Metal staircase to the second floor: types, manufacturing, assembly and installation

When building a two-story cottage, it is impossible to do without installing an interfloor staircase.Choose a reliable structure and think through its design. A metal staircase is what comes to mind first.

Simple assembly does not require additional labor. You can implement the project together with a friend. He will help with physical strength and support with a cheerful joke.

A properly designed metal staircase will become a reliable portal for moving to the second floor and a piece of decoration for your interior.

The content of the article:

Advantages and disadvantages of metal stairs

A metal staircase to the second floor made of profile pipes is superior in technical characteristics to wood products. Among the obvious advantages, the following are worth highlighting:

- The good imagination of the master will give the metal staircase the most unusual shape. It will easily become a central item that will attract the attention of friends, relatives and other guests.

- A metal frame assembled in compliance with all engineering construction standards will provide the owner with a reliable and safe structure for interfloor movement.Correct assembly will guarantee that in the coming years your structure will cost without additional repairs and restoration.

- Metal is a fairly malleable material, and with sufficient experience of the craftsman, it can be used to create forms that please the eye and warm the soul. A combined model, assembled from several materials, will decorate any type of interior.

- One of the advantages of metal structures is the speed of assembly. A master with experience in the design and installation of stairs acts according to a proven scheme, checking the correctness of the actions according to the drawings with the exact dimensions.

- The design of a metal staircase does not require connection to the construction of a house. Assembly can be carried out both before and after its completion.

- Metal stairs are universal and can be assembled both indoors and outside the house. High strength indicators and beautiful design will help a metal staircase become a decoration of the home, regardless of where it is installed.

- For self-assembly it is not necessary to involve a lot of people. One assistant is enough.

- The high strength of the metal allows you to create the simplest staircase layouts with the installation of a single guide in the center of the structure. The reliability of a metal ladder leaves no room for doubt. It will support the weight of more than one person.

It is not always possible to place massive metal structures inside the house. In addition, a beautiful design can complement the exterior design of the house.

Even the listed advantages do not guarantee complete flawlessness. A metal staircase has its disadvantages:

- Sometimes, while increasing the reliability of a metal staircase, you have to make sacrifices with a partial loss of the beauty of the design.The metal staircase consists of massive parts. Only preliminary consideration of every detail will help you place a metal staircase without compromising the design of the room.

- To obtain complex curves and bizarre shapes, the master needs experience and professional tools to carry out the work.

After analyzing the pros and cons of metal stairs, you can finally cast aside all doubts about choosing the best design for freely crossing the interfloor space.

A metal staircase means reliability. Its assembly takes several times less time than a wooden model of the same size.

Read the article: Convenient and safe stairs to the basement with your own hands. Stairs to the attic.

Types of staircase structures

Profile pipe is a universal material and is used for the manufacture of various types of structures. Let's look at a few of the most popular ones.

Marching staircase

The staircase consists of one or more flights. The separation of spans is carried out by horizontal platforms of square or rectangular shape. They provide a place for short-term rest when carrying heavy things. In private homes they are used to install large flower pots or small pieces of furniture. There are two types of such stairs:

- Sometimes in a private house you can find single-flight structures. These types require more free space for installation. If space is limited, then when installing single-flight stairs you have to increase the angle of inclination, sacrificing the comfort of use. To make climbing steep stairs easier, side rails and handrails must be installed. The advantage of single-flight metal stairs is that free space is created under them, which is not entirely correct to leave unattended. To save space, owners assemble spacious cabinets for storing things under the stairs. It is more convenient to use single-flight metal stairs on the street side of the building. Then the space under the flight of stairs can remain free. Although, by placing an electrical panel under it, you will not harm the design of the exterior of the building.

- Multi-flight structures are more mobile and allow the installation of metal stairs in a more limited space. The structure accommodates two or more marching spans, which are placed perpendicular to each other. All multi-flight models can be divided into two more categories.

