Types of gas tanks: classification basics + review of popular brands

When choosing a tank for storing liquefied gas, everything is important: from the operating principle of the device to its physical parameters.There are various types of gas tanks on the gas equipment market that differ in performance, size and installation method.

To better understand modern models, we recommend studying the basics of classification and features of popular types.

The content of the article:

Gas holder and reasons for its acquisition

A gas holder in the broadest sense of the term is a reservoir for storing substances in a gaseous state. At industrial facilities, natural gas, biogas, and liquefied petroleum gas are stored in large tanks. For country houses of permanent residence, dachas, cottage villages, sports centers, and holiday homes, gas tanks are used, equipped for storing LPG - a liquefied mixture of gaseous hydrocarbons.

The substances that make up the base (about 40 and 60% of the total volume) are propane and butane. To convert them from a normal gaseous state to a liquefied one, the pressure in the tank is increased; for the reverse process, a built-in evaporator is needed (but for household models, natural evaporation is characteristic at above-zero temperatures).

Storing gas in separate tanks is relevant for residential buildings and industrial facilities that are located outside the central gas supply area. Certainly, main natural gas remains the cheapest type of energy source, but not all areas are gasified.

Before choosing a model, it is necessary to make calculations to correctly determine the volume of the tank and its performance. You can calculate it yourself, but for more accurate results it is better to contact the company that sells the equipment. The simplest choice is made by comparing the volume of the container with the area of the house (taking into account the number of gas consumers).

One way or another, it would be a good idea to study the nuances of various models in advance, learn about working conditions and design features.

Classification of gas storage tanks

Many modifications have been created for storing various types of gases under excess pressure. Not all models on the market are suitable for use on private land. Let's try to find out which gas tanks are household and which are used only in the industrial segment.

By excess pressure

The pressure inside the tanks may differ, and therefore it is customary to divide all gas tanks into two categories:

- high pressure (0.7 kgf/cm2 — 30 kgf/cm2 and more or up to 3 MPa) – have constant geometric volume parameters;

- low pressure (0.05 kgf/cm2. or up to 4-5 kPa) - characterized by variable geometric volume and constant pressure.

Low pressure equipment is produced for private use.During the production process, it is taken into account that the devices operate at low temperatures (up to -40 ° C) and in a fairly humid environment (ground models are exposed to precipitation, and underground ones are in contact with groundwater). Therefore, low-carbon steel St3 (GOST 380-60) is used for the manufacture of the body.

Especially for installation in the Far North, where temperatures often drop below -40°C, models are produced from low-alloy steel (for example, grades 09G2S (M), 10G2S1).

Ordinary steel St3, as well as grades 09G2S (N), 15HSND (NL-2) are used in the production of high-pressure gas tank housings.

Division into types according to the method of work

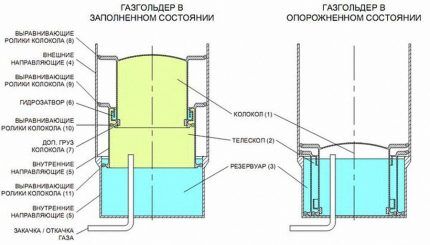

There are two large groups of low-pressure gas tanks: dry and wet. This division is justified both by the design features and the operating principle.

Suitable for use in MG are gases of low concentration, which tolerate moisture well with water and do not cause corrosion of steel elements.

On the contrary, dry-type tanks store concentrated gases that do not tolerate contact with water (for example, propylene or ethylene).

In a gas-filled tank, the bell is in the upper position. As the volume of gas decreases, it moves down along the guides. The water in the reservoir acts as a water seal and prevents the gas from spreading beyond the boundaries of the bell. Due to the presence of water, it is necessary to maintain the temperature at least +4-5 °C. MGs are often used as buffer tanks for compressors.

The SG body resembles a dome, welded or steel sheets 5 mm thick, the upper part is covered with 3 mm steel. Inside the case there is a horizontal washer, which changes its position depending on the filling. SG, unlike MG, is easier to maintain and is suitable for storing high concentration gases.

Constant and variable volume

Gas tanks of variable volume can be dry or wet, reaching 50 thousand cubic meters of volume. They are constructed from steel sheets or reinforced concrete. Their main purpose is not to store a gaseous medium, but to regulate the required level of gas pressure, which inside the tanks is at a temperature similar to the environment. These are bulky structures that are now used extremely rarely.

Due to the development of technology and the emergence of new, more durable materials, gas holders of variable volume have been replaced by devices of constant volume.They can withstand increased loads, do not corrode even when storing aggressive media, and when installing control valves, they allow you to control the gas pressure within normal limits. Household varieties of gas holders belong precisely to this type.

Grouping by design shape

The shape of gas holders is often cylindrical (vertically or horizontally directed), less often – spherical. Domestic grade tanks usually have a volume of 2.5 m3 up to 10 thousand m3 and look like a cylinder with rounded ends.

Manufacturers of horizontal gas tanks claim that such tanks have an increased evaporation surface area. This has a positive effect both on the process of changing the liquid phase into a gaseous phase, and on maintaining the required operating pressure in the system.

However, vertical models are no less productive and have proven themselves in northern regions, where temperatures often drop to -40 °C.

Spherical (spherical) tanks are designed for storing gaseous media on an industrial scale and usually have large volumes - from 5 thousand m³ to 10 thousand m³. A reservoir built in France broke all records - 87 thousand m³.

