Gas holder for a summer residence: mini options for arranging summer cottages

Not all dacha areas are provided with centralized gas supplies. Heating a house with electricity is expensive.A good alternative is autonomous gasification. If you are not satisfied with the group of cylinders, then the solution will be a gas holder - a special tank that is filled with a mixture of liquefied hydrocarbons.

We will help you choose the optimal gas holder for your dacha. The article we presented describes in detail all the varieties that are actively exploited in suburban areas. A detailed description of the models will give an idea of the features of the installation and use of containers for autonomous gas supply.

The content of the article:

Features of installing a gas tank

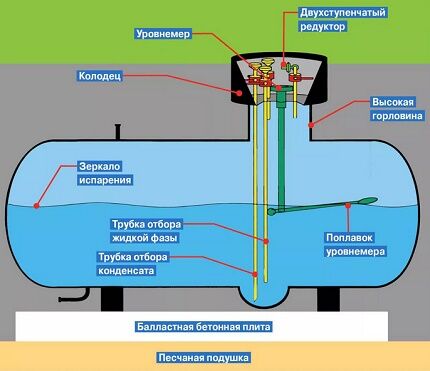

A gas holder is not only a container for storing the fuel mixture, but also a place where the liquid phase transforms into a gaseous state for further supply to the heating main under constant pressure. An important point in the design of an autonomous gas system is the competent choice of a gas tank, which requires calculation of its technical parameters.

To determine the volume of the container, the heated area is multiplied by the average amount of fuel consumed by boilers with an efficiency of 60 to 70%. It is approximately 17 liters for winter, when there are few days with very low temperatures.

If winters in the region are consistently severe or the dacha has heated floors, a pool, the water in which needs to be heated, the calculated volume is increased.In summer or in the off-season, 3.3 liters is enough to heat 1 m².

To operate a mini-gas tank or a tank whose volume does not exceed 10 t. liters, no permission from Rostechnadzor is required, provided that the SNIP requirements for installation are met, and the power of the heating devices is not more than 100 kW. If you are not satisfied with this power and need to exceed it, then you will have to obtain a permit.

There is also no need to ask for consent from the owners of neighboring plots if communications will not take place in close proximity to the boundary line. In any case, in order to avoid any misunderstandings, it is good to have a quality certificate in hand. It must be obtained from the company that sold the equipment and has a license to install it.

Main components of the gasification project

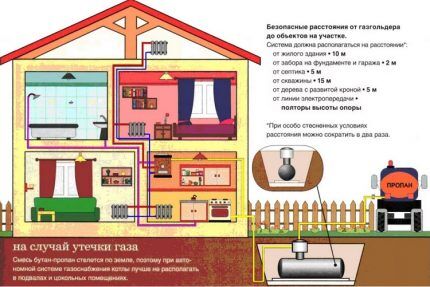

Not every place on the site is suitable for installing a propane-butane tank. In order for all conditions to be met, it must have the appropriate dimensions. The main thing is that the tank needs free access, otherwise its refueling and maintenance becomes impossible.

All communications can only be laid underground. The container itself should not be located under a driveway or other road.

The optimal distance from the road to the tank is 5 m.You should retreat at least 8 m from household buildings on your site. To the foundation of the house - 10 m, and from the neighbor's house - 20 m. The plate with the factory data must be in sight. Rules for choosing a location for a gas tank are given in the articlededicated to this issue.

It is allowed for the installed tank to rise above the ground by a maximum of 0.6 m. It must be grounded, and if static voltage is present in the area, measures to protect against electrochemical corrosion are necessary.

In terms of autonomous gasification, it consists of a tank manufactured and passed all stages of testing in the factory, pressure regulators, protection, and a gas pipeline. The protection consists of magnesium electrodes located at a distance of about 0.35 m from the container. The purpose of the condensate collector is to collect liquid butane, which then evaporates on its own.