The single-flight metal structure takes up a lot of free space. If a large house is chosen for its installation, then this is not a problem, but what if there is limited space in it?

Interesting! So that the space under the stairs does not go to waste, business men equip small workshop rooms under it. It is suitable for small, low-dynamic work.

- With a platform. The designs have a clear division into separate flights. Platforms in multi-level metal stairs provide additional rigidity, which cannot but affect the reliability of the structure. In terms of convenience, flight stairs with a platform are more practical.

- Winder steps. An option in which rotating steps are installed instead of large platforms. To make turning more comfortable, craftsmen install two or more winder steps. The winder steps have a trapezoidal shape with widening towards the outside and narrowing closer to the wall.This form looks more attractive - the turning steps are more compact and do not burden the overall appearance of the staircase. However, this makes moving up the steps less safe. This point must be taken into account if elderly people live in the house.

Such a metal staircase looks attractive, but is inconvenient for climbing the steps to the second floor.

The interior space of some private houses does not allow the installation of comfortable and at the same time large flights of stairs with an intermediate landing. It is for such situations that models with winder steps were invented.

Spiral staircase

This variety is an excellent option for rooms with limited space. For installation screw a metal staircase requires two square meters of free space, while marching structures require a larger area. Even if we are talking about the option with winder steps.

The appearance of the spiral staircase is very attractive. It can become a decoration for almost any interior. The main thing is to design wisely and think through even the smallest design details.

Despite the attractive design and compact placement, the metal spiral staircase has a number of disadvantages that cannot be corrected. They are a disadvantage of the presented form:

- Most often, such structures have a narrow span of steps. It involves lifting people of standard build. For a larger person, the lift will be limited by the side railings. Of course, the problem can be solved by expanding the span, but in this case, more than a dozen valuable centimeters will have to be taken away from the interior space of the room.

- It is impossible to try to lift a wardrobe to the second floor or a sofa using such stairs. Firstly, this is a continuous turn, and secondly, again, cramped conditions for movement.

- As a rule, standard models have steep stairs going up. If for a young healthy person this problem does not seem significant, then in the case of a user whose age has crossed the fifth decade, this drawback will seem major.

Unfortunately, the structure limits freedom of movement. If even two people can separate on a marching metal staircase, then to do this on a screw model, you need to try very hard. There's no need to even talk about moving furniture.

Considering all the listed disadvantages, a spiral staircase cannot be called the main means of ascending to the second floor if the internal space allows for a more convenient structure to be placed. The model can be installed as an additional decorative piece of furniture.

Attention! To lift furniture to the second floor, you definitely need to think through this point and create a separate, dimensional and practical metal staircase.

There is another version of the model - this is a turning staircase, where each step is made like a trapezoidal winder design - narrowing in one part and widening in the other part.

The flight of stairs of the turning staircase is wide, and there is enough space not only for the free movement of the home owners, but also for lifting large furniture. The same degree shapes will not cause any discomfort when climbing to the second floor.

Attention! It is necessary to understand that for planning, marking and developing drawings, a turning staircase will require more care and will take a lot of time. The finished product will decorate a private home and will delight its owners with its convenience.

A large number of small details, the turning radius and other nuances force the craftsman to carefully consider the future design of the metal staircase with a screw. The slightest flaws will be very visible and therefore unacceptable.

This is interesting for you! How to make a staircase to the second floor with your own hands. Do-it-yourself turning staircase.

Metal stepladder

In a private house, you will need a stepladder to improve your site. In order not to buy it in the store, you can assemble it yourself.

A stepladder is a ladder with two supporting flights. Used for gardening or small chores. At the owner’s request, they can be equipped with steps on both sides or on one, to save material.

The steps are made from a profile pipe with a smaller cross-section than the support posts. For convenience, metal linings are mounted on top of the pipes. Thus, the width of the step increases.

