Autonomous gasification of a private house: arrangement of a gas supply system with cylinders and a gas holder

What to do if there is a house, but the gas main is not connected to it? The answer is simple - we need autonomous gasification of a private home, ensuring the supply of blue fuel to the gas stove and heating boilers. This is not an easy task; it requires careful design, strict adherence to building codes and special knowledge.

But it is still worth considering this gasification option in more detail, since it has many advantages. We will tell you how the system works, which working units are included in the autonomous complex.

We will describe the specifics of operating a gas tank and bottled gas supply, and also outline the rules for the design, design and installation of a local gas pipeline.

The content of the article:

How it works?

A gas stove connected to a liquefied gas cylinder is a common occurrence. Using the same principle, you can supply blue fuel to a gas boiler to provide heating and hot water supply to the entire house. You just need a larger container or even several tanks of liquefied gas.

The fuel used in such systems is an analogue of natural gas, which consists of a mixture of butane and propane. This mixture is called LPG - liquefied petroleum gas.

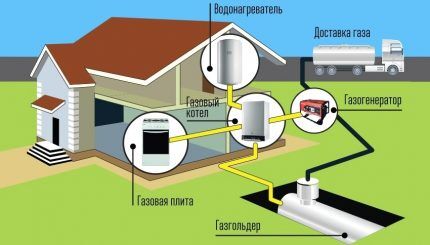

To organize an autonomous or alternative gas supply system at home, it is necessary to combine the following elements into a single system:

- LPG storage capacity - one or more;

- evaporator (pressure regulator) for gas;

- gas pipes;

- system controls;

- appliances that run on liquefied gas: stove, water heater, boiler, etc.

Special gas appliances are not needed for autonomous gas supply to a country house. If the boiler or water heater can operate from the main gas network, then a cylinder or gas holder can be connected to it. This is very convenient if in the future you plan to connect a centralized gas main to the house, you will not have to change the equipment.

The main reason why owners of private houses refuse electric and solid fuel heating boilers The benefit of gas units is their relatively low operating costs.

Gas, including liquefied gas, is cheaper than electricity or coal. The difference even covers the cost of installing an autonomous gas supply system.

Another advantage liquefied gas boilers — high degree of equipment automation. If the operation of gas-consuming appliances is configured correctly, they will turn on and off automatically, heating the coolant and/or hot water to the set temperature.

This is convenient and also allows you to optimize gas consumption. If all safety measures are followed, liquefied gas can be stored for a very long time, taking only the required amount. You can refill the gas tank or cylinders only once or twice a year.

What you need to know about LPG?

Both propane and butane in a liquefied state occupy very little space, which is why LPG is so convenient to use for autonomous gas supply. As soon as the valve of the container opens, the pressure inside decreases.

Some of the gas changes from liquid to gaseous form and then collects at the top of the cylinder. The gas pipe carries the fuel to the appliance consuming gas.

The process continues continuously, allowing the operations associated with the operation of the alternative gas system to be largely automated. When the cylinder valve is closed, the pressure stabilizes and the transition of gas from liquid to gaseous state stops.

Any flammable substance must be handled with care, and LPG is no exception. The volume of filling the container with liquefied gas should be no more than 85%.This allows you to leave some space so that the fuel can be released when the container is heated, and at the same time the pressure inside the cylinder does not reach a critical level.

Propane expands faster when heated, while butane expands slower. The ratio of these components in cylinders varies, so some cylinders can be used in winter, while others can only be used in summer.

During the summer, the ambient temperature can rise significantly, gas cylinders naturally heat up, and the gas inside expands. This point should be taken into account when planning alternative gas supplies.

Cylinders intended for use in summer should not be used in winter, but for different reasons. Low temperatures prevent the pressure in the cylinder from increasing, and in the “summer” version this ability of the mixture is already reduced. If you choose the wrong cylinder, its operation will be ineffective.

