Plumbing methods for connecting pipes: an overview of all possible options

In order for the water supply systems and the circuits through which the coolant circulates to flawlessly cope with their responsibilities, their components must be correctly assembled and correctly connected. The result of the plumbers' efforts must be airtight so as not to create problems for the owners and their neighbors. Do you agree?

All current methods of connecting pipes that ensure normal operation of the system are given in our proposed article. We have described in detail the technological options depending on the material from which the articulated parts are made and the category of the pipeline. Our tips will help you achieve the perfect result.

The content of the article:

Overview of detachable plumbing connections

All known methods of connecting pipes can be classified into two classes - detachable and permanent. In turn, detachable connections are flanged and coupling. Permanent methods include connections such as socket, collet, butt welding, and adhesive.

Connections that, if necessary, can be disassembled and then returned to place, greatly simplify the maintenance and repair of pipelines. These connections are used mainly in the formation of internal communications.

The advantage of this method is its ease of implementation. No chemical or thermal effects are used here.A malfunction of a pipeline connected by this method can be easily identified and eliminated.

A tight fit during plumbing pipe connections is ensured by using special parts. There are 2 types of joints of the detachable type: flange and fitting. The first is used when it is necessary to connect large-diameter pipes, while the second is more suitable for home pipelines.

He will familiarize himself with the types, characteristics and markings of polypropylene pipes and fittings used in connections. next article, which we recommend reading.

Fittings used in plumbing systems are installed at control points, at turns, and branches. They are cast and compression. From a functionality point of view, the following types of fittings can be distinguished:

A set of fittings is selected depending on the specifics of a particular pipeline. According to the method of attaching them to the pipe, fittings can be clamped, threaded, pressed, threaded, used for welding and soldering.

Release fittings for metal-plastic pipes, they are used in the formation of crimp and press connections. To connect polypropylene pipes, fittings are produced, used both in connection by gluing and welding. For copper pipes They produce fittings for both press connections and soldering.

The process of assembling a metal-plastic pipeline using compression fittings will be presented in the following selection of photos:

Socket connection method

A socket is a mounting extension designed to create a reliable connection.The principle is based on the fact that the end of a pipe with a smaller cross-section is inserted into a pipe of larger diameter. The connection is sealed by using a sealant placed in the socket or gluing with a composition that is resistant to water.

Depending on the material of the pipes and their diameter, one of several existing options for socket joints is selected: with a sealing ring, without a ring, welding, gluing.

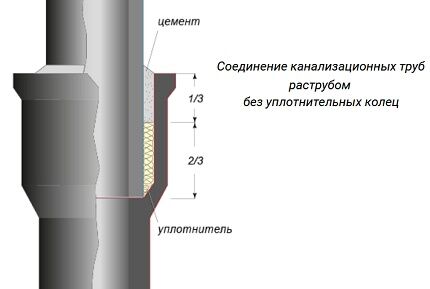

Connection without ring seal

Cast iron pipes are most often connected without an O-ring. The inserted pipe is shortened, the end is processed so that there are no nicks or mother-in-laws left in it. The tail part of the articulated pipe is inserted into the socket.

The resulting gap is filled with oiled hemp rope or tarred linen strands. First, the seal is placed in a ring and caulked into the socket by tapping it with a hammer on a special wooden spatula or screwdriver. It is important to ensure that the ends of the material do not get inside the pipeline.

Continue laying the sealant layer by layer until the socket is filled to 2/3 of its depth. For the last layer, an untreated sealant is used, because oils or resins will impair adhesion when filling the remaining space in the socket with cement.

To obtain the solution you need cement grades 300 - 400 and water for diluting it. The components are taken in a ratio of 9:1. The cement is compacted into the socket and covered with a wet rag for better setting.

Sometimes, instead of cement, an asbestos-cement mixture is used, made from M400 cement and high-quality asbestos fiber in a 2:1 ratio.

Water is added immediately before laying in an amount of about 11% by weight of the dry mixture. Instead of cement-based sealants, they use bitumen, silicone sealants, clay, the last layer of which is strengthened by applying bitumen or oil paint.

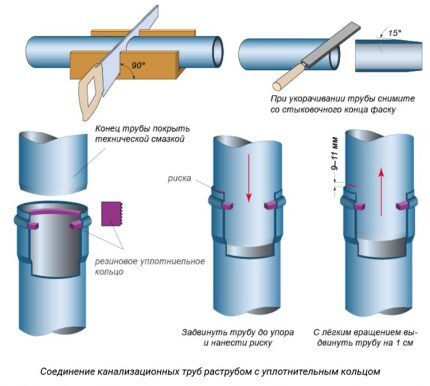

Socket connection with O-ring

This method is most often used when installing an intra-house sewer system. A rubber ring sandwiched between the socket and the pipe inserted into it creates a tight connection. Therefore, the method is not only simple, but also reliable.

The sealing ring to some extent smoothes out the differences in axes between the two pipes being connected. However, this is only the case if the axes on each meter of the composite pipeline are shifted by an amount that does not exceed the limits of the pipe wall thickness.

