The cost of installing a gas tank in a private house: prices for gasification work

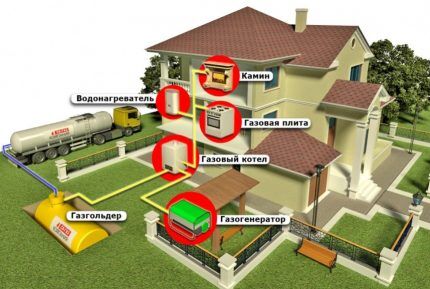

The problem of heating a private house is best solved by connecting it to a central gas pipeline.But even in areas located in close proximity to the capital, there are places where this possibility does not exist. The best option in such circumstances is autonomous gasification.

Many are confused by the considerable cost of installing a gas tank in a private home, but the money spent will be repaid by the cost-effectiveness of maintaining such a system.

We offer you to understand what advantages arranging individual gasification provides, how to choose the right tank and what requirements to adhere to when installing it. Understanding the installation technology will help you control the quality of the work performed - the uninterrupted and safe gas supply to your home depends on this.

The content of the article:

Benefits of installing a gas tank

If we compare autonomous gas heating with electrical systems or heating using liquid boilers, then the total monthly payment will be several times less.

By installing a gas tank on his property, the owner of a country property will receive the following benefits:

- Reliability of the complex. Guarantee of uninterrupted and safe operation of the heating system, confirmed by relevant certificates.

- Ease of use. It will open and end the heating season itself, independently regulating the supply of blue fuel taking into account the need for it.

- Economical. Will refill the gas tank a maximum of twice a year, which is much less compared to most other types of fuel.

How often the tank will have to be refilled depends on the rate of gas consumption and the capacity of the gas tank itself. When choosing this important autonomous gasification unit, one should proceed not only from the intensity of gas consumption, but from the economic feasibility in each specific case.

It happens that more frequent refueling for a smaller amount is beneficial than the cost of a large amount of fuel at once, which may be beyond the budget.

To supply your home with fuel without interruption, you need to replenish its reserves when a maximum of 25% of liquefied gas remains in the gas tank. At the same time, if we take into account the fact that in the period February – June the volume of gas consumption usually falls and the price for its delivery decreases, then you can also save.

The composition of the gas also depends on the time of year. At the end of autumn and towards the end of the winter period, suppliers fill with “winter” type of gas. It has an optimal percentage ratio between the amount of propane and butane in blue fuel, which contributes to maximum volatility of hydrocarbons.

This is true for country houses where people live permanently. For properties intended for summer holidays, where gas is needed only for cooking and showering, the gas tank can be refilled in the summer.

List of works on autonomous gasification

Only those organizations that have the appropriate license have the right to carry out work related to autonomous gasification.

The list of work they perform may vary, but mainly it includes:

- design;

- equipment assembly and delivery;

- excavation;

- installation of a gas tank;

- laying the necessary communications to the house;

- crimping;

- backfilling;

- filling the system with a gas mixture;

- periodic maintenance of the tank.

Some companies install the necessary equipment in the house itself. By agreement, the contractor can also perform additional work: installation of an air collector, gas sensor, ground loop, system configuration, installation and gas boiler piping.

The company's services are expensive, but after completing all the work, it will also bear responsibility for it.

If you decide to independently collect all the necessary documents, you need to start by writing an application to the State Registration Service for the issuance of technical conditions for autonomous gasification.

Specifications are issued free of charge. You will then need to pay an advance in order for the design work to begin. An on-site specialist will assess the conditions and give an opinion on the basis of which specifications will be drawn up.

After receiving them, you will have to submit a new application to the design organization, on the basis of which and the received technical conditions the project will be developed. Next, you need to coordinate it with the supervisory authorities - environmental, fire, architectural, electricity, as well as with the gas supply service.

A permit for autonomous gasification is issued by Rostechnadzor after all documents are registered there.

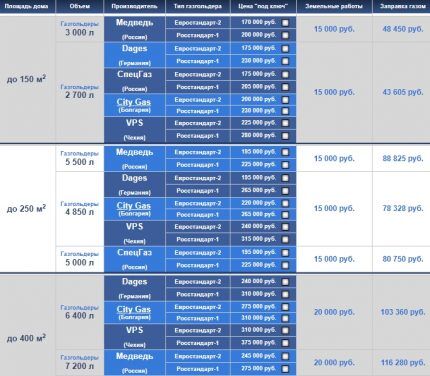

Afterwards it will remain choose a gas tank, buy pipes and components, ensure that all requirements set out in the specifications are met. The price of installation is directly influenced by the volume of tanks and their number, and the list of work performed. Depending on how much a good gas tank costs, it will pay for itself in 2-3 years.

