Toilet cistern fittings: how the drainage device is designed and works

Even the most reliable plumbing fixture can break down.It is especially unpleasant if this product is used daily by all family members. If the toilet cistern fittings have failed, you don’t want to wait a couple of days for a plumber to come, don’t you agree? Moreover, such a problem can be successfully solved on your own.

Before you begin the repair, you need to understand the design of the tank, the structure of the drain mechanism and understand the principle of operation of the drain. The article discusses in detail all of the above points, and also describes possible breakdowns of the toilet fittings and how to eliminate them.

The content of the article:

Toilet tank: what's inside?

The toilet occupies a central place in any bathroom. If you can do without a shower or bathtub using a tray for ablutions, then the toilet is an indispensable device not only for every family member, but even for some pets.

Therefore, it is simply necessary to know its features and structure so that on a Saturday morning you do not find yourself face to face with such a breakdown.

Features of cisterns

Toilet tanks differ in the material they are made of, the method of installation and connection to the water supply, and the type of button/lever location.And the price range of this type of plumbing fixtures is very wide - from inexpensive domestic models to exclusive design options from famous plumbing manufacturers.

Based on the material of manufacture, the following types of toilet cisterns are distinguished:

- earthenware;

- plastic;

- cast iron.

The drainage fittings used for toilets are mainly made of plastic. This applies even to expensive models.

Earthenware tanks received recognition and wide spread throughout the world. It is this material that can most often be found in bathrooms where a pair of toilet + cistern is installed.

Plastic models drain tanks have a flattened shape. This is due to the specifics of their application - the so-called wall hung toiletswhen the flush device is installed in the wall. The design is reliable, easy to maintain and has a long service life.

Cast iron tanks – this is a relic of the past. Heavy, bulky and unpresentable designs are still used by many zealous residents of our country. But during renovations, old cast iron products are often replaced with beautiful modern plumbing fixtures.

Depending on the method of connection to the water supply, there are toilet tanks with upper and lower connections.The latter are more preferable - they look more presentable and create less noise during operation.

There are three possible ways to install the cistern:

- top mount;

- installation in a false wall;

- on the toilet shelf.

Top mount - This is a retro option. This arrangement of the drainage device is used in retro-style bathrooms.

Toilet installation used for hanging models when the tank is hidden in the wall. This allows you to save space in the bathroom and harmoniously fit the plumbing into the overall style of the bathroom/toilet room.

Mounting on a toilet shelf - traditional solution. These are the usual models of a plumbing pair, when the drainage system is attached to the shelf of the toilet bowl.

Advantages: simplicity and affordability. And the choice is very wide - you can choose both a domestic version and elite plumbing fixtures from Italian, French or German manufacturers.

Internal structure of the tank

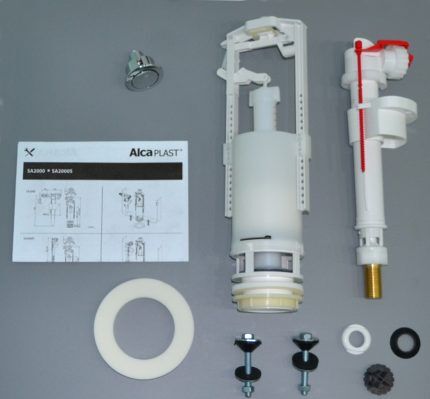

Inside each flush cistern there is a shut-off valve to control the operation of the toilet.For many models, the fittings come complete with all the necessary fasteners and nuts.

Based on the method of water supply and installation location in the tank, the following types of fittings are distinguished:

- top eyeliner;

- bottom eyeliner;

- universal.

Top connection design built into the collection tank. A flexible water supply tube is connected from above. This must be taken into account, because such fittings are not suitable for every model of cistern. Basically, only domestic manufacturers provide top connections in their plumbing products.

Fittings with bottom connection Comes complete with most Western-made waste cisterns. Moreover, the design is plastic, but the quality of all components is high.

Universal fittings on the toilet flush tank is convenient in that it can be placed in both a container with bottom and top water supply. If unnecessary, the second hole is fitted with a special plug included in the kit.

According to the type of material from which the reinforcement is made, there are:

- plastic structures;

- metal made of bronze or brass alloy.

Most models are equipped with plastic fittings. Moreover, if individual parts wear out, you can always purchase the necessary plumbing supplies at a plumbing store. If you don’t find what you need, you can buy a new design.

The cistern fittings consist of 3 main components:

- filling;

- drain;

- overfill protection.

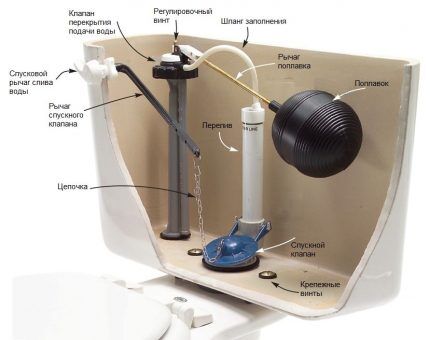

Filling - a unit that ensures the filling of a container with water entering through a flexible pipe. The design of the fittings includes a special valve that blocks the access of water at the right time. Its operation is ensured by a float made of foam or other lightweight material.