The gas pipeline is assembled from pressure polyethylene pipes. Laying a gas pipeline before entering the house, mounted from metal pipes and equipped with a shut-off valve and a bellows-type compensator. The internal pipeline is equipped with thermal shut-off valves.

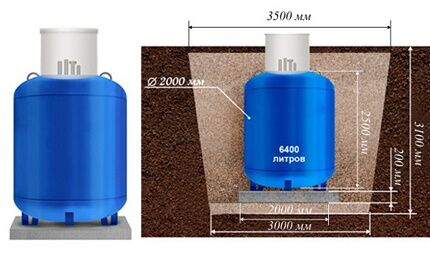

For immersing the gas tank prepare a pit, at the bottom of which a cushion of sand and gravel is placed. Next, a monolithic base with a height of at least 160 mm is poured. Without this, the unit may be squeezed out of the pit by groundwater. Sometimes the tank is immediately fixed to a finished reinforced concrete slab, and then the whole thing is lowered into a pit.

After fastening the tank, it is coated with a special lubricant that protects the metal from corrosion. The next stage is the anodic-cathodic protection device.After this, the gas pipeline is laid and the pit and it are filled with soil.

Types of gas tanks for summer cottages

Gas tanks for autonomous gasification suburban areas are both stationary and mobile. Stationary tanks are divided into above-ground and underground. For a home where people live permanently, a stationary tank is more suitable, and in the case of a summer house intended for seasonal use, it is rational to use a mobile option.

Ground Models

Ground gas tanks are characterized by ease of installation, since no excavation work is required. The reason for the unpopularity of this option is that the fuel mixture evaporates very slowly at low temperatures. Therefore, the tank must not only be insulated, but also equipped with evaporators.

It is irrational to do this for one country house, but if a large-capacity tank is used to provide fuel for an entire country village, this option is better. This is due to the fact that the decision to bury a gas tank with a volume of up to 6 tons m² in the ground will cost much more.

Options for underground placement

Underground tanks are placed in the ground below the freezing point.

This solution has advantages:

- the design of the site does not suffer;

- there is no need for additional equipment that supports stable evaporation of the gas mixture.

Underground reservoirs are used to supply gas to a village consisting of several houses. When installing a gas tank underground, the minimum distance from the ground level to the top point of the tank is on average 0.6 m. This parameter is greatly influenced by the climatic conditions of the area.

High-quality gas holder for underground installation must be equipped with a high neck, which will allow it to be placed at the required depth. This will make it easier to periodically check the tank walls and welds for strength.

The tank must have walls with a minimum thickness of 6 mm and a thickness of the anti-corrosion epoxy polymer shell of at least 1 mm.The company selling the tank must present a certificate confirming that the product meets all requirements, as well as permission from Rostekhnadzor for its use.

The process of installing a gas tank immersed in the ground includes a number of standard steps:

Features of mobile gas tanks

Mobile tank with a volume of about 500 m3 placed on a trailer. Connecting such a gas tank to the gas main is not difficult, and this operation is performed very quickly.

In fact, this is the same gas cylinder, only larger in volume and having a gas heating system. This amount of liquefied fuel can heat a small cottage throughout the winter.

Such mini-tanks are compact - about 2 m long and 0.6 m in diameter. Their service life is quite long - up to 25 years.

If gas is needed exclusively for cooking, then this volume mobile gas tank enough for 2 years. To use the house year-round, you will need a tank with a capacity of 2.5 tl., but when you also need to heat outbuildings, the storage size will have to be increased.

Mini tanks and their advantages

If we compare a miniature gas tank with a volume of 500 or 1000 liters with its large counterpart, we can note the following advantages:

- It is much cheaper, so it has a shorter payback period.

- You can install it yourself.

- The container does not need to be hidden in the ground, and this significantly reduces installation time.

- There are no strict requirements for the installation location. Clause 8.2.3. SP 62. 13330. 2022 states that a mini-reservoir can be placed directly against the wall of the house.

