Convenient and safe stairs to the basement with your own hands: calculation, production, installation

Private houses without a basement are becoming less and less common.These premises are reserved for the storage of canned goods, recreation areas or sports leisure rooms. Regardless of its purpose, descending to the lower level requires a basement staircase. Reliability and convenience are the main requirements for the structure.

The basement can be adapted for various needs - conservation storage, a recreation room or a gym. Regardless of the chosen functionality, it requires the installation of a flight of stairs, which will provide a safe and comfortable descent into the equipped room.

The content of the article:

Types of structures

A private house, garage or cellar - these are objects adapted for arranging the ground floor. To make the descent and ascent into it comfortable, a ladder is mounted between the base of the floor and the lower level of the basement pit. In this case, the choice of design is partially influenced by the functional significance of the basement.

Marching stairs

A good option for arranging a safe and comfortable descent. However, for its installation you need a spacious room. Recreation rooms or sports leisure rooms may meet these requirements. If the main emphasis is on convenience, try a two-flight model, installing it at a stronger angle of inclination.

You also need to decide what to choose as a rotating intermediate zone: a turning platform or winder steps? If moving up the stairs involves carrying furniture or household appliances, then it is better to choose the option with a platform. It’s convenient to stop here for a break or to change your grip to a more comfortable one.

In cases where the stairs to the basement are only a path for ascent and descent, the final choice can only be influenced by the design of the room or the personal beliefs of the homeowner.

Winder steps have one drawback: they limit traffic safety for older users. As a rule, trapezoidal steps are used when turning, which reduce driving comfort. If you stumble, it is easy to break your leg.

You'll love it! How to make a staircase to the second floor with your own hands: step-by-step manufacturing and installation instructions. Metal staircase to the second floor: types, manufacturing, assembly and installation.

Ladders

Not a bad solution for going down to the cellar. This model assumes a stronger tilt angle, which reduces driving comfort. An extension ladder is installed in a permanent place or used as a mobile structure for descending to the basement.

The originality of the design is in the stops representing the cut of the end parts of the guides of the flight of stairs. The cut determines the angle of inclination of the stairs to the basement. The smaller it is, the steeper the rise, and vice versa.

If the basement allows for a permanent staircase, be sure to secure it to the wall and floor. To do this, use anchors or bolts. A good option is metal models.A wooden staircase is not so good, as it periodically requires restoration or complete replacement of the marches.

The ladder to the basement is made of wood. The model does not require daily excavation and is installed in a permanent location.

Spiral escapements

High ceiling height but limited perimeter area? Consider the spiral staircase to the basement. It represents a vertical structure with a pillar installed in the center and steps attached to it.

A round cellar and a spiral staircase installed in the center of the room are an example of an ideal combination. On your way up, you can grab a couple of jars of pickles. To ensure that the space under the turns of the steps is not empty, place boxes with root vegetables there.

The material can be metal, wood, or a combination of both. To increase the safety of the structure, it is necessary to install railings.

Attention! A steep climb with constant turns can cause dizziness in a person of above average age. The railing will make it easier to climb, protecting it from falling.

Choosing material

The choice of material for the stairs to the basement must be approached very carefully. In this case, take into account the humidity of the room, the expected load on the steps, the cost of construction and the complexity of installation.

For high humidity conditions, avoid metal and wood. Concrete and brick are suitable, but such stairs to the basement do not look very nice - they load the room.

Brick

A brick staircase to a basement is a structure that takes up a lot of free space. For proper installation, you need to lay out the cabinet. It is up to the owner of the house to decide whether it will be hollow or monolithic. But from a practical point of view, the first option is better.

The remaining space under the stairs should be allocated as a small storage room for storing household utensils. However, you will have to install a concrete floor. Or even simpler: install a concrete flight of stairs right away.

A basement staircase made entirely of brick, including steps, is less durable than other alternatives. Over time, the corners of the bricks on the steps break, forming unsightly chips. Of course, repairs are possible, but it will turn into an annual routine. Therefore, when choosing a brick staircase to the basement, opt for a combined model: brick + concrete.

