highway through the neighbors’ plots.

It is better to immediately discuss this issue with them, obtain permission and agree on the specifics of the work. This way you can avoid many problems and delays.

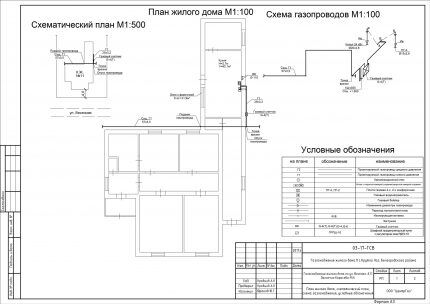

Based on the technical specifications, a package of design documentation for gasification of a specific house and plot. Only after this will it be possible to hire a contractor to carry out a complex of installation work.

The installation of the external and internal parts of the gas pipeline, connecting it to the common pipeline, connecting gas equipment and other important stages will be carried out.

In the process, you will have to draw up a number of important agreements, such as:

- for carrying out research work and drawing up technical specifications for designers;

- for the preparation of project documentation;

- to carry out installation work on laying internal and external water supply systems;

- for the supply of natural gas, etc.

In addition, it is necessary to obtain a number of permits. For example, you will need permission to gasify the site from the local architectural department.

You should also invite specialists who will inspect the existing chimney in the house (or one specially built for a gas boiler and other gas appliances). The satisfactory condition of the structure is confirmed by the relevant act.

With the cost of connecting a suburban area with a house to a centralized gas supply read the article, completely devoted to this issue.

Stage #2 - connecting the pipeline to the house

Almost all elements, devices and materials that will be used in the gasification process should have quality certificates. For gas pipeline installation It is usually recommended to use low-alloy or low-carbon steel pipes. The diameter of the structure should be 150 mm with a wall thickness of 5 mm.

The use of non-galvanized seamless steel alloy pipes is allowed. The pipeline is assembled by welding, the quality of which must be impeccable for individual sections of the pipeline. Threaded connections are used at installation points of shut-off valves.

In addition to steel pipes, polyethylene structures have been increasingly used for the installation of gas pipeline systems in recent years. They are lighter in weight, easier to install, well resistant to cold, heat, aggressive chemicals, do not conduct electricity, etc.

When laying polyethylene pipes in the ground, you can do without additional protective measures, as is done for steel structures. However, plastic is used only for the installation of external gas pipelines; the entrance to the house and the internal system must be metal. Plastic is also not applicable in areas with very harsh winters and increased seismic hazard.

Laying a gas pipeline underground is, for obvious reasons, more expensive, but if it is done correctly, then such a pipe will be reliably protected from outside influences and accidental damage.

If the pipe needs to be laid across the road, the contractor will have to block the road and draw up a detour traffic pattern. The scheme is approved by the local traffic police department, on the basis of which the executor receives a warrant.

It is recommended to give preference to the above-ground laying of a gas pipeline in areas where the soil has increased corrosion characteristics, but if power lines are located nearby, then it is better to give preference to underground communications.

On one site, you can combine both types of laying, for example, lay a gas pipeline underground across the road, above ground through the neighbors’ property, etc.

Once the project is ready, you can proceed directly to the installation work. Of course, they will be carried out by specialists who have the necessary training and equipment.

Stage #3 - arrangement of the boiler room

But even before starting to lay the gas pipeline, it is recommended to take care of the premises where gas appliances will be installed: gas floor boiler or wall column, stove, etc.

Both the boiler room and the kitchen should have a window that can be opened at any time for ventilation. The opening area must be at least half a square meter. The ceiling height should be at least 220 cm. Door leaves should be made to open outward rather than inward.

It should be taken into account that the number of burners on a gas stove depends on the size of the kitchen. Thus, in a room with an area of less than eight square meters, it is allowed to install only stoves with two burners; for a stove with three burners, at least 12 square meters are required. m, for a four-burner device - at least 15 sq. m, etc.

