Plastic cesspool: how to choose a container and properly arrange a plastic pit

The simplest design among the available options for installing a storage tank for an autonomous sewage system is a plastic cesspool.

The key to stable operation of the sewer system is the competent choice of a storage plastic tank and strict adherence to installation technology.

Let's try to understand all the intricacies of choosing, installing and operating plastic waste containers

The content of the article:

Advantages and disadvantages of plastic tanks

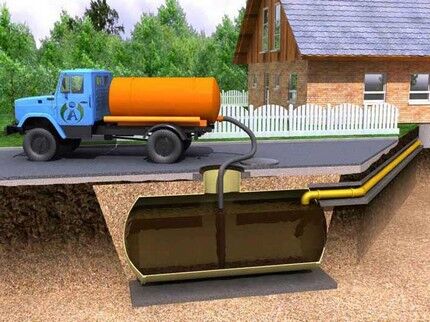

A cesspool is a storage tank for the collection and subsequent pumping of wastewater coming from the house through sewer pipes. The use of polymer materials for the manufacture of such sewer storage tanks is determined by economic feasibility.

The cost of containers and polypropylene is 3-5 times lower than analogues made from the same concrete rings or monolithic concrete.

Excellent performance polymer containers acquired due to the properties of the material used for their manufacture. Polypropylene is a thermoplastic polymer with a density of 0.9 g/cc.

It softens only at a temperature of +140°C, thanks to which it is able to calmly, without deformation, tolerate fluctuations in ambient temperature.

Polymer compounds are chemically resistant materials.

Among the undeniable advantages of plastic storage tanks, it is worth highlighting the following qualities:

- high strength;

- low gas and vapor permeability;

- resistance to repeated bending and light impacts;

- the ability to spontaneously restore shape after deformation effects;

- excellent wear resistance, increasing with increasing molecular weight;

Properly installed plastic cesspools are famous for their long service life. If the installation technology is followed and the structure is properly maintained, it can last for more than half a century.

But the decisive argument when constructing cesspools using plastic sewage tanks is their tightness. All unpleasant odors and fumes remain inside the structure without damaging the environment.

Due to the high tightness of the tank and the absence of surface seams, sewage entering the tank remains inside, without penetrating into the ground and without polluting groundwater.

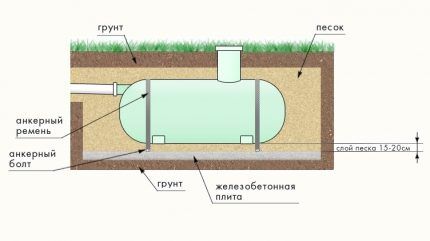

But the low weight of the structure can serve not only as an advantage, but also as a disadvantage. Over time, under the pressure of the surrounding soil, a lightweight container can simply be pushed to the surface.

To prevent this situation from occurring, the container is placed on a durable base made of reinforced concrete slab and secured to it.

Some users who have installed plastic waste tanks on their sites note that such structures require careful handling during installation. Since any chip or crack formed due to violation of installation technology makes the operation of the structure unacceptable.

Criteria for choosing a container correctly

Specialized companies are engaged in the production of plastic tanks for cesspools. When manufacturing storage tanks, they are guided by generally accepted sanitary standards, according to which sewerage devices must, first of all, be safe for both people and the environment.

Depending on the type of future location, plastic barrels are available in two versions:

- Horizontal – produced specifically for areas with high groundwater levels. The disadvantage is the need to construct a large pit, which is why they are used mainly in large suburban areas.

- Vertical – a classic option, suitable for areas of any size. Models of this type are installed in a deep, but small pit. Suitable for areas with groundwater levels below 3.5 - 5.0 m from the day surface.

Depending on the cross-section, plastic tanks are divided into round and rectangular.

The finished designs already take into account the main points to simplify installation and connection to pipes.

Most tanks intended for the construction of cesspools already have:

- head equipped with an opening lid;

- technological holes for connecting pipes;

- air duct for installing a ventilation pipe;

- anchoring brackets - fastening to a concrete base.

The neck of the tank must be wide enough so that various fecal pumps can be operated without obstruction. The lid, equipped with a screw thread, must have technological projections and handles.

For the construction of cesspools, it is better to choose containers that have increased resistance to deformation under compressive stresses arising under the influence of soil, and tensile stresses under the pressure of the accumulated medium.

Manufacturers obtain increased strength by creating multilayer structures. The inner walls of the tank have a smooth surface, thereby preventing the formation of deposits and sediments.

