Design, types and rules for installing coaxial chimneys

An autonomous heating system, if it does not run on electricity, cannot do without a device that removes combustion products.If previously it could only be a traditional chimney, now there are other options that are more effective and practical.

Installing a coaxial chimney provides many advantages; in addition, it can be installed in an already constructed building. What is so good about a coaxial type chimney? We'll figure out.

The content of the article:

Coaxial chimney: what is it?

In technology, the concept of “coaxial” means the presence of two objects located so that one is inside the other. Thus, a coaxial type chimney is a double-circuit structure made of pipes of different diameters.

Inside the larger element is a smaller part. The distance between them is strictly the same along the entire length of the structure, including all bends and elbows.

For this purpose, special jumpers are placed between the pipes. In cross section, such a system looks like a pair of concentric rings. The channel for removing smoke is an internal, smaller diameter pipe.

Through the gap between the two parts, oxygen necessary to maintain combustion enters the heating device from the outside. Thus, gases within the system move in opposite directions.

The design features of a coaxial type chimney give it the ability to perform functions at once. The device ensures an uninterrupted supply of air, which is necessary to maintain the combustion process.

In addition, it successfully removes combustion products from the boiler. The length of the structure usually does not exceed two meters. Most often, systems are installed horizontally, but there are also vertical variations.

A coaxial type chimney is a system of modules, which allows the manufacture of chimneys of various configurations, taking into account the architectural features of the building. All elements included in the system are standardized, which greatly simplifies their installation.

The standard kit consists of several modules:

- Straight pipes. The chimney itself is formed from straight pipe sections.

- Tee. Installed in the system only if two or more boilers are used.

- Connecting elements. These are 90° and 45° bends and couplings.

- Condensate discharge device. Such a kit is necessarily provided for each vertically oriented area. It is equipped with a water seal, which prevents the pressure of the gas-air mixture in the chimney from decreasing.

- Elements with inspection hole. They are intended for inspection and cleaning of the system.

- Output and input nozzles. Supplied complete with ends, they are used to remove combustion products and intake clean air. The outlet nozzle is always mounted at a distance from the air intake point so that it does not mix with the exhaust gases.

- Adapter. Used to connect the system to the boiler.

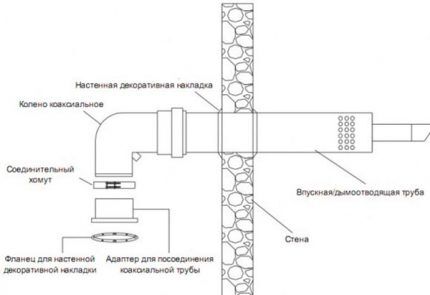

- Fittings for fastening. These include brackets, clamps and flanges.

- Seals. Devices required to ensure the tightness of the passage of a pipe through a wall or roof.

- Decorative overlays. Flanges that cover the passage of the chimney trunk through building structures.

To manufacture parts for coaxial chimneys, galvanized or stainless steel is used. It is resistant to high temperatures, durable and lightweight.

Some models are made of aluminum alloys or heat-resistant plastic. For joints, seals made of heat-resistant polymers that can withstand temperatures of about 230-250° are used.

Types of coaxial type chimneys

There are several types of “pipe-in-pipe” construction. Let's look at each of them in detail.

External and internal systems

All coaxial chimneys, depending on their location, are divided into external and internal. The first are located on the outside of the building and are fixed directly to the facade.

Considering that such structures somewhat spoil the appearance of the building, they try to place them on the inner sides of the building. A distinctive feature of an external type chimney is its ease of maintenance and installation.

Internal structures are mounted in specially laid shafts that run inside the building and are separated from the living quarters. In some cases, traditional chimneys can be used as such shafts.

It is important that their design and dimensions fully comply with modern fire safety requirements. Internal systems are quite complex to maintain and install.

Non-insulated and insulated devices

In cold weather, especially in severe frosts, the channel supplying air to the system may freeze. In this case, the amount of oxygen entering the combustion chamber sharply decreases, which leads to deterioration in the operation of the heating device.

In some cases, even to its stop. Therefore, where low temperatures last for a fairly long period of time, as well as where severe frosts are common in winter, it is recommended to install insulated systems.

The insulated coaxial chimney differs from the standard one by the presence of one more pipe. The system looks like three parts nested inside each other.

The free space between the two extreme elements is insulated. For this purpose, it is filled with any suitable insulation. This reliably protects the air channel from icing and freezing.