- Gasification using such a gas holder is very fast - it only takes about 2 hours.

There are many advantages when compared with a conventional gas cylinder. The main thing is that the gas holder is not explosive. The valves included in its package do not allow pressure to rise above the established norm.

To replenish gas mixture reserves, it is not necessary to visit a gas station. If the gas tank is not installed on a trailer, but simply on a site near the house, then it can be refueled locally.

Unlike a cylinder, it can supply gas not only to the stove, but also to other more powerful equipment. Due to the fact that there is a level gauge on the tank, you can always find out how much mixture is left in it. This allows you to plan refueling in advance.

Vertical gas tank installations

Depending on the design features, underground gas tanks for dacha development are divided into horizontal and vertical, which take up 3 times less space than horizontal ones.

This option is well suited for country housing, with a small local area. Ideally, it has a high neck, then it is buried to a depth of approximately 4 m. This will help avoid gas condensation during cold weather.

While as fuel is consumed from a horizontal tank, the area of gas evaporation decreases, in a vertical gas tank, when the mixture level is lowered, the area of the mirror remains constant.

Despite the lower productivity, this is a serious advantage, but due to the considerable height of the container and the depth of freezing of the ground, a lot of effort will be required to prepare the place for it.

Models of this type are suitable for country houses whose area does not exceed 150 m². Good vertical gas tanks are produced in Italy, in particular, those produced by the company Antonio Merloni. They are equipped with a thermal protective layer that allows you to maintain a stable temperature during extreme cold.

Vertical tanks from the Bulgarian company CITI GAS are also popular. The model range consists of tanks with a volume of 2700, 4800 and 6400 gas liters. The gas tanks of these two companies differ not only in volume, but also in the color of the tanks and branding on them.

The cost of vertical tanks is higher than that of horizontal samples. They effectively supply a gas mixture in the temperature range -40 - +40⁰. Their service life is 30 years.

Horizontal gas tanks

Horizontal gas tanks are more productive than vertical ones. There is one caveat - this indicator is unstable. As soon as the level of the gas mixture drops to 1/3 of the volume, it begins to fall, so the system cannot function stably without a special reducer.

Horizontal tanks are effective for heating a house with an area of 200 m² or more or several buildings at once.To install a horizontal tank, a shallow pit is prepared.

Its volume must be taken 20% more than the estimated fuel requirement. This is necessary to ensure that there is enough gas to maintain productivity after its volume has been reduced to a critical value.

The metal body of the gas tank can withstand pressure no higher than 1.8 MPa. Antonio Merloni is also a leader among manufacturers of horizontal units.

There are also units on the market from the Czech company Deltagaz and the Polish company Chemet. Normal functioning of these tanks is possible even in unusual situations and in the harshest winters.

Detailed characteristics of gas tanks of domestic, Czech and Italian production is given here. We recommend that you read the useful information.

Features of filling gas tanks with a mixture of gases

The frequency of filling tanks with propane-butane depends on their volume and how intensively it is used. On average this is 1 – 3 times a year. The main thing is not to miss the moment when the balance is about 30%. Fill the tank not to the top, but not more than 85%.

The supplier of the gas mixture must have a license and special transport. The easiest way to fill mobile modifications of mini gas tanks for servicing summer cottages is because they can be transported on a car trailer. Before filling the gas tank, be sure to check the indicators of the devices.

Will introduce you to the cost of installing a gas tank on a private plot next article, which we recommend reading.

Conclusions and useful video on the topic

Video #1. About the gas tank installation technology:

Video #2. About mobile gas tanks:

The purchase and installation of any gas tank must be preceded by calculations of its volume and the payback time of the unit. The calculation results must be compared with alternative types of heating and only then a decision must be made.

Would you like to share your personal experience gained during the installation and operation of a gas tank on your suburban area? Do you have information that will be useful to site visitors? Please write comments in the block below, ask questions, publish thematic photos.