If this condition is violated, then the likelihood of leaks as a result of uneven deformation of the seal increases.

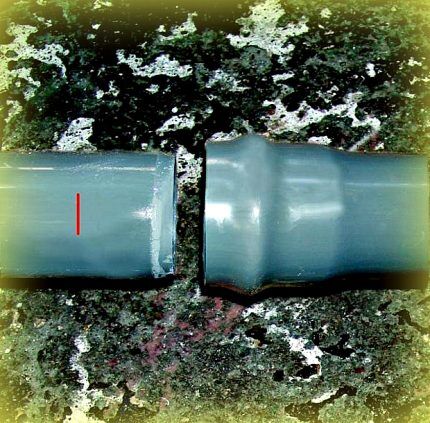

To determine the depth of pressing of the free pipe shank into the socket, the sealing ring is temporarily removed. Then, placing the pipe in the socket until it stops, mark the place where the inserted part comes into contact with the socket.

During installation, the pipe is pushed out slightly in relation to the mark - by 0.9 - 1.1 cm. This distance will balance the internal stresses that appear in the system during temperature fluctuations.

Before placing the ring, it is recommended to dip it in soapy water and squeeze it a little. This will greatly simplify its insertion into the recess of the bell. In order to minimize the amount of misalignment, some manufacturers began to produce fittings with an angle of 87⁰ instead of 90⁰. The pipe enters the socket at an angle and the ring does not warp.

If there is a need to connect pipes made of different types of materials, adapter pipes are used. The size of the pipe, such as the internal diameter, must correspond to the outer section of the connected pipe. If the socket of a polymer pipe is connected to a cast iron pipe, a double seal is applied to the end of the second one and the pipe is mounted.

Bonding parts of a plastic pipeline

PVC pipes are connected to a socket using the gluing method. For better adhesion, the socket inside and the tail of the inserted pipe are sanded to make the surface rough. Next, the chamfer is removed, and the treated parts are degreased using methylene chloride as a primer.

Before making a connection, check the pipes for compatibility. A pipe of smaller diameter should fit into the socket freely, but not too much.Then a line marks the boundary for applying glue - this will help to join the parts without errors.

On the surface of the connected elements - 2 thirds of the socket recess, as well as a fully calibrated end of the pipe, evenly apply glue thin layer. The pipe is inserted into the socket and turned a quarter turn to improve contact between the elements being connected. The joined parts are held until the glue sets.

The process takes only 20-30 seconds. If a uniform layer of glue appears at the joint, it is immediately removed using a piece of clean cloth. From gluing to complete stabilization of the connection and testing the pipeline for leaks, at least a day should pass.

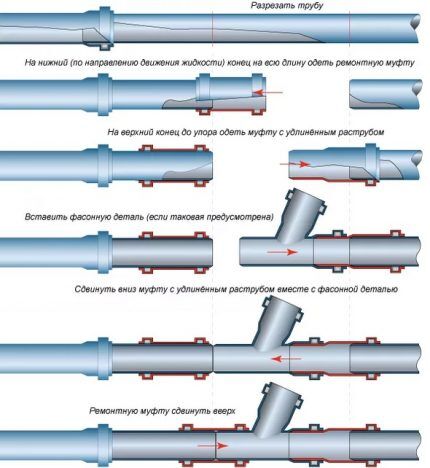

To repair existing pipelines, shaped parts are used in the form of repair couplings or products with an extended socket. A section of pipe is cut out, the ends are chamfered, and special glue is applied to the ends. The coupling is placed on the bottom of the pipeline.

A coupling with a long socket is placed on the top of the pipeline until it stops; if required, a shaped part is mounted on it. Move the coupling along with the shaped part down until it connects with the bottom of the pipeline. The sliding coupling is moved upward so that it covers the joint area.

If even after this there is a leak, the joint is filled with silicone sealant. The bottom and top are determined depending on the direction of movement of the transported substance.

Using resistance welding

To use this method of connecting pipes, you must have a welding machine. It can be mechanical or manual, but it must be equipped with a special tool that heats the elements to the required temperature.

When using socket technology, a sword-shaped device is used to connect pipes.It is a set made of metal and consisting of a sleeve designed to heat the outer surface of the pipe and a mandrel (pin) that melts the part from the inside.

An important point is the selection of the kit. Its parameters must correspond to the diameter of the assembly.

The technology of socket connection of pipes using resistance welding is simple:

- A restrictive clamp is placed on the inserted pipe. The distance between the edge of the pipe and the clamp should be equal to the depth of the socket plus another 2 mm. The difference between the inside diameter of the clamp and the outside diameter of the pipe being joined should be 0.2 mm.

- The kit is heated by first installing it on the device.

- Place the bell on the mandrel and the smooth tail of the pipe on the sleeve until it stops.

- Heating is carried out for the specified time.

- Remove the parts from the kit at the same time and connect them, holding the parts from moving until the melted material hardens.

Weld seams are inspected to identify possible distortions, voids, and unevenness of the seam.