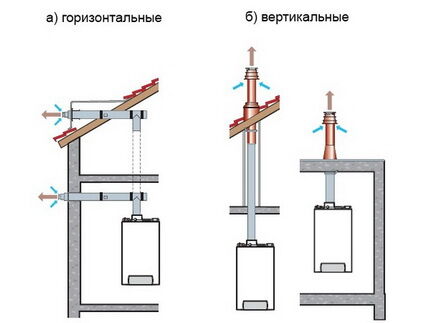

Horizontal or vertical output

Initially, coaxial chimneys were developed as horizontally oriented systems, but in practice such an arrangement is not always possible. Most chimneys of this type are mixed structures.

They may contain both vertically oriented and horizontal sections. This is due to the location of the heating device in the building. In some cases, it is possible to use vertical chimneys, but only for boilers without forced draft.

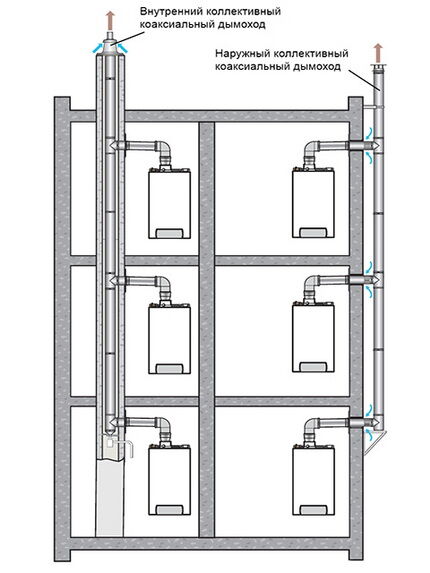

Collective and individual designs

To service one heating device, individual coaxial chimneys are used. These are simple systems without branches that can have different configurations.

To work with several boilers, a collective chimney is installed. This is a mine system with several branches. In this case, each of the branches goes to one of the heat generators. This design can only be vertical.

Why choose coaxial systems?

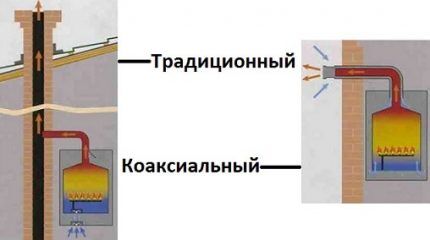

The design features of a coaxial type chimney give it the opportunity to work on a principle different from a traditional chimney. To ensure combustion, oxygen must be supplied to the boiler furnace and combustion products must be removed.

Boilers equipped with separate chimneys take air from the room in which they are installed. This is quite dangerous for humans and requires constant ventilation of the room.

Exhaust gases are discharged outside through natural draft. Appliances with coaxial chimneys work differently. Such chimneys are a combined system of air supply and smoke removal.

The draft necessary for the operation of the device is created naturally or with the help of a fan, which allows the use of small structures.

Thus, complete isolation of the exhaust of combustion products and the supply of oxygen makes it possible to completely eliminate their impact on the composition of the air in the room where the boiler is installed.

There is no “burning out” of oxygen, as a result of which there is no need to ventilate the room.The amount of air in the combustion chamber is optimal, which increases the percentage of fuel combustion and, as a result, the boiler operates more efficiently and environmentally friendly.

Hot smoke from the heating device is discharged through the internal pipe. It passes inside another, through which cold air moves. Thus, there is no thermal effect on the walls and ceilings within which the chimney is laid.

This significantly increases its fire safety, which is very important for buildings made of wood and other fairly flammable materials.

The coaxial system increases the efficiency of the heating device. This occurs due to the fact that the air supplied to the firebox, passing through the internal cavity of the structure, is heated from the pipe that removes hot smoke.

Another significant advantage of chimneys of this type is their compactness and relatively small size, especially compared to traditional chimneys.

It would be a mistake to think that the system has no flaws. They are. First of all, this is the rather high cost of such a design. On average, it is 40% more expensive than the traditional one. Another one is due to the design of a coaxial type chimney.

Pipes with hot smoke and cold air come into contact, which inevitably leads to the formation of condensation, especially in cold weather. Thus, the system requires a special drain for condensate and additional insulation, which further increases its cost.

Features of choosing device size

The technical documentation that comes with the chimney must indicate its diameter. The designation consists of two numbers written through a fraction.

The first of them shows the diameter of the inner pipe, the second – the outer one. Finding the right size is quite simple. It must be indicated in the passport of the boiler that will be connected to such a chimney.

The determining indicator in this case will be not only the diameter of the system, but also its length. The latter is defined as the sum of the lengths of all sections of the chimney.

It has limitations stated in the installation instructions and is measured in equivalent meters. In addition, all these nuances are indicated in the selection table, which should be attached to the technical documentation of the heating equipment.

Installation of a chimney in the light of regulations

A coaxial smoke exhaust system can be installed in a private or apartment building. The latter is also quite common, especially in connection with the widespread installation of individual heating systems in apartments.

Until 2012, the design and installation of coaxial type chimneys in apartment buildings and private buildings were regulated by one SNiP and did not differ.