The most convenient season for performing work on autonomous gasification is the summer. Typically, the owner of a country house completely relies on the contractor regarding compliance with standards and the technical side of the process.

Even taking into account the fact that the owners of gas tanks are of little interest to Gosnadzor, the contractor must comply with all regulatory requirements and rules for the use of LPG tanks.

Regulatory requirements for autonomous gasification

Poor quality installation can have unpredictable consequences, so it is advisable for the customer to monitor the progress of the work. It is necessary to delve into the essence of the issue at the design stage. The main thing is to choose the right container in accordance with the area of the house. The volume of the tank for a private house ranges from 2700-10,000 liters.

Regulatory compliance is important distance from the gas tank to the house and other objects. The indicator depends on the volume of the tank. Thus, the minimum distance between a gas tank is 10 cubic meters. m and house - 10 m.

There are several basic regulatory documents relating to the operation of gas tanks.

Although the requirements set out in many of them apply to entrepreneurs and enterprises, regulatory authorities can also apply them to individuals:

- In the appendices to Federal Law No. 116, the gas tank is called a dangerous object. In this regard, the safety regulations set out in this law apply to such a tank.

- Set of rules 62.13330 concerning design, material for gas pipelines, installation, quality of the gas mixture, corrosion protection of LPG objects.

- There are several requirements for LPG containers regarding installation and testing in the codes of rules SP42.101 and SP42.103 from 2003, as well as SP.42.102 from 2004.

In order not to bear responsibility for the consequences of unprofessional installation of a gas tank, you need to conclude an agreement with the company for the provision of services, which stipulates the warranty period for the object, in addition, there must be a project.

What requirements should the tank meet?

A good gas tank must meet the requirements for metal thickness, quality of anti-corrosion coating, waterproofing of the body, safety and control valves. It will be equipped with reliable supports, eliminating the possibility of deformation processes at the bottom of the tank.

A prerequisite for an underground container is the presence of a high neck.

Based on the requirements of GOST, gas tanks are made of rolled steel sheets with a minimum thickness of 5.5 mm. The container has a protective coating on the outside and inside.

On our website there is a series of articles devoted to choosing a gas tank for a private home and summer cottages. We advise you to read:

- Gas holder for a summer residence: mini options for arranging summer cottages

- Mobile gas tank: purpose, design and installation features, placement requirements

- Gas tank Antonio Merloni (Antonio Merloni): model range and equipment selection criteria

The nuances of installing a gas tank

In the CIS, gas tanks are not as popular as in Europe. The rules for their installation are also somewhat different. If in European countries they mainly use above-ground tanks, in the CIS this option is not always acceptable. There are more stringent requirements for the distance from the gas tank to various objects.

If they are carried out, in most standard areas there is simply no room for an above-ground tank, and in Europe they are installed even close to the house.

In Europe, gas tanks are filled with pure propane, but here we use a mixture of propane and butane in a ratio of 1:1 or 7:3. In order for the LPG mixture to work, evaporation must occur, and at low temperatures this is not possible. In order not to be left without heat in winter, the tank must be equipped with a special evaporation unit.

The cost of the equipment itself and its installation depends on the model of the tank, the volume of excavation work, and additional equipment. Questions about how much domestic and imported gas tanks will cost need to be clarified in advance.

Note that prices do not vary much.Containers produced by our manufacturers, unlike European products, as a rule, have a high neck.

The design without it is cheaper, but then the position of the platform with the reinforcement will not be so convenient. Its location on a hill allows it to be protected from moisture, especially during spring floods. If water enters the reducer, the gas supply will stop.

Recently, gas tanks without a neck have appeared. Instead, the design includes a series of tall tubes covered with a metal casing. This solution made it possible to reduce the cost of the product and place the fittings at a safe height.

Structurally, the gas tank is designed to prevent both gas leaks and ignition. Its monolithic structure resists pressure from the inside and various influences from the outside.

In addition to valves, the tank is equipped with safety valves designed to relieve excess pressure, and ball valves with which the fuel flow is regulated.

Some companies offer to buy refurbished tanks at a price significantly lower than new ones.Don’t be tempted by the cheapness; the consequences of such savings can be the most unpredictable.

When installing a tank, there are several nuances that need to be monitored during the installation process. Everything that will be hidden in the ground must be reliably protected from corrosion. In this case, conventional fasteners are not suitable; they are made of stainless steel or provided with anti-corrosion protection.

Contractors often consider cathodic protection as an additional service. In fact, without this option, the metal tank, as a result of exposure to stray currents, salts and water, will collapse much faster than its allotted service life.

When concluding an agreement, you must insist that it include a clause on the installation of electrochemical protection.