If the boiler power exceeds 30 kW, you will need to build a boiler room for it, located at some distance from the house. Good forced ventilation should be provided here, the walls, floor and ceiling should be finished with fire-resistant materials.

You should not use the boiler room as a storage room; the presence of foreign objects and materials can cause an accident.

The boiler room, which is located in the house, must be supplied with water, as well as a sensor to determine the level of carbon monoxide in the air. It is recommended to install an alarm system that will shut off the gas supply in the event of a leak. You should not install more than two low-power boilers in one boiler room.

For a 30 kW device, a room with a volume of at least three cubic meters is required; for high-power boilers, more than 60 kW, at least 11.5 cubic meters are needed. m of space. People should not be in the boiler room for more than four hours a day.

The covering of the floor, walls and ceiling in the boiler room must not only be resistant to fire, but also not produce dust. Dirt often causes breakdowns of gas equipment.

A prerequisite for connecting to the main gas supply is the installation gas meter. Our recommended article will familiarize you with the rules for choosing a gas flow meter and the specifics of its installation.

Stage #4 - entering communications into the house

In order to correctly introduce gas into the house during the installation of your own gas supply system, make a hole in the lower part of one of the external walls, but not in the thickness of the foundation.

An insert in the form of a steel sleeve is first inserted into the hole, and then a pipe is inserted into the house through it. The main riser and internal gas pipeline are then connected to it.

The riser is usually placed vertically, 15 cm away from the wall and secured with special hooks to secure the vertical position. The pipe is installed at a slight slope towards it.

All places where gas pipes pass through walls deserve special attention. The holes need to be made large enough, since they also need to include protective sleeves through which the pipes are passed.

Previously, all areas of communications that will be located in the wall should be covered with several layers of oil paint. The gap between the surface of the pipe and the sleeve should be filled with a layer of tow impregnated with resin, and also filled with a layer of bitumen.

In this case, you need to make sure that there are no places in the wall that are connected by welding or threading. Only a solid pipe can be located in the thickness of the wall.

The fewer connections there are in the gas pipeline, the larger the sections of solid pipes, the better for the safety of the structure. In order not to cut the structure when it needs to be bent and changed direction, it is allowed to heat the area with a gas burner, but this method should not be abused.

The individual parts of the gas pipeline are connected on the ground, then the pipes are installed along the walls, connected, and secured with special brackets.Narrow pipes, less than 40 mm in diameter, can be fixed to the wall using clamps or special brackets.

Thicker structures are suspended on brackets, as mentioned above. In any case, you need to firmly fix such fasteners in the wall using concrete mortar and wooden plugs.

Welding gas pipes is a special art. In order for the seam to be truly smooth and durable, it is necessary to carefully prepare the surfaces to be joined. The edges of communications should be trimmed, leveled and cleaned to one centimeter. Only after this can you begin welding work. It is recommended to use high quality electrodes.

Threaded connections should be made as few as possible. They must be carefully sealed to eliminate any risk of gas leakage. First, the thread is treated with whitewash, then a sealant is wound around it (linen thread, FUM tape, etc.), only after that the connection is screwed in.

Stage #5 - trial run and final activities

After assembling the system and introducing gas into a private house, you will have to go through a number of final steps. Before starting up and setting up the equipment, home owners must undergo safety training. To lay the internal and external gas pipelines, you can, if desired, invite either one contractor or two different ones.

These can be either specialists from a local gas organization or third-party organizations that have the appropriate licenses. But direct connection to the main gas pipeline must be carried out by a separate tie-in service.

After this, the first gas is released into the system and the checking for leaks. This service is paid separately. By this time, a service agreement for existing gas equipment should already be concluded.

After the first start-up of gas, a specialist from the service company must set up such equipment; this is an important point on which the validity of the warranty obligations depends.

