How to make a spiral staircase with your own hands: design, calculation, step-by-step instructions for creation

A spiral staircase is an axis around which steps are arranged in a spiral. Can be installed for passage to the second floor or attic space in the house. Of course, the screw design is less convenient compared to the classic marching one, but it looks more original and is compact in size.

It is possible to assemble a spiral staircase even without outside help. This will help with minimal carpentry skills and following step-by-step instructions.

The content of the article:

What rooms is it suitable for?

The spiral staircase system is not only a means of climbing between floors in private homes, but also a decorative element that can be matched to the specific style and interior of the room. The structure looks weightless and has several advantages:

- Originality and attractiveness. Modern spiral staircases are less common than marching staircases, so they add originality to the interior. The complex shape attracts attention, making the furnishings of the room look expensive.

- Compactness. Spiral staircases require much less free space compared to marching ones. They do not clutter up the space. Such designs are ideal for small rooms.

- Economical. This design requires relatively few building materials. Therefore, independent construction turns out to be quite budget-friendly.

Screw compact stairs to the second floor, despite their beautiful shape and compactness, are less common than marching ones.This is due to the disadvantages of such designs:

- Uncomfortable climb. Screw structures are narrower than marching ones. The steps have a narrowed shape at one edge. Because of this, climbing such stairs is less convenient than standard ones, especially for children and the elderly.

- Less resistance to loads. In screw lifts, the load-bearing part is often only the support column. Because of this, the shape of the staircase is not suitable for rooms with increased load.

- Inability to lift large items. Due to the compactness and twisted shape of the staircase, it will not be possible to bring assembled furniture and other large non-dismountable items to the second floor.

- Less safety compared to marching structures. This is facilitated by the complete ascent, the shape of the steps is not convenient for everyone, and the lack of platforms.

If the described features do not seem to be an obstacle to the construction of a spiral staircase, then you should make sure that this option is suitable for the chosen purposes. Twisted steps are used in private and country houses with not very high flows to climb to the next floor. The structure is also suitable for access to the attic.

Spiral staircases are not suitable for public buildings. They should be abandoned if it is planned to build an entrance to the upper floor from the street.

A spiral building is sometimes erected as an emergency lift to the second floor. This is convenient in cases where the main entrance is located on the street.

Swirling designs are suitable for two-story apartments, which often do not have enough space for larger structures. With the help of flights of stairs, living spaces located above each other are combined.

This is interesting! Do-it-yourself turning staircase: calculations, drawings with step-by-step instructions.

What materials to choose

Convenience, shade, cost, durability and labor intensity of building a modern spiral staircase depend on the material from which it is made. To make the stairs to the second floor, the following types of raw materials are used:

| Material | Description |

| Tree | The most common material in private homes for the construction of spiral staircases. Wooden risers look stylish and noble, they look organically in any interior style. They are characterized by durability, ease of assembly, and low cost. The ability to paint and quickly repair the structure in case of breakage of any part adds points to this material. Disadvantage: low resistance to high humidity, fungi, mold, and bacteria. |

| Metal | Metal spiral staircases are hopeful and durable. Look good in modern and industrial styles. The design with artistic forging will fit well into classic interiors. To independently install such a metal structure, you need experience in welding work, as well as special tools. High humidity causes metal to rust, unless it is stainless steel. |

| Glass | In such staircases, the steps or railing are made of high-strength glass. For strength, a metal frame is used. Screw structures made of transparent material look stylish and weightless, visually expanding the space. Look good in ultra-modern interiors. Disadvantages - high cost, difficulty in self-installation, slippery steps. |

| Concrete | Spiral staircases made of concrete look monumental and are suitable for modern interiors.They are characterized by durability, high resistance to loads and negative environmental factors. However, it is necessary to lay a spiral staircase made of concrete at the stage of construction of the building. The structure visually conceals free space and is difficult for independent installation. |

| Natural or artificial stone | Looks beautiful in both industrial and romantic styles. Usually a metal frame and stone steps are combined. The material has high resistance to stress and abrasion. Disadvantages: high cost and complexity of self-installation. |

Each material has pros and cons. Some shortcomings are easy to correct. For example, to protect wood from moisture, fungi and bacteria, it is coated with varnish, protective impregnation or wood oil. The tendency of metal to corrode can be neutralized by covering the stairs with paint.