In order to use the same container with liquefied gas at any time of the year, it is necessary to provide it with a stable temperature environment. This can be achieved by placing the container in the ground. The immersion must be deep enough - below the freezing level.

What types of gas tanks are there?

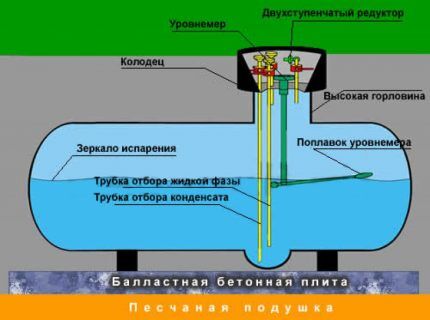

Gas holders are special containers designed for storing liquefied gas. Variable-volume tanks are widely used in industry, but in everyday life only gas tanks of constant volume should be used. This is due to security requirements. The operating gas pressure in the gas tank should be 16 atmospheres.

Such a tank looks like a cylinder, although sometimes spherical models are also found. The volume can vary within a very wide range - up to fifty thousand cubic meters, although such large volumes are not needed for a private home. There are gas holders for installation underground, but there are also above-ground models.

The choice largely depends on the nature of the gas used. For a summer cottage that is not used in winter, a ground-based gas holder is suitable. Can be used mobile gas tank.

But if people live in a house or cottage all year round, you should definitely install an underground tank.

Although it is easier to install an above-ground gas tank, there are more problems with its operation. Due to the influence of high and unstable temperatures, such devices are subject to more stringent safety requirements. The cost of above-ground installations is also usually higher than for underground counterparts.

As a rule, land-based models are installed where large gas consumption is not planned. The container will be emptied periodically, so you need to immediately think about whether to prefer a stationary or mobile option. Refueling of mobile models equipped with wheels for towing is carried out as follows:

If there is a need to use a ground model in winter, i.e.At lower temperatures, you will need to use an evaporator. This is an electrical device that provides safe heating of a gas container.

As a result, LPG quickly turns into a gaseous state and enters the system, providing sufficient pressure.

Gas tanks designed for installation underground are considered more reliable and safe. However, their installation will require more time, cost and effort.

This is due to large-scale work. Installation above soil freezing is not allowed, and in many regions this figure is 1.5 m or even more.

The contents of the reservoir, located inside the soil, are almost completely at a temperature of 5-8°C. A special evaporator is not needed for this model.

For a specific site and project, a gas tank is selected in accordance with the technical conditions developed for an autonomous gas supply system. Typically, the organization tasked with completing the project will purchase the device itself, taking advantage of discounts that manufacturers provide to such customers.

Independent searches and purchase of a gas holder usually do not give the owner of the site the opportunity to save, but increase the risk of purchasing a low-quality or unsuitable device.

On our website there is a series of articles devoted to the selection and installation of gas tanks.

We advise you to read:

- Types of gas tanks: classification basics + review of popular brands

- Turnkey gas tank: how to install a gas tank and install equipment

- The cost of installing a gas tank in a private house: prices for gasification work

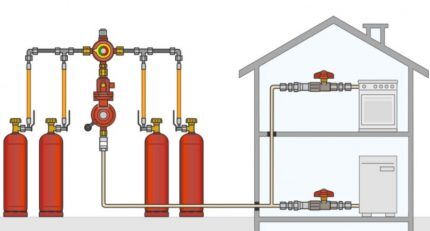

In addition to gas holders, liquefied gas cylinders can also be used for autonomous gas supply. One such capacity is usually not enough; several are combined into a common network.

Features of bottled gas supply

This option is usually used only for small summer cottages with modest volumes of gas consumption. Some gas cylinders installed in a separate room. It is not recommended to allocate a room in a residential building for these purposes.

It is better to build a separate utility room for storing cylinders, although it is acceptable for this room to be adjacent to the house.

There should be a separate entrance here, and not a door leading out of the house. The area of the room must exceed the size of the cylinders that will be installed there by eight times.