Selection of types according to installation location

All gas holders can be divided into 2 types - above-ground and underground.The first ones are installed on a solid foundation directly on the ground, and the second ones are buried in the ground, having previously placed a concrete slab on the bottom of the pit. To perform this or that type of installation, a number of conditions must be met.

For industrial applications, outdoor installation is preferred. Gas tank parks are rows or groups of tanks connected by a collector device. Large-volume above-ground containers are easier to maintain - monitor tightness and pressure, and perform a visual inspection. An evaporator is a mandatory element, since the temperature can drop below +5°C.

In cottage villages, underground models are mainly used.

Installation in the ground has a couple of important advantages:

- the evaporation process occurs naturally, since thanks to the warmth of the earth, the temperature does not drop below +5 ° C, therefore, an evaporator is not needed;

- a tank installed in the ground does not bring disharmony to the landscape design (although the space savings are very conditional - you cannot install buildings above it, place flower beds or plant trees).

The disadvantage is the costly installation associated with earthworks. Also, after a certain period (depending on the model), it is necessary to check the integrity of the tank. According to federal standards, every 8 years it is necessary to carry out hydrotesting for strength or an ultrasonic flaw detection procedure. It is aimed at checking the thickness and strength of the walls, since underground models are more susceptible to corrosion.

You can read more about how gas tanks are installed on site Here. If it is not possible to install the gas tank yourself, you can order turnkey installation.

In addition to underground and above-ground installations, there are stationary and mobile. In the first case, the tanks are permanently mounted on a concrete base, secured with anchors or cables, after which their movement is prohibited. In the second, on the contrary, they are transported depending on the purpose of use.

Mobile models are distinguished by their small volume (up to 1 thousand liters), the ability to be installed on a vehicle, and the ease of refueling from a cylinder or at a gas filling station.

The most popular types of household gas tanks are presented in the photo gallery:

Before choosing equipment, it is necessary to make preliminary calculations of consumption, survey the territory, and analyze the possibilities of various types of installation.

Tips for choosing a gas tank for your home

When buying a gas tank for long-term use, country property owners try to provide for all the nuances of the tank design and its installation on their site.

The main criteria are:

- tank volume;

- installation method;

- for underground installation - horizontal or vertical orientation;

- for above-ground models – mobility.

You should start from the volume - it is important to choose a model that can be refilled 1-2 times a year. There are mini-options that need to be refilled more often, but only with constant use. If the dacha is rarely visited, then a container of 500-600 liters is quite enough.

To calculate how much volume is needed for one home, tables compiled by equipment manufacturers are most often used. For example, for a residential building with an area of 150 m², the recommended volume is 2650-2700 l, and for 400 m² - 6400 l.

For large volume tanks, it is necessary to decide on the installation method.In the southern regions, land-based models can also be used, but provided there is no frost, otherwise you may encounter gas supply problems. And the requirements for the installation site are more stringent than for underground analogues. By and large, ground gas tanks are chosen as a last resort if there are no conditions for placing underground models.

Underground models are more popular, although they are more expensive. An important condition for installing a gas holder buried in the ground is a free plot of territory at a distance of 10 m from the house (some manufacturers indicate a shorter distance - from 5 m). Read more about maintaining distances when placing a gas holder Further.

The dimensions of the pit depend on the dimensions of the tank; they are usually indicated in the technical documentation.

When choosing an underground model, you need to decide whether a horizontal or vertical model is better. The vertical one saves space, and the horizontal one better maintains the required level of pressure. If your house is located in a region with cold winters, then the best option for uninterrupted gas supply for a large cottage is a horizontal underground model.

Review of popular brands

The market is filled with high-quality models from Russian and foreign manufacturers, so choosing equipment for autonomous use is really difficult. Household gas tanks from Italy compete with products from Poland, and Bulgarian ones compete with Russian ones. Standards adopted in different countries may differ, as well as installation nuances.

It has been noted that Russian models differ from Czech or Italian gas tanks in having thicker casing walls - 8 mm, however, the protective epoxy coating may be weaker than that of European equipment. The disadvantage is usually compensated for by electrochemical protection.

Some foreign-made models are not designed for low temperatures, so when purchasing, you must make sure that the equipment is supplied with the permission of Rostechnadzor. You should also be aware of one small but important nuance for refueling: special gas carriers are required to service imported gas tanks.

Conclusions and useful video on the topic

More information about the designs of gas tanks and their installation can be learned from people who are involved in the production and sale of gas equipment, as well as from experienced users.

Information about Antonio Merloni products:

More information about mobile devices from Chelyabinsk:

Reviews - what are the benefits of vertical models:

Tips for choosing neck height:

How to install a gas tank:

As you can see, it is quite difficult to understand the types of modern gas tanks. However, there are rules with which you can independently select the right model. If you cannot calculate the volume of the tank or calculate the cost of purchase with installation, we recommend that you contact specialists - representatives of companies that sell equipment for autonomous gasification.

Do you have any questions, found any shortcomings, or have valuable information that you can share with visitors to our site? Please leave comments and share your experience in the block below.

A gas tank is a real solution for people whose homes are still not connected to a centralized gasification system. But according to the experience of many friends who use a gas tank, this is not without its drawbacks. In particular, when it comes to pumping liquefied gas into a container. Many people notice that gas injection specialists, unfortunately, deceive clients. They pump less than agreed upon, and charge as for a “full tank.” And there’s no way to check what’s important! You can’t stick your nose into this tank.

Unfortunately, the gas tank has too many disadvantages. I also thought that this was the way out, but after delving into everything, I don’t recommend anyone to install them.