Screw lifts are most often assembled from wood. The following rocks are usually used to construct the structure:

- Pine and spruce. The most inexpensive species suitable for the construction of spiral staircases. They are distinguished by a beautiful warm shade and the ability to produce phytoncides that are beneficial to health. Negative qualities are the relative softness of the wood and, as a result, low wear resistance. Over time, such structures lose their attractiveness and look untidy. This option is suitable if the stairs are not used often. For example, a pine riser can be installed in a country house.

- Larch. An expensive material that is loved for its beautiful white color of wood, high strength and durability. The breed has high fire resistance.

- Oak. Beautiful noble material with a pronounced pattern and a rich dark shade.It is famous for its high strength, durability, and resistance to high humidity. Spiral oak staircases are an expensive option.

- Maple. A beautiful durable breed with a light shade. The material slowly absorbs impregnation, so it is considered difficult to process.

- Birch. Ideal value for money. The species is quite durable, although inferior to oak. Withstands local loads and retains its attractive appearance for a long time.

- Ash. Wood with an unusual shade and pattern. It has the highest strength of the presented rocks. It is afraid of moisture, so it needs moisture-proof and antiseptic impregnation.

- Beech. The uniform light shade without a pronounced wood pattern is attractive. The material is strong and durable. Requires additional treatment with protective impregnations.

The type of wood for a spiral staircase should be chosen based on personal needs and financial capabilities. The desired shade of wood can always be given with the help of stain.

Design Variations

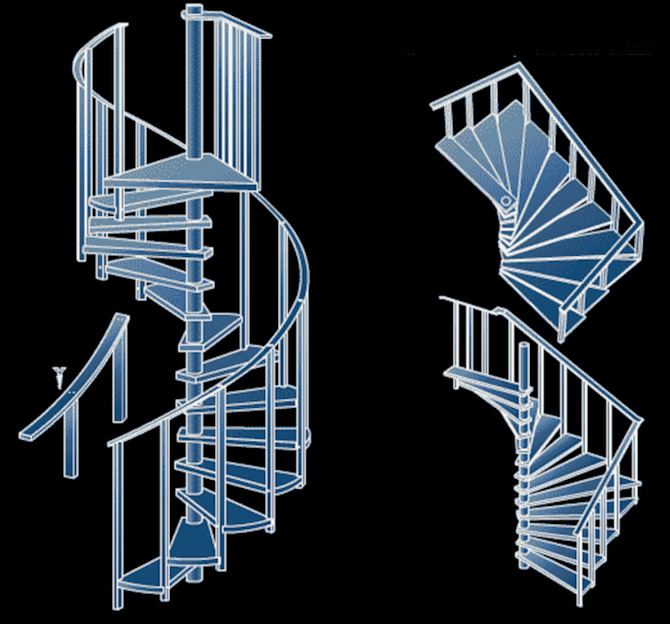

Compact spiral staircases always have a spiral shape. They differ in type of design and shape. If you look at the descent from the top floor, the span will have the shape of a circle or polygon.

Types of spiral staircases by shape:

- Spiral. It is this shape that is imagined when they talk about a spiral staircase. In a spiral lift, the steps are folded into even turns around a support pillar. Moreover, the radius of each revolution remains the same. This shape looks elegant, takes up minimal space, and forms a cross-section in the shape of a regular circle.

- Rectangular. Spiral staircases have this shape, which simultaneously rest on the central support pillar and on the wall.Thanks to two support points, the lift can withstand increased loads. This option is only suitable for rooms with low ceilings, since such structures usually have only one span.