You should know that there are two types of such protection - active and protective. The first of them is used in conjunction with Russian-made tanks made of 09G2S steel. This material has little resistance to rust.

To increase the service life of the tank, a 0.75 kW cathodic protection station is installed that consumes electricity. For this reason, this method of protection is expensive.

Imported gas tanks are made from higher quality material. They are protected from corrosion by a protective anode-cathode system. It consists of aluminum elements with electronegative potential, connected by wire to an underground gas tank.

The consequences of negative influences affect the protector - it oxidizes, and the surface of the metal container is restored.

On gas tanks made in Europe with a complete epoxy coating, the protectors are replaced on average after 5 years. The steel from which Polish Avtonomgaz tanks are made is practically non-corrosive. The protection here is updated every 15 years.

On domestic tanks with a bitumen coating, and on imported ones with an epoxy coating that was not tested during installation, the protectors are replaced annually. In this case, the protective anode is consumed very quickly, because due to the increased permeability of the coating, he has to actively restore the surface of the container.

How to recognize a poor-quality installation

To avoid having to invest additional funds in an autonomous gasification system for your home due to poorly performed work by the contractor, you need to pay attention to several important points.

It happens that a contractor, when installing a domestically produced gas tank made of steel with weak anti-corrosion characteristics, installs passive protection or is even going to miss this point.

In this case, you need to be persistent and force him to install an active cathodic protection system, regardless of the coating material. The cost of the gas tank will increase, but its service life will increase.

The surface of a container with a layer of bitumen coating of more than 2 mm shrinks during operation and begins to crack. Passive defense in this case is powerless. Active electrochemical protection is required.

The coating of a gas tank of domestic or imported epoxy or bitumen must be checked with a spark flaw detector before placing the container in the pit. If the contractor has not done this, cathodic active protection is required.

The customer should also check the quality of fastening of the container to the plate. According to the rules, it must be secured with stainless steel anchor pins using special claws.

If there are no supports in the form of paws, use ballasting slings that secure the tank to a plate with a rubber gasket. The use of these slings must have permission from Rostechnadzor.

The tank must not be installed on a hollow slab, as this may cause it to float up along with the base. It is necessary to ensure that a condensate collector is installed, otherwise, when the liquid freezes, it will form ice plugs in the pipeline and interfere with the movement of gas.

The gas pipeline must be laid below the freezing level of the soil layers. It must be installed in such a way that a slope is formed in relation to the condensate collection tank.

The gearbox must be mounted on the tank itself. For gas pipelines of both medium and high pressure, only steel pipes in high-quality polymer insulation are used.

PE 100 polyethylene pipes are most suitable for installing a low-pressure gas pipeline. The reducer or filling valve must not be installed below the zero mark.

There must be a compensator at the base input, otherwise the input may collapse as a result of shrinkage of the house. The base input itself must be all-welded and with a steel tap.

Additional information about the technology for installing a gas tank on a private plot is presented in this article.

Conclusions and useful video on the topic

What is a gas tank and its design:

Advantages of a gas holder from the point of view of the site owner:

To ensure that the price of installing and connecting a gas tank for a country house does not turn out to be unduly burdensome, and that the costs are recouped in a short time, it is necessary that the work be carried out by experienced specialists - design engineers, welders and installers who have passed the appropriate certification.

Of great importance is the choice of a gas tank of optimal volume, which will allow you to refill it not too often. A professionally selected and installed tank will serve for a long time and will not cause much trouble.

Do you have anything to add, or do you have any questions about arranging autonomous gasification at home? You can leave comments on the publication, participate in discussions and share your own experience in choosing and installing a gas tank. The contact form is located in the lower block.

Gas in a private home is a very convenient thing, but, unlike a main gas pipeline, a gas tank has a decent number of disadvantages. And first of all, it is a high cost. The initial costs for obtaining permits, purchasing equipment and installing it are very significant. Plus refueling 2 times a year, plus maintenance. In general, I personally abandoned the idea of installing a gas tank, especially since they promise to extend a gas main to us within 5 years.

Well, yes, and you will also be assigned to a certain company that will service and refill the gas tank. Naturally, according to their tariffs with a markup as far as one's conscience suffices.

Gas is very harsh today, in any case. The cost of connection eats up all subsequent “cheapness”... Even in my case, when I install everything with my own hands, and the gas tank is not a very cheap thing, since the gas itself has become very expensive.

It turned out to be cheaper to use electricity: boiler, microwave, electric kettle... + energy-saving technologies. Although I left the use of gas (gas holder) as an auxiliary system. But I have already developed a hydrogen system, and I am starting installation. It turns out to be many times cheaper.