The interior surface of the room must be covered with fire-resistant materials. Forced ventilation is required.

Sometimes it is allowed to store cylinders not in a separate room, but in a large metal box outside the house.It is forbidden to heat the storage area for gas cylinders; any heating devices and, of course, the use of open fire are prohibited.

If the room is ready, the following operations must be performed:

- Install cylinders along one of the walls.

- Lay gas pipes from the place where cylinders are stored to devices consuming liquefied gas.

- Assemble the system from reducers and pressure gauges for parallel connection of cylinders.

- Connect cylinders and devices to the main line.

- Check the finished system in the presence of employees of the regional gas industry.

- Obtain official permits documents for operating a cylinder gas system.

The cylinders are installed on special pallets, and they must be given a strictly vertical position. Each container contains from 2.5 to 80 liters of gas; based on this standard, their total quantity is calculated. Such a system will be cheaper than a full-fledged gas supply with a gas holder, but the cylinders will have to be charged quite often.

Design and documentation

A “personal” gas system must be as reliable and safe as a centralized mains. Negligence in these matters is unacceptable, since even a small gas leak can cause huge problems and even lead to death.

If the owner of the house does not have special knowledge, then gas pipeline design must be entrusted to a licensed specialist.

Or rather, this is done by entire design organizations that have the right to design and carry out work on gasification of residential facilities.

This can be either a private company or a specialized division of the gas service of a district, region, etc. Private traders charge a little more for work than government specialists, but they will also take care of the registration.

When working with oblgaz, the home owner will have to do the registration himself, but you can save a little.

When completing a project, you will not only have to make a couple of statements, but also attach a number of documents to them:

- owner's passport;

- certificate of ownership of the land plot;

- site plan;

- characteristics of the heating system, etc.

First, specialists develop technical conditions for gasification of the building, which take into account fire safety requirements. Then field research is carried out and place for installing a gas tank taking into account the standards.

The gas tank should be located at a distance:

- not less than 10 m from residential buildings;

- not less than 15 m from sources of drinking water and other bodies of water;

- not less than 5 m from trees and outbuildings;

- not less than 2 m from fences.

In addition, it is necessary to take into account the presence of power lines near the installation site of the gas tank. The minimum distance to such structures should be half the height of the support. Another important point is the availability of convenient access roads for a car with a liquefied gas tank to refill the gas tank.

At the design stage, the features of the site are also assessed: soil corrosion activity, level of stray currents, etc.

Based on these data, a decision will be made about the features of the gas tank, for example, whether it needs additional galvanic protection, which will not affect the price of the device for the better.

In this way, the technical conditions for gasification of the facility are determined. With their help, specialists will draw up a project that includes a number of documents: characteristics of the gas tank, evaporator, condenser, site plan, plan diagram of the gas pipeline system, recommendations for grounding, chemical protection, lightning protection, etc.

These documents must be agreed upon with the fire inspectorate, gas supply services, electricians, architects, ecologists and other specialists from local departments. The result of registration will be obtaining a building permit.

Installation of an autonomous gas pipeline

If the owner of a site wants to reduce the cost of installing an autonomous gas pipeline, he can independently dig a pit for a gas tank. But this must be done in strict accordance with the project. It is better to entrust all other work to specialists so that everything is done in full compliance with safety requirements.

All gas pipes should only be laid openly; they cannot be hidden under screeds, false panels or other decorative elements. You should carefully consider the layout of pipes for liquefied gas.

It is not allowed to carry out such communications in transit through residential premises, through the kitchen or other utility rooms in which appliances that run on liquefied gas are already installed (or will be installed).

The process of installing a gas tank in a pit includes a number of traditional steps:

Another categorical prohibition associated with the installation of gas pipes is detachable connections. Of course, connectors are needed at the beginning of the network, i.e. where the network is connected to cylinders or a gas tank. And finally, when connecting a pipe to a boiler or column, it is also necessary to install a connector.