- Local. This is an intricately curved structure that can be L-, U- or S-shaped. The inner and outer radii of different turns are not the same. Local spiral staircases look original, but take up quite a lot of space.

When choosing a shape, you should rely not only on the appearance of the staircase, but also on the amount of free space in the room, as well as on the height of the ceiling.

Screw lifts also differ in the method of fastening the structure. The following types are found:

- On the walls and axle. In this case, the central pillar is installed near the wall. The steps are attached with one side to the axial rod and the other to the wall. Thanks to two support points, the design is reliable.

- Cantilever mount. The steps are mounted on an axial support column using consoles. The walls are not used, so you can even place the lift in the center of the room.

- Bowstring. This is an unusual way to install a modern spiral staircase. The structure is erected without an axial element. Instead, a bowstring or stringer curved in a spiral shape is used. Steps are attached to them, as well as balusters with railings or wide wooden strips that act as railings. It is impossible to make curved elements without a special tool. Assembling the entire structure is also more complicated than standard structures.

- Prefabricated modules. In this case, the support column is, as it were, cut into parts, between which the steps are fixed. Essentially, the staircase is assembled by placing each element on top of the previous one. The steps do not rest on the wall.For self-installation, this option is complicated, although it turns out to be reliable.

The easiest way is to make a spiral spiral staircase with a cantilever mount. This variety consists of simple elements that can be ordered from a craftsman or made independently.

You'll love it! Metal staircase to the second floor: types, manufacturing, assembly and installation.

Schemes, calculations and drawings

The most important stage in making a spiral staircase with your own hands is calculating its dimensions and drawing up drawings. The appearance, reliability and durability of the finished structure depend on how correctly the circuit is made.

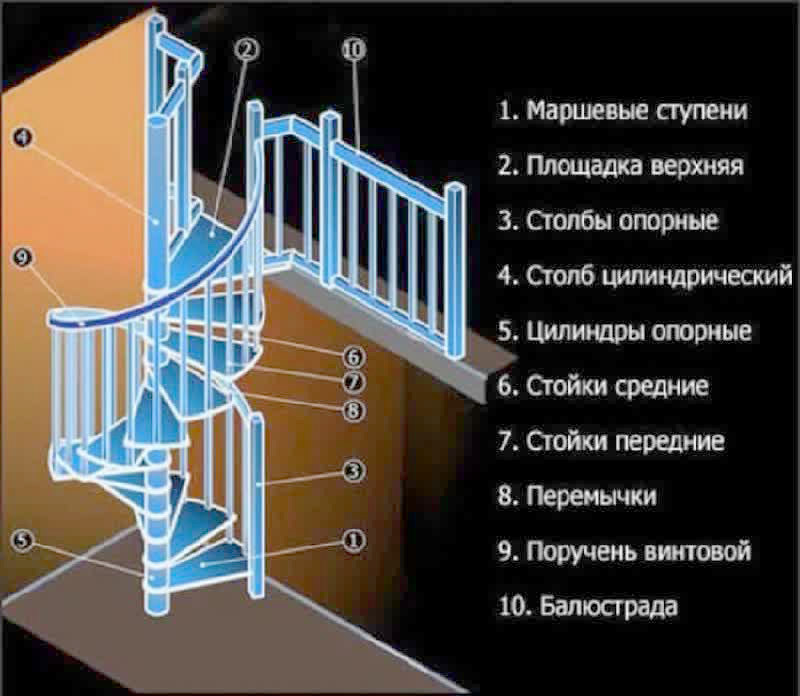

To perform the calculations, you need to know the main details of the spiral staircase.

It consists of:

- Axis. This is the central supporting pillar to which the steps of the spiral staircase are attached. The main load falls on it, so this part is made quite thick, from high-quality material.

