Gas tank Antonio Merloni (Antonio Merloni): model range and equipment selection criteria

To install autonomous life support systems for country houses, gas holders are often used - mobile or stationary tanks for natural gas.The choice of gas storage should be approached responsibly - the installation technology, convenience and safety of operation of the system depend on it.

The Italian gas holder Antonio Merloni is a piece of equipment that is fully equipped for installation, which is why it has gained popularity among users.

If you plan to purchase such a unit, then you need to familiarize yourself with the manufacturer’s model range, learn more about the device, the specifics of installation and maintenance of various gas storage facilities. Our article is devoted to solving these issues.

The content of the article:

Features of equipment of the Italian brand

When choosing a gas tank for a country cottage or a small enterprise located far from the city, first of all you need to pay attention to the technical characteristics and equipment. It is also important to understand how it works and what difficulties may be encountered during transportation and installation.

The appointment of gas tanks by Antonio Merloni

The Merloni family was at the origins of the production of liquefied gas tanks (since 1947), and the products produced in modern industrial enterprises are still the standard. The equipment undergoes special testing and is manufactured taking into account the climatic characteristics of the regions to which it is supplied.

Gas tanks, single and double, are designed for uninterrupted operation both in harsh winter conditions and in the hot south. This can be judged by the gas evaporation temperature – from -40ºС to +50ºС. Accordingly, the material of the tank body is selected so that it can easily withstand pressure and freezing of the soil.

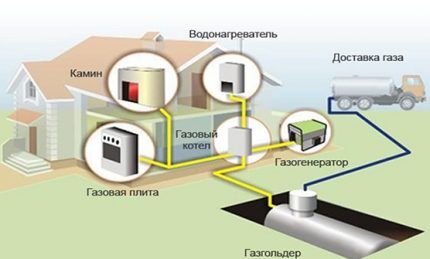

Gas tanks are part of autonomous gasification systemsupplying the house with gas. In addition to a safe and reliable tank, which is installed near a residential building, the system includes a gas pipeline buried in the ground and basement equipment for introducing the pipe into the house.

One of the advantages of the Italian brand is that for installation you do not need to look for fittings and other components - everything is supplied with the tank.

It is difficult to calculate the exact gas consumption in advance, since it depends on several factors: the number of permanent and temporary gas consumers, the characteristics of gas equipment inside and outside the house, etc.

Thanks to the line of gas tanks with a volume from 1000 l to 10,000 l, they are used to supply gas to buildings for various purposes:

- country houses temporary residence;

- country cottages for permanent residence;

- small enterprises where there is no main gas supply;

- sports centers and hotels, etc.

Domestic hot water supply, heating, and power supply systems run on natural gas.If you supply gas to the summer kitchen, you can connect a stove, as well as a fireplace on the veranda or a barbecue located outside.

Construction of vertical and horizontal models

Many manufacturers of gas storage facilities consider the product's advantage to be light weight, which simplifies the installation process. However, representatives of the Antonio Merloni company draw attention to the heavy weight of the equipment and argue that lightweight material cannot be reliable enough and last long.

Low-alloy steel is resistant to low temperatures, so the lower limit for using tanks is 40ºC below zero.

The steel body is covered on both sides with a protective layer: the outside is painted three times with an epoxy anti-corrosion compound (800 microns), and the inside is coated with special paint. Products based on dried epoxy resins are recognized as one of the most effective for protecting metal structures located underground.

From the negative effects of inducing and stray currents, anode-cathode protection is provided, consisting of 3 components: 2 cathodes + 1 anode. It is powered by a battery, the charge of which is sufficient for the entire life of the device.

Marsupio's bag performs several functions at once:

- protects the body from mechanical damage;

- protects the external coating of the equipment from scratches and damage during ground movements;

- supports the operation of anodic-cathodic protection;

- promotes heating of liquefied gas;

- makes installation into the pit easier.

Antonio Merloni's above-ground and underground equipment complies with European standards and has certificates.

