Silent sewerage: design principles and installation examples

Noise creates a significant level of discomfort. And it is not at all necessary that the noise be pronounced.Even quiet but constant sounds, for example, the flow of water in pipes, can lead to disorders of the nervous system.

Modern residential buildings create comfort for people thanks to running water, heating, and sewerage. But this comfort is limited if silent sewage is not provided, as well as noise insulation of other communications.

The content of the article:

Is there a sewer system without noise?

Technologies for the production of plastic pipes, which enjoy a high level of popularity in construction, are being consistently improved.

If at the first stages of production products were produced with frankly low noise reduction characteristics, now the situation is changing. You can increasingly see so-called silent pipes on the market.

What are silent sewer pipes? These are products for the production of which, along with traditional materials, materials that can dampen sound waves are used.

The structure of a silent sewer pipe is formed from several working layers:

- polyethylene (hard);

- mineralized polypropylene;

- polyvinyl chloride (soft).

According to various estimates, a three-layer hose with a similar structure reduces the noise level from liquid flowing in pipes to at least 20 dB. This value fully complies with European standards (DIN EN 14366).

An integral part of silent sewer pipelines are special support clamps.

Using these parts, polymer pipes are secured to the mounting base. The clamp itself is a simple product - a metal hoop. But along with it, a soft polymer insert is used, the material of which effectively dampens mechanical vibrations.

Principles of designing a low-noise system

Of course, silent domestic sewerage does not become so only due to the replacement of conventional main lines with lines made of silent pipes. This option is one of several that can be used to combat unwanted sounds.

If isolated standard sewer pipeline sound-absorbing material and replace hard supports with fasteners with a soft insert, you can already get a good result.

Considering that it is difficult and expensive to completely remodel an existing sewer system, it is reasonable to limit ourselves to the creation of insulating boxes. In combination with an insulating material, this approach will have a double effect.

If you are installing a sewer system from scratch, then you should carefully approach the installation procedure. Correct installation, work with shaped elements - these criteria also give a good effect of silence during the future operation of the system.

Option #1: socketless connection

For example, it is recommended to connect socketless pipes to each other as follows:

- Align the cut ends of polypropylene pipes (cut angle 90º) and remove burrs.

- Use a sewer coupling as a fitting.

- Remove the sealing collars from the inside of the slip-on coupling and place them on the pipe nozzles.

- Apply water-based lubricant to the sealing collars.

- Insert the pipes (applying some force) inside the coupling until they stop.

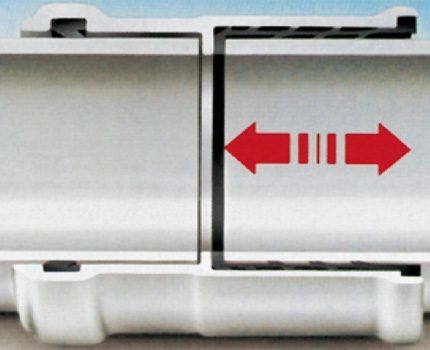

The same principle applies to bell-shaped pipe connection, connection with tees and corner fittings. In this case, in most cases of socket installation, the creation of thermal expansion compensators is taken into account.

Option #2: socket connection

Connections of pipes and fittings made without the use of a push-on coupling, installed on a pipeline section up to 3 meters in length (horizontal section), require compensation for thermal expansion.

That is, during installation, it is necessary to remove the pipe back by 10 mm after inserting it into the socket until it stops. The effect of thermal expansion can only be ignored in diagrams of socket connections between fittings.

Method for creating a socket connection:

- Clean the pipe, the inside of the socket, and the area of the sealing ring from dirt.

- Make sure that the fit of the bell O-ring meets the installation requirements (no twisting, damage, or dents).

- Apply water-based lubricant to the pipe fitting.

- Insert the pipe all the way into the socket and then push it back 10 mm.

- Install a fastening clamp near the connection point.