- Steps. Attached to a screw post. They consist of a main part (tread) and a riser, which connects adjacent elements to each other. Some projects do not have risers.

- Balusters. Railings are attached to these elements. In spiral staircases, balusters combine the steps into a single structure.

- Handrail. Attached to the top of the balusters. The form of the soar should put the form of a ladder rifle.

- Skirting board. Not always used. The element is a wide strip that follows the curve of the staircase. Attach this part to the steps and the base of the balusters. This addition increases the strength of the structure.

Sometimes a wide wooden plank is attached to the outer end of the steps, repeating the curve of the staircase. It can be the base of balusters or completely replace the railing.

To make a diagram of a spiral staircase, you can use an online calculator or contact a company engaged in calculations and drawings. In the second case, you won’t even need to take measurements, since specialists usually work on-site.

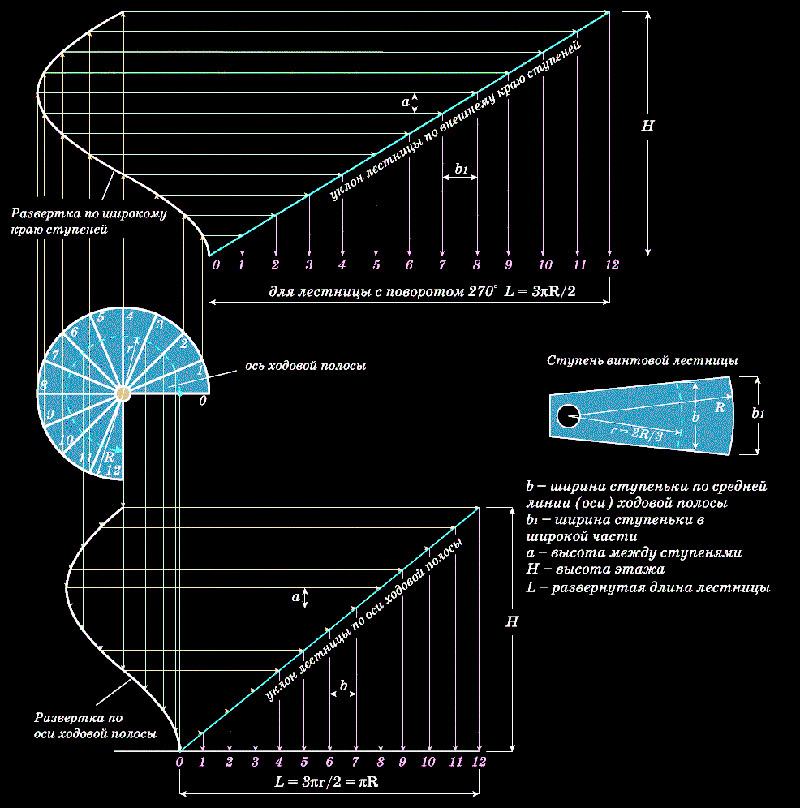

Of course, you can make a drawing yourself. It is important to consider the recommendations common to such structures:

- To make it convenient to climb the steps, but the structure remains quite compact, its width is made within the range of 70-100 cm.

- The optimal inclination for a screw lift is 45 degrees. Steeper stairs are unsafe. A smaller angle is convenient, but takes up a larger area.

- One turn of the staircase contains 11-12 steps.

- The height of the interfloor turns is calculated taking into account the height of the tallest resident of the house + 10-20 cm. Otherwise, the person will have to bend over when climbing, which will reduce safety and convenience.

- In order for the staircase screw system to be reliable, the thickness of the metal support axle must be at least 5 cm, and the diameter of the support made of other materials must be at least 15 cm.

- For screw products, the most convenient size for raising steps is considered to be 15-20 degrees.