The body of the gas holder is a container with two walls, assembled using the “flask-in-flask” technology. A solution with a high degree of thermal conductivity is poured between the walls. This allows you to maintain the temperature necessary for boiling and evaporation of the gas.

The housing is also equipped with pressure control sensors, leakage protection (with alarm), and a grounding system. The internal volume is completely filled with gas. Thanks to the constant pressure, neither air nor any source of fire can enter the tank, therefore, it is 100% protected from fire and explosion.

If the container is heated (theoretically), then its nominal value of 6 bar gradually increases to 17.5 bar, after which the emergency valve opens and the gas leaves the storage facility.

Model range of gas tanks by Antonio Merloni

Analysis of the sales market revealed models that are in greatest demand. Now there are 8 of them: 7 are vertical and 1 is horizontal.

Models of the same type differ in volume, which is selected individually for each specific home. If the volume of one gas tank is not enough, then several tanks are combined in a cascade.

Type #1 – vertical single

The four vertical models differ in tank capacity, as well as size and performance.

The company’s engineers calculated the approximate area of the house that one or another model is designed for:

- 1000 l – for a house with an area of 100 m²;

- 1650 l – 170 m²;

- 2250 l – 250 m²;

- 5000 l – 500 m².

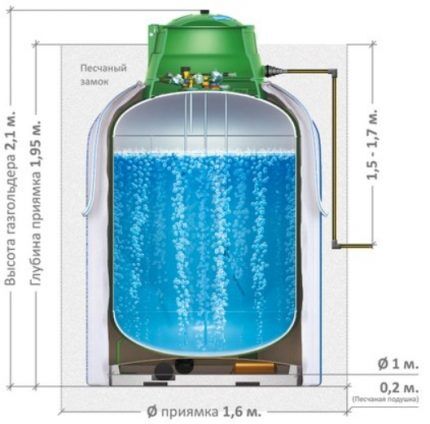

Let's look at the main characteristics using the example of the smallest gas tank. It is designed for 1000 liters of LPG/GPL/LPG gas, has a height of 2.1 and a diameter of 1 m. The pit for installation is larger in diameter - 1.6 m, but smaller in depth - 1.95 m, since after installation and backfill The neck with the lid remains above the ground.

The hatch with a HDPE cover, required for maintenance, is hermetically adjacent to the neck. In addition to the body, the kit includes a Marsupio bag and a concrete-alkaline slab, the thickness of which for the 1000 l model is 0.15 m.

Also required is a thermal lock, a reducing head with 2 stages (for high and low pressure), a level meter, valves for filling, protection, liquid fraction and ventilation, a pressure gauge and a padlock.

The remaining models differ in dimensions, weight, pit dimensions, body wall thickness, and performance. Let's assume that the most voluminous gas holder of 5000 liters weighs 2450 kg, has a height of 3.08 m, a wall thickness of 10 mm, gas evaporation rate of 40 l/h (during operation up to 2 hours) and 15 l/h (up to 8 hours).

The cost of a gas tank with a minimum volume is 3100 €, with a maximum volume – 7900 €.

Type #2 – vertical double

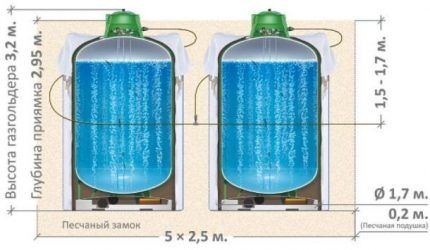

If a larger volume of tanks is needed, then install a set of 2 gas tanks. Moreover, their volume can be the same (2500 l + 2500 l) or different (2250 l + 5000 l). The installation of 2 models is called double redundancy, and their connection is called cascade.

Calculation based on building area:

- 4500 l – for a house with an area of 500 m²;

- 7250 l – 750 m²;

- 10000 l – 1000 m².

Let’s assume that to supply a house of 750 m² with gas, a tank of 7200-7500 liters is needed. There is no such thing, and therefore they install a pair - 5000 liters and 2250 liters. The width of the pit increases (the dimensions of both tanks are added together), and the depth is determined by the larger gas tank.