But along the entire length of the autonomous gas main, connections should only be made permanent. The part of the gas pipeline that is laid outside needs additional care.

The entire external network should be carefully insulated using special fire-resistant materials. In addition, it is necessary to ensure condensate drainage, this will reduce the likelihood of pipe corrosion.

The gas boiler must be installed in a separate room - you will need arrangement of a boiler room. Its volume must be at least 15 cubic meters. m. It is necessary to make a window in the room, the opening area of which is at least half a cubic meter.

Such a hole in the outer wall will create an exit for the blast wave in the event of an accident. If gas explodes in a room with solid walls, the entire building could be seriously damaged.

At the entrance to the boiler room you should install a door that opens outward.Another point that cannot be neglected is the ventilation of the boiler room. There must be a constant supply of fresh air to ensure combustion of the gas.

It is necessary to ensure sufficiently good air exchange so that the gas does not concentrate in a room with an open fire in the event of an accidental leak.

Ventilation will also prevent poisoning from combustion products if problems arise with the chimney. If it is not possible to allocate a separate room for the boiler, it is possible to install some models in the basement or on the ground floor.

But in this case, it is imperative to install a system in the room with the boiler to monitor the level of hazardous gases in the air.

Installation work on autonomous gasification with a gas tank usually takes two or three days. But after they are completed, a number of documents must be drawn up and some approvals must be made. The finished system must be tested for leaks under the supervision of specialists from the regional gas organization and Rostechnadzor.

After checking, the gas tank is filled with sand, after which you need to wait about three weeks before filling the tank with liquefied gas for the first time. Completion of work must be documented by an official acceptance certificate. At the same time, a service agreement is usually concluded.

Sometimes it is more convenient to invite different contractors to install external and internal gas pipelines.In this case, experts recommend dividing responsibility between the performers and formalizing this point in a separate act. It also doesn't hurt to take out liability insurance.

Conclusions and useful video on the topic

You can learn more about the installation features of the gas tank in this video:

The procedure for autonomous gasification of a private house is described here:

Installing your own gas supply system on site is a troublesome and costly task. However, using your own gas is very convenient; refueling can only be done a couple of times a year.

In addition, such a system is cheaper than endless electricity bills, and solid or liquid fuel is inferior to a gas boiler in economic terms.

Are you thinking about installing a tank for autonomous gasification? Or have you already installed a gas tank on a suburban area? Please share with readers your experience in operating such an installation, tell us how justified the financial costs are. You can leave comments in the block below.

You need to install a gas tank if you never have a connection to gas, or the gas main is located further than 5 km. In other cases, it is not economically feasible. When choosing a gas tank, it is better to prefer an underground one with a condensate trap and the possibility of either pumping it out or collecting it in a separate container. This way you will save on repairs and cleaning of all equipment, since it tends to get into the pipes and block the flow of gas. Bury the container itself at a slight angle so that condensation drains there.

Buy gas in large quantities in the summer, it is cheaper and more profitable.Enter into an agreement with those companies that remove condensate and do not include it in the cost of supplied gas. That is, last summer you bought a ton of gas, 100 liters of condensate came out, now you are filling up again with a ton, but with a discount of 100 liters and free condensate pumping.

Agree. It's not worth it, in my opinion. Gasification in our country is in full swing, and if a gas pipeline has not yet been installed in some village, then this is most likely a matter of five years, no more. I definitely wouldn’t spend money on a gas tank now. With this autonomous gasification, there is also so much paperwork, bureaucratic red tape and running around that, well... It’s too troublesome.

5 years... However, you are an optimist. We live on gas and oil. Lukoil is producing, but there is no gas in the private sector and is not expected. The gas pipeline runs nearby, the cost of supplying the pipeline is more than 400 thousand rubles. for 140 m, and also a decent amount for the supply and wiring in the house. Therefore, the old fashioned way or electricity, because... The payback period for gas will be more than 15 years. “Gazprom - dreams come true” - this slogan is only for those who work there.