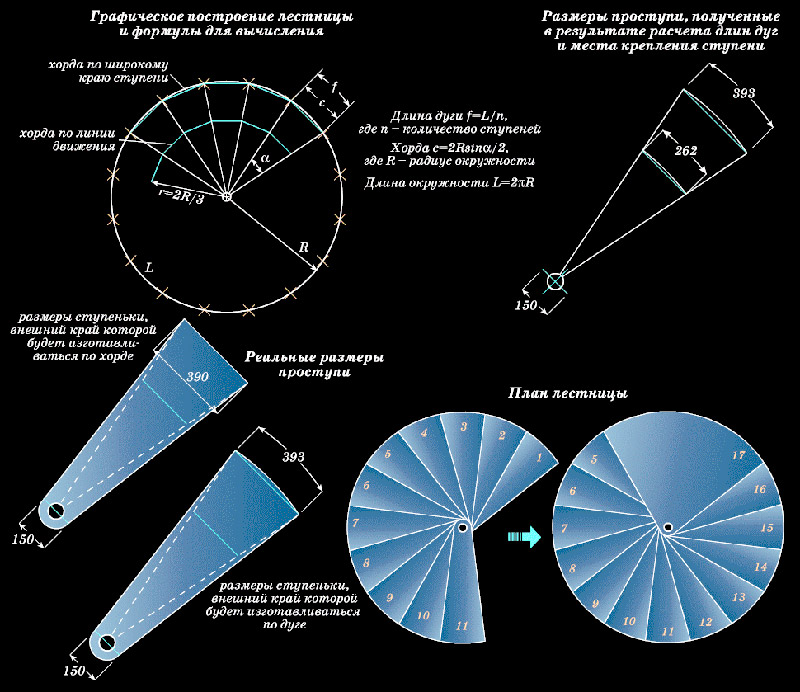

To put a drawing on paper and find out the dimensions of the main elements of a screw structure, a series of calculations are made. First, find out the overall diameter of the screw lift by adding the diameter of the central axis to twice the width of the opening. The resulting circle is transferred to paper on a scale of 1:10.

Inside this circle, another circle is drawn, indicating the trajectory of the person’s movement. To find out its radius, divide the sum of the radius of the axial column and the width of the rise in half.

To calculate the number of steps in a full turn, it is necessary to multiply by 2 and the number π (3.14) the radius of the circle of the person’s movement trajectory. The result is divided by the average width of the step (usually 25 cm). If the number is not an integer, then it is rounded up.

To calculate the total number of steps, divide the height of the spiral span from the floor of the first floor to the floor of the second by the height of one step.

To calculate the number of revolutions of a screw structure, the total number of steps is divided by the number of steps in one revolution.

This is useful! How to choose and install beautiful railings for stairs in a private house.

Step-by-step creation instructions

It is more difficult to build a spiral staircase than a marching staircase, due to the narrowed steps on one side. Difficulties may arise due to the railings, which must follow the curve of the structure. Therefore, it will be more convenient to make all the elements to order and then assemble the structure.

You can make all the parts yourself. To do this you will need carpentry skills and special tools.