Combined model for descending into the basement. Made from hollow brick and concrete mixture. Even a person with minimal experience can cope with this task.

If you overlook the minor shortcomings of the brick staircase to the basement, then such a structure is very good. At least this is a fairly strong structure that can maintain it for a long period. Even in conditions of high humidity, brick can last for decades.

Reinforced concrete monolithic structures

This structure can perhaps be called the most reliable. It is not subject to rotting, tolerates conditions of high humidity, and is resistant to mechanical damage. The list of advantages can be continued indefinitely; such a staircase to the basement, once installed, is unlikely to be repaired or changed due to breakdown.

Reinforced concrete staircases are well suited for large rooms, where their installation will not constrain the conditions too much. Installation of a reinforced concrete flight of stairs requires the use of construction equipment.Therefore, it would be more practical to install the structure during the construction of a private house. Otherwise, you will have to spend a lot of time and effort.

Attention! Installation of reinforced concrete stairs in the basement requires complex technological calculations. The slightest flaw will cause the flight of stairs to collapse, which increases the risk of traumatic situations.

Stationary wooden stairs

For many years, wooden stairs have remained the most popular in the improvement of basements and cellars. At the same time, wood is a material that does not tolerate contact with moisture well. Therefore, when choosing a type of wood for making stairs to the basement, you need to give preference to resinous, moisture-resistant species.

All coniferous trees can be included in this category. But when looking for strong and durable varieties, you can’t find a better option than larch. The high density of the material prevents the free penetration of moisture into the structure of the material. Consequently, the probability of rotting of such a species is much lower than that of the same pine.

The cost of larch wood varieties is high, and not every ordinary buyer can afford to assemble a basement staircase from such material. In addition, regardless of the wood chosen, it requires mandatory treatment with antiseptics and additional moisture-repellent coatings. And this, in turn, further increases costs.

Not a bad option for going down to the basement. However, the material requires pre-treatment and placement in a dry room.

As a recommendation, we can recommend two options:

- Make an attached model that will go down.As a rule, such a solution can be seen when equipping cellars. In this case, the ladder will serve you for decades. However, if we consider that only women and children live in the house, then the regular procedure of lowering and raising the ladder will cause a lot of inconvenience. Even if a man lives in the house, this does not guarantee that he will always be nearby. Therefore, the majority of owners choose another option.

- Stationary flight of stairs. In this case, you will have to take care of all the ways to protect the wood from rotting and premature aging, impregnating it with antiseptics and covering it with paints and varnishes.

Regardless of the installation method chosen, wood requires regular maintenance. At best, once every two to three years you will have to clean the surface and lay a secondary layer of paint and varnish materials. However, if the basement has ideal humidity conditions, then this need disappears.

Steel escapement

The staircase to the basement made of metal impresses with its reliability. Therefore, owners of private houses prefer this type of material. Black steel is considered the most popular.

A channel or profile pipes are chosen as guides, and reinforced rods and metal plates are used for the steps. If handrails are needed, it is more convenient to make them from a profile pipe with a small cross-section.

The advantage of metal is that stairs made from it can be mounted on a site with any area: limited or spacious. To do this, it will be enough to change the angle of inclination and, possibly, the step between steps.

The only difficulty is having welding skills.If they are not there, then it is better not to undertake independent work, since it will not be possible to implement the work without errors. An even and tight seam is the key to the reliability of a flight of stairs.

Another disadvantage is the high prices for metal. To purchase the necessary material to assemble a metal staircase to the basement, you will have to pay a lot of money.

A massive, reliable structure requires welding skills and the purchase of expensive material.

If the metal staircase is intended for a rest room, then we can recommend stainless steel for its manufacture. Such models are usually sold ready-made. The owner will only have to assemble and fix it in a permanent place.

The cost of a stainless steel staircase is even higher, but a one-time purchase will save your nerves and effort invested in assembling the structure yourself.

Combined use of materials

Alas, basement stairs made from the same material do not always look beautiful. If you want to get an aesthetically correctly built model, then for assembly it is recommended to use a combination of several decorative materials.

