Rules for connecting a double-circuit gas boiler to gas

The main purpose of domestic gas boilers is to provide housing with heating and hot water.You cannot install such equipment yourself, since installation work and operation of gas appliances are associated with certain risks.

However, the owner of the house is directly involved in the design of the boiler room, wiring of the heating circuit, etc. In order to be able to control the performers, you need to understand how the unit works, what is the connection diagram of the double-circuit gas boiler to the central gas pipeline and cylinders with blue fuel.

The answers to these questions are described in detail in the article. In addition, we have outlined technical requirements that are important to comply with in the process of designing the boiler piping, its installation and the use of gas equipment.

The content of the article:

How do double-circuit gas boilers work?

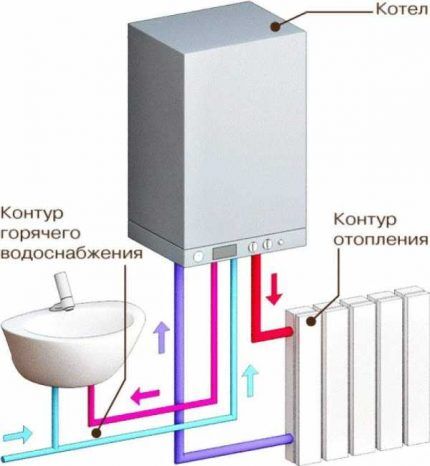

As a rule, gas-fired devices are installed under the heating system. closed system, where the water pressure value is not higher than 0.3 MPa. If we talk about how to properly connect a home gas boiler, the answer is obvious.

Traditionally, a scheme of artificial coolant circulation with an expansion vessel is used. To prepare hot water with gas equipment, a centralized cold water supply with a pressure of 0.02 - 1.0 MPa is used.

True, the exact values are determined by the specific brand of equipment and manufacturer. Selecting a double-circuit boiler made taking into account specific installation conditions.

Boiler heating circuit diagram

By default, the heating circuit of a gas boiler is designed to fill the central water supply with cold water. It is also allowed to operate heating equipment when water with glycol-based antifreeze (C) is used as the coolant.2H4(OH)2), certified according to GOST.

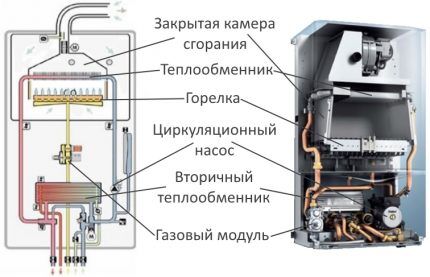

The coolant coming from the return line of the heating circuit is directed through a filter into a heat exchanger, the design of which allows for the initial filling and periodic replenishment of the heating circuit with water from a centralized water supply.

Further movement of the coolant is activated by a circulation pump, the design of which contains an automatic air vent. Then the water flow passes through the zone of the minimum coolant flow sensor and is supplied to the input of the first (external) circuit of the coaxial type heat exchanger.

Moving through the heat exchanger, the water is heated by the energy of gas combustion.

At the outlet of the heat exchanger, on the coolant supply pipeline, there is a submersible temperature sensor. Mounted here safety valve spring action, equipped with a pressure release mechanism.

The upper limit for opening the safety device is 0.3 MPa. A membrane-type expansion tank is also included in the supply line.

Functioning of the DHW circuit

The DHW scheme works something like this: cold tap water under pressure from a centralized water supply is supplied through a mesh filter to the water block. The block design, made of brass, allows for initial filling and periodic replenishment of the DHW system.

Next, through the installation area of the water flow sensor and through the magnetic anti-scale device, water flows to the internal channel of the coaxial heat exchanger made of copper. Due to the selection of heat from the walls of the heat exchanger, heated by the coolant passing inside the heating circuit, the cold water is heated.

The hot water preparation mode provides for temporary shutdown of the boiler circulation pump. At the outlet of the heat exchanger there is an immersible temperature sensor that measures the operating parameters of the supply line.

Here, on the boiler supply line, a second spring-action safety valve with a pressure relief mechanism is installed. The response limit is usually 1.0 - 1.1 MPa.

Connection to natural gas

The gas boiler is designed to connect natural gas, the technical characteristics of which correspond to GOST 5542. Fuel, as a rule, is supplied from a low-pressure gas pipeline with a value of 0.0013 - 0.0020 MPa.A filter mesh and a valve-regulator for the flare ignition device are installed on the supply line.

The electromagnetic gas valve maintains the stability of the gas pressure at the inlet to the boiler burner mechanism. Therefore, regardless of fluctuations in gas pressure on the line, stable, safe functionality with high efficiency is ensured.

Electronic control regulates the power of the gas burner within 40-100% of the declared rated power.

Method of connection to the gas main

Before considering options for connecting natural gas to the boiler, you should recall the established rules for operating such equipment. Boilers operating on gas are technological objects of increased danger.

Installation, connection and operation of such systems requires compliance with established safety standards.

Gas boilers are installed only inside premises suitable for installation (kitchens, corridors, utility rooms). This refers to the premises of public industrial buildings, private houses, cottages. All these properties must comply with the requirements for the presence of effective ventilation.