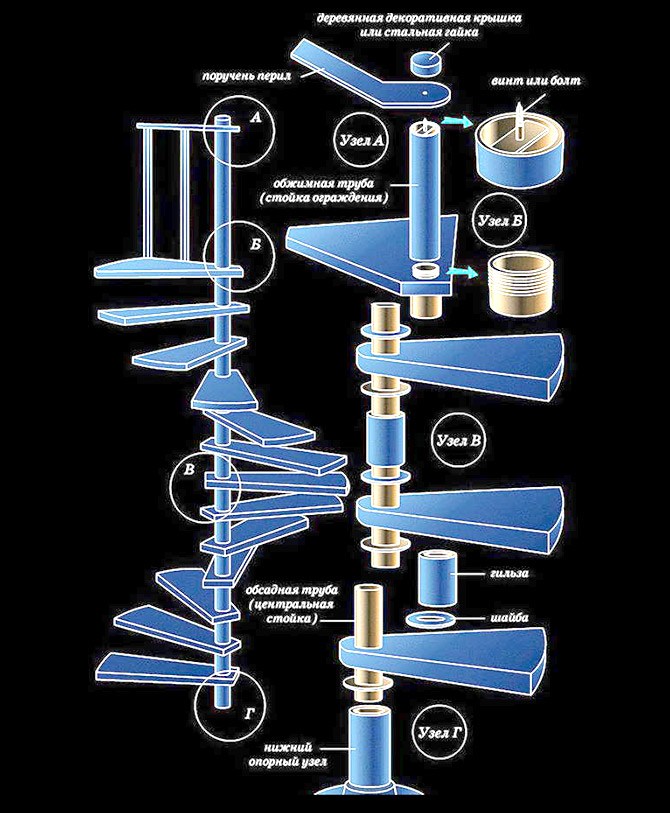

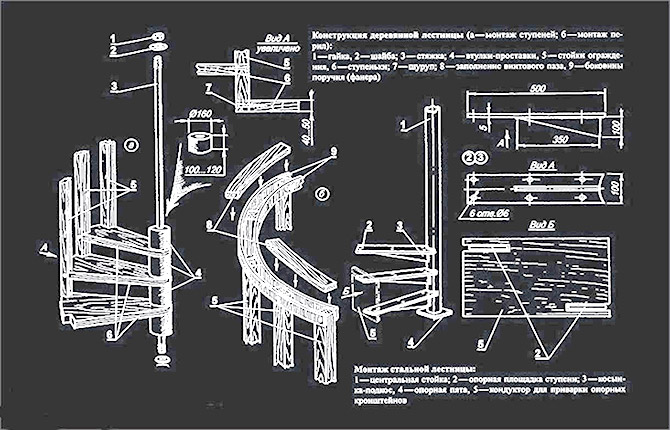

Making a support pillar

The support post in the screw design also serves as the central axis. It is important that it turns out strong and reliable.

For a wooden structure, a wooden stand is suitable. Its diameter is in the range of 15-30 cm. It is convenient to attach steps to this material with metal corners.

The stand can have a round, square or polygonal cross-section. It is important to securely secure it at the top and bottom. To do this, in addition to reliable fasteners, they make recesses for support in the floor and ceiling.

The support pillar is made of metal, concrete or brickwork. In order to secure the steps, couplings or bolts are attached to the central axis.

Making steps

The steps for a spiral staircase must be stable and durable, since they are subject to significant load. When assembling parts, it is important to consider the following nuances:

- The thickness of the steps must be at least 5 cm, provided that the staircase is not higher than 2 m. For higher rises, the minimum thickness of the steps is 6 cm.

- For steps, it is important to choose wood that has already been planed and evenly dried. If the material dries unevenly, the step will become deformed during operation. Because of this, the entire structure will warp and lose strength.

Glued laminated wood is often chosen to make steps. The panels can be glued together using wooden blocks yourself.

To ensure that all the elements are the same, a template of steps is made according to the previously planned dimensions. It is cut out of cardboard or thick paper.

The steps are cut out according to the template. If the elements have holes for a support post, then you need to cut them out according to a pre-prepared stencil.

The top step is usually significantly larger. It requires a separate stencil.

The cut steps are processed manually or on a special machine. They are polished and the edges are given a rounded shape.

Slots for balusters are pre-drilled in the steps. Such holes make connections more reliable.

We make balusters and railings

Traditionally, balusters are cylindrical in shape with varying or curved elements. To create such elements you will need a lathe and skills to work on it. Therefore, it is easier to buy ready-made railing supports.

Of course, you can make balusters from square timber. However, such climbs look less aesthetically pleasing.

The outer posts are supporting.They are under increased pressure. Therefore, they are shaped in such a way that they simultaneously fix two adjacent steps. This gives additional rigidity to the structure.