The lower end parts of the support posts are closed with plastic plugs. this will prevent lumps of dirt from clogging the inside of the pipe. To save money, it is enough to weld metal plates.

Attention! It must be understood that an additional part added to improve the design increases the original weight. Thus, while improving a product on the one hand, it is possible to worsen its performance characteristics on the other.

A homemade stepladder made from a metal profile pipe will make life easier for an amateur gardener.

To make a stepladder at home, you will need to prepare the following list of materials:

- profile pipe - for racks 40x40 mm or 50x50 mm, for steps 20x20 mm;

- hinge - specialized (more preferable) or for mounting interior doors;

- end caps for profile pipes - stores offer plastic models;

- bolts - for fixing special hinges.

The stepladder hinge is more preferable because it has a stopper, which will make gardening easier. The part is fixed using bolts. That is, if it breaks, it can easily be replaced with a new part. The rest of the work on assembling the stepladder is done by welding.

Types of guides

The guide, or stringer, forms the basis of the flight of stairs. Its reliability determines the safety of using a metal ladder. There are several varieties:

- One stringer. For production, profile pipes with a cross-section of at least 100 mm or channels are taken. The guide is placed in the middle of the structure. the shape can be broken or straight.

- Double stringer. More reliable support for a flight of stairs. Used for massive structures with two or more spans. There are also broken and straight guides.

Schemes and drawings

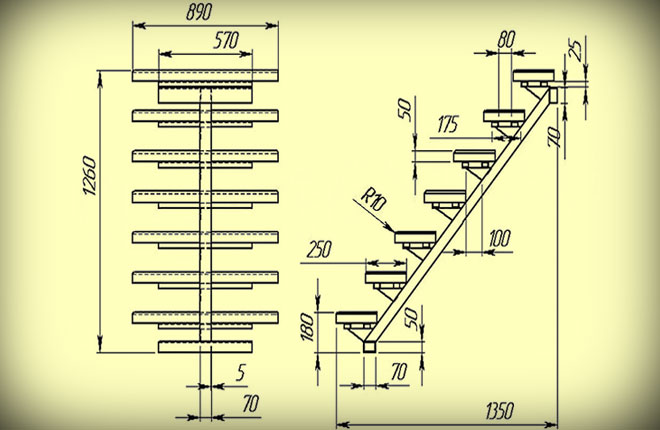

There should not be any difficulties with constructing a schematic drawing and fully indicating the dimensions on the finished drawing. After all, to assemble a metal staircase at home, no detailed drawing is required while maintaining the scale of the diagrams.

Schematic sketch of one flight of metal stairs.

Necessary tools for taking measurements

To find out the dimensions of the space allocated for the assembly of a metal staircase and, based on the data obtained, to plan a future model, you will need to collect a set of necessary tools:

- construction tape - the length of the accessory must correspond to the dimensions of the future structure;

- bubble level, laser - necessary for accurately drawing lines on the wall surface;

- pencil or chalk for applying identifying marks on the surfaces of walls, floors and ceilings.

The presented set includes only the most necessary tools. The selection is carried out based on the specific situation and the expected model of the metal staircase.

Material and tool for creating a drawing

To create a drawing and transfer the dimensions of parts onto it, you need to prepare several office accessories:

- ruler up to 30 cm;

- compass - required if you plan to create a spiral staircase;

- graphite pencil with a sharpened end;

- a sheet of paper for drawing a schematic drawing.

When drawing a diagram of a future structure, you need to be careful and accurate. The slightest discrepancy will lead to a decrease in the quality of the structure, which will make movement along the steps to the second floor unsafe.

The set of drawing tools can expand or decrease depending on the task of drawing details.

What parameters do you need to know to draw a drawing?

The diagram is created based on the measurements taken. In order not to exhaust yourself with unnecessary body movements, you need to clearly understand where to take measurements and what parameters are important for the correct construction of the drawing:

- Height - measurements are taken from the floor to the top attachment point of the metal ladder.