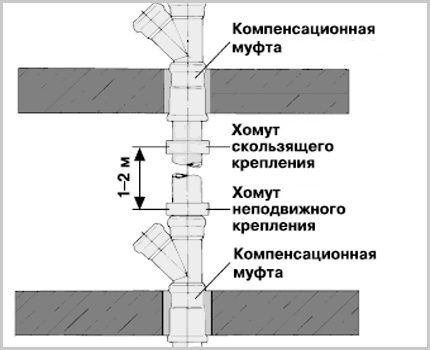

Separately, it is worth considering the method of fastening silent sewer pipes (for example, Skolan brand). Here laying pipelines requires to be performed in such a way as to eliminate physical stress and the possibility of linear expansion.

The now popular polymer sewer pipes can be secured with standard clamps, but under the hoop of the clamp you should definitely use pads based on profile rubber.

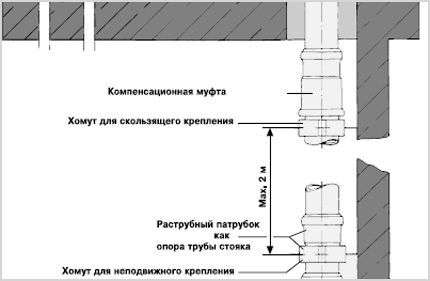

Recommended principles for mounting clamps:

- On a horizontal line, the distance between the clamps is equal to 10 times the pipe diameter.

- On a vertical line, the distance between clamps is no more than 2 meters.

- On risers, it is mandatory to install rigid and floating fastenings with clamps.

- Rigid fastenings on socketless pipes are installed above the fitting in the area of the lower pipe.

- Floating clamp fastening is achieved by partially tightening the lag screws.

- The floating mount is installed next to the rigid fastener on the side of the pipe inserted into the socket.

Subject to following the noted principles when installation of a sewer system, it is realistic to obtain acceptable noise characteristics of domestic sewerage at a level of 12-20 dB.

Installation details that affect noise levels

Under no circumstances should machine oils or similar lubricants be used as a lubricant for connection elements. All of them have a negative impact on the structure of rubber seals.

Rubber loses its technical properties, cracks and structural irregularities appear on the seals.Such a compaction not only becomes a source of increased noise, but also threatens to burst at any moment.

It must be remembered that connections “straight pipe - socket” are always installed taking into account the installation of the edge of the socket against the flow of waste. Under such conditions, maximum smoothness of the internal surface of the sewer line is ensured, which in turn is accompanied by a low flow noise level.

The noise characteristics of the sewerage system are also affected by the value pipe slope. It is not recommended to deviate from established standards and norms that determine the amount of slope depending on the diameter of the sewer hose.

For pipes with a diameter of up to 50 mm, the slope value is no more than 35 mm; for diameters from 50 to 100 mm, a slope of no more than 20 mm is recommended. Pipelines with a diameter of 150 mm or more are installed with a slope of no more than 8 mm.

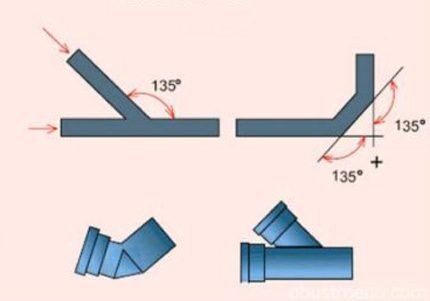

Turns of pipeline lines, as well as branches, are made by installing oblique tees or half bends (angles 30-45º). The principle of constructing networks in this way helps reduce sewer noise.

The effect of noise suppression during volley discharges into the sewer system is especially noticeable. In addition, the smooth bends of the turns create better conditions in case of cleaning the system with a sewer cable.

Plastic pipelines on straight horizontal sections should be fixed with clips, support clamps, and hangers every 7-9 meters. If you deviate from these requirements, there is a risk that after some time of operation you will end up with sagging areas in such areas.

Pipeline sagging is a change in the parameters of the movement of wastewater and, as a result, an increase in noise level. At socket joints, fastening is carried out by default.

Branded Low Noise Sewage Products

There are brands that have proven themselves to be of excellent quality and have a strong foothold in the domestic sewer products market.

Vavin Asto and ASTOLAN

In recent years, market offers have surprised us with a wide selection of branded silent sewage systems. Among the available examples for installation, we can note, for example, a product under the Vavin Asto brand.