The size of the balusters should be such that it is comfortable for a person of average height to hold onto the railing. This is approximately 120-130 cm.

Depending on the mounting method, it may be necessary to drill slots or «keys» at the bottom of the balusters. This installation will allow you to achieve a more reliable connection.

Railings for spiral staircases have a curved shape. You can make such a handrail in one of three ways:

- The handrail of the desired shape is assembled from parts cut from solid wood.

- The railings are cut from pieces of timber glued together. In this case, individual elements are assembled into a single structure.

- The railings are glued together from thin wood veneer. The elements are first bent, giving them the desired shape.

To make a railing you will need not only a lathe, but also equipment to give the element the desired shape and fix it in a certain position. If you don’t have the necessary skills and equipment, it’s better to contact a specialist. The specialist will take the necessary measurements, determine the bend, make railings and baseboards.

You can order a finished product, which all you have to do is assemble it according to the instructions and install it. This option, of course, requires significantly more money, but does not take much time.

Assembling a spiral staircase

The first step when installing a staircase is to choose the location for installing the central axis. If the steps will be attached only to the support post, then this element should be located at a distance from the wall. When fixing the structure to a pole and wall, the width of the steps is taken into account.

On the ceiling in the selected location, draw and cut out a circle equal to the diameter of the screw lift. The opening is immediately decorated with finishing materials.

In the center of the opening on the ceiling, a suspension is attached, which is lowered to the floor. An axial element is installed at the resulting point.

For quick and easy installation of a spiral safety staircase, bars are attached to the wooden stand, the height of which is equal to the distance between the steps. The bars are placed vertically. The optimal cross-sectional diameter of the elements is 5 cm. For the first stage, this parameter may be larger.

In addition to beams, ready-made metal fastenings are used. These can be corners, bolts with balls, hidden fasteners.

The steps are attached to the beams with self-tapping screws. It is better to do the assembly before installing the axial pillar. A support pillar with steps is installed, securely securing the structure at the top and bottom.

The next stage is the installation of balusters. The balusters are placed in the grooves prepared for them, but not secured. First, markings are made for cutting the top of the elements at an angle.

After cutting the balusters, they are secured. It is recommended to do this using both self-tapping screws and glue.

The handrail is attached to the balusters using self-tapping screws. To increase the strength and safety of the interfloor rise, a wide plinth is installed at the bottom of the railing.

The finished staircase is covered with several layers of paint and varnish. Each new layer is applied when the previous one has dried. If desired, the structure can be painted or stained, and then a varnish coating can be applied.

An interfloor spiral staircase is a beautiful and compact design that is optimal for installation in a country house and in small private houses.However, the manufacture of its elements, as well as their installation, is much more complicated than in the case of marching structures. Therefore, if you do not have the skills to do such work, it is better to turn to professionals or choose a classic lift.

Have you ever installed a spiral staircase yourself? Share your experience. To avoid losing the article, save it to bookmarks or repost it on social networks.

When I built my house, I planned to make a spiral staircase. I knew that it was less convenient compared to marching structures, but I really liked the way it looked. Reminds me of going up in ancient castles. However, when I read how difficult it is to do it, I changed my mind. It’s expensive to buy ready-made parts, and I wouldn’t be able to cut out all the components myself, since I have neither experience nor tools. Therefore, I still had to stop on the march

I have two apartments on the third and fourth floors connected into one two-story apartment. The rise is screw, as it takes up little space and looks stylish. I ordered all the parts from a friend who does this. Measurements were taken together and calculated using an online calculator. We also collected together with this friend.It turned out relatively inexpensive and very beautiful.

Vinyl interfloor risers have always attracted attention due to their appearance. However, after reading about their disadvantages, I realized that I would make a staircase in my house. She's safer. This is important, especially if there are small children in the house. Also, due to the shape of the elements, it is difficult to make them without the help of a professional, and I don’t want to order ready-made parts of the structure.