If for some compelling reason connecting to the main gas system is not yet possible, pay attention to the option with installation of a gas tank. It is possible that at the moment this method of organizing gas supply to the house will be more attractive to you personally.

Conclusions and useful video on the topic

Detailed information about the procedure for gasifying a private house is presented in this video:

Here are practical tips that will help you avoid common mistakes in the gas installation process:

Carrying out gasification work at any facility is a job for professionals with the appropriate skills and licenses. The owner of the site is responsible for completing the necessary documents, selecting a contractor, etc..

The whole procedure is usually expensive, but the result is worth the money and effort.

Please write comments, ask questions, post photos on the topic in the block below. Tell us about how you connected your site to the centralized gas supply.It is possible that your experience will be useful to site visitors who will have to go through a similar path.

Gas workers have their own tricks that they use for their own benefit. And the increased cost of connection is not the worst of their methods. They love to save materials. I was at work when the pipeline was installed. So: the main pipes now pass through my yard. Now we can’t build a shed or build a garage. According to initial calculations, as I now know, they were supposed to go around my yard. But the wife signed their plan, which they made on the spot. They said all sorts of things, but she didn’t understand. Now, if you have to redo the laid section of the gas pipeline, then only at your own expense. They have protected themselves; they have nothing to show. Be careful not to end up in the same situation.

I, too, experienced all the delights of butting heads with gas workers, having inherited a house in the suburbs. There is gas in the village, but there is no connection to us, although the pipe goes above my gate. They gave me so much money for the tie-in project that I sat down.

What to do, they have a monopoly on all gas work, so there are no options. We had to fork out money for the project, and for the tie-in for all the work, and for the meter, and even for starting the boiler.

They also counted their own materials, at greatly inflated prices, as if their pipes were made of gold.

Yes, gas workers are trying to push through more money, and if the owner is not indignant and pays, then they are happy. After examination of the project, the price should be recalculated downwards. You can save a lot of money if you handle all the approvals yourself. But you have to figure out the issue and run.

It's just an ordeal that we have to go through! Install alarms, paint the pipes yellow, no, you installed them wrong, rearrange them! How does a pensioner get so much money? People make ends meet. They put up such fabulous bills that now that there is an arch at home, you see they need a door! I have no words. It hurt.

Hello. All documents with clauses about doors in the furnace room are no longer valid. But the gas workers will still be right, they will take it and refer to the fact that ventilation standards are not provided, and in addition, that your gasified premises communicate with a residential one, which is prohibited according to the standards. We sympathize with you, hold on, be patient.

There is high pressure gas passing along the fence boundary, will I be able to connect?

It is not possible to connect directly to the high pressure pipe....., a pressure reducing system is required. Why don’t you connect to a low-pressure pipe to the street gas pipeline, like all the normal neighbors on your street?

Snow falling from the roof of a house onto a gas pipe is a common occurrence. There are examples on the Internet. Project defect - the gas pipe is supplied to the house in the snow melting area. Corrections are needed in the regulatory documentation. Otherwise, rake, rake, rake.

Where do prices come from, how do they add up???? And how do you understand the connection if you have already paid for gas supply to the house????

They laid a gas pipe in the village according to PPRF 1547, and charged a price of 175,000 rubles. I began to study documents on gasification, and realized that we were being stupidly scammed out of money. 1. A project in private housing construction is not needed. Clause 74b of the resolution, see also clauses 12,26,80 and read the entire resolution .2.amendments were made to PPRF 815 dated 05/28/21 (PPRF 914 dated 05/20/22) and clauses 39 and 41c were deleted as of 09/01/22. and all that remains is RF PP 870 dated 10.29.10, clause 95. If you want to save money, study the RF PP, which are mandatory for execution. Also see Art. 48 part 3 of the Town Planning Code of the Russian Federation. as soon as you agree to the project and sign everything that the designer wants, you are obliged to pay, and he and the contractor will include everything to the maximum. Good luck.