- Height of steps - as a rule, the height of the first step corresponds to the height of subsequent elements.

- The width of the step - for correct placement of the foot, it should not be less than 25 cm.

- The distance from the last step to the ceiling of the second floor - the height should be greater than the height of the tallest person in the house.

- If the staircase is a marching staircase with landings, then you need to determine the height of all landings.

When taking measurements from these areas, immediately transfer them to a schematic image on a sheet of paper.

Nuances

When creating drawings, pay attention to some nuances:

- Height measurement is carried out in compliance with the angle of inclination, if required by the design model.

- The design is calculated in such a way that the upper landing of the metal staircase falls on the floor of the second floor, and not the ceiling of the first.

- When planning to install a metal structure at home, you need to understand that this structure has an impressive weight, so it must be mounted on a solid foundation and attached to walls designed for this load.

Installing a metal structure under the base of the floor increases stability.

After the drawing is drawn, check the drawn dimensions and proceed directly to assembling the structure.

Self-assembly of a homemade metal staircase

The most difficult stage, which requires mental investment in the result, is now over. Ahead lies the marking and production of parts, fitting and assembly of the frame. Of course, you will have to sweat, but physical labor is not so terrible. And if it gets too difficult, you can always invite a friend.

Attention! Each owner independently chooses the method of assembling a metal structure.Assembly for welding is considered the simplest. It is less labor-intensive and does not require the most accurate calculations.

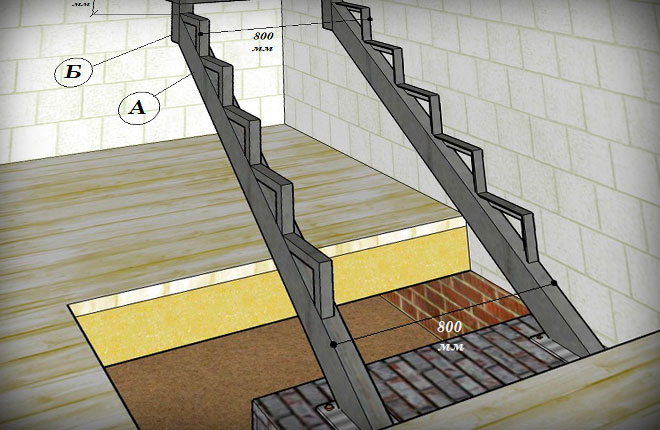

Straight metal stairs

The simplest type of structure that you can assemble yourself at home is a straight flight of stairs on stringers. A stringer is a supporting element of a flight of stairs. It can be made of a metal channel or a profile pipe installed on an edge.

There are two types of stringers used to assemble flights of stairs:

- straight;

- broken.

Both of them can be assembled into two strings or into one support beam.

On a straight stringer

If a profile pipe was chosen as a supporting element, then its cross-section must be at least 150 mm. This size should be at the widest part. A rectangular pipe is preferable to a square pipe. The fact is that a smaller distance between the stop walls of the pipe creates more reliable support.

Metal staircase on straight guides.

To create a frame for the steps, you need to mount corner stops on top of the stringer. The most convenient way to do this is by cutting a profile pipe of the appropriate size. Otherwise, you will have to assemble it from metal plates about 3-4 mm thick.

Step-by-step instruction:

- Take measurements of the distance from the upper stop, where you plan to attach the stringer, and to the lower platform. Prepare the profile support: cut to size and weld the stop pads on both sides.

- Having attached the stringer to a permanent place, mark the locations for the holes for installing fasteners. Drill and insert anchors and bolts into place.

- Install stringers with full fixation.

- Withstanding 90O corner, weld previously prepared corners to support the steps. The size should be slightly smaller than the width of the step.

- For greater reliability, the stop corners of the steps are welded together using reinforced rods.

- The steps are assembled - vertical and horizontal walls are mounted.