The outer layer of a polypropylene container is cast from fiberglass based on fiberglass and epoxy resins.

It is executed:

- in the form of flat screens;

- in the form of a corrugation.

The volume of the container is calculated based on the number of household members. According to clause 2.4 SNiPa 2.04.03-85 It is generally accepted that on average 25 liters of water are consumed per day for the needs of one person in points not equipped with a central sewerage system.

On sale there are barrels with a capacity of 1200 liters, intended for arranging a drainage system or organizing a summer shower, and with a volume of up to 5500 liters or more.

The regularity of pumping directly depends on the volume of the installed tank. If you purchase a waste storage tank that is too small, you will have to pump it out monthly.

When planning to upgrade the system in the future, when choosing drives, give preference to designs that provide for the possibility of developing the system in the future. For ease of system maintenance, choose tanks equipped with a float or a light that lights up when the tank is full.

Sewage tank installation technology

Considering the relatively light weight of the container, installation of a plastic cesspool can be done on your own without the use of special equipment.

Choosing a location

The choice of location for installing a cesspool is related to current sanitary standards, violation of which may entail administrative liability. Standard distance requirements guaranteeing soil protection from contamination are specified in SanPiN 42-128-4690-88.

The plastic cesspool is a sealed structure that is relatively safe to use. Therefore, a waste tank with a closed bottom can be placed five meters from the facade of the house.

If there is a well, a well or any other source of water on your or a nearby site, you must maintain a distance of 20 meters from them. The distance from the fence and road should be within two meters.

When choosing a location, it is also necessary to take into account the composition of the soil, taking into account the level of groundwater and the depth of freezing when the temperature drops below zero.

To ensure efficient operation of autonomous sewer system On the route to the pit, the number of pipe turns should be minimized. Therefore, it is better to place the cesspool so that the pipeline connected to it is laid in a straight line if possible.

Carrying out excavation work

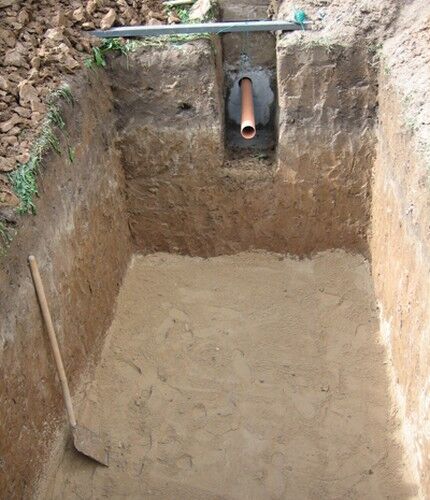

Having determined, taking into account sanitary standards, a place for arranging a cesspool, mark the surface using stakes and twine.

Having leveled the surface, they begin to dig a pit. To prevent freezing of the wastewater in the storage tank during the cold season, it is buried below the seasonal soil freezing horizon. When extracting the soil, the top fertile layer can be evenly distributed over the garden beds.

The dumped soil will have to be transported off-site. If the dump is predominantly sandy and has a small amount of clay layers, then it is advisable to leave 1.5 cubic meters of sand to fill the container to the top of the hatch.If there are a large number of clay inclusions, the soil should be completely replaced with river or quarry sand.

The width of the pit is made larger than the structure itself in order to simplify loading the tank and provide space for the construction of a protective frame along the outer walls. The depth of the pit corresponds to the height of the tank, taking into account the hatch, plus 20-60 cm for the arrangement of a concrete base with the construction of a ceiling (for installation in the northern regions).

To carry out the work, you need to prepare a set of tools:

- building level;

- bayonet and shovel;

- a couple of buckets for excavating soil;

- tamping;

- roulette;

- ladder.

If the soil in the excavation pit crumbles and does not hold the walls well, the walls of the pit are reinforced with brick to prevent mechanical damage and provide additional protection.

To prevent the container from sinking deeper as it is filled, the bottom of the dug pit is concreted. In areas with high humidity levels, experts recommend making a reinforced slab 20-25 cm thick under the tank.

The reinforcement grid is assembled from 10-12 mm metal rods, fastening them together with knitting wire, and then laid on the bottom of the pit and filled with cement mortar.

To concrete the bottom of the pit, cement mortar is poured onto a leveled and compacted base and wait until it acquires the required strength. While the solution has not hardened, two metal hooks are inserted on each side along the edges of the screed to secure the container to them.

It will take at least 14 days for the cement layer to harden, although according to the rules, at least 28 days must pass from the day of pouring to the day of installation of the tank.