As a rule, compliance is determined by SNiP 42-01-2002 and SNiP 2.04.08-87.When solving the problem of how to connect a boiler to a gas line, you need to remember that the operation of the equipment requires the construction of a mechanism removal of smoke into the atmosphere. In addition, it is necessary to provide a supply of atmospheric air for an efficient combustion process.

Gas boilers that support the function of natural exhaust of combustion products must be installed in close proximity to chimneys with natural draft.

For equipment whose design provides for air suction directly at the installation site, a normal level of air vacuum should be ensured. Inside such premises, the air must be cleaned of dust and chemical impurities.

Technical nuances of connection

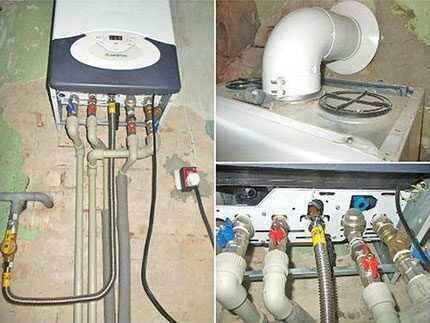

The process of connecting a gas boiler to a gas pipeline using a flexible hose has its own technological and technical features. Thus, laying a gas pipeline and subsequent connection to the boiler can only be carried out by gas specialists.

Before connecting the gas boiler, the supplied section of the gas pipeline should be cleaned of foreign substances, impurities, and contaminants. This requirement is especially relevant for installation on used systems.

The gas inlet must be equipped with shut-off valves designed for gas service, complete with a thermal shut-off device (TAE). Before connecting the gas pipeline to the boiler, it is necessary to check the tightness of all connections and connections of the gas pipeline with a test pressure of at least 0.15 ATI.

The cross-section of the flue gas pipeline must correspond to the diameter of the pipe on the flow protection device. Narrowing of the passage part of the exhaust gas pipe is allowed, but only if the correct functioning of the line is justified by calculations (according to GOST standards).

The exhaust gas pipeline is made shortened (if possible), with a slight slope in the section of the rise to the chimney.

The line supplying gas to the boiler is usually made of a metal pipe. It is allowed to construct supply lines based on steel and copper pipes.

Meanwhile, permitted installation with polymer pipes (multilayer, with a metallized layer) is also not excluded. True, polymers are only allowed to be used inside buildings no more than three floors high.

Using a flexible hose

It is permissible to connect the gas source to the boiler using flexible hose.

Condition for using flexible hose:

- resistance to gas environment;

- compliance with working (test) pressure;

- compliance with operating (test) temperature.

The noted characteristics and parameters can be taken from the technical data sheet of the boiler equipment.In this case, the flexible hose used must have a diameter of 20 mm, and the length of the hose can be no more than 1.5 m.

Connection with flexible hoses (sleeves) must be carried out in full accordance with the installation rules specified in the accompanying documentation of the product manufacturer.

Features of connection with cylinders

Flexible hoses (sleeves) are often used to connect SG cylinders with boiler installation. However, to switch the boiler into this particular fuel feeding mode, it is necessary to make a number of settings to transfer the equipment to operation with bottled gas.

If the boiler design supports such a power supply option, the instructions describe the sequence of operations.

Here, the technological requirements for hoses of a flexible structure are practically no different from the requirements for connecting to a centralized main line. Also, the diameter of the hose is at least 20 mm with a length of no more than 1.5 m. However, the gas cylinder should be equipped gearbox, set to a pressure of 2.9 kPa (steam environment).

For cases of feeding boilers with bottled liquefied gas, separate standards have been approved, in particular those related to the storage and operation of cylinders. For example, these standards prohibit placing vessels in areas exposed to sunlight, near heat sources and open flames.

One of the main prohibitions is the taboo on installing gas equipment directly inside buildings.

An overview of gas boilers operating on liquefied bottled gas is given in this article.

Thus, the use of gas boilers in practice, including the domestic sphere, must be considered a responsible action, the accuracy of which determines the degree of safety.

Conclusions and useful video on the topic

Some useful tips for installing a gas boiler will help you check the correct installation of the equipment.

With all the perfection of gas equipment, with the presence of automation and serious technological protection, connecting the system requires compliance with established rules and regulations. Without this, it is impossible to guarantee the reliable operation of gas boilers.

Do you have anything to add, or do you have any questions about connecting a double-circuit gas boiler? You can leave comments on the publication and participate in discussions about the material presented. The feedback block is below.

It is written in a detailed and accessible manner, the text is supplemented with practical advice and nuances. From personal experience I can add the following regarding connecting a gas double-circuit boiler: you need to hang (mount) it at the correct height. Because the master hung it too high for us, almost to the ceiling itself, which led to the accumulation of gases.The ventilation ducts couldn't cope. There was a smell of gas in the house, and the boiler constantly flared up when turned on. This caused our equipment to break down.

Although the house has a boiler for heating water, when designing the gas supply and installation of the boiler, I specified a double-circuit type in the contract. I read your information and realized that I was right. Although many “experts” recommended single-circuit. I still have to buy it, find a suitable option for my limited budget. And I and my family will be happy in winter, otherwise the firewood will run out :)