To install an additional gas tank, a more spacious pit will be required. But this should not worry the owners of the site, since all design and installation work is carried out by the company’s specialists. Installing the second (and each subsequent) tank costs about 100€.

Type #3 – horizontal

Among the 8 popular models, only one is horizontal, and this is a well-thought-out marketing policy of the company. It is believed that the functioning of the horizontal model is not so effective. Evaporation occurs at temperatures of -20ºС and above, while vertical gas holders work perfectly down to -40 ºС.

It is also estimated that the work intensity of vertical models is much higher.They are approximately 2.2 times more productive than their horizontal counterparts and do not require the installation of expensive evaporators, as they work using geothermal technology.

A disadvantage of horizontal models is the larger pit, which requires additional free territory.

The line of underground and above-ground horizontal gas tanks includes tanks from 1000 l to 5000 l. Unlike vertical ones, which are always in stock, horizontal ones must be ordered in advance. The cost of the 5000 l model is 6500 €. In the same way, above-ground vertical gas tanks with a volume of 500 l and 1000 l are also available to order.

Installation work and connection

The installation and connection of the gas tank should be carried out only by qualified representatives of the company who know all the standards and installation nuances down to the smallest detail. When constructing a pit, they are guided by PB 12-609-03 and SNiP 01/42/2002.

Work order:

- The preparatory stage is digging a pit and trench for laying a gas pipeline.

- Installation of the concrete support slab.

- Transportation of a gas tank (one or several) to the site.

- Lowering the tank into the pit, fixing it on a concrete slab.

- Equipped with anodic-cathodic protection.

- Installation and connection of the gas pipeline.

- Arrangement of the basement entrance to the house.

- Internal installation work.

- Crimping and testing.

- Backfilling the pit and trench with sand.

- Gas filling and commissioning.

- Commissioning and connection to consumers.

Each point is worked out by specialists, so the installation of equipment is carried out within one day. It is prohibited to independently build a pit, install a gas tank or install a gas pipeline.

Recommendations for carrying out the main stages of installation:

Special attention is paid to the sand backfill (“castle”). River sand is used rather than ordinary soil, because it prevents the spread of flame, performs the function of drainage, conducts the heat of the earth well, and protects the tank from deformation during possible soil movements.

On our website there is a series of articles devoted to describing the technology for installing gas tanks, we recommend that you read:

- The cost of installing a gas tank in a private house: prices for gasification work

- How to correctly determine the distance from a gas tank to a residential building: choose a suitable location on the site

- Turnkey gas tank: how to install a gas tank and install equipment

How to choose a gas holder Antonio Merloni

When choosing the design and volume of a tank (one or several), they are guided by the number of consumers and intensity of use.

It is calculated that the volume of the gas tank is directly related to the area of the house, so they start from this indicator. For example, for a house of 170 m², a tank with a volume of 1650 liters is recommended.

If you choose on your own, you may encounter difficulties, so manufacturers recommend consulting with a specialist and visiting the site. The engineer analyzes the individual technical features of the building and selects the best option from variety of gas holders.

Conclusions and useful video on the topic

You can learn about the features of Antonio Merloni’s equipment and the secrets of installing a gas tank from useful videos.

About the advantages of autonomous gasification and installation of a gas holder:

Details about the technical nuances of the equipment:

Reviews about products and installation quality:

Gas tanks by Antonio Merloni have proven themselves as reliable, efficient, durable equipment for arranging an autonomous suburban gas supply. By choosing a tank of optimal volume, you can forget about problems with heating, air conditioning and water supply.

Do you have experience using a gas holder from an Italian manufacturer? Please tell us what technical parameters you took into account when choosing a tank, are you satisfied with the work of autonomous gasification? Comment on the post and participate in discussions. The feedback block is located below.

Good gas tanks, nothing to say. But the price... And it’s so expensive with all the permits and installation. In short, Merloni is for very wealthy people.