The company manufactures and sells polypropylene pipes and fittings, the basis of which is ASTOLAN - a material modified by mineral additives.

Thanks to the modification, engineers were able to increase the wall density of sewer pipes to 1.9 g/cm3 and enhance indicators such as viscosity and specific gravity. As a result, virtually silent sewage systems “Vavin Asto” appeared.

According to company representatives, there is no vibration noise during system operation. The penetration of sewer sounds through airspace is also excluded.

German quality Ostendorf

Another example of a modern noise-free system is sewerage based on pipes and fittings of the Ostendorf brand. The base material is the same, mineral-modified polypropylene.

But the density indicators in this case are somewhat inferior - 1.6 g/cm3. At the same time, the temperature parameters of the Ostendorf sewer system are higher - up to 100ºС, and pH values are in the range of 2-12.

The Ostendorf branded product is characterized not only as low noise. All production elements are characterized by a high degree of corrosion resistance, durability, and resistance to aggressive environments. An extensive range of shaped parts and pipes ensures the creation of communications for various purposes.

Rehau and REHAU RAUPIANO Plus

Rehau systems also show a high percentage of popularity. In particular, the product REHAU RAUPIANO Plus is persistently advertised. The technological approach, however, is not much different from the two previous firms.

In the fight against noise, Rehau also places emphasis on the production of multilayer plastic pipes, on reinforcing the wall thickness of corner fittings, and on the production of so-called “noise-absorbing” clamps.

The practice of operating such a sewer system shows a noise reduction of approximately 25-30%.If desired, similar indicators can be achieved if standard work on sound insulation of a domestic sewage system is performed using available insulating materials.

Will familiarize you with guidelines for choosing the best pipes for installing an internal sewerage system next article, containing a lot of useful information.

Conclusions and useful video on the topic

Some useful tips on how to reduce the noise level of the sewer system and make your life more comfortable.

The installation of a low-noise sewer system is possible, as evidenced by numerous proposals in the plumbing industry. Meanwhile, problems with noise parameters of drains practically did not exist as long as good old cast iron pipes were used.

As soon as lightweight and inexpensive polypropylene came into use, problems with silence in the house arose. There is something to think about for both plastic manufacturers and residential building owners.

Please write comments in the block below. Tell us about how you built a silent sewer system in your own house/apartment, or about technological nuances not covered in the article. Ask questions, share useful information, post photos on the topic.

Sewer lines sometimes make very unpleasant sounds, which is why silent pipes began to be used. Some people soundproof regular pipelines. But I think it’s easier to immediately use silent pipes, since they dampen sounds perfectly. They are easy to install, and the service life of the engineering systems assembled from them is very long.

If it were easier to make silent sewerage, we would do it, but now noise insulation for conventional pipelines is MUCH more popular. Based on this you can draw a conclusion. Yes, just look at the difference in price.

In addition, the desired noiselessness effect (at least those parameters specified by the manufacturer of these products) can only be achieved if the installation technology is very strictly followed throughout the entire building, and not just in your apartment.

That's news! In fact, the market does not stand still, new technologies are constantly appearing, just keep up with them. This is the first time I learned that there are silent sewers. Just a month ago I completely changed the wiring in the bathroom. I would be happy to install such pipes if I knew about them. Otherwise, ordinary polypropylene ones make no less noise than cast iron ones.

Does the project need to be previously agreed upon with the housing office or somewhere else? For an ordinary one-room apartment in Khrushchev, how much will such a pleasure cost?

You need to coordinate the design of such a silent sewer with the management company of your home, otherwise in the event of a breakthrough or some kind of accident, they will not bear any responsibility if you made a replacement without approval. As for the cost, it is difficult to give an exact figure, since there is little information about the current wiring, the state of communications in your apartment, among your neighbors, and so on.

For example, Pipe d. 100x250 mm. silent Ostendorf Skolan costs about 9-10 dollars, you can calculate the required amount yourself, plus adapters, sealants and other little things, also coordination of the project and the work of a specialist. I think that for a one-room apartment in Khrushchev you can budget for 250-300 dollars.If you install it yourself, then even $200 is a realistic investment.