There should be no defects on the outer surface of the parts that appear if the permissible temperature is exceeded. Visually from the outside, the weld should have the shape of a symmetrical bead, having the same width and distributed evenly around the perimeter of the pipe.

The maximum height of the roller on a pipe with a wall thickness of up to 1 cm is a maximum of 2.5 mm. For pipes in which this size exceeds 1 cm, a roller height of 3–4 mm is considered acceptable. The edges of the welded joint can be offset relative to each other by no more than 10% of the pipe wall thickness.

PP pipe welding technology in detail is given here. We recommend that you familiarize yourself with the contents of our proposed article.

Welding of polymer pipes with a diameter of more than 50 mm and a wall thickness of more than 4 mm is recommended to be done using a stationary or mobile device with a disk heating element:

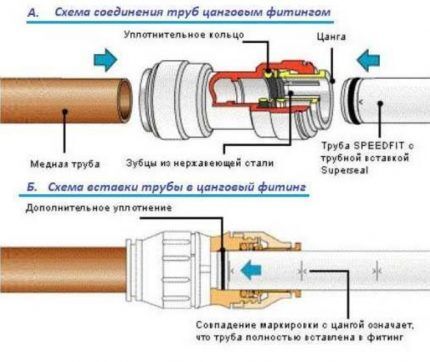

Application of clamp fitting

The concept of collet pipe connection means the use of a clamping or collet fitting. With its help, it becomes possible to implement a variant of collapsible articulation of pipeline elements made of different materials. Features of its implementation described here. The clamp fitting is selected based on the type and diameter of the pipe.

The joining algorithm for plastic pipes is as follows:

- Calibrate the hole of the required pipe section using a calibrator and remove the internal chamfer using a chamfer remover.

- Disassemble the fitting by unscrewing the nuts from the ends and removing the round seals from the fittings.

- Place the union nut on the end of the pipe, then the fitting collet.

- Insert the fitting shank inside the pipe, applying force so that it fits completely.

- Manually tighten the nut onto the fitting body.

- Repeat the same manipulations with the second pipe, then join the parts to be connected and tighten the union nut without tightening 1-2 turns.

Tighten the nut carefully so as not to damage the pipe. In the process, the clamping ring is deformed, due to which the end of the pipe and the side of the fitting cartridge are pressed tightly against each other.

Experienced plumbers recommend doing the first turns by hand when tightening the tightening nut, and then using a spanner.

Push-in connections are primarily used in the assembly of copper pipelines:

Formation of threaded connections

A thread is a spiral or helical surface used to make a threaded connection. The use of threaded pipe connections in plumbing systems is a classic installation method.

It is used where it is possible to periodically monitor the joints, because threads tend to weaken under the influence of various factors.

There are different types of pipe threads. Each of them is characterized by such parameters as the profile of the surface on which the thread is applied, direction, location, and number of thread starts.

The list of the most popular types of pipe threads includes:

- cylindrical or Whitward;

- conical;

- round;

- NPSM

The first of them is designated by the letter G and has 2 accuracy classes.The profile visually resembles an isosceles triangle. At the apex there is an angle of 55⁰. They connect pipeline sections with a diameter of up to 6 inches, which are subject to special requirements for tightness, using inch threads. For larger diameters, welding is used.

Inch-type conical threads are used for conical connections and to create joints of conical threads made on the outside and cylindrical inside the pipe. The letter R marks the external thread, the internal thread - Rc, LH - directed to the left. The sealant is the thread itself plus the sealant.

To connect frequently disassembled plumbing fittings: water stop taps, faucets, round threads are mainly used. It is designated by the symbols Kr.

The table summarizes the main thread parameters for a pipe that can be cut with your own hands. An important value for an inch thread is its pitch. This is the distance between adjacent ridges or troughs. Its value along the entire length remains unchanged, otherwise the thread will not work

The NPSM thread profile has a triangle shape and an angle of 60⁰. The size range in inches is from 1/16 to 24. This American standard thread is a type of cylindrical thread. It differs from the domestic one only in the size of the profile angle.

Conclusions and useful video on the topic

The author talks about the nuances and problems that arise when joining pipes during sewer installation:

The author of this video shares how to solve his problem:

Properly connecting pipes is very important. The joint has always been the weakest point of the pipeline. If it is performed incorrectly, then, as a result, leaks, blockages, and sometimes pipe ruptures will certainly occur.

Therefore, before you begin installing plumbing communications yourself, you need to study all existing connection methods. If the matter seems complicated, you can always contact a plumber.

Tell us about your own experience gained while assembling plumbing systems. It is possible that you know the nuances of installation and formation of connections that will be useful to site visitors. Please write comments in the block below, post photos with the steps of the process, and ask questions.

Is it necessary to use a sealant when making threaded connections? If yes, which one is better to use? Linen, fumlenta or Tangit type thread?

The seal is not needed everywhere, it depends on the type of connection. As for which one to choose, flax is a thing of the past, not everyone can use fum tape correctly, and this is more of a temporary option; modern polymer and anaerobic sealants should be used.