A set of rules was adopted in 2012 SP 60.13330.2012, which is an updated edition SNiP 41-01-2003. The document divided the conditions for installing a coaxial chimney in an individual and apartment building.In the latter case, it is prohibited to install individual chimneys in apartments, as was previously permitted, and the installation of a collective chimney is prescribed.

Therefore, you need to be very careful and know that if designers propose to arrange an individual exhaust gas outlet from a heat generator located in one of the apartments of an apartment building, this is contrary to current standards.

The distance from the ridge of the roof of the building to the section of the smoke exhaust duct must be at least 1.5 m. The same value for a private house is from 0.5 m.

No special acts regarding individual buildings have been adopted, therefore it is believed that their arrangement should not contradict the requirements applied when installing chimneys in apartment buildings. Based on the new edition of SNiP, coaxial systems of any type can be installed in private houses. In apartment buildings - only vertical ones.

An important nuance. If smoke vents were installed in a building before 2012 that contradict the current edition, they can be left unchanged if they do not cause inconvenience to neighbors. Read more about the standards for installing a coaxial chimney Further.

Some installation features

For each boiler, the direction of the channel discharging combustion products is determined individually. Horizontal systems can only be used for devices with forced ventilation.

But even in this case, the maximum length of such a section should not be more than 3 m.It happens that the manufacturer sets other standards for its boilers, so you should read the technical documentation of the device.

Vertical-type structures for private houses are used only if there are reasons that prevent the smoke exhaust duct from exiting through the wall.

This could be windows located close to the outlet pipe, a narrow street on which the building is located, and the like. In some cases, if it is very necessary, an inclined installation of a coaxial chimney pipe is allowed.

The system is connected to the heating device using a tee, elbow or pipe. In this case, the diameters of the outlet channel and the boiler outlet must be the same.

During the installation process, all subsequent parts are fixed in the preceding ones so that no obstacles are formed that could disrupt the movement of combustion products. The number and type of elements for assembly directly depend on the location of the outlet pipe.

If it is located on the side, a horizontal system is assumed, if on top - a vertical one. The latter option is easier to install.

In the process of arranging a coaxial chimney, transition units are necessarily used with rigid fastening of the junction areas of two elements using clamps. Some “craftsmen” prefer to use homemade options.

These can be adapters made by yourself, tape windings or sealant seals.Such things are unacceptable to use because they are extremely unreliable. A system assembled using such elements is considered unsafe to operate.

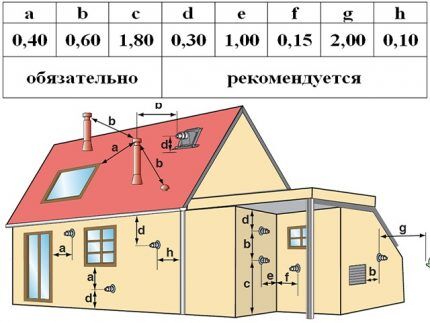

In addition, the following rules are observed during the installation process:

- The section of the horizontal chimney going outside should be inclined 3° downwards. The horizontal section of the chimney entering the common section is inclined in the opposite direction, that is, it decreases towards the boiler. This is necessary for unimpeded drainage of condensate.

- There should be no more than two bends along the entire length of the chimney duct.

- Inspection hatches, adapters and a device for discharging condensate must be easily accessible for periodic inspection.

- The chimney cannot be installed below ground level. In this case, the distance from the outlet of the coaxial chimney to the neighboring building must be more than 8 m. If a deflector is installed on the pipe, this distance is reduced to 2 m for a blank wall and 5 m for a wall with window openings.

- If a horizontal chimney is installed in a place where winds prevail, the direction of which is opposite to the direction of smoke removal, a sheet metal barrier must be installed at the pipe outlet. The distance between it and the outlet must be at least 0.4 m.

- On coaxial chimneys rising less than 1.8 m above ground level, it is necessary to install a deflector grille. It will work as protection against hot smoke.

All structural elements must fit tightly to each other. Each subsequent part must fit inside the previous one at a distance equal to at least half the diameter of the channel cross-section.

To guide the structure around any obstacle, bends specially designed for this purpose are used. Their angle of inclination may be different.If the system is vented through the roof, all fire safety requirements must be met.

For this purpose, special insulating pipes and non-flammable insulating materials are used. There must be an air gap between the pipe and the ceiling.

To avoid contact between the smoke exhaust duct and fragments of the roofing pie, a protective casing is used. The exit of the structure through the roof is carefully sealed. The joint areas are covered with a special apron.

Coaxial chimney installation technology

The installation process for external and internal coaxial chimneys is different. Let's consider both options.