The combination of a wooden staircase to the basement with inclusions of several types of wood looks very good. Contrasting rocks of dark and light tones will help create a very beautiful flight of stairs. For example, the main part is made of light wood, and places such as balusters and the top of the steps are made of dark varieties.

A good design option is metal + wood. Massive metal staircase to the basement with steps and railings made of light wood. As a rule, these are coniferous varieties: larch, pine.

If you want to get an expensive-looking model for going down to the basement, try considering the option of brick or concrete plus natural stone cladding. There are many design options here

Firstly, there are several assembly methods for making a flight of stairs. This is a hollow structure with a small utility room under the span, installation of a reinforced concrete march on concrete pillars, or a monolithic model.

Combined model for going down to the basement made of metal and wood. If one of the stages breaks down, it can be easily replaced with a new one.

Secondly, a large number of types of natural stone allows you to select the most attractive ones and create an individual design. The final result will depend on the imagination of the master.

Which option is suitable for a novice builder?

If a novice master does not have the proper experience for assembling staircase structures, then we can recommend first trying assembling models from one material. The simplest option is a wooden ladder. This option does not require much knowledge in constructing objects; even a teenager can cope with the task.

A more complex option is a metal ladder to the basement. This is where welding skills and knowledge of how to correctly carry out calculations will come in handy. The structure is suitable for equipping premises that do not require the installation of aesthetically well-built flights of stairs, for example, for a cellar.

Assembly consists of installing two guides, installing mortgages and fixing horizontal plates under the steps. In this matter, the main thing is not to make mistakes in the calculations and secure the parts in the right places.

Another option is a concrete structure.This type of material allows you to create flights of stairs of different levels of complexity: from monolithic to assembled from separate parts. If the craftsman’s imagination works as it should, then you can make a very beautiful structure with supporting pillars and balusters.

However, this type of material, just like brick, requires an investment of effort. Therefore, beginners try to avoid it.

You'll love it! How to make a staircase to the attic in a private house: varieties, step-by-step manufacturing instructions. Roof ladders: types of structures and manufacturing methods.

Calculation of staircase structure

Drawings and schematic sketches form the basis. Without compiling them, it is very difficult to obtain a high-quality product that meets all safety requirements. Therefore, if you have no experience in this matter, hire professional workers or contact a knowledgeable friend.

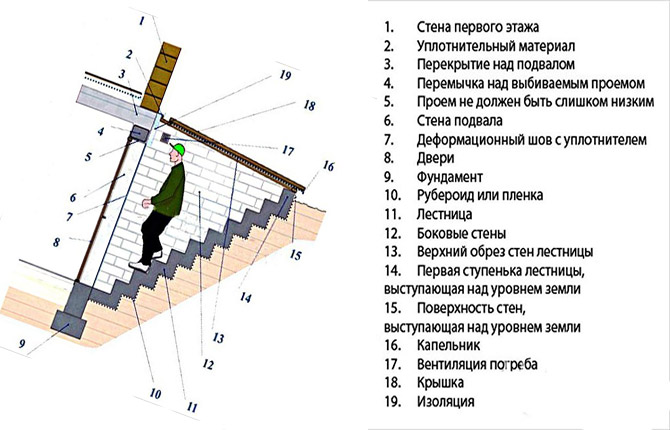

Schematic representation of the descent to the basement from the street.

For correct calculations, you should always keep the following parameters in mind:

- width of the stairs - for the comfortable movement of one or two people, a span of 90 cm to 1 meter is sufficient;

- instep - lifting the foot above 20 cm in a person of average height causes unnecessary stress;

- step width - comfortable can be considered from 25 to 30 cm;

- flight of stairs - from 2 meters.

Attention! All indicators are averaged and require modification taking into account the individual characteristics of the residents of the house: foot size, height and age category.

For the angle of inclination, the standard values used in the arrangement of buildings are accepted - this is 45O. However, this is only a recommendation, and the dimensions can be changed at the request of the master.For example, if the staircase is installed in a cellar and involves periodic lifting of heavy loads, then for comfortable movement along the steps it is necessary to reduce the angle of inclination to 30O.