Drain. The main part of this unit is drain valve. It is activated by traction when the user presses a button/lever.

Overfill protection or overflow. The main element of this safety device for the drain tank fittings is a plastic tube, empty inside. It is installed vertically in the container.

Operating principle of the drainage device

The drainage device of the toilet tank is put into operation by the user acting on the external mechanism of the fittings. Moreover, depending on the principle of operation of the mechanism, the design itself will differ.

Features of the tank drain function

Among the operating elements used to activate the flush function are:

- button;

- lever arm;

- pedal.

The most common option is a button. Moreover, there are models of fittings with one or 2 different buttons - for releasing small and large volumes of working fluid. 2 flush versions allow you to save not only the planet’s water resource, but also reduce your monthly water supply payment.

When a button or lever is pressed, a thrust is generated that opens the drain valve.Water from a container with a volume of 10-12 liters rushes down into the toilet bowl, cleaning it and flushing away everything that was in it before.

How is filling done?

Simultaneously with the emptying of the tank, the float lowers, which leads to the opening of the valve that shut off the water supply from the water supply system. Water gradually fills the container and as soon as the float is at a certain level, previously set by the user, the float rod will completely shut off the water supply to the toilet flush tank.

How does overfill protection work?

When a failure occurs in the process of supplying the working fluid or one of the valve mechanisms fails, a safety device—overflow—is triggered. This is an empty tube that connects to the drain valve.

The principle of its operation is simple - as soon as the water level in the tank becomes higher than permissible, the water will begin to overflow into this tube and flow into the toilet bowl.

Problems with toilet cistern fittings

A high-quality toilet + cistern set from a manufacturer with a good reputation can last about 20 years. But drainage fittings, even the most reliable ones, will fail sooner. Therefore, it is important to identify and eliminate any breakdowns that occur.

Most often you may encounter the following problems:

- filling does not occur;

- water constantly flows into the toilet bowl;

- lack of response when pressing a button/lever;

- leaks at joints;

- weak drain pressure.

Problem #1. Filling does not occur if the inlet membrane is severely clogged. Then you cannot do without cleaning or replacing it. If the membrane is in working condition, but the tank is not filled with working fluid, then you need to check the correct functioning of the float. Perhaps there will be adjusting or replacing the float.

Problem #2. Water constantly flows into the toilet, increasing the reading of the cold water meter. This problem occurs when large debris or other objects get into the tank. Anything unnecessary interferes with the normal operation of the tank’s filler fittings. Necessary disassemble the tank and remove foreign objects from it.

Also constant leak in the toilet may cause misalignment, loosening or breakage of the float. You can repair the float valve without much difficulty with your own hands:

If everything is in order with the float, you need to check the condition of other plastic parts of the fittings - the rod, the diaphragm lever or the float spoke.

Problem #3. When I press the flush button, nothing happens. Here you have to check for gaps in places where they should not be - at the joints. Also, the plastic parts of the fittings may be broken, which is especially common in cheap models that have served for more than 3 years.

A frequent cause of disruption of the water supply to the tank is the inappropriate length of the drain and fill tubes or their damage. To combat the situation, we take the following steps:

Problem #4. Another problem that arises with the toilet cistern is leaks at the threaded connections. To eliminate this problem, you will need to replace the sealing gasket. If this part has not yet worn out, then you need to check whether the nuts are tightened well and whether there are any distortions.

Problem #5. The situation when drainage occurs, but its pressure is weak, is also a fairly common occurrence. This indicates a flushing failure due to a rubber hose getting into the outlet hole or some other foreign objects.

If a leak is detected in the area of the flush valve, we perform the following actions:

If serious repairs are required with the replacement of many parts, then it will be easier and cheaper to install a new drain mechanism followed by setting up fittings.

You also need to treat its purchase responsibly - buy a new one in a company store or select a suitable model from another manufacturer. It is important to consider the diameter and location of the liner near your toilet.

Conclusions and useful video on the topic

How to remove and rinse or replace the fittings of a tank built into the wall is demonstrated in the video:

The operating principle of the toilet cistern drainage fittings is described in detail in the video:

The design and assembly of the fittings installed in the toilet cistern is described in the video clip:

Description and characteristics of the toilet flush mechanism can be seen in the video:

A visual and useful video about repairing toilet flush units:

Having studied the external structure of the cistern, you can not be afraid of unpleasant surprises. If suddenly the tank stops filling or water constantly leaks, you can try to figure out the problem on your own by inspecting the fittings and disassembling the corresponding working unit.

If a plumber is involved in fixing the breakdown, then it will be much easier to accept the results of his work.

Share with readers your experience in repairing cistern fittings. Please leave comments on the article, participate in discussions and ask questions that interest you. The feedback form is located below.

We had problems with the intake valve and then with the exhaust valve. The float did not work and the water did not stop flowing. It was especially unpleasant that the water was rustling all night while we were sleeping, a lot flowed away. I did everything with my own hands, costing little. Because it is quite expensive to change the entire mechanism, I made a homemade float from a ball from a children's toy. It's been working like this for six months now, no more problems.