Installation of the internal system

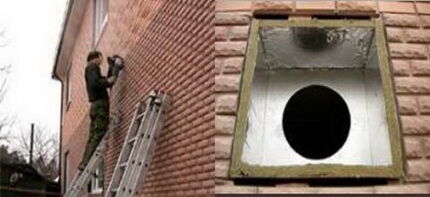

First of all, we check that the diameters of the boiler outlet pipe and the chimney match. Then we begin to prepare a hole in the wall through which the smoke exhaust duct will go outside.

Its diameter must exactly match the dimensions of the coaxial pipe. After making the hole, you can begin installing the structure. It begins with the boiler outlet pipe, to which the corresponding chimney element is attached.

The resulting connection is fixed with a clamp and secured on both sides with bolts. Next, the entire structure is assembled sequentially. Each element is inserted into place and secured with special clamps to give the system additional reliability. Decorative overlays are installed on top of the fastenings, thus maintaining the attractive appearance of the structure.

The chimney is led through the wall to the street. If necessary, install on the outlet pipe deflector or additional wind protection.The passage section in the wall is sealed. At the same time, fire safety requirements are observed. A special protective casing is put on the pipe. The joints of the passage are sealed and covered with an apron.

Installation of external structure

Before it starts, determine the exit point of the coaxial chimney and mark its location on the wall of the building. Then a hole is made in the wall with a diameter corresponding to the cross-section of the smoke exhaust duct.

Next, all internal work is carried out. They start by connecting the pipe to the heating device. For this, a single-circuit elbow and a double-circuit tee are used.

The latter is needed to secure the structure in a vertical position. The resulting structure is fixed to the wall surface with special brackets.

Further, all work is carried out similarly to the method described above. The chimney outlet section is sealed and pipe assembly continues to the desired height. The structure is secured to the wall with clamps. Adapter units are used to connect double-circuit pipes.

Conclusions and useful video on the topic

Construction and installation of a coaxial chimney:

Installation of a coaxial type chimney in a wooden house:

How to install a coaxial chimney yourself:

A coaxial type chimney is an effective and practical device that significantly increases the efficiency of a heating device. In addition, it is absolutely safe to use, compact and quite easy to install.

Its only significant drawback can be considered the rather high cost of arranging such a system, which, however, pays off with its long-term effective operation.

Please leave your comments on the article, share your experience of use and the features you know about installing coaxial chimneys, and ask questions. We are always ready to clarify unclear points.

The question is simple, but still requires an answer from professionals.

A friend’s parents built a house from timber, and the builders installed a similar pipe with insulation for them. Everything is fine, they moved into the house, winter came and, naturally, on especially frosty days the stove was heated a little more. By the way, the pipe was strictly vertical. As a result, the interwall insulation in the pipe melted, flowed down and a fire occurred.

Thank God everyone remained alive and well, but the damage was enormous, firefighters flooded the entire house, all the equipment and furniture became unusable, as well as the wiring and interior decoration, only the walls and the lives of the residents were saved.

The question is why their insulation melted, maybe the builders did something wrong to them? How dangerous are such structures?

In this case, there is unscrupulous work of the specialists who were involved in the installation of the chimney. Do you have a fire inspection report on the cause of the fire? They usually issue such papers after an examination. You can try to resolve this issue with representatives of the company who did the installation out of court. If you cannot agree on compensation, you will have to go to court.

The most important question is what is listed as the cause of the fire in the fire inspector's report?

I’ll add to Alexey’s question.Apart from the report from the fire department, was there a formal contract with the builders? But in this whole story, I was much more alarmed by the combination of a stove and a coaxial chimney... What kind of stove is there? Is it really a solid fuel or gas nozzle stove?

To be honest, I'm confused. This is the first time I’ve just heard about coax on a stove...

It’s strange, the situation is somehow unreal. The melting point of mineral wool is 1500 - 1700º, the temperature of flue gases during the combustion of solid fuel is 500 - 700º (this is the limit). The insulation simply could not melt in such an environment.

Most likely, they did not have a coaxial chimney, but a sandwich type analogue. When assembling it, it is necessary to observe the direction of connection of the modules so that condensation does not flow down the inner surface and corrode the walls. The corrosion of the chimney due to the aggression of condensate could well have been the cause of the subsequent fire. If so, then the builders are really to blame.

“The melting point of mineral wool is 1500 - 1700º.”

Where does this information come from? Mineral wool can be very different. It all depends on the density and composition. There is cotton wool, for example, from Technonikol, which holds up to 400C. And here the big question is what kind of cotton wool the chimney manufacturer used. Taking into account that everyone is trying to do it cheaper, it may well be some kind of rubbish that is used to insulate hot and cold water supply pipes as a thermal insulation layer.

Many thanks to the author of the article for such a detailed and professional description of chimneys, in particular the coaxial one!! Very useful and clear information, answers to all questions.Sincerely, guys - THANK YOU SO MUCH!!