The choice of the angle of inclination of a flight of stairs is also determined by the types of stair structures. So for attached models, this figure is higher and can reach up to 75O. But too gentle slopes are not as convenient for walking as it might seem at first glance. Fatigue sets in much faster than climbing steep steps.

To determine the number of steps per flight of stairs, it is necessary to measure the height from the base of the floor in the basement to the floor of the first floor. The obtained data is divided by the estimated riser height and rounded to the nearest whole number. Then the height of the basement is divided by the resulting number of steps, as a result of which it is possible to find out the exact size of the riser.

Determine the length of the future flight of stairs. To do this, the value determined for the step width is multiplied by the quantity. In this case, the size of the basement and the visually comfortable location of the structure indoors should be taken into account.

Attention! If the capacity of the basement does not allow the installation of a full single-flight flight, you can install a staircase with several levels and an intermediate platform.

Production of monolithic reinforced concrete stairs with lower formwork

Before you begin building a reinforced concrete staircase, you need to prepare a reliable and strong foundation. It can be a reinforced concrete floor or foundation.

The turning spiral staircase to the basement requires complex calculations. Without knowledge of drawing arithmetic, you should not take on this project.

A concrete staircase to the cellar can be made with your own hands according to one of the scenarios described below. There are two known ways to assemble a concrete flight of stairs into a basement with your own hands:

- Installation of ready-made monolithic slopes with further filling of steps. The necessary elements are purchased at the factory of finished reinforced concrete products. After fixing in place, filling work is carried out.

- Self-pouring of concrete spans using formwork.

Regardless of which method is chosen, it involves a labor-intensive process that requires significant effort.

Reinforcement and installation of formwork

It should be noted right away that the procedure for pouring a concrete staircase differs from foundation work. To do this, you need to go through several stages of assembling the formwork and reinforcing the flight of stairs:

- Preliminary marking of stop locations. According to the previously drawn up drawing, appropriate marks are applied to the supporting wall and the base of the floor, indicating the location of the future staircase to the basement.

- Installation of the lower support formwork. It represents a support for future concrete pouring, so it must be reliable. When assembling the formwork, exclusively strong materials are used.

- Assembly of the reinforcing frame. First of all, you need to draw up a schematic sketch of the location of the main rods and jumpers. Next, assembly occurs on the base of the lower formwork.

- Frame strapping. For tying you need pieces of binding wire.

- In order for the reinforcing frame to be completely immersed in concrete, it needs to be raised using purchased or self-made clamps.

- Hammer metal rods into the wall if the staircase is being installed in close proximity and does not require a technical gap.

- Reinforcement is carried out in two rows. With a contour repetition of the outlines of future steps.

- If necessary, reliable vertical pillars are installed under the base of the formwork.

The simplest option for going down to the basement does not require pouring, just installing a finished staircase.

The preparatory work has been completed, it’s time to move on to concreting the flight of stairs.

Pouring concrete

Tips for completing the work:

- There is one very important nuance in pouring concrete - the liquid mixture is poured in one go. Otherwise, cracking cannot be avoided.

- In order not to end up inside the basement without the ability to get out at the end of the work, the filling procedure begins from the lower steps.

- In places where railings are supposed to be installed, metal or wooden embedded parts are placed in the concrete. In the second case, the parts are treated with a bitumen solution.

- To avoid the formation of air pockets, it is recommended to use a vibrating machine during work or perform this task mechanically: using a trowel or a reinforced rod.

After a day, the formwork can be disassembled. Next, all that remains is to level the surface and you can proceed to decoration, if so provided for in the work plan.

A staircase in a garage, cellar or private house to the basement involves several construction options. Differences may lie in design options, types of material used and other equally significant nuances. Regardless of the chosen type of basement staircase, experience and endurance are required to obtain a quality structure.

Building a staircase yourself is a very labor-intensive process that requires not so much physical stress as mental stress. Of course, if your goal is not a standard ladder made of two bars and several steps. Here you need to calculate everything very well, then make sure that the calculations are correct, and only after that start construction. Don't think it's easier than steamed turnips. Unfortunately no.