How to choose and install a pipe plug - what types are there and from what material

A pipe plug is a fitting that has several purposes.It seems like an insignificant detail, but it marked a whole direction in plumbing. Hence the broad classification, where divisions are made according to the material of manufacture, shape, method of fastening and other characteristics.

The content of the article:

Where and in what cases is it used

Plugs are mainly used for:

- protecting pipes from dirt and moisture;

- when carrying out pipeline repair work;

- to tightly shut off a pipe line for various reasons: technical, technological, etc.

What types of plugs are there?

The classification is broad. The first criterion for dividing is by form. Here are several positions:

- round;

- square;

- oval;

- elliptical.

By installation method:

- threaded;

- plug-in;

- welded;

- flanged;

- pneumatic.

At installation location:

- external;

- internal.

In size - depending on the diameter of the pipe that needs to be closed.

What materials are they made from?

Here are several main positions and options related to the group - specific plugs.

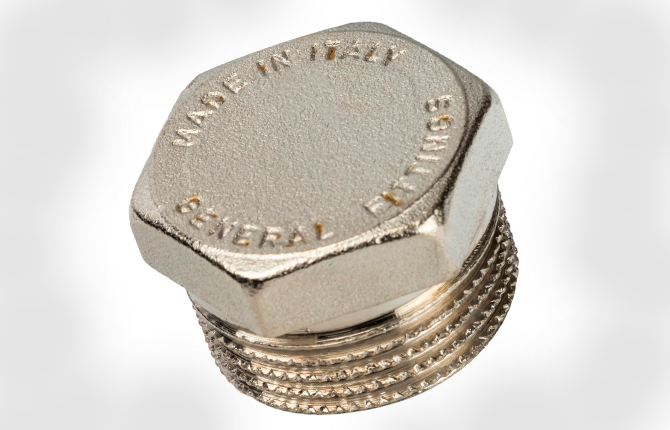

The first is a metal pipe plug. The material of manufacture (in this case) is steel, cast iron, stainless steel, brass.

Characteristics of the steel version:

- withstands temperatures from -70 ℃ to +600 ℃;

- pressure – up to 30 atm;

- service life – up to 100 years depending on the medium passing through the pipeline.

Cast iron models have lower performance because they are installed in sewer systems.According to GOST, they do not regulate the temperature regime of the medium flowing through the pipes. It's the same with pressure.

They are made of malleable cast iron, so they can easily withstand high humidity and water for a long time. There are two models on sale:

- standard cast iron black;

- galvanized gray.

Such models can be used not only in sewerage, but also in heating and gas pipelines.

Brass products have the following characteristics:

- temperature – up to +200 ℃;

- pressure – up to 30 atm.

They cannot be used in systems with aggressive environments.

Stainless steel fittings are the strongest and most durable. They easily withstand humidity conditions and do not become magnetized. But very expensive compared to other types.

Rubber

These are parts made from rubber or a synthetic substitute. They are used to temporarily shut off a pipe - either during the repair of a pipeline system, or when it is necessary to temporarily disconnect one of the pipeline hoses.

Rubber plugs for pipes are divided into two groups:

- ordinary ones in the form of caps that are placed on the end of the pipe;

- pneumatic.

The latter are spherical or cylindrical hollow bags or cylinders, which are filled with air when used.

Plastic

It is a cheap alternative to metal. They cannot withstand high temperatures, so they are more often used in household pipe networks or as a decorative element covering the top of the post in fences, gates and other similar structures. Plastic models are also used in the furniture industry when making objects from pipes. They are decorative plugs for pipes.

Today they have found application in the designs of vessels (pneumatic and hydraulic) operating under pressure. Plastic is more often used than other materials to produce fittings, which are used to close the openings of pipes ready for transportation.

Manufacturers offer products with the following characteristics:

- pressure – up to 25 atm;

- petrol and oil resistant with reinforcement;

- chemically resistant, made from a special polymer;

- for gas pipelines in the form of flanges with paronite gasket.

Plugs for plastic pipes - products of different colors. The manufacturing technology is injection molding, hence the high geometric accuracy and strength.

Specific models

This group includes products made of fabric and composite materials. The first ones are installed on air ducts, so the place of application is the ventilation system.

The latter are made on the basis of polymers, glass, ceramics and other materials with the addition of strengthening additives. Such plugs are used in aircraft or rocket production because they have characteristics superior to even stainless steel varieties.

What to consider when choosing

There is more than one factor to consider when choosing a plug. The operating conditions of the pipeline come first. Eg:

- if it is necessary to plug the heating circuit or hot water supply, then there is no better metal product;

- for sewerage you need to choose either cast iron or plastic, depending on the installed pipe (plastic or cast iron);

- It is better not to install threaded analogues on high-pressure gas pipelines that will allow gas to pass through;

- Plastic plugs can be installed in water supply networks;

- the same goes for furniture, pipe racks.

The second factor is parameters. This refers to shape and size. It’s easiest with them - they must match the pipes, their shape and cross-section. For example, today many plugs for profile pipes made of plastic are produced. Square or rectangular shape, any sizes for pipe products.

The third factor is the material from which the plugs are made.

The fourth factor is the tasks assigned to the stubs. If this is a decorative element, then there are no special requirements for it. Its task is simply to close the open end of the pipe so that dirt and water do not get inside.

How to install a plug

Before placing a plug on the pipe, you need to decide pressure inside the pipeline. The larger it is, the higher the characteristics the fitting should have.

Installing a plug in a system without pressure

Any type of plug can be used here. If the pipe is metal, then you can plug it by welding an elliptical model to the end. The method is expensive and requires experience, skills, and special welding equipment.

A screw plug can be installed. But to do this, you will have to cut a thread on the pipe or weld a bend to it, which again requires special tools and skills.

Therefore, the best option is a plastic plug that is put on or inserted into the pipe. You can use glue to strengthen it. If the main line is assembled from plastic pipes, then the PVC plug is installed using the same welding machine (iron).

Some models are equipped with an aluminum tube passing through the plug. This type is installed on vertical channels. The purpose of the tube is to monitor the flow passing through a horizontal pipe.

Installation in a pressurized system

Here you also need to take into account the material from which the pipe is made. For steel ones, you need a threaded plug or a welded one. For plastic ones - welded or threaded, secured with glue.

Welded and glued belong to the category of fittings used for permanent connections. That is, when dismantling they will have to be cut off. But it is precisely these models that ensure 100% tightness of the joint.

Threaded ones, when installed correctly, will not be inferior to the previous two. To do this, it will be necessary to additionally use sealing material, which will ensure the tightness of the connection.But such plugs are convenient in that they can be removed at any time and used in another place.

Installation with further dismantling

To do this, you will only have to install threaded or plug-in elements. The latter are fittings often used on racks and furniture, as well as on pipes prepared for transportation. The latter are designed to protect the edges from impact loads. If struck, the fitting will be damaged, but the edge will not.

The dismantling version makes it possible to remove the plugs if necessary and use them in the future on other areas, racks and other structures.

As you can see, the huge variety of pipe plugs developed by man confirms that this fitting is practically necessary. Where there is a pipeline, such an irreplaceable part will definitely be required.

Did you know how wide the scope of application of pipe plugs is? Tell us in the comments. Save this article to your bookmarks bar so you always have it at hand.

I wanted to buy caps for an installed fence that is painted green. I couldn’t find any in the store other than black and brown. They say multi-colored ones are rare. I had to take what I had.

For sewerage, the best plug is a threaded one. There is a rubber cuff inside it that ensures a tight seal. The smell will not be missed. It’s easy to unscrew and tighten – all by hand.