Often, in order to speed up the sewer construction process, a ready-made reinforced concrete slab of the appropriate size is used instead of pouring. In such cases, the installation of the storage tank can begin immediately after the slab is immersed in the pit.

The only difficulty is that the slab will need to be leveled strictly to the horizon in order to prevent distortions in the location of the tank.

Installing the tank on the base

The plastic container is tied with ropes and carefully lowered into the hole. When placing the tank, the inlet pipe should be directed towards the sewer pipe.

Using hooks fixed in the concrete screed, the position of the tank is fixed. To reduce the pressure of the soil thickness on the tank, the outer walls are lined with bricks.

The arrangement of the upper floor should be foreseen and thought out in advance. It can be made from wooden boards treated with an antiseptic, knocked together into panels, or from concrete screed.

The size of the overlap should be such that it completely covers the walls of the plastic container. In areas with a harsh climate, it is advisable to provide external thermal insulation of the hatch and areas around the walls to the freezing depth, using available materials.

To reduce excess pressure on a filled tank in the cold season, the voids between the walls of the pit are filled with an earth-sand mixture. It is laid in layers and compacted every 5-7 cm.

If in the area where the cesspool is located the groundwater comes quite close to the surface, experienced craftsmen recommend compacting the space around the container using a mixture of cement and sand taken in a ratio of 1:4.

To prevent deformation and cracking of the plastic under soil pressure as the walls are compacted, the container must be filled with water. The level of liquid poured into the tank should be 20 cm higher than the level of the soil compacted along the walls. Subsequently, it will not be difficult to pump out the liquid by immersing the pump in it.

Arranging a hatch and installing a ventilation pipe

To minimize the entry of rainwater into the pit, the tank is equipped with sewer hatch. Its traditional diameter is 56-70 cm. The inspection hatch is equipped with a hermetically sealed lid included in the kit. It can be removable or folding.

At a depth below the freezing point of the soil, which is about 90 cm, a sewer pipe is supplied, not forgetting to maintain an inclination angle within 3%. The sewer pipe is connected to the pipe using a double-sided coupling.

Before finally filling the upper part of the tank with soil, check once again whether the ventilation pipe is installed correctly and whether the pipes leading to the tank are sealed.

When backfilling the upper part of the tank, clay is used to create a moisture-proof layer above the tank, and vegetable soil is used to decorate the head of the tank.

Rules for using the drive

To extend the service life of sealed structures when using plastic cesspools, it is necessary to adhere to a number of recommendations:

- Avoid getting polyethylene into the tank. Candy wrappers and bags are absolutely non-degradable items.

- Do not allow solutions of potassium permanganate, various oxidizing agents and chlorine-containing preparations used in washing to enter with wastewater.

- Minimize the entry of medications and animal hair into the reservoir.

It is also advisable not to pour the remains of mushrooms and rotten vegetables into the cesspool. It is better to compost food waste.

The ingress of machine oil and antifreeze into the autonomous sewer system can also cause great harm.

To facilitate the work of cleaning the cesspool and speed up the decomposition of household waste, it is recommended to use biological products. They successfully cope with the task without harming the plastic container.

Active microorganisms of bioactivators not only accelerate the decomposition process, but also effectively liquefy sewage waste, reducing its volume.

According to current sanitary standards and regulations, the drive must be cleaned with sterilizing mixtures twice a year. This procedure is performed after sewer cleaning in order to be able to completely neutralize the effect of pathogenic bacteria for some time.

For disinfection, gentle acidic chemical solutions are used that do not corrode plastic.

Conclusions and useful video on the topic

How to make a cesspool with your own hands:

Installing a plastic cesspool allows you to solve the problem of drainage in the shortest possible time. Thanks to the construction of a simple-to-execute structure, you will ensure comfortable living in a suburban area, enjoying the usual benefits of civilization.

Looking for a plastic waste container? Or do you already have experience in using similar structures? Please leave comments on the article, share the nuances of using plastic cesspools, and ask questions.

We have a vertical cesspool made of plastic on our site because it is the cheapest option, but at the same time quite high quality and does not require special maintenance. There is no smell in the area. We pump out approximately once every 3-4 months. A team of specialists was called in for installation. So far we are very pleased, we haven’t found any complaints or shortcomings with this design.

Still, the simplest option for a cesspool is old tires and a layer of gravel as a filter. I also call it “I don’t care about all the neighbors’ water wells.” Plastic is the simplest and most adequate option for people who respect their neighbors and the environment.

won't it burst in cold weather?