- The next stage involves installing railings and handrails, if required by the design feature.

- At the final stage, surface finishing is carried out - decorating the steps, painting metal parts, etc.

Broken stringer

The method is approximately identical to the previous option, however, not a straight profile is used as a support, but a broken string that follows the contours of the steps. The advantage of this design is that it saves more money on the purchase of building materials. So, for making a stringer, a pipe with a cross-section of 40x60 mm is suitable.

A broken stringer is an excellent option for a soft room design.

Unlike marches on straight supports, a broken string takes more time to assemble the string itself. First you need to cut all the parts taking into account an angle of 45O. Afterwards, assemble the support frame. This should be done on a straight surface to avoid distortions in the structure.

Another plus - Now there is no need to assemble stops for steps. They are already prepared and all that remains is to weld the vertical and horizontal walls.

Screw design for small spaces

The limited area of some houses sometimes does not allow placing a full flight of stairs. It is for such cases that the spiral staircase was invented. In addition to the fact that the spiral staircase solves the issue of limited space, it also looks better than other models. Its assembly requires much fewer parts, which makes it easier to look at.

When planning a future staircase, it is necessary to think through and calculate not only the main dimensions, but also the diameter of the structure. It's quite easy to define. To do this, you need to know the length of the step and the diameter of the support pillar. Now you need to add up the values of the two stages and add the pipe diameter to the resulting one.

At the design stage, the question may arise: how to calculate the number of steps for a specific model? And there really is nothing complicated here. According to the rules of SNiP, the height of the offense should not be more than 15-20 cm.

The height of the steps on a metal staircase should not limit the movement of the person moving.

There are also approximate parameters for the narrow and wide parts of the trapezoidal step. In the place where the narrow part adjoins the post, it should be at least 10 cm, the wide part - from 25 to 30 cm. This option is the most preferable, as it can ensure safe, and most importantly - comfortable movement to the second floor.

Step-by-step installation instructions:

- Experienced builders recommend starting the installation of a support column at the stage of building a house. The fact is that to increase stability, it is concreted to a depth of 40 cm. It will be much more difficult to do this when the renovation of the house is completed.

- Next, the steps are prepared: cut to size and sheathed with a frame. In order not to return to this stage again, it is recommended to prepare all the details.

- Fastening the steps can be done either with bolts or by welding. The first option is more practical, the second is more reliable.

- Since the spiral staircase has a rather narrow passage, the design must have side railings.

The final stage is decorating the flight of stairs.This can be done with wooden elements, stone or surface painting.

Recommendations for installing a spiral staircase

Installation tips:

- It is necessary to leave a small gap between the wall and the metal staircase.

- To maintain the width of the steps, the railings are welded from the outside.

- After welding, the seams are ground, primed and painted with a protective coating.

- Wooden elements are installed after the painted surface has completely dried.

- You should not experiment if you have no experience in welding.

- A properly assembled staircase is a safe and comfortable structure.

Only a true master of his craft is able to make a metal staircase that will decorate the house.

Regardless of which metal staircase design is chosen as a permanent structure, it requires much less investment than options made from other materials. The finished spiral staircase is light in appearance and can become a decoration of any interior.

Now you can find many options for flights of stairs for a comfortable climb to the second floor. For installation, designs can be selected for internal installation or outside the house.

The second option requires less responsibility and skills, so such a staircase is assembled with your own hands from metal without the involvement of outside help. The first option requires experience and enough skills to create a safe and at the same time beautiful product.

Built a house. It's time to assemble the ladder, and I just can't decide which one to choose. There is a lot of free space, so there shouldn’t be any problems with placement. Friends advised me to choose a broken stringer. They say this staircase looks very nice. But I somehow doubt it. It seems to me that a wide span is not suitable for this model, and it will look awkward in a spacious room. Maybe someone has experience with such a choice